Sample Drawings 5

Uploaded by

Sherwin DominguezSample Drawings 5

Uploaded by

Sherwin Dominguez- General and Specific Notes: Provides technical notes and specifications for construction materials, regulations, and methodologies.

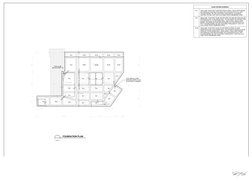

- Foundation Plan: Diagram showing the layout and specifications for the project's foundation structures.

- Pool Foundation Plan: Illustrates foundation specifications and layout for a pool.

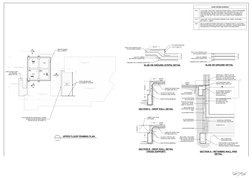

- Upper Floor Framing Plan and Details: Details framing plan for the upper floors, including specific construction details for slabs and drop wall sections.

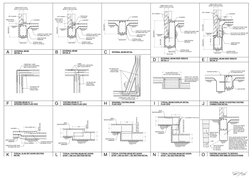

- Construction Details: Provides various construction details for typical footings, retaining walls, and beam sections.

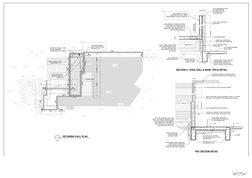

- Retaining Wall Plan and Sections: Includes detailed plans and sections for constructing retaining walls and related structural elements.

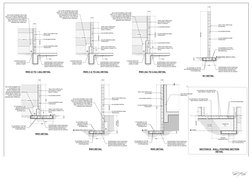

- Wall and Footing Sections: Depicts sections detailing wall and footing specifications for various wall heights and conditions.

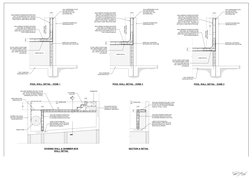

- Detail Drawings: Illustrates detailed drawings of pool walls, skimmer box details, and sections.

GENERAL NOTES MASONRY NOTES LOAD BEARING WALL NOTES

G1 THESE DRAWINGS SHALL BE READ IN CONJUNCTION WITH ALL DESIGNER'S AND OTHER M1 ALL WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH AS3700 EXCEPT WHERE LB1 THE CENTRE LINE OF EACH WALL SHALL BE CONCENTRIC OVER ITS FULL HEIGHT UNLESS

CONSULTANT'S DRAWINGS, THE SPECIFICATIONS AND WITH SUCH OTHER WRITTEN INSTRUCTIONS AS VARIED BY THE CONTRACT DOCUMENTS. OTHERWISE NOTED. REFER TO DRAWINGS FOR THE WALL THICKNESS AND DETAILS.

MAY BE ISSUED DURING THE COURSE OF THE CONTRACT. M2 THE DESIGN STRENGTH OF MASONRY SHALL BE IN ACCORDANCE WITH THE MASONRY LB2 DETAILS OF ALL OPENINGS IN WALLS NOT SHOWN ON STRUCTURAL DRAWINGS SHALL BE

G2 ANY DISCREPANCY ON THE DRAWINGS OR BETWEEN THE DRAWINGS AND/OR THE SCHEDULE SHOWN ON THIS DRAWING. MORTAR ADMIXTURES SHALL NOT BE USED WITHOUT WRITTEN SUBMITTED TO THE ENGINEER FOR APPROVAL PRIOR TO CONSTRUCTION.

SPECIFICATION AND/OR THE AUSTRALIAN STANDARDS SHALL BE REFERRED TO THE CLIENT AND A APPROVAL. LB3 CARE SHOULD BE TAKEN IN PLACING CONCRETE IN CORE-FILLED WALLS TO ENSURE THAT THE

WRITTEN INSTRUCTION RECEIVED PRIOR TO PROCEEDING WITH THE WORK. M3 NO CHASES SHALL BE CUT INTO LOAD BEARING MASONRY WITHOUT THE APPROVAL OF THE CONCRETE IS PROPERLY PLACED AND COMPACTED.

G3 THE DOCUMENTED DESIGN CONSTITUTES THE MAIN STRUCTURAL FRAMING BUT DOES NOT ENGINEER.

INCLUDE A FULL SCOPE OF SECONDARY STEEL OR TIMBER FRAMING TO SUPPORT FACADE CLADDING, M4 MORTAR JOINTS SHALL BE 10mm THICK AND HAVE A MAXIMUM TOOLED DEPTH OF 3mm U.N.O.

FORMWORK NOTES

INTERNAL PARTITION WALLS, ETC. ALL PERPENDS AND BED JOINTS ARE TO BE FULLY FILLED WITH MORTAR.

G4 THE DRAWINGS SHOW TYPICAL CONNECTION DETAILS ONLY. THE SHOP DRAFTER IS REQUIRED M5 CLEANOUT HOLES SHALL BE PROVIDED AT THE BASE OF ALL CORES OR CAVITIES WHICH ARE TO

TO DEVELOP ALL CONNECTION DETAILS NOT SPECIFICALLY SHOWN. THE CONTRACTOR IS REQUIRED BE GROUTED OR FILLED. FW1 FORMWORK SHALL BE DESIGNED AND CONSTRUCTED IN ACCORDANCE WITH AS3610 EXCEPT

TO PRICE FOR ALL CONNECTIONS NOT SPECIFICALLY SHOWN. M6 ALL MORTAR OBSTRUCTIONS IN CORES OR CAVITIES SHALL BE REMOVED PRIOR TO GROUTING. WHERE VARIED BY THE CONTRACT DOCUMENTS.

G5 THE STRUCTURAL DRAWINGS DO NOT SHOW ALL DETAILS OF FIXTURES, INSERTS, SLEEVES, THIS MAY BE DONE USING A ROD FROM THE TOP OF THE WALL. ALL MORTAR THUS REMOVED SHALL FW2 THE CLASS AND COLOUR OF THE CONCRETE SURFACE FINISH SHALL BE AS SPECIFIED ON THE

OPENINGS, ETC. REQUIRED BY THE VARIOUS TRADES. ALL SUCH DETAILS INCLUDING OPENINGS FOR BE CLEANED FROM THE BOTTOM OF THE WALL BEFORE THE CLEANOUT HOLES ARE CLOSED FOR DESIGN DRAWINGS. APPROVAL OF THE CONCRETE MIX DOES NOT ABSOLVE THE CONTRACTOR OF

CONSTRUCTION PURPOSES, MUST BE APPROVED BY THE CLIENT BEFORE PROCEEDING WITH GROUTING. THE NEED TO COMPLY WITH THE REQUIRED CONCRETE COLOUR REQUIREMENTS.

CONSTRUCTION. M7 REINFORCING STEEL SHALL BE SECURELY FIXED IN POSITION BEFORE GROUTING. FW3 EITHER BACKPROPPING OR AN UNDISTURBED SUPPORT SYSTEM OF FORMWORK IS TO BE

G6 WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH THE RELEVANT CURRENT M8 GROUT FOR BOND BEAMS, CORE FILLING OR CAVITY FILLING SHALL COMPROMISE OF 1 PART ADOPTED. A RESHORING SYSTEM IS NOT TO BE USED.

AUSTRALIAN STANDARDS INCLUDING ALL AMENDMENTS, AND THE REQUIREMENTS OF THE LOCAL CEMENT, 0.25 PART LIME, 3 PARTS 10mm AGGREGATE U.N.O. MAXIMUM SLUMP TO BE 230mm. FW4 MINIMUM FORMWORK STRIPPING TIMES ARE TO BE AS FOLLOWS - VERTICAL SURFACES MAY

M9 CORES AND CAVITIES SHALL BE FILLED IN 1000mm MAXIMUM LIFTS. GROUTING OF CAVITIES BE STRIPPED OF FORMWORK WHEN THE MINIMUM MEAN COMPRESSIVE STRENGTH OF CONCRETE fcm

STATUTORY AUTHORITIES, EXCEPT WHERE VARIED BY THE CONTRACT DOCUMENTS.

BETWEEN MASONRY SKINS IS NOT TO TAKE PLACE UNTIL 3 DAYS AFTER MASONRY HAS BEEN LAID. HAS REACHED 5.0 MPa. IF THE STRENGTH CANNOT BE ACCURATELY ASSESSED VIA THE USE OF TEST

G7 ALL DIMENSIONS ARE IN MILLIMETRES UNLESS NOTED OTHERWISE. ALL LEVELS ARE IN METRES

M10 GROUT SHALL BE THOROUGHLY COMPACTED USING A PLAIN BAR. CYLINDERS STORED ON SITE AND CURED IN A SIMILAR MANNER TO THE PERMANENT STRUCTURE

UNLESS NOTED OTHERWISE.

M11 WALL TIES SHALL BE PROVIDED AT 600mm MAXIMUM CENTRES HORIZONTALLY AND VERTICALLY THEN THE MINIMUM FORMWORK STRIPPING TIME IS TO BE 2 DAYS PROVIDED THE AVERAGE AMBIENT

G8 ALL DIMENSIONS RELEVANT TO SETTING OUT AND OFF-SITE WORK SHALL BE VERIFIED BY THE

AND CONSIST OF 3.1mm DIAMETER GALVANISED WIRE U.N.O. TEMPERATURE OVER THAT PERIOD IS BETWEEN 12 AND 20 DEGREES CELSIUS. REMOVAL OF

CONTRACTOR BEFORE CONSTRUCTION OR FABRICATION COMMENCES. THE ENGINEER'S DRAWINGS

M12 CONTROL JOINTS SHALL BE PLACED IN ALL MASONRY WALLS AT 6000mm MAXIMUM CENTRES FORMWORK SUPPORT (PROPS) TO BEAM AND SLABS MAY BE UNDERTAKEN WHEN THE MINIMUM MEAN

SHALL NOT BE SCALED. HORIZONTALLY AND 4000mm MAXIMUM CENTRES VERTICALLY U.N.O. REFER TO THE DRAWINGS FOR COMPRESSIVE STRENGTH OF THE CONCRETE fcm HAS REACHED 28 MPa. IF THE STRENGTH CANNOT

G9 DURING CONSTRUCTION THE CONTRACTOR SHALL BE RESPONSIBLE FOR MAINTAINING THE SPECIFIC LOCATIONS. CONTROL JOINTS SHALL ALSO BE PLACED ABOVE ONE CORNER OF ALL DOOR BE ACCURATELY ASSESSED VIA THE USE OF TEST CYLINDERS STORED ON SITE AND CURED IN A

STRUCTURE AND ADJACENT STRUCTURES IN A STABLE CONDITION AND ENSURING NO PART SHALL BE AND WINDOW OPENINGS U.N.O. SIMILAR MANNER TO THE PERMANENT STRUCTURE THEN THE MINIMUM FORMWORK STRIPPING TIME

OVERSTRESSED UNDER CONSTRUCTION ACTIVITIES. M13 MORTAR DROPPINGS OR OTHER HARD MATERIALS SHALL BE KEPT CLEAR OF ALL CONTROL IS TO BE 18 DAYS PROVIDED THE AVERAGE AMBIENT TEMPERATURE OVER THAT PERIOD IS BETWEEN

G10 THE APPROVAL OF A SUBSTITUTION SHALL BE SOUGHT FROM THE CLIENT BUT IT IS NOT AN JOINTS. PLACE POLYSTYRENE OR SIMILAR IN ALL VERTICAL JOINTS TO AVOID MORTAR DROPPINGS 12 AND 20 DEGREES CELSIUS.

AUTHORISATION FOR A VARIATION. ANY CLAIM FOR A VARIATION MUST BE SUBMITTED TO THE CLIENT FILLING THE JOINTS DURING CONSTRUCTION FW5 HORIZONTAL LOADS ON FORMWORK ARE TO BE RESISTED BY THE FORMWORK BRACING.

BEFORE THE WORK COMMENCES. M14 JOINTS IN WALLS SHALL BE FILLED WITH COMPRESSIBLE FILLER STRUTTING OF THE FORMWORK FROM THE PERMANENT STRUCTURE TO RESIST HORIZONTAL LOADS

G11 ALL PROPS AND FORMWORK FOR FLOOR BEAMS AND SLABS SHALL BE REMOVED BEFORE M15 WALL FINISHES MUST BE JOINTED AT THE SAME LOCATION AS THE MASONRY CONTROL JOINTS

IS NOT PERMITTED.

CONSTRUCTION OF ANY MASONRY WALLS OR PARTITIONS ON THE FLOOR. TO AVOID UNCONTROLLED CRACKING IN WALL FINISHES.

G12 ALL NON-LOAD BEARING WALLS SHALL BE KEPT 20mm CLEAR OF THE UNDERSIDE OF SLABS AND FW6 REFER TO THE DRAWINGS FOR LOCATIONS OF CONSTRUCTION JOINTS.

M16 ALL MASONRY IS TO BE FIXED TO ADJOINING CONCRETE, STEEL OR TIMBER FRAMED

BEAMS ABOVE UNLESS NOTED OTHERWISE. SUPPORTING MEMBERS BY MFA 3/3 MASONRY ANCHORS (OR AN APPROVED EQUIVALENT) AT 600mm FW7 THE SEQUENCE OF CONCRETE PLACEMENT IS TO BE SPECIFIED BY THE CONTRACTOR.

G13 DESIGN WIND LOADINGS ARE IN ACCORDANCE WITH AS1170.2 AND AS4055 AS FOLLOWS: MAXIMUM CENTRES VERTICALLY AND MFA4/M MASONRY ANCHORS (OR APPROVED EQUIVALENT) AT FW8 PROPPING OF COMPOSITE CONSTRUCTION IS TO BE AS SPECIFIED ON THE DRAWINGS.

WIND REGION: A1 WIND CLASS: N2 1000mm MAXIMUM CENTRES HORIZONTALLY U.N.OI. FW9 DESIGN LOADS FOR THE PERMANENT STRUCTURES ARE NOTED ON THE DRAWINGS.

TERRAIN CATEGORY: TC2.5 SERVICEABILITY DESIGN GUST WIND SPEED: 26 m/s M17 MASONRY ANCHORS ARE TO BE INSTALLED IN ACCORDANCE WITH THE MANUFACTURER'S FW10 DETAILS OF THE REQUIREMENTS OF PERMANENT FORMWORK SHALL BE AS SPECIFIED ON THE

TOPOGRAPHY: T1 ULTIMATE DESIGN GUST WIND SPEED: 40 m/s SPECIFICATIONS. DRAWINGS.

SHIELDING: PS M18 SOLID BRICKS, SOLID BLOCKS OR CORE FILLED HOLLOW BLOCKS ARE BE USED AT ALL MASONRY

G14 DESIGN LIVE LOADINGS ARE IN ACCORDANCE WITH AS1170.1. THE STRUCTURAL WORK ON ANCHOR LOCATIONS.

THESE DRAWINGS HAS BEEN DESIGNED FOR THE FOLLOWING LOADS:

EXCAVATION NOTES

M19 MILD STEEL LINTELS IN NON-LOAD BEARING MASONRY WALLS SHALL BE IN ACCORDANCE WITH

THE FOLLOWING TABLE. PROVIDE 200mm MIN. BEARING EACH END. LONG LEG VERTICAL ON ALL EX1 THE CONTRACTOR IS TO NOTIFY ALL SERVICE AUTHORITIES AND ARRANGE FOR

AREA SDL kPa LIVE LOAD kPa UNEQUAL ANGLES. LINTEL SIZES ASSUME MASONRY ARCHING IS POSSIBLE, AND NO OTHER VERTICAL DISCONTINUANCE OF SERVICES OR SUPPLY AS APPLICABLE AND DO ALL CUTTING, DISCONNECTION

INTERNAL FLOORS 0.2 1.5 LOADS ARE APPLIED TO THE MASONRY WALL EXCEPT FOR SELF-WEIGHT OF THE MASONRY. OR SEALING OFF OF SERVICES AND DRAINS AS REQUIRED. SERVICES OR SUPPLY LINES THAT ARE TO

0.2 2.0 BE RETAINED SHALL REMAIN UNDAMAGED AND GIVEN ALL NECESSARY PROTECTION.

STAIRS AND LANDINGS MASONRY SCHEDULE EX2 THE CONTRACTOR SHALL PROVIDE AND DO ALL BRACING OR SHORING NECESSARY TO RETAIN

ROOF 0.1 0.25 MIN EARTH BANKS, ROADS, PAVEMENTS, WALLS AND FOOTINGS OF ADJOINING PROPERTIES AND

CHARACTERISTIC MORTAR MIX

NON-HABITABLE ROOF SPACES 0.2 0.5 PREVENT CAVING AND DISPLACEMENT OF ADJACENT SOIL OR STRUCTURES AND PROVIDE ALL

ELEMENT UNCONFINED

COMPRESSIVE NECESSARY COMPONENTS OF SUCH BRACING.

CEMENT LIME SAND EX3 THE CONTRACTOR SHALL PROVIDE PUMPS, TEMPORARY SUMPS, AND DRAINS TO DO ALL

STRENGTH (MPa)

FOOTING NOTES

BAILING ETC. AS MAY BE NECESSARY TO ENSURE THAT NO WATER IS PERMITTED TO REMAIN IN THE

NON LOAD BEARING BLOCKWORK WALLS 12 1 1 6

F1 THE MINIMUM SAFE BEARING CAPACITY OF THE FOUNDATION MATERIAL IS TO BE: EXCAVATION.

100 kPa FOR RAFT FOOTINGS LOAD BEARING BLOCKWORK WALLS 15 1 0.25 3 EX4 EXCAVATION BATTERS AROUND THE PERIMETER OF THE SITE ARE TO BE AS SHOWN BELOW

REFER TO GEOTECHNICAL BOREHOLE LOGS FOR GUIDANCE. UNLESS NOTED OTHERWISE ON THE DRAWINGS:

NON LOAD BEARING BRICKWORK WALLS 40 1 1 6

F2 THE ASSUMED FOUNDING LEVELS OF THE FOOTINGS ARE TO BE ON NATURAL GROUND TYPICAL

AS DESCRIBED IN THE GEOTECHNICAL BOREHOLE LOGS. BEFORE ANY REINFORCEMENT OR 40 3 EDGE OF STRUCTURE

LOAD BEARING BRICKWORK WALLS 1 0.25

CONCRETE IS PLACED, THE SAFE BEARING CAPACITY OF THE GROUND IS TO BE VERIFIED BY THE

GEOTECHNICAL ENGINEER.

F3 THE CONTRACTOR IS TO ALLOW FOR THE ENGAGEMENT OF THE GEOTECHNICAL ENGINEER TO 1:1 BATTER

VERIFY THE FOUNDING MATERIAL.

F4 OVER-EXCAVATION WITHIN THE INFLUENCE ZONE (DEFINED BY A 45 DEGREE LINE DOWN FROM

THE BASE OF EXISTING FOOTINGS) OF ANY FOOTINGS IS NOT ALLOWED WITHOUT THE PRIOR

APPROVAL OF THE EXCAVATION SEQUENCE BY THE CLIENT. 1000

PROJECT CLIENT DRAWING TITLE

FOR CONSTRUCTION

AMBER HOUSE ENDURO BUILDERS STRUCTURAL DESIGN

LOT 250 KINTYRE ROAD 177 MOUNT BARKER RD GENERAL NOTES (A1)

SCALE (A3) DATE 11/08/22

123 Kiewa Valley Hwy PrincipalTHE HUB, 5 PEEL ST

WOODFORDE, SA 5072 HAHNDORF, SA 5245 Mount Beauty, Victoria ADELAIDE SA 5000

DRAWING NO. REV

1 11/08/22 ISSUED FOR CONSTRUCTION M. THOMSON EB-ME-22096-01 1

M: 0437 0400 25 m: 0412 878 490

0 07/06/22 ISSUED FOR CLIENT REVIEW M. THOMSON Martin Kusz RBP-EC 40076

e: matt@metamorphosis.engineering

REV DATE DESCRIPTION APPROVED E: admin@kuschgroup.com.au BE(Hons) MIEAust CPEng PROJECT NUMBER EB-ME-22096

CONCRETE NOTES CONCRETE NOTES (CONTINUED) STRUCTURAL STEELWORK NOTES (CONTINUED)

C1 ALL WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH AS3600 EXCEPT WHERE C24 BARS SHALL BE EVENLY DISTRIBUTED OVER THE WIDTH OF THE STRIP INDICATED ON THE S9 UNLESS SHOWN OTHERWISE ON THE DRAWINGS, ALL CONNECTIONS SHALL BE IN ACCORDANCE

VARIED BY THE CONTRACT DOCUMENTS. DRAWINGS UNLESS NOTED OTHERS. WITH THE FOLLOWING MINIMUM REQUIREMENTS:

C2 BEAM DEPTHS ARE WRITTEN FIRST U.N.O AND INCLUDE SLAB THICKNESS. BEAMS AND SLABS C25 ALL EMBEDMENTS SHALL BE HOT DIP GALVANISED. ALL WELDS SHALL BE 6mm CONTINUOUS FILLET WELDS ALL AROUND.

ARE TO BE POURED TOGETHER UNLESS NOTED OTHERWISE. C26 CONCRETE SHALL BE SEPARATED FROM SUPPORTING MASONRY BY TWO LAYERS OF MALTHOID ALL BOLTS SHALL BE M20 8.8/S WITH A MINIMUM OF 2 BOLTS PER CONNECTION.

C3 SIZES OF CONCRETE ELEMENTS DO NOT INCLUDE THICKNESS OF APPLIED FINISHES. (OR AN APPROVED EQUIVALENT). VERTICAL FACES OF CONCRETE SHALL BE KEPT FREE OF ADJOINING PURLIN BOLTS TO BE M12 8.8/S WITH A MINIMUM OF 2 BOLTS PER PURLIN END.

C4 NO HOLES, CHASES OR EMBEDMENT OF PIPES OTHER THAN THOSE SHOWN ON THE SURFACES BY 10mm THICKNESS OF ABLEFLEX (OR APPROVED EQUIVALENT) U.N.O. ALL NON-LOAD ALL GUSSET AND CLEAT PLATES SHALL BE 10mm THICK

STRUCTURAL DRAWINGS SHALL BE MADE IN CONCRETE MEMBERS WITHOUT PRIOR APPROVAL OF BEARING WALL SHALL BE KEPT CLEAR OF THE UNDERSIDE OF SLABS AND BEAMS BY 20mm UNLESS ALL CAP PLATES SHALL BE 6mm THICK

NOTED OTHERWISE ON THE DRAWINGS. ALL BASE PLATES SHALL BE 16mm THICK

THE ENGINEER.

C27 BRICKWORK MUST NOT BE BUILT ON CONCRETE SLABS OR BEAMS UNTIL FORMWORK S10 COLUMNS AND MULLIONS SHALL HAVE THEIR BASE PLATES FULLY GROUTED IN ACCORDANCE

C5 CONSTRUCTION JOINTS SHALL BE PROPERLY FORMED AND USED ONLY WHERE SHOWN ON THE

SUPPORTING THE CONCRETE HAS BEEN REMOVED. WITH THE SPECIFICATIONS AFTER PLUMBING AND LEVELLING ON NEOPRENE PACKERS.

DRAWINGS OR SPECIFICALLY APPROVED BY THE ENGINEER.

S11 SUBSTITUTIONS FOR STEEL SECTIONS SHOWN ON DRAWINGS SHALL NOT BE MADE WITHOUT

C6 ALL EXPOSED CONCRETE CORNERS TO HAVE 15mm CHAMFER U.N.O.

REINFORCING BAR SPLICE SCHEDULE (mm) THE WRITTEN APPROVAL OF THE ENGINEER.

C7 CAMBER TO SUSPENDED SLABS SHALL BE POSITIVE UPWARD CAMBER OF 3mm PER 1000mm S12 ALL STEELWORK BELOW GROUND OR FINISHED SURFACE LEVEL IS TO BE ENCASED IN 75mm

SPAN UNLESS NOTED OTHERWISE. VERTICAL BAR, OR BAR WITH LESS THAN BAR WITH MORE THAN 300 mm OF MINIMUM CONCRETE ALL AROUND.

C8 FORMWORK AND BACK PROPPING SHALL BE DESIGNED, CONSTRUCTED AND STRIPPED IN BAR SIZE 300 mm OF CONCRETE BELOW BAR CONCRETE BELOW BAR S13 THE ENDS OF ALL TUBULAR MEMBERS ARE TO BE SEALED WITH NOMINAL THICKNESS PLATES

ACCORDANCE WITH AS3610. REFER TO DESIGNER'S DRAWINGS AND THE SPECIFICATION FOR AND CONTINUOUS FILLET WELDED U.N.O.

CONCRETE GRADE CONCRETE GRADE

CLASSES OF SURFACE FINISH. S14 ALL HOT DIP GALVANISED MEMBERS SHALL BE PROVIDED WITH VENT AND DRAINAGE HOLES IN

25 MPa 32 MPa OR MORE 25 MPa 32 MPa OR MORE

C9 CONCRETE COMPONENTS AND QUALITY SHALL BE AS FOLLOWS: ACCORDANCE WITH THE GALVANISER'S RECOMMENDATIONS.

N10 250 250 350 350 S15 WHERE MEMBERS SHOWN ON THE STRUCTURAL OR DESIGNER'S DRAWINGS ARE REQUIRED TO

ELEMENT f'c MPa SPECIAL REQUIREMENTS

BE CURVED, BENT OR ROLLED, THE CONTRACTOR SHALL BE RESPONSIBLE FOR THE METHODS

N12 350 300 400 400

TRENCH PIERS S25 - REQUIRED TO ACHIEVE THE REQUIRED SHAPES WITHOUT LOCALISED DISTORTION OF THE MEMBERS.

N16 550 500 650 600 S16 THE CONTRACTOR SHALL PROVIDE AND LEAVE IN PLACE, UNTIL PERMANENT BRACING

SWIMMING POOL S40 -

ELEMENTS ARE CONSTRUCTED, SUCH TEMPORARY BRACING AS IS NECESSARY TO STABILISE THE

- N20 800 700 950 850

SLABS, BEAMS, FOUNDATIONS, U.N.O. S25 STRUCTURE DURING CONSTRUCTION.

ITEMS NOT OTHERWISE NOTED S32 - N24 1050 950 1300 1150 S17 STEEL PURLIN AND GIRT DESIGN HAS BEEN BASED ON LYSAGHT PURLINS. ALTERNATIVE

PURLINS OF EQUAL OR GREATER LOAD CAPACITY MAY BE SUBSTITUTED ONLY WITH THE WRITTEN

MAXIMUM AGGREGATE SIZE SHALL BE 20mm. APPROVAL FROM THE ENGINEER.

C10 ALL CEMENT IS TO BE "GP" GENERAL PURPOSE PORTLAND CEMENT OR "GB" GENERAL PURPOSE STRUCTURAL STEELWORK NOTES S18 BRIDGING SHALL BE IN ACCORDANCE WITH THE MANUFACTURER'S DETAILS U.N.O.

BLENDED CEMENT OR TYPE "SR" SULFATE RESISTING CEMENT AS REQUIRED COMPLYING WITH S19 TRIMMING MEMBERS FOR PENETRATIONS ARE NOT NECESSARILY SHOWN.

AS3972 UNLESS NOTED OTHERWISE ON THE DRAWINGS. EXTRA RAPID HARDENING S1 ALL WORKMANSHIP AND MATERIALS SHALL BE IN ACCORDANCE WITH AS4100, AS/NZS4600, S20 TRIMMING MEMBERS FOR VALLEYS, FREE EDGES, RIDGES, ETC. ARE NOT NECESSARILY SHOWN,

SUPER-SULPHATED AND HIGH ALUMINA CEMENTS AND CEMENTS CONTAINING CHLORIDE SHALL NOT AS/NZS1554 AND AS/NZS HB62 U.N.O. BUT SHALL BE PROVIDED AT NO ADDITIONAL COST TO ALL EDGES OF SHEETING AT AN ANGLE OF

BE USED. THE USE OF FLY ASH AND/OR SILICA FUME AS A CEMENT SUBSTITUTE. OTHER THAN THAT S2 UNLESS NOTED OTHERWISE, ALL STEEL SHALL BE: OTHER THAN 90 DEGREES TO THE PURLIN/GIRT. REFER TO PURLIN MANUFACTURER FOR DETAILS.

PROPORTION ALLOWED AS PART OF THE "GB" CEMENT CONTENT WILL ONLY BE PERMITTED AS PART S21 THE CONTRACTOR SHALL PROVIDE ALL CLEATS AND DRILL ALL HOLES NECESSARY FOR FIXING

GRADE 300 PLUS FOR HOT ROLLED SECTIONS

OF A DESIGNED CONCRETE MIX WHICH HAS BEEN APPROVED IN WRITING BY THE CLIENT. GRADE 300 PLUS FOR MERCHANT BAR (ROUND, SQUARE AND FLAT) STEEL, TIMBER AND OTHER ELEMENTS TO STEEL WHETHER OR NOT DETAILED ON THE STRUCTURAL

C11 CONCRETE SLUMP TO BE A MAXIMUM OF 80mm UNLESS NOTED OTHERWISE ON THE DRAWINGS. GRADE 250 FOR PLATES DRAWINGS.

C12 FREE DROPPING OF CONCRETE FROM A HEIGHT GREATER THAN 1000mm IS NOT PERMITTED. GRADE C350 FOR RHS, SHS AND CHS S22 THE FABRICATION AND ERECTION OF THE STRUCTURAL STEELWORK SHALL BE SUPERVISED BY

S3 COMMERCIAL GRADE BOLTS SHALL CONFORM TO AS/NZS1111 AND AS4100. HIGH STRENGTH QUALIFIED PERSONNEL EXPERIENCED IN SUCH SUPERVISION TO ENSURE THAT ALL REQUIREMENTS

C13 SURFACES RECEIVING GROUT SHALL BE LEFT ROUGH AND FREE OF LAITANCE.

BOLTS SHALL CONFORM TO AS/NZS1252 AND AS4100. WELDS SHALL CONFORM TO AS/NZS1554 AND OF WORKPLACE HEALTH AND SAFETY AND THE DESIGN ARE MET.

C14 CONCRETE MUST BE CURED FOR SEVEN DAYS AFTER POURING.

WELDING ELECTRODES TO AS/NZS1553. THE INSPECTION AND TESTING OF WELDS SHALL BE IN S23 STRUCTURAL STEELWORK SHALL HAVE THE FOLLOWING SURFACE TREATMENT IN ACCORDANCE

C15 REINFORCEMENT IS REPRESENTED DIAGRAMMATICALLY AND NOT NECESSARILY SHOWN IN

ACCORDANCE WITH THE FOLLOWING: WITH AS/NZS2312 AND THE SPECIFICATION.

TRUE PROJECT OR SCALE.

C16 REINFORCEMENT SYMBOLS: AREA TESTING METHOD EXTENT (% OF TOTAL LENGTH) ELEMENT SURFACE PREPARATION PRIME COAT TOP COAT/S

N - NORMAL DUCTILITY CLASS HOT ROLLED DEFORMED BARS OR MESH TO AS/NZS4671 WITH fsy

SHOP FILLET WELDS VISUAL EXAMINATION 100 ALL MEMBERS (EXCEPT CLASS 1 75 MICRONS NIL

= 500 MPa HDG) NOT EXPOSED TO

SITE FILLET WELDS VISUAL EXAMINATION 100 WEATHER

R - NORMAL DUCTILITY CLASS 250 N PLAIN ROUND BAR TO AS/NZS4671 WITH fsy = 500 MPa

L - LOW DUCTILITY CLASS 500L REINFORCEMENT IS NOT TO BE USED OTHER THAN WHERE SITE FILLET WELDS ULTRASONIC OR MAGNETIC 10 ALL MEMBERS (EXCEPT CLASS 2.5 EPOXY PRIMER ACRYLIC 2-PACK

SHOWN ON DRAWINGS. LOW DUCTILITY CLASS L REINFORCEMENT IS NOT TO BE USED OTHER THAN PARTICLE TESTING HDG) EXPOSED TO 75 MICRONS 50 MICRONS

WHERE SHOWN ON DRAWINGS. BUTT WELDS, GP OR SP VISUAL EXAMINATION 100 (SITE OR SHOP) WEATHER

C17 MINIMUM COVER (mm) TO ALL REINFORCEMENT SHALL BE AS FOLLOWS U.N.O.: BUTT WELDS, GP OR SP ULTRASONIC OR MAGNETIC 100 (SITE) MEMBERS TO BE ENCASED IN CONCRETE OR FIRE SPRAYED MUST NOT BE PAINTED AND MUST BE

ELEMENT PARTICLE TESTING 10 (SHOP)

MINIMUM COVER NOTES FREE OF SCALE

S4 ALL DETAILS, GAUGE LINES, ETC., WHERE NOT SPECIFICALLY SHOWN ARE TO BE IN S24 CAMBERS - ALL RAFTERS AND BEAMS OVER 6000mm IN LENGTH SHALL BE CAMBERED 5mm

SLABS ON GROUND 30 mm CAST AGAINST 0.2 mm FORTECON DPM.

FORTECON TO BE LAPPED AND TAPED AT ALL ACCORDANCE WITH AISC DESIGN CAPACITY TABLES FOR STRUCTURAL STEEL AND AISC UPWARDS FOR EVERY 2000mm OF LENGTH UNLESS NOTED OTHERWISE ON THE DRAWINGS.

JOINTS AND TEARS. STANDARDISED STRUCTURAL CONNECTIONS.

STRIP FOOTINGS 40 mm CAST AGAINST 0.2 mm FORTECON DPM. S5 BEFORE FABRICATION COMMENCES THE CONTRACTOR SHALL SUBMIT COPIES OF THE SHOP

FORTECON TO BE LAPPED AND TAPED AT ALL DRAWINGS TO THE SUPERINTENDENT FOR REVIEW. REVIEW DOES NOT INCLUDE CHECKING OF THE

JOINTS AND TEARS. DIMENSIONS.

S6 ALL WELDS SHALL BE SP (SPECIAL PURPOSE) IN ACCORDANCE WITH AS1554. ALL BUTT WELDS

C18 MINIMUM LAP FOR ALL FABRICS SHALL BE THE SPACING OF TWO TRANSVERSE WIRES PLUS SHALL BE FULL STRENGTH COMPLETE PENETRATION WELDS. ALL ELECTRODES SHALL BE CLASS

25mm. GRADE 500N BARS SHALL BE LAPPED IN ACCORDANCE WITH THE STANDARD LAP LENGTH E48XX.

TABLE U.N.O. S7 BOLT DESIGNATION SHALL BE:

C19 WELDING OF REINFORCEMENT SHALL NOT BE PERMITTED WITHOUT THE APPROVAL OF THE 4.6/S REFERS TO COMMERCIAL BOLTS OF STRENGTH GRADE 4.6 TO AS1111 TIGHTENED TO A

ENGINEER. SNUG TIGHT CONDITION.

C20 ALL REINFORCEMENT SHALL BE SECURELY SUPPORTED IN ITS CORRECT POSITION DURING 8.8/S REFERS TO HIGH STRENGTH STRUCTURAL BOLTS OF GRADE 8.8 TO AS1252 TIGHTENED TO

CONCRETING BY APPROVED BAR CHAIRS, SPACERS OR SUPPORT BARS AT 1000mm MAXIMUM c/c A SNUG TIGHT CONDITION.

SPACING. THE CHAIR MATERIAL SHALL SUIT THE EXPOSURE CONDITIONS. 8.8/TB REFERS TO HIGH STRENGTH STRUCTURAL STEEL BOLTS OF GRADE 8.8 TO AS1252 FULLY

C21 2N12 DIAGONAL CORNER BARS 1200mm LONG ARE REQUIRED AT ALL RE-ENTRANT CORNERS TENSIONED TO AS4100 AS A BEARING JOINT (SOME SLIP ALLOWED).

AND AROUND OPENINGS IN SLABS. S8 ALL BOLTS, NUTS AND WASHERS TO BE HOT DIP GALVANISED.

C22 REINFORCEMENT LENGTHS INDICATED ARE IN THE MILLIMETRES AND ARE PLAN LENGTH ONLY.

TURN DOWNS AND CRANKS ARE NOT INCLUDED IN THAT DIMENSION.

C23 BARS SHOWN STAGGERED ON PLAN SHALL BE PLACED ALTERNATIVELY.

PROJECT CLIENT DRAWING TITLE

AMBER HOUSE ENDURO BUILDERS FOR CONSTRUCTION

STRUCTURAL DESIGN

LOT 250 KINTYRE ROAD 177 MOUNT BARKER RD GENERAL NOTES (A1)

SCALE (A3) DATE 11/08/22

123 Kiewa Valley Hwy THE HUB, 5 PEEL ST

Principal

WOODFORDE, SA 5072 HAHNDORF, SA 5245 Mount Beauty, Victoria ADELAIDE SA 5000

DRAWING NO. REV

1 11/08/22 ISSUED FOR CONSTRUCTION M. THOMSON EB-ME-22096-02 1

M: 0437 0400 25 m: 0412 878 490

0 07/06/22 ISSUED FOR CLIENT REVIEW M. THOMSON Martin Kusz RBP-EC 40076

e: matt@metamorphosis.engineering

REV DATE DESCRIPTION APPROVED E: admin@kuschgroup.com.au BE(Hons) MIEAust CPEng PROJECT NUMBER EB-ME-22096

SLAB/ FOOTING SCHEDULE

SL1 100mm MIN. THICK RAFT SLAB WITH 300mm WIDE x 700mm DEEP BEAMS.

3N16 BARS BOTTOM AND 2N16 BARS TOP CONTINUOUS IN ALL RAFT

FOOTING BEAMS, R8-1000 LIGATURES THROUGHOUT. SL82 MESH

CENTRAL IN SLAB, CAST ON 0.2mm DAMP PROOF MEMBRANE (DPM).

SL2 200mm MIN. THICK RAFT SLAB. N20-200 BARS TOP AND BOTTOM IN SLAB

PERPENDICULAR TO RETAINING WALL. N12-200 BARS TOP AND BOTTOM

IN SLAB PARALLEL TO RETAINING WALL. 300mm WIDE x 800mm DEEP

BEAMS. 3N16 BARS BOTTOM AND 2N16 BARS TOP CONTINUOUS IN ALL

RAFT FOOTING BEAMS, R8-1000 LIGATURES THROUGHOUT. CAST ON

0.2mm DAMP PROOF MEMBRANE (DPM)

SL2A 150mm MIN. THICK RAFT SLAB. N16-200 BARS CENTRAL IN SLAB

PERPENDICULAR TO RETAINING WALL. N12-200 BARS CENTRAL IN SLAB

PARALLEL TO RETAINING WALL. 300mm WIDE x 700mm DEEP BEAMS.

3N16 BARS BOTTOM AND 2N16 BARS TOP CONTINUOUS IN ALL RAFT

FOOTING BEAMS, R8-1000 LIGATURES THROUGHOUT. CAST ON 0.2mm

DAMP PROOF MEMBRANE (DPM).

6605 1010 15530

SL2 SL2A SL2A SL2A SL2A

CARPORT SETDOWN

3880

4070

4070

SL2 SL2A FFL SL2A

196.890 SL2A SL2A

POOL SLAB

(REFER SHEET 04)

SL2 BEAM AT SL1/SL2 INTERFACE

190

140

SL2

SL1

SL2 SL1 SL1 SL1 2-N12 2000mm LONG

FFL 196.890 FFL 196.890

3300

DIAGONAL BARS AT ALL

4645

RE-ENTRANT CORNERS

FFL 196.890 50mm WET AREA SETDOWN

6550

50D REBATE

23

70

10

50mm WET AREA SETDOWN

40

240 90 3100 3810 1800 90 1700

SL2 SL1 SL1 SL1

7855

SL1

FFL 196.940 SL1

75

SL2

240

55

SL1 SL1

4485

560

240 90 SL1

1890

75

54

2720

SL2 SL2

2480

SL2

1780

SL1 SL1

1225

FFL 196.890 SL1

1280

140

50mm SETDOWN

150mm SETDOWN FOR LIFT

14490 5150 3140 360

FOUNDATION PLAN

-

PROJECT CLIENT DRAWING TITLE

AMBER HOUSE ENDURO BUILDERS

FOR CONSTRUCTION

STRUCTURAL DESIGN

LOT 250 KINTYRE ROAD 177 MOUNT BARKER RD FOUNDATION PLAN (A1)

SCALE (A3) DATE 11/08/22

123 Kiewa Valley Hwy Principal THE HUB, 5 PEEL ST

2 11/08/22 ISSUED FOR CONSTRUCTION M. THOMSON WOODFORDE, SA 5072 HAHNDORF, SA 5245 Mount Beauty, Victoria ADELAIDE SA 5000

DRAWING NO. REV

1 10/07/22 ISSUED FOR CLIENT REVIEW M. THOMSON EB-ME-22096-03 2

M: 0437 0400 25 m: 0412 878 490

0 07/06/22 ISSUED FOR CLIENT REVIEW M. THOMSON Martin Kusz RBP-EC 40076

e: matt@metamorphosis.engineering

REV DATE DESCRIPTION APPROVED E: admin@kuschgroup.com.au BE(Hons) MIEAust CPEng PROJECT NUMBER EB-ME-22096

SLAB/ FOOTING SCHEDULE

PSL1 200mm MIN. THICK RAFT SLAB WITH 300mm WIDE x 700mm DEEP BEAMS.

4N16 BARS BOTTOM AND 3N16 BARS TOP CONTINUOUS IN ALL RAFT

FOOTING BEAMS, R8-300 LIGATURES THROUGHOUT. N12-200 BARS TOP

AND BOTTOM BOTH WAYS IN SLAB WITH ENDS COGGED INTO EDGE

BEAMS, CAST ON 0.2mm DAMP PROOF MEMBRANE (DPM).

NOTE POOL WALLS REFER TO SHEET 07 FOR DETAILS

500mm LONG N12 DOWELS AT 200mm C/C,

100mm INTO POOL SLAB, 400mm INTO

LOWER SLAB. USE HIT-HY 200-R EPOXY

6605 1010 ON EMBEDMENT INTO POOL 15530

SLAB.

CORE FILLED 190mm BLOCKWORK

DWARF WALLS ON PSL1 BEAMS, PSL1

SHOWN HATCHED. N12-400 BARS

=(2)

VERTICAL AND HORIZONTAL.

PSL1

TRENCH PIERS TYPICALLY

CARPORT SETDOWN

2000mm TO 2400mm. 2500mm

3880

4070

4070

INTO NATURAL GROUND. FFL 196.890

=(2)

PSL1

190

140

=(1)

PSL1

FFL 196.890 FFL 196.890

3300

500mm LONG N12 DOWELS AT 200mm C/C,

4645

COMPACTED FILL IN BETWEEN

FFL 196.890 100mm INTO POOL SLAB, 400mm INTO 50mm WET AREA SETDOWN

DWARF WALLS TO ACT AS

=(1)

PSL1 LOWER SLAB. USE HIT-HY 200-R EPOXY

6550

50D REBATE

FORMWORK FOR THE SHOTCRETE 23

ON EMBEDMENT INTO POOL SLAB. 70

10

50mm WET AREA SETDOWN

40

240 90 3100 3810 1800 90 1700

7855

=(1)

PSL1

FFL 196.940

75

240

TYPICAL PSL1 FINISHED BASE SLAB LEVEL (WITHOUT

55

SHOTCRETE AND FINISHES) TO BE CONSTRUCTED AT

4485

APPROXIMATELY 196.940 FSL. TBC ON SITE BASED ON CIVIL

560

240 90 1890

CUT/FILL LEVELS AND ANY BUILDABILITY CONCERNS.

75

54

2720

2480

1780

FINISHED POOL LEVELS TO BE BUILT ON TOP OF DWARF

WALLS USING SHOTCRETE IN STRICT ACCORDANCE WITH

1225

FFL 196.890

1280

THE POOL LINING CONTRACTORS SPECIFICATIONS.

140

50mm SETDOWN

150mm SETDOWN FOR LIFT

14490 5150 3140 360

POOL FOUNDATION PLAN

-

PROJECT CLIENT DRAWING TITLE

AMBER HOUSE ENDURO BUILDERS FOR CONSTRUCTION

STRUCTURAL DESIGN

3 14/10/22 ISSUED FOR CONSTRUCTION M. THOMSON LOT 250 KINTYRE ROAD 177 MOUNT BARKER RD POOL FOUNDATION (A1)

SCALE (A3) DATE 14/10/2022

123 Kiewa Valley Hwy Principal THE HUB, 5 PEEL ST

2 11/08/22 ISSUED FOR CONSTRUCTION M. THOMSON

WOODFORDE, SA 5072 HAHNDORF, SA 5245 Mount Beauty, Victoria ADELAIDE SA 5000 PLAN DRAWING NO. REV

1 10/07/22 ISSUED FOR CLIENT REVIEW M. THOMSON EB-ME-22096-04 3

M: 0437 0400 25 m: 0412 878 490

0 07/06/22 ISSUED FOR CLIENT REVIEW M. THOMSON Martin Kusz RBP-EC 40076

e: matt@metamorphosis.engineering

REV DATE DESCRIPTION APPROVED E: admin@kuschgroup.com.au BE(Hons) MIEAust CPEng PROJECT NUMBER EB-ME-22096

SLAB/ FOOTING SCHEDULE

SL3 110mm MIN. THICK RAFT SLAB WITH 300mm WIDE x 700mm DEEP BEAMS.

3N16 BARS BOTTOM AND 2N16 BARS TOP CONTINUOUS IN ALL RAFT

FOOTING BEAMS, R8-300 LIGATURES THROUGHOUT. SL92 MESH IN

SLAB TOP AND BOTTOM, CAST ON 0.2mm DAMP PROOF MEMBRANE

(DPM).

SL4 120mm MIN. THICK SUSPENDED BONDEK SLAB 1.0BMT. SL92 MESH

BOTTOM. f'c = 32MPa

BP2 600mm DIAMETER BORED PIER WITH 3m MINIMUM DEPTH. 8-N16 BARS

WITH R6-200 CIRCULAR LIGATURES FULL LENGTH. LONGITUDINAL BARS

COGGED INTO STIFFENED RAFT AND STRIP FOOTINGS ABOVE.

N12 LONGITUDINAL BAR

300 LAP N12 AT 300mm C/C

100mm THICK CONCRETE SLAB

RW6 RETAINING WITH SL82 MESH CENTRAL

2260 C 6205 WALL (UNDER)

- 100mm THICK CONCRETE SLAB

STEEL MAN HOLE LID IN GARAGE SLAB FOR WITH SL82 MESH CENTRAL

ACCESS TO CONCRETE TANK BELOW.

100 100

100 100

BP2 BP2

20mm Q.R. SUBBASE 20mm Q.R. SUBBASE

(98% MODIFIED COMPACTION) (98% MODIFIED COMPACTION)

SUBGRADE (100% COMPACTION)

SL3 SL3 FLOOR TRUSS AS SHOWN

IN HATCH

SUBGRADE (100% STANDARD COMPACTION)

3675

SLAB ON GROUND (STEPS) DETAIL SLAB ON GROUND DETAIL

CONCRETE SLAB BEARS ON

5665

CONCRETE TANK BELOW

6340

990 2065

BP2 BP2

FFL 200.024

550

100mm THICK SLAB

ON GROUND.

1050 1210 SL3 SL3

REFER DETAIL A GARAGE WALL. CORE FILL BOTTOM

- 800mm DIRECTLY ABOVE SHOTCRETE

POOL WALL. N12-200 VERTICAL AND

400 GARAGE HORIZONTAL IN CORE FILLED SECTION

SUSPENDED BONDEK SLAB

SLAB 4

BP2 BP2 STEEL BEAMS AND

FFL 200.024 COLUMNS BY OTHERS GARAGE 4-N12 LONGITUDINAL BARS

6740

FFL 200.024

SLAB AROUND CORBEL SHEAR LIGS

6190

SL4

B

1000 MAX

-

4750

3815

COMPACTED QUARRY SAND

4075

FLOOR TRUSS AS SHOWN

IN HATCH

150 OR RUBBLE (MIN 75mm)

N12-150 SHEAR LIGATURES IN

SL3 SLAB MESH 300x300 CORBEL, BEARING

N12-300 C/C VERTICAL AND

FLOOR TRUSS AS SHOWN REFER TO SCHEDULE DIRECTLY ON TOP OF

HORIZONTAL BARS CENTRAL

IN HATCH

BLOCKWORK WALL

260

400

N16-200 STARTER BARS 20mm COMPRESSIBLE FILLER

1430 835 6205 2785 3055 DAMP-PROOFING MEMBRANE

INTO SLAB ABOVE SLIP JOINT BETWEEN

SL3 BEAM

POOL SECTION SHOWN SHOTCRETE WALL AND

INDICATIVELY. REFER BLOCKWORK WALL

SHEET 07 FOR DETAILS

190mm CORE-FILLED

SECTION C - DROP WALL DETAIL BLOCKWORK RETAINING

WALL

N16-200 BARS CENTRAL

BLOCKWORK RETAINING WALL UNDER TIMBER FLOOR TRUSS

BONDEK SLAB SHOWN DASHED. (BY OTHERS) N12-400 HORIZONTAL

REFER DETAIL ON SHEET 07. BARS THROUGHOUT DWARF WALL SUPPORTING

SHOTCRETE POOL STRUCTURE

400 GARAGE

SLAB

COMPACTED FILL

1000 MAX

N16-200 STARTER BARS

150

COMPACTED QUARRY SAND

OR RUBBLE (MIN 75mm)

400

UPPER FLOOR FRAMING PLAN N12-300 C/C VERTICAL AND 400mm WIDE x 700mm DEEP

HORIZONTAL BARS CENTRAL STRIP FOOTING. 4-N16 BARS POOL FOUNDATION

-

TOP AND BOTTOM. R8-300 SHOWN INDICATIVELY

SL3 BEAM LIGATURES THROUGHOUT.

DAMP-PROOFING MEMBRANE STRIP FOOTING TO BE POURED HARD

AGAINST POOL FOUNDATION TO

RESTRAIN AGAINST LATERAL MOVEMENT

SECTION B - DROP WALL DETAIL

(TRUSS SUPPORT) SECTION A - RETAINING WALL RW6

DETAIL

PROJECT CLIENT DRAWING TITLE

AMBER HOUSE ENDURO BUILDERS FOR CONSTRUCTION

4 31/10/22 ISSUED FOR CONSTRUCTION M. THOMSON STRUCTURAL DESIGN

3 14/10/22 ISSUED FOR CONSTRUCTION M. THOMSON LOT 250 KINTYRE ROAD 177 MOUNT BARKER RD UPPER FLOOR FRAMING (A1)

SCALE (A3) DATE 31/10/22

123 Kiewa Valley Hwy THE HUB, 5 PEEL ST

Principal

2 11/08/22 ISSUED FOR CONSTRUCTION M. THOMSON WOODFORDE, SA 5072 HAHNDORF, SA 5245 Mount Beauty, Victoria ADELAIDE SA 5000 PLAN DRAWING NO. REV

1 10/07/22 ISSUED FOR CLIENT REVIEW M. THOMSON EB-ME-22096-05 4

M: 0437 0400 25 m: 0412 878 490

0 07/06/22 ISSUED FOR CLIENT REVIEW M. THOMSON Martin Kusz RBP-EC 40076

e: matt@metamorphosis.engineering

REV DATE DESCRIPTION APPROVED E: admin@kuschgroup.com.au BE(Hons) MIEAust CPEng PROJECT NUMBER EB-ME-22096

REBATE WIDTH TO SUIT

REBATE WIDTH TO SUIT REFER TO ARCHITECTURAL

REBATE WIDTH TO SUIT REFER TO ARCHITECTURAL

REBATE WIDTH TO SUIT

REFER TO ARCHITECTURAL REFER TO ARCHITECTURAL

DPC FLASHING

DPC FLASHING SLAB MESH

DPC FLASHING DPC FLASHING PROVIDE MIN.

SLAB MESH SLAB MESH 400 mm

4 TOP BARS

REBATE DEPTH

REBATE DEPTH SLAB MESH SLAB MESH

30 mm MIN TO

30 mm MAX

100 mm MAX

BEAM DEPTH

1000 mm MAX

150 mm COMPACTED QUARRY SAND

BEAM DEPTH

BEAM DEPTH

OR RUBBLE (MIN 75mm)

COMPACTED QUARRY SAND

BEAM DEPTH

COMPACTED QUARRY SAND

OR RUBBLE (MIN 75mm) OR RUBBLE (MIN 75mm) N12 AT 300 mm C/C VERTICAL AND

COMPACTED QUARRY SAND COMPACTED QUARRY SAND HORIZONTAL BARS CENTRAL

OR RUBBLE (MIN 75mm) DAMP-PROOFING

OR RUBBLE (MIN 75mm)

MEMBRANE

DAMP-PROOFING DAMP-PROOFING

EXTERNAL BEAM

300 mm

MEMBRANE MEMBRANE BEAM WIDTH

250 mm MIN

BEAM DEPTH

REFER TO SCHEDULE DAMP-PROOFING

EXTERNAL BEAM EXTERNAL BEAM MEMBRANE

BEAM WIDTH BEAM WIDTH DAMP-PROOFING

REFER TO SCHEDULE REFER TO SCHEDULE

MEMBRANE

EXTERNAL BEAM

EXTERNAL BEAM EXTERNAL BEAM

A DETAIL A B DETAIL B C INTERNAL BEAM DETAIL BEAM WIDTH

400 mm MIN

REFER TO SCHEDULE

BEAM WIDTH

EXTERNAL BEAM

REFER TO SCHEDULE

EXTERNAL BEAM DEEP REBATE EXTERNAL BEAM DEEP REBATE

D DETAIL A E DETAIL B

CORNER BAR / L-BARS, L-BARS,

LAPPING ONTO LONGITUDINAL LAPPING ONTO LONGITUDINAL

BARS TO MATCH BAR DIA BARS TO MATCH BAR DIA

TOP AND BOTTOM

LONGITUDINAL/

L EXISTING FOOTING DOWELS AS NOTED. REFER

STRAIGHT BARS

AS INDICATED ON PLAN TO FOUNDATION PLAN.

BUT NOT LESS THAN 60 BAR DIA

4 BARS (2 TOP, 2 BOTTOM)

AT EACH END OF OVERLAP

(BARS TO BE SAME SIZE AS

MAIN REINFORCEMENT)

TOP AND BOTTOM

3:1 MAX

LONGITUDINAL /

STRAIGHT BARS

TOP AND BOTTOM

LONGITUDINAL /

NEW FOOTING

STRAIGHT BARS

CORNER BARS/ L BARS LAPPING

INTO LONGITUDINAL BARS

FOOTING BEAM AT "L" FOOTING BEAM AT "T" DIAGONAL FOOTING BEAM TYPICAL BEAM OVERLAP DETAIL EXTERNAL BEAM TO EXISTING FOOTING

F INTERSECTIONS PLAN VIEW G INTERSECTIONS PLAN VIEW H PLAN VIEW I PLAN VIEW J CONNECTION DETAIL

BEAM

REINFORCEMENTS

LIGATURES AT 300 mm C/C

STEP GREATER THAN 200 mm

BEAM

REINFORCEMENTS

STEP GREATER THAN 2D

MAX SETDOWN

D

1.5D

BEAM

BUT LESS THAN 2D

MAX SETDOWN

REINFORCEMENTS

200 mm

CONTINUOUS TRENCH

300 mm MESH LAP 1.5D FOOTING BEAM OR

100 mm

SLAB MESH PROVIDE CONCRETE

D

PIERS TO BELOW THE

DAMP-PROOFING LINE OF INFLLUENCE

SERVICE TENCH SHOWN.

MEMBRANE

D

BACKFILL IN

ACCORDANCE

D

WITH AS2870

D

NOTE: UNLESS SHOWN OTHERWISE

ON DRAWINGS PIERS SHALL BE

D

DAMP-PROOFING

DAMP-PROOFING MEMBRANE MINIMUM 1000mm LONG WITH CLEAR

MEMBRANE PIPE SPACING NOT EXCEEDING 1500mm.

ALTERNATE MESH MAY

400 mm MINIMUM BE DRAPED TO SUIT DAMP-PROOFING PIERS SHALL NOT BE USED WHERE

MEMBRANE SOILS HAVE BEEN DESCRIBED AS

COMPACTED QUARRY SAND LINE OF INFLUENCE: HAVING COLLAPSE POTENTIAL OR

OR RUBBLE (MIN 75mm) 30° FOR SAND ARE LOW BEARING STRENGTH.

45° FOR CLAY REFER TO SRFACE SOIL BORELOG.

60° FOR ROCK

TYPICAL SLAB SET-DOWN SECTION TYPICAL FOOTING BEAM SET-DOWN TYPICAL FOOTING BEAM SET-DOWN TYPICAL FOOTING BEAM SET-DOWN FOOTING ADJACENT TO SERVICE

K DETAIL L (STEP < 200 mm) SECTION DETAIL M (STEP > 200 mm BUT < 2D) SECTION DETAIL N (STEP > 2D) SECTION DETAIL O TRENCHES AND SIMILAR EXCAVATIONS

PROJECT CLIENT DRAWING TITLE

FOR CONSTRUCTION

AMBER HOUSE ENDURO BUILDERS STRUCTURAL DESIGN

LOT 250 KINTYRE ROAD 177 MOUNT BARKER RD TYPICAL FOUNDATION (A1)

SCALE (A3) DATE 11/08/22

123 Kiewa Valley Hwy THE HUB, 5 PEEL ST

Principal

WOODFORDE, SA 5072 HAHNDORF, SA 5245 Mount Beauty, Victoria ADELAIDE SA 5000 DETAILS DRAWING NO. REV

1 11/08/22 ISSUED FOR CONSTRUCTION M. THOMSON EB-ME-22096-06 1

M: 0437 0400 25 m: 0412 878 490

0 07/06/22 ISSUED FOR CLIENT REVIEW M. THOMSON Martin Kusz RBP-EC 40076

e: matt@metamorphosis.engineering

REV DATE DESCRIPTION APPROVED E: admin@kuschgroup.com.au BE(Hons) MIEAust CPEng PROJECT NUMBER EB-ME-22096

20mm COMPRESSIBLE FILLER

200 190 SLIP JOINT BETWEEN

4

SHOTCRETE WALL AND

BLOCKWORK WALL

200mm MINIMUM THICKNESS

SHOTCRETE POOL WALL. REFER

REINFORCEMENT DETAILS ON SHEET 09

190mm THICK CORE-FILLED

BLOCKWORK

1100 TO 2200 MAX

200mm MINIMUM THICKNESS SHOTCRETE

VARIES FROM

POOL BASE. N16-125 BARS TOP AND

BOTTOM, BOTH WAYS. SUPPORTED ON

DWARF WALLS AND COMPACTED FILL TO

POOL FOUNDATION BELOW.

3200 MAX

N12-200 BARS CENTRAL

200

DWARF WALL SUPPORTING

4

SHOTCRETE POOL STRUCTURE

N12-200 L-BARS TO MATCH MAIN COMPACTED FILL N12-400 HORIZONTAL BARS

CONCRETE BENCH

WALL REINFORCEMENT LAPPED THROUGHOUT

SHOTCRETE WALL TO BE

TW 200.024 199.057 SEAT, REFER DETAIL

INTO POOL BASE AND POOL SL2. SEE REINFORCEMENT

199.325

PLACED AGAINST

ON SHEET 09 198.816

198.387 WALL. REFER TO NOTES FOR DETAILS BELOW

TW 198.240

FORMWORK, BY OTHERS FFL 198.039 FFL 199.274 RW2 LAP LENGTHS.

199.113 199.274 BL 197.539 BL 198.774

TW 196.790 TW 198.240 FFL 196.790 TW 198.240 197.272

RW2

198.452 TW 198.040

TW 199.864 A BL 196.290

TW 198.240

-

POOL FOUNDATION

ZONE 3

TW 197.640 SHOWN INDICATIVELY 75 MICRON FORTECON

TW 198.240 STARTER BARS TO MATCH MAIN WALL

LAYER TAPED AND

REMCO BENCH SEAT LAPPED AT JOINTS REINFORCEMENT LAPPED INTO

RW1A

(REMOVABLE LID) FOOTING AND BLOCKWORK WALL.

TW 196.890

TW 199.864 FFL 196.890 REFER TO NOTES FOR LAP LENGTHS.

FFL 198.565 FFL 198.999 FFL 199.816 BL 196.390

ZONE 2

RW6 POOL SLAB

FFL 200.024

BL 199.524 SECTION A - POOL WALL & BASE / RW1A DETAIL

RW1A

DIVIDING WALLS. LAP VERTICAL BARS INTO CONCRETE ABOVE

TW 198.240 REFER DETAIL ON WHERE RW1 INTERFACES WITH BONDEK SLAB

198.597 TW 199.864

SHEET 09

TW 199.864 196.787

SKIMMER BOX 190

FFL 198.453 FFL 198.763

198.659 RW1A

ZONE 1

BL 198.474 199.923 FFL 200.024

198.638 198.527

RW5

FFL 198.974 4 BL 199.524

=

W1

FFL 199.124 TW 198.445

N16-200 CENTRAL ON 190mm THICK BLOCK WORK

RW3

196.721

198.606 TW 198.240 B

08

FFL 198.212 FFL 199.274 198.327 FFL 196.940

FFL 200.024

RW5

BL 199.524 198.452 TW 198.240 BL 196.440

FFL 199.424

TW 196.940

FFL 199.574 RW1

FFL 199.724 199.499 290mm THICK CORE-FILLED BLOCKWORK AT HEIGHT 0 TO 1600mm

RW1A 196.972

TW 196.940 AND 190mm THICK CORE-FILLED BLOCKWORK ABOVE 1600mm.

FFL 199.874 FFL 198.240 195.461

RW3

RW1

TW 198.240 TW 198.240

198.069

SITE FILL

3000 MAX

199.149 FFL 196.890

198.224 4 BL 196.390

197.857

198.082 290

197.091 197.307

RW4

196.766 195.323 N12-400 HORIZONTAL BARS THROUGHOUT

196.879

198.062 B197.252

RW4

TW 197.979 08

TW 198.240 N16-200 IN 2 LAYERS WITH 75mm COVER FROM

OUTSIDE FACE ON 290mm THICK BLOCK WORK.

1600

197.754

197.333 196.210

195.227 200 mm MIN THICKNESS X 600 mm MIN N20 AT 200 mm C/C TOP AND

DEPTH, 20 mm GRAVEL DRAINAGE LAYER BOTTOM BARS PERPENDICULAR

WITH 80 mm AGRICULTURAL DRAINAGE TO THE RETAINING WALL

PIPE WRAPPED IN FILTER FABRIC AT

SL2 SL1

BASE. LAID ON FALL TO ALLOW FOR

DRAINAGE AWAY FROM WALL.

200

75 MICRON FORTECON SL2 BEAM

LAYER TAPED AND SL2 BEAM

600

LAPPED AT JOINTS N12 AT 200 mm C/C TOP AND

RETAINING WALL PLAN BOTTOM BARS PARALLEL TO THE

- RETAINING WALL

ADDITIONAL N12 AT 200 mm

STARTER BARS TO MATCH MAIN WALL C/C SIDE BARS TO SF1.

REINFORCEMENT LAPPED INTO

FOOTING AND BLOCKWORK WALL.

REFER TO NOTES FOR LAP LENGTHS.

RW1 SECTION DETAIL

PROJECT CLIENT DRAWING TITLE

FOR CONSTRUCTION

4 31/10/22 ISSUED FOR CONSTRUCTION M. THOMSON

AMBER HOUSE ENDURO BUILDERS STRUCTURAL DESIGN

3 14/10/22 ISSUED FOR CONSTRUCTION M. THOMSON LOT 250 KINTYRE ROAD 177 MOUNT BARKER RD CIVIL PLAN (A1)

SCALE (A3) DATE 31/10/22

123 Kiewa Valley Hwy THE HUB, 5 PEEL ST

Principal

2 11/08/22 ISSUED FOR CONSTRUCTION M. THOMSON WOODFORDE, SA 5072 HAHNDORF, SA 5245 Mount Beauty, Victoria ADELAIDE SA 5000 RETAINING WALLS DRAWING NO. REV

1 10/07/22 ISSUED FOR CLIENT REVIEW M. THOMSON EB-ME-22096-07 4

M: 0437 0400 25 m: 0412 878 490

0 07/06/22 ISSUED FOR CLIENT REVIEW M. THOMSON Martin Kusz RBP-EC 40076

e: matt@metamorphosis.engineering

REV DATE DESCRIPTION APPROVED E: admin@kuschgroup.com.au BE(Hons) MIEAust CPEng PROJECT NUMBER EB-ME-22096

190

200 mm MIN THICKNESS X 600 mm MIN 190

DEPTH, 20 mm GRAVEL DRAINAGE LAYER 200 mm MIN THICKNESS X 600 mm MIN

WITH 80 mm AGRICULTURAL DRAINAGE DEPTH, 20 mm GRAVEL DRAINAGE LAYER

200 mm MIN THICKNESS X 600 mm MIN PIPE WRAPPED IN FILTER FABRIC AT WITH 80 mm AGRICULTURAL DRAINAGE

DEPTH, 20 mm GRAVEL DRAINAGE LAYER BASE. LAID ON FALL TO ALLOW FOR

190 PIPE WRAPPED IN FILTER FABRIC AT

WITH 80 mm AGRICULTURAL DRAINAGE DRAINAGE AWAY FROM WALL. BASE. LAID ON FALL TO ALLOW FOR

PIPE WRAPPED IN FILTER FABRIC AT

DRAINAGE AWAY FROM WALL. 190mm THICK CORE-FILLED

BASE. LAID ON FALL TO ALLOW FOR

DRAINAGE AWAY FROM WALL. BLOCKWORK AT HEIGHT

190 800mm TO 24000mm

190mm THICK CORE-FILLED

190mm THICK CORE-FILLED N12-200 BARS CENTRAL BLOCKWORK

BLOCKWORK AT HEIGHT

400mm TO 2000mm

N12-200 BARS CENTRAL

3000 MAX.

2400 MAX.

190mm THICK CORE-FILLED N12-200 BARS CENTRAL N12-400 HORIZONTAL BARS

SITE FILL

BLOCKWORK THROUGHOUT

2000 MAX.

SITE FILL N12-400 HORIZONTAL BARS

SITE FILL 1600 MAX. N12-200 BARS CENTRAL N12-400 HORIZONTAL BARS THROUGHOUT

THROUGHOUT

N16-200 BARS CENTRAL

N12-400 HORIZONTAL BARS

290mm THICK CORE-FILLED 290mm THICK CORE-FILLED

800

THROUGHOUT N12-200 BARS C/C TOP AND

BLOCKWORK AT HEIGHT 0 TO BLOCKWORK AT HEIGHT 0 TO

400mm 800mm BOTTOM BARS PARALLEL TO

400

RETAINING WALL

VARIES FROM +196.94 TO +197.94

SL2A SL2A SL2A

200

75 MICRON FORTECON 75 MICRON FORTECON 75 MICRON FORTECON

LAYER TAPED AND STARTER BARS TO MATCH MAIN WALL LAYER TAPED AND STARTER BARS TO MATCH MAIN WALL LAYER TAPED AND STARTER BARS TO MATCH MAIN WALL

LAPPED AT JOINTS REINFORCEMENT DEVELOPED INTO LAPPED AT JOINTS REINFORCEMENT DEVELOPED INTO LAPPED AT JOINTS REINFORCEMENT DEVELOPED INTO

FOOTING AND BLOCKWORK WALL. FOOTING AND BLOCKWORK WALL. FOOTING AND BLOCKWORK WALL. 900

REFER TO NOTES FOR LAP LENGTHS. REFER TO NOTES FOR LAP LENGTHS. REFER TO NOTES FOR LAP LENGTHS.

STARTER BARS TO MATCH MAIN WALL

N12-200 BARS C/C TOP AND

REINFORCEMENT DEVELOPED INTO

BOTTOM BARS PERPENDICULAR

FOOTING AND BLOCKWORK WALL.

TO RETAINING WALL

RW2 (0 TO 1.6m) DETAIL RW2 (1.6 TO 2m) DETAIL RW2 (2m TO 2.4m) DETAIL REFER TO NOTES FOR LAP LENGTHS.

W1 DETAIL

190 190 190

200 mm MIN THICKNESS X 600 3

mm MIN DEPTH, 20 mm

GRAVEL DRAINAGE LAYER 190mm THICK CORE-FILLED

BLOCKWORK AT HEIGHT N12-200 BARS C/C TOP AND BOTTOM

WITH 80 mm AGRICULTURAL

400mm TO 2000mm 190mm THICK CORE-FILLED BARS. REFER TO RW4/W1 DETAIL.

DRAINAGE PIPE WRAPPED IN

BLOCKWORK POOL SECTION SHOWN

FILTER FABRIC AT BASE. LAID

ON FALL TO ALLOW FOR N12-200 BARS CENTRAL INDICATIVELY

DRAINAGE AWAY FROM WALL.

190mm THICK CORE-FILLED N12-200 BARS CENTRAL

200 mm MIN THICKNESS X 600 mm MIN BLOCKWORK N12-200 BARS C/C TOP AND BOTTOM

2000

SITE FILL DEPTH, 20 mm GRAVEL DRAINAGE LAYER BARS. REFER TO RW4/W1 DETAIL.

WITH 80 mm AGRICULTURAL DRAINAGE N12-200 STARTER BARS

N12-400 HORIZONTAL BARS

THROUGHOUT PIPE WRAPPED IN FILTER FABRIC AT

BASE. LAID ON FALL TO ALLOW FOR N12-200 BARS CENTRAL

N12-400 HORIZONTAL BARS

DRAINAGE AWAY FROM WALL.

3000 MAX

N12-200 BARS C/C TOP THROUGHOUT

3000

AND BOTTOM BARS

PERPENDICULAR TO 290mm THICK CORE-FILLED

RETAINING WALL BLOCKWORK AT HEIGHT 0 TO

N12-400 HORIZONTAL BARS

400mm

400

THROUGHOUT

+197.94

200

SOIL HEIGHT

1000 MAX

1000

1400 MAX

N12-200 BARS C/C TOP N12-200 BARS C/C TOP

1500 AND BOTTOM BARS AND BOTTOM BARS COMPACTED

PERPENDICULAR TO PERPENDICULAR TO NATURAL

STARTER BARS TO MATCH MAIN WALL GROUND FILL

N12-200 BARS C/C TOP AND RETAINING WALL RETAINING WALL

REINFORCEMENT DEVELOPED INTO

BOTTOM BARS PARALLEL

FOOTING AND BLOCKWORK WALL.

TO RETAINING WALL

REFER TO NOTES FOR LAP LENGTHS. VARRIES FROM +196.94 TO +197.94 +196.94 +196.94

200

200

RW3 DETAIL

2400 MAX

1000 1000

SUSPENDED SPAN

N12-200 BARS C/C TOP AND STARTER BARS TO MATCH MAIN WALL N12-200 BARS C/C TOP AND STARTER BARS TO MATCH MAIN WALL REFER TO RW4/RW5 WALL

BOTTOM BARS PARALLEL REINFORCEMENT DEVELOPED INTO BOTTOM BARS PARALLEL REINFORCEMENT DEVELOPED INTO AND FOOTING DETAIL

TO RETAINING WALL FOOTING AND BLOCKWORK WALL. TO RETAINING WALL FOOTING AND BLOCKWORK WALL.

REFER TO NOTES FOR LAP LENGTHS. REFER TO NOTES FOR LAP LENGTHS.

RW4 DETAIL RW5 DETAIL SECTION B - WALL FOOTING SECTION

DETAIL

PROJECT CLIENT DRAWING TITLE

AMBER HOUSE ENDURO BUILDERS

FOR CONSTRUCTION

STRUCTURAL DESIGN

3 31/10/22 ISSUED FOR CONSTRUCTION M. THOMSON LOT 250 KINTYRE ROAD 177 MOUNT BARKER RD RETAINING WALL (A1)

SCALE (A3) DATE 31/10/22

123 Kiewa Valley Hwy THE HUB, 5 PEEL ST

Principal

2 14/10/22 ISSUED FOR CONSTRUCTION M. THOMSON WOODFORDE, SA 5072 HAHNDORF, SA 5245 Mount Beauty, Victoria ADELAIDE SA 5000 DETAILS DRAWING NO. REV

1 11/08/22 ISSUED FOR CONSTRUCTION M. THOMSON EB-ME-22096-08 3

M: 0437 0400 25 m: 0412 878 490

0 10/07/22 ISSUED FOR CLIENT REVIEW M. THOMSON Martin Kusz RBP-EC 40076

e: matt@metamorphosis.engineering

REV DATE DESCRIPTION APPROVED E: admin@kuschgroup.com.au BE(Hons) MIEAust CPEng PROJECT NUMBER EB-ME-22096

20mm COMPRESSIBLE FILLER 20mm COMPRESSIBLE FILLER 20mm COMPRESSIBLE FILLER

SLIP JOINT BETWEEN SLIP JOINT BETWEEN SLIP JOINT BETWEEN

200 SHOTCRETE WALL AND 200 SHOTCRETE WALL AND SHOTCRETE WALL AND

200mm MINIMUM THICKNESS SHOTCRETE 200

BLOCKWORK WALL BLOCKWORK WALL BLOCKWORK WALL

200mm MINIMUM THICKNESS SHOTCRETE POOL POOL WALL. N12-100 BARS EACH FACE,

200mm MINIMUM THICKNESS SHOTCRETE

WALL. N12-200 BARS EACH FACE, VERTICAL VERTICAL AND HORIZONTAL FROM 0 TO

POOL WALL. N16-125 BARS EACH FACE,

AND HORIZONTAL THROUGHOUT. CONCRETE 0.7m HEIGHT, N12-200 BARS EACH FACE,

VERTICAL AND HORIZONTAL FROM 0 TO

TO BE PLACED AT SAME TIME AS POOL BASE. VERTICAL AND HORIZONTAL FROM 0.7m

1.1m HEIGHT, N12-200 BARS EACH FACE,

HEIGHT TO TOP OF WALL. CONCRETE TO

VERTICAL AND HORIZONTAL FROM 1.1m

BE PLACED AT SAME TIME AS POOL BASE.

ADJACENT RETAINING WALL ADJACENT RETAINING WALL HEIGHT TO TOP OF WALL. CONCRETE TO ADJACENT RETAINING WALL

SHOWN INDICATIVELY SHOWN INDICATIVELY BE PLACED AT SAME TIME AS POOL BASE. SHOWN INDICATIVELY

1600 TO 1800 MAX

1100 TO 1600 MAX

1100

200mm MINIMUM THICKNESS SHOTCRETE 200mm MINIMUM THICKNESS SHOTCRETE

VARIES FROM

VARIES FROM

POOL BASE. N12-200 BARS TOP AND POOL BASE. N12-200 BARS TOP AND

BOTTOM, BOTH WAYS. SUPPORTED ON BOTTOM, BOTH WAYS. SUPPORTED ON 200mm MINIMUM THICKNESS SHOTCRETE

DWARF WALLS AND COMPACTED FILL TO DWARF WALLS AND COMPACTED FILL TO

1800 TO 2200 MAX

POOL BASE. N16-125 BARS TOP AND

VARIES FROM

POOL FOUNDATION BELOW. POOL FOUNDATION BELOW. BOTTOM, BOTH WAYS. SUPPORTED ON

DWARF WALLS AND COMPACTED FILL TO

POOL FOUNDATION BELOW.

200

DWARF WALL SUPPORTING DWARF WALL SUPPORTING DWARF WALL SUPPORTING

200

SHOTCRETE POOL STRUCTURE SHOTCRETE POOL STRUCTURE SHOTCRETE POOL STRUCTURE

N12-200 L-BARS TO MATCH MAIN N12-200 L-BARS TO MATCH MAIN

WALL REINFORCEMENT LAPPED WALL REINFORCEMENT LAPPED

200

INTO POOL BASE AND POOL INTO POOL BASE AND POOL

WALL. REFER TO NOTES FOR WALL. REFER TO NOTES FOR

LAP LENGTHS. COMPACTED FILL LAP LENGTHS.

COMPACTED FILL

COMPACTED FILL

N12-200 L-BARS TO MATCH MAIN

WALL REINFORCEMENT LAPPED

INTO POOL BASE AND POOL

WALL. REFER TO NOTES FOR

LAP LENGTHS.

POOL FOUNDATION

POOL FOUNDATION

SHOWN INDICATIVELY

SHOWN INDICATIVELY

POOL FOUNDATION

SHOWN INDICATIVELY

POOL WALL DETAIL - ZONE 1 POOL WALL DETAIL - ZONE 2 POOL WALL DETAIL - ZONE 3

150mm MIN THICKNESS POOL SEAT. N12-200 SKIMMER BOX

TOP AND BOTTOM BARS PARALLEL TO N12-200 BARS

WALL. N12-300 TOP AND BOTTOM BARS EACH WAY

PERPENDICULAR TO WALL, TYPICAL

A

REMCO BENCH SEAT - 150

(REMOVALBLE LID)

WATER LEVEL 75 WATER LEVEL 150mm MIN THICKNESS POOL SEAT. N12-200

TOP AND BOTTOM BARS PERPENDICULAR

TO WALL. N12-300 TOP AND BOTTOM BARS

500

150 N12-200 BARS VERTICAL, 150 PARALLEL TO WALL, TYPICAL

CENTRAL, N12-300 BARS

150

HORIZONTAL THROUGHOUT

150

150mm MIN THICKNESS DIVIDING WALL. 150mm MIN THICKNESS DIVIDING WALL.

EXTERNAL POOL WALLS N16-200 BARS VERTICAL EACH FACE, N16-200 BARS VERTICAL EACH FACE,

AND POOL FOUNDATION N12-200 BARS HORIZONTAL EACH FACE N12-200 BARS HORIZONTAL EACH FACE

SHOWN INDICATIVELY

L-BARS TO MATCH MAIN WALL L-BARS TO MATCH MAIN WALL

REINFORCEMENT LAPPED INTO POOL REINFORCEMENT LAPPED INTO POOL

BASE AND DIVIDING WALL. REFER TO BASE AND DIVIDING WALL. REFER TO

NOTES FOR LAP LENGHTS NOTES FOR LAP LENGHTS

REMCO COVER

DIVIDING WALL & SKIMMER BOX SECTION A DETAIL

WALL DETAIL

PROJECT CLIENT DRAWING TITLE

AMBER HOUSE ENDURO BUILDERS

FOR CONSTRUCTION

STRUCTURAL DESIGN

LOT 250 KINTYRE ROAD 177 MOUNT BARKER RD POOL DETAILS (A1)

SCALE (A3) DATE 07/11/22

123 Kiewa Valley Hwy THE HUB, 5 PEEL ST

Principal

WOODFORDE, SA 5072 HAHNDORF, SA 5245 Mount Beauty, Victoria ADELAIDE SA 5000

DRAWING NO. REV

EB-ME-22096-09 0

M: 0437 0400 25 m: 0412 878 490

0 07/11/22 ISSUED FOR CLIENT REVIEW M. THOMSON Martin Kusz RBP-EC 40076

e: matt@metamorphosis.engineering

REV DATE DESCRIPTION APPROVED E: admin@kuschgroup.com.au BE(Hons) MIEAust CPEng PROJECT NUMBER EB-ME-22096

You might also like

- Bridge Technical Note 2018 - 007 Noise Attenuation Walls June 2018No ratings yetBridge Technical Note 2018 - 007 Noise Attenuation Walls June 20183 pages

- Australian/New Zealand Standard: Cold-Formed Steel StructuresNo ratings yetAustralian/New Zealand Standard: Cold-Formed Steel Structures8 pages

- Seismic Load Calculation for Rwanda Power Plant0% (1)Seismic Load Calculation for Rwanda Power Plant8 pages

- HB 2.2 - 2003 Australian Standard Structural EngineeringNo ratings yetHB 2.2 - 2003 Australian Standard Structural Engineering218 pages

- Non-Structural Components Design ReviewNo ratings yetNon-Structural Components Design Review82 pages

- Rectangular Concrete Footing Design GuideNo ratings yetRectangular Concrete Footing Design Guide4 pages

- AS 1163-1991 Structural Steel Hollow SectionsNo ratings yetAS 1163-1991 Structural Steel Hollow Sections27 pages

- Wind Load Analysis As Per Australian Standard AS1170No ratings yetWind Load Analysis As Per Australian Standard AS11701 page

- Stellar 1N+66 - AIKO-A-GRH66Dw 635-665W - (2382x1134x30mm) - V1.1 - 202412 - DSDR - EN PDFNo ratings yetStellar 1N+66 - AIKO-A-GRH66Dw 635-665W - (2382x1134x30mm) - V1.1 - 202412 - DSDR - EN PDF2 pages

- Reinforced Masonry Under Compression Changes To As 3700 2018No ratings yetReinforced Masonry Under Compression Changes To As 3700 20185 pages

- Norseman Nordic Void Technical & Submittal Information December 2014No ratings yetNorseman Nordic Void Technical & Submittal Information December 201422 pages

- Structural Reinforcement Detailing GuideNo ratings yetStructural Reinforcement Detailing Guide5 pages

- Technical Specification: 20' X 8' X 8'6" ISO 1CC TYPE Steel Dry Cargo ContainerNo ratings yetTechnical Specification: 20' X 8' X 8'6" ISO 1CC TYPE Steel Dry Cargo Container22 pages

- 61 - Summary of Items Discussed in APSEC Discussion Forum On 13 January 2017No ratings yet61 - Summary of Items Discussed in APSEC Discussion Forum On 13 January 201714 pages

- Structural Modeling of Cold-Formed Steel Portal Frames by Zhang and Rasmussen 2015No ratings yetStructural Modeling of Cold-Formed Steel Portal Frames by Zhang and Rasmussen 201511 pages

- Structural Design Guidelines For Aluminum Framed SkylightsNo ratings yetStructural Design Guidelines For Aluminum Framed Skylights1 page

- PSA Metric Threaded Connections Design Guide Oct 23No ratings yetPSA Metric Threaded Connections Design Guide Oct 2336 pages

- Section 9: Steelwork: Tenaga Nasional Berhad Part 2: Technical Specifications Section 9: SteelworkNo ratings yetSection 9: Steelwork: Tenaga Nasional Berhad Part 2: Technical Specifications Section 9: Steelwork4 pages

- Edoc - Pub As 4084 2012 Steel Storage RackingNo ratings yetEdoc - Pub As 4084 2012 Steel Storage Racking2 pages

- Australian/New Zealand Standard: Built-In Components For Masonry Construction Part 1: Wall TiesNo ratings yetAustralian/New Zealand Standard: Built-In Components For Masonry Construction Part 1: Wall Ties7 pages

- YCDC Building Rules & Regulation, LS Duties PDFNo ratings yetYCDC Building Rules & Regulation, LS Duties PDF20 pages

- Engineers Structural Drawings - StampedNo ratings yetEngineers Structural Drawings - Stamped14 pages

- Connections To Masonry - Powerpoint PresentationNo ratings yetConnections To Masonry - Powerpoint Presentation173 pages

- Rfi 10 Bpi Marikina W. Paz - Exposed RebarsNo ratings yetRfi 10 Bpi Marikina W. Paz - Exposed Rebars3 pages

- Meralco Guidelines For Customer Owned Poles100% (2)Meralco Guidelines For Customer Owned Poles10 pages

- Memory Jogger Prospect Building Workbook - GoPro100% (6)Memory Jogger Prospect Building Workbook - GoPro72 pages

- Solis Energy Storage Inverter Battery Matching Pamphlet S6-EH3P (8-15) K02-NV-YD-L GLOBAL V2,01 202509No ratings yetSolis Energy Storage Inverter Battery Matching Pamphlet S6-EH3P (8-15) K02-NV-YD-L GLOBAL V2,01 2025094 pages

- Basic References:: Ateneo de Manila University School of Law Constitutional Law I - Syllabus (Candelaria) (SY 2019-2020)No ratings yetBasic References:: Ateneo de Manila University School of Law Constitutional Law I - Syllabus (Candelaria) (SY 2019-2020)6 pages

- Collateralized Debt Obligation (CDO) - Can Be Collateralized Bond Obligations or Collateralized Loan Obligations. How A CDO Works - Step-by-StepNo ratings yetCollateralized Debt Obligation (CDO) - Can Be Collateralized Bond Obligations or Collateralized Loan Obligations. How A CDO Works - Step-by-Step4 pages

- Gender Pay Gap & Female Unemployment AnalysisNo ratings yetGender Pay Gap & Female Unemployment Analysis29 pages

- Research of Sorting Technology Based On Industrial Robot of Machine VisionNo ratings yetResearch of Sorting Technology Based On Industrial Robot of Machine Vision5 pages

- Twin Slash Duals Installation Instructions Part# 16853No ratings yetTwin Slash Duals Installation Instructions Part# 168535 pages

- NE100, NE101 Spectra Theodolite Data SheetNo ratings yetNE100, NE101 Spectra Theodolite Data Sheet2 pages

- Flexible Ac Transmission Systems (Facts) - Full Paper Presentation - Eeerulez - Blogspot100% (11)Flexible Ac Transmission Systems (Facts) - Full Paper Presentation - Eeerulez - Blogspot20 pages