Professional Documents

Culture Documents

Washing Wi Ok

Uploaded by

DURAIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Washing Wi Ok

Uploaded by

DURAICopyright:

Available Formats

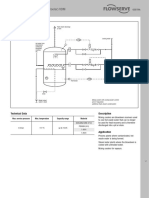

KIKUWA INDIA PVT LTD

Work Instruction Page No. 1\1

Title : Washing process for housing Doc.No. WI-PRD-087

Rev.No. 0

Issue Date: 9/3/2014

S.No. Picture Work Process Significant point Machine / Equipment Result of nonconformity Document

for that,Heat DM(De-Mineralised water) by water

After machining complete dip castings into hot heater. If we didn't dip castings into hot water, castings

1 water.for removing oilness on casting surface. Water temperature is must be 45-50degree

water heater,Bucket

oily will not cleaned.

maintain.

Dip castings into hot water . By using stainless

steel grilled bucket.'

2 Dip castings into hot water . use De-mineralised water for cleaming purpose grilled bucket

only.Change water for after 35 pcs copleted once.

(1box)

Dip castings into hot water for 3times for

3 Dip castings into hot water . maximum 2minutes,unless it is waste for dipping.. grilled bucket.

By using stainless steel grilled bucket.'

After water treatment complete ,use air blow on check visually when the casting is any NC Free If did not air blow on casting water drops will

4 casting out side & inside. from the dent &damage porosity

AIR gun

placed inside of bore.

** If dropped parts or NG parts was found, PPE

Rem1. A symbol of SC/CC point according to customer requirement will input in symbol's put it into a red box immediately ....

Glasses Rubber Fabric Safety Smock Safety Boot Ear Other

2. A symbol which is concerning with safety point ( ) will determine at the end of content. USE / NO USE Gloves Gloves Helmet Muff

Ear

Plug

Environment ใช้ / ไม่ใช้

- Waste from production have to separate according to ISO 14001

- Any equipment must not have Any forbidden chemical, if Any, must not exceed quantity which is required by customer or law.

Regulation Rev. 00 Safety section

- When a problem about work, machine or Any alarm were found, must stop and wait for leader toFormat No. Check Approve Check Prepare Rev.No. Date Change FORMAT

KIP/ID/WI/001 Revised Details

You might also like

- Rsa Netwitness Endpoint: Detect Unknown Threats. Reduce Dwell Time. Accelerate ResponseDocument8 pagesRsa Netwitness Endpoint: Detect Unknown Threats. Reduce Dwell Time. Accelerate ResponseRaghavNo ratings yet

- Strengthening RC Structures with Steel Plate Bonding MethodsDocument29 pagesStrengthening RC Structures with Steel Plate Bonding MethodsSiti Rohani Isdris100% (1)

- Synergy of Demand Water Heaters With Solar and Radiant Floor HeatingDocument5 pagesSynergy of Demand Water Heaters With Solar and Radiant Floor HeatingKhurram ShahzadNo ratings yet

- Sapphire Hotel Quotation For Iron Centre and Dispenser 30 Nov 2020Document2 pagesSapphire Hotel Quotation For Iron Centre and Dispenser 30 Nov 2020Hotel sapphireNo ratings yet

- Journal_Self-Cleaning Fluidised Bed HE for Severely Fouling Liquids and Their ImpactDocument38 pagesJournal_Self-Cleaning Fluidised Bed HE for Severely Fouling Liquids and Their ImpactIynulF.OmarNo ratings yet

- Delayed Coker Blowdown System Water Reuse Moloney ExxonMobil DCU Budapest 2017Document23 pagesDelayed Coker Blowdown System Water Reuse Moloney ExxonMobil DCU Budapest 2017Obrejan CosminNo ratings yet

- Fractional DistillationDocument7 pagesFractional DistillationInspector Chulbul PandayNo ratings yet

- Name: Year/Course: Subject/Section: Instructor: Date Performed: Experiment No: Experiment Title: I. ObjectivesDocument4 pagesName: Year/Course: Subject/Section: Instructor: Date Performed: Experiment No: Experiment Title: I. ObjectivesCLNo ratings yet

- CEeNews2 04 PDFDocument6 pagesCEeNews2 04 PDFJohn AnthoniNo ratings yet

- NERI Expt1 GravimetryDocument5 pagesNERI Expt1 GravimetryMarie Angelie Neri100% (1)

- Barbacoa Beefeater SignatureseriesDocument20 pagesBarbacoa Beefeater SignatureseriesAbad CondoriNo ratings yet

- Heat recovery from continuous blow down waterDocument3 pagesHeat recovery from continuous blow down waterTan Nguyen HuuNo ratings yet

- L5. MSFDocument28 pagesL5. MSFМухаммад АбдуллатифNo ratings yet

- Intersolar Systems Pvt. Ltd. AN ISO 9001: 2000 CODocument27 pagesIntersolar Systems Pvt. Ltd. AN ISO 9001: 2000 COlovleshrubyNo ratings yet

- Melting and boiling pointsDocument14 pagesMelting and boiling pointsRatul RanjanNo ratings yet

- Simple and Steam Distillation I. Simple DistillationDocument1 pageSimple and Steam Distillation I. Simple DistillationPaula AquinoNo ratings yet

- 3 Wood RepDocument1 page3 Wood RepParisa MusaviNo ratings yet

- Fix and repair wood dents with heat and steamDocument1 pageFix and repair wood dents with heat and steamParisa MusaviNo ratings yet

- Skill Builder Video: Michael Dresdner: Along The Way It's Inevitable That You'll Pick Up Some Nicks and Dents in YourDocument1 pageSkill Builder Video: Michael Dresdner: Along The Way It's Inevitable That You'll Pick Up Some Nicks and Dents in YourParisa MusaviNo ratings yet

- Absorbent Water Battery Set Up in The Vat of Oil TransformersDocument3 pagesAbsorbent Water Battery Set Up in The Vat of Oil TransformersKiran VedanteNo ratings yet

- TUP CHEMISTRY HEAT OF COMBUSTION EXPERIMENTDocument1 pageTUP CHEMISTRY HEAT OF COMBUSTION EXPERIMENTJohn Felix PalenciaNo ratings yet

- Brochure Power Industry EN WebDocument32 pagesBrochure Power Industry EN Websudheer kumarNo ratings yet

- The New Old Chiller: Rajesh DixitDocument21 pagesThe New Old Chiller: Rajesh DixitNaresh Kumar GovindanNo ratings yet

- CLAGE Storage Heaters CatalogueDocument9 pagesCLAGE Storage Heaters CatalogueDAVID CARRILLONo ratings yet

- Distillation of Mixtures: Activity 2.3Document4 pagesDistillation of Mixtures: Activity 2.3...No ratings yet

- Cambridge International General Certificate of Secondary EducationDocument12 pagesCambridge International General Certificate of Secondary Educationmarize medhatNo ratings yet

- Introduction To Heat TreatmentDocument7 pagesIntroduction To Heat TreatmentNIDHI NAIRNo ratings yet

- Troubleshooting Guide: Start Up ConditionsDocument4 pagesTroubleshooting Guide: Start Up ConditionsShouzab AbbasNo ratings yet

- Chipper: Turpentine ChipsDocument1 pageChipper: Turpentine ChipsMeghanathi BhavinNo ratings yet

- 02 Rice Final Design DescriptionDocument1 page02 Rice Final Design DescriptionMason del RosarioNo ratings yet

- Chemical BondsDocument8 pagesChemical BondsEziah Pearl Joy AlaveraNo ratings yet

- Hitchcock - Boiling Ice InvestigationDocument4 pagesHitchcock - Boiling Ice Investigationpkdm6n8g84No ratings yet

- MHP Raw Salt Acacia Mangium Eucalyptus Pellita Chemical Plant Wood Log Chips Pulp Bleaching ProcessDocument1 pageMHP Raw Salt Acacia Mangium Eucalyptus Pellita Chemical Plant Wood Log Chips Pulp Bleaching Processanis wahyu ningsihNo ratings yet

- SRS-UK Stonecast A4Document2 pagesSRS-UK Stonecast A4Jacinto alvaresNo ratings yet

- 13B Heat of FusionDocument8 pages13B Heat of FusionManish KumarNo ratings yet

- Tesa I. Ambarita - Distillation and RecrystallizationDocument8 pagesTesa I. Ambarita - Distillation and RecrystallizationTesa AmbaritaNo ratings yet

- How To Build A Safe Effective WoodFired Hot Water HeaterDocument5 pagesHow To Build A Safe Effective WoodFired Hot Water Heaterlmt76No ratings yet

- Latent Heat and Change of StateDocument23 pagesLatent Heat and Change of StateThallium TINo ratings yet

- Plate Heat Exchanger Brochure EnglishDocument3 pagesPlate Heat Exchanger Brochure EnglishAli KarimNo ratings yet

- Cold Brew Tea Brewing GuideDocument14 pagesCold Brew Tea Brewing Guidesamiao90No ratings yet

- Heat Exchangers Concept Map - Diego ManjarresDocument4 pagesHeat Exchangers Concept Map - Diego ManjarresluisNo ratings yet

- 3A Steam Jet Heaters BrochureDocument16 pages3A Steam Jet Heaters Brochurealfonso salamanca echeverriNo ratings yet

- Thermometer Calibration GuideDocument2 pagesThermometer Calibration GuideAngel Supplies SRLNo ratings yet

- More User Manuals On: Instructions For UseDocument12 pagesMore User Manuals On: Instructions For Useantonio1992No ratings yet

- Thormal Power PlantDocument23 pagesThormal Power PlantsusobhanmahakudNo ratings yet

- CIRP Annals - Manufacturing Technology 64 (2015) 281–284Document4 pagesCIRP Annals - Manufacturing Technology 64 (2015) 281–284vinayakNo ratings yet

- Yeast nutrient and ethanol production processDocument1 pageYeast nutrient and ethanol production processMubashar RehmatNo ratings yet

- Generation of Steam - Steam Properties1Document31 pagesGeneration of Steam - Steam Properties1Titus RNo ratings yet

- 1 Objective Learn The Basic Techniques For The BacterialDocument1 page1 Objective Learn The Basic Techniques For The BacterialLucy LimNo ratings yet

- 2K Clear Coat / Top Coat Basecoat Primer Substrate Treatement SubstrateDocument51 pages2K Clear Coat / Top Coat Basecoat Primer Substrate Treatement SubstrateVenkatesanNo ratings yet

- Brochure Yellow StoneDocument2 pagesBrochure Yellow StonetachizwNo ratings yet

- Lyra Instant CatalogueDocument2 pagesLyra Instant Cataloguechn_rakesh3120No ratings yet

- Electron Beam Lithography SOPDocument1 pageElectron Beam Lithography SOPOktaUBNo ratings yet

- Acw and CW Cooling Water SystemDocument31 pagesAcw and CW Cooling Water SystemPrudhvi RajNo ratings yet

- Short Path Evaporation: FeaturesDocument2 pagesShort Path Evaporation: FeaturesmisaelNo ratings yet

- Author Topic: Making Hot Water With Cavitations... (Read 48170 Times)Document14 pagesAuthor Topic: Making Hot Water With Cavitations... (Read 48170 Times)ramatajamaNo ratings yet

- Blowdown Receiver (Mixing Cooler) VDM: Description Technical DataDocument1 pageBlowdown Receiver (Mixing Cooler) VDM: Description Technical DataadrianioantomaNo ratings yet

- AP (Acid-Peroxide) Process Flow SheetDocument1 pageAP (Acid-Peroxide) Process Flow SheetAFLAC ............100% (1)

- Logbook September 2023Document15 pagesLogbook September 2023theresiana sitompulNo ratings yet

- Internship ReportDocument171 pagesInternship ReportShahrukh MunirNo ratings yet

- Fusion Accounting Hub 304046 PDFDocument14 pagesFusion Accounting Hub 304046 PDFrpgudlaNo ratings yet

- Auditing Theory - Audit ReportDocument26 pagesAuditing Theory - Audit ReportCarina Espallardo-RelucioNo ratings yet

- ASSIGNMENTDocument5 pagesASSIGNMENTClifford Jay CalihatNo ratings yet

- ACL Reconstruction BookDocument18 pagesACL Reconstruction BookSergejs JaunzemsNo ratings yet

- ClassifiedrecordsDocument23 pagesClassifiedrecordsChetana SJadigerNo ratings yet

- Maputo Port Approach Passage PlanDocument1 pageMaputo Port Approach Passage PlanRitesh ChandraNo ratings yet

- Questionnaire For ThesisDocument5 pagesQuestionnaire For ThesisRamiz HassanNo ratings yet

- Pulse of Fintech h2 2020Document72 pagesPulse of Fintech h2 2020OleksandraNo ratings yet

- EN - Ultrasonic Sensor Spec SheetDocument1 pageEN - Ultrasonic Sensor Spec Sheettito_matrixNo ratings yet

- Unit-II Inheritance and PointersDocument140 pagesUnit-II Inheritance and PointersAbhishekNo ratings yet

- Bus Crash LawsuitDocument7 pagesBus Crash LawsuitNewsTeam20No ratings yet

- DNV Casualty Info 2011 #3Document2 pagesDNV Casualty Info 2011 #3Sureen NarangNo ratings yet

- Davall Stock Gears Worm Wheel Gear Sets 17pages PDFDocument17 pagesDavall Stock Gears Worm Wheel Gear Sets 17pages PDFharish ahireNo ratings yet

- Response of Hollow-Core Slab Floors To Concentrated LoadsDocument16 pagesResponse of Hollow-Core Slab Floors To Concentrated LoadsJuan Carlos GonzálezNo ratings yet

- How To Sell Hillstone 306. Cloudhive v2.8Document98 pagesHow To Sell Hillstone 306. Cloudhive v2.8Emmanuel CoriaNo ratings yet

- Editable Classroom Officers TemplateDocument6 pagesEditable Classroom Officers TemplateRachelle AbalosNo ratings yet

- MCQ (Trigo)Document10 pagesMCQ (Trigo)RaghavNo ratings yet

- WheelHorse Power Take Off Manual 8-3411Document4 pagesWheelHorse Power Take Off Manual 8-3411Kevins Small Engine and Tractor ServiceNo ratings yet

- Natural Fibres For Composites in EthiopiaDocument12 pagesNatural Fibres For Composites in EthiopiaTolera AderieNo ratings yet

- Digest Office of The Ombudsman V Samaniego 2008Document3 pagesDigest Office of The Ombudsman V Samaniego 2008Lea Gabrielle FariolaNo ratings yet

- Plan & Elevation of Dog-Legged StaircaseDocument1 pagePlan & Elevation of Dog-Legged Staircasesagnik bhattacharjeeNo ratings yet

- Module 3 - Design RulesDocument19 pagesModule 3 - Design RulesSamNo ratings yet

- Meritor 210 220 230 240 2SpeedSingleAxlesDocument27 pagesMeritor 210 220 230 240 2SpeedSingleAxlesYhojan DiazNo ratings yet

- F INALITYp 3Document23 pagesF INALITYp 3api-3701467100% (1)

- ISLAND SAILING CLUB COWES 2012 ROUND THE ISLAND RACE RESULTSDocument64 pagesISLAND SAILING CLUB COWES 2012 ROUND THE ISLAND RACE RESULTSmatthias_25No ratings yet

- Factors Influencing Consumer Behavior and Marketing Plan ComponentsDocument6 pagesFactors Influencing Consumer Behavior and Marketing Plan ComponentsK59 Ng� V? Minh Th?No ratings yet

- 2X16-24 Monorail Hoist-04 - 2Document1 page2X16-24 Monorail Hoist-04 - 2RafifNo ratings yet