Professional Documents

Culture Documents

Freeflow e 23 04 03

Uploaded by

Robin ZhaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Freeflow e 23 04 03

Uploaded by

Robin ZhaoCopyright:

Available Formats

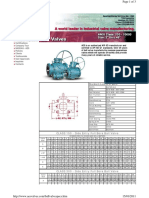

FREE FLOW Plate Heat Exchangers

Your benefit:

Long service life

due to free flow channels.

FREE FLOW plate heat exchangers cover those

applications where conventional plate heat

exchangers reach their limits. Their special

features include the constant-width gap cross-

section between the individual plates and the

rough-wave profiling of the plates (the clearance

between the plates is up to 12 mm/0,47").

The FREE FLOW

product range

offers you the following features:

■ Operation without clogging due to

constant-width gaps

■ THE alternative to shell-and-tube

and spiral heat exchangers due to

■ low investment and operating costs

■ low space requirement

■ FA 159 and FA 161 without metal

supports

■ Plates are available in different sizes,

gap widths, and materials

■ Gasket materials NBR and EPDM.

Special gaskets, e.g. made of VITON‚

are available for some types

■ Suitable for products containing

fibres and solids (fruit juices contain-

ing fibres and pulp, waste water in

the paper and pulp, textile and sugar

industries as well as highly viscous

products)

Specifications Cross-sections of GEA Ecoflex

FREE FLOW plates

FA 159 FA 161 N 40 FA 184 FA 192

Plate length mm/inch 1082/42.6 1455/57.3 1406/55.4 1794/70.6 2305/90.7

Plate width mm/inch 320/12.6 472/18.6 432/17 678/26.7 985/38.8

Max.

m3/ h/gpm 35/154 115/506 220/968 550/2422 1350 / 5944

flow rate

Painted

50/2" 100/ 4" 125/5" 200/8" 350/14" N 40

Connection sizes frame

5 5

(max.) 0.2" 0.2"

Stainless

50/2" 80/3" 100/4"

steel frame

Max.

bar/psi 6/ 87 6/87 10/145 6/87 8/116

operating pressure

Painted • • • • •

With

stainless • • •

Frames steel facing

Completely

made of • FA 159

stainless steel FA 161

Subject to technical modifications. 04/03 inform advertising

6 6

1.4401 / 0.24" 0.24"

• • • • •

AISI 316

1.4439 /

• • • •

AISI 317

Plate material 1.4547 /

• • • •

254 SMO

Hastelloy

• •

C-276

Titanium • FA 161

FA 184

Glueless gasket FA 192

• 12 6

system

0.47" 0.24"

GEA Ecoflex

For more than 75 years, GEA Ecoflex has been developing customer- HVAC pulp / paper

oriented and cost-optimised plate heat exchanger solutions for the general industry food

following fields of application: refrigeration pharmaceutical

sugar marine

chemical power

textile

Your contact:

The specifications contained in this printing unit are intended only to serve the

non binding description of our products and are not subject to guarantee.

Karl-Schiller-Str. 1-3, D-31157 Sarstedt Binding specifications, especially pertaining to performance data and suitability

Phone: +49 (0) 5066 / 601- 0 · Fax: +49 (0) 5066 / 601-104 for specific operating purposes, are dependent upon the individual circumstances

www.gea-ecoflex.com · e-mail: info@gea-ecoflex.com at the operation location and can, therefore, only be made in terms of precise

requests.

You might also like

- Concrete Slab Load Calculation PDFDocument54 pagesConcrete Slab Load Calculation PDFEddie TaiNo ratings yet

- Empty BOQ SampleDocument9 pagesEmpty BOQ SampleCyprian Metobo100% (1)

- Modelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleFrom EverandModelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleRating: 5 out of 5 stars5/5 (1)

- Astm A 500 GRBDocument1 pageAstm A 500 GRBMuhammed ShafiNo ratings yet

- CNFree FlowserielsDocument2 pagesCNFree FlowserielsRobin ZhaoNo ratings yet

- NRS Flanged Ends 3288 300 FLFDocument1 pageNRS Flanged Ends 3288 300 FLFgoviaNo ratings yet

- Piston ValvesDocument2 pagesPiston ValvesFlowBiz Exports Pvt. Ltd.No ratings yet

- OS&Y Gate Valves - Flanged Ends: Schematic DrawingDocument1 pageOS&Y Gate Valves - Flanged Ends: Schematic Drawingbhima irabattiNo ratings yet

- LIFECO Model 3299 300 FLF OSY Resilient Seated Gate ValveDocument1 pageLIFECO Model 3299 300 FLF OSY Resilient Seated Gate ValveEng.Ibrahim OthmanNo ratings yet

- Technical Data Sheet: OS&Y Resilient Seated Gate Valve - Flanged Ends-300PSIDocument1 pageTechnical Data Sheet: OS&Y Resilient Seated Gate Valve - Flanged Ends-300PSIshoaibmahmood312No ratings yet

- API607 Ball ValvesDocument2 pagesAPI607 Ball Valvesdarkevilx003No ratings yet

- Visual Flow Indicator With Flap & Scale Plate PDFDocument2 pagesVisual Flow Indicator With Flap & Scale Plate PDFClarkFedele27No ratings yet

- MECH - Valvula de Compuerta OSY XZ41XDocument1 pageMECH - Valvula de Compuerta OSY XZ41XAlfredo BravoNo ratings yet

- Plummech OS&Y Gate ValvesDocument1 pagePlummech OS&Y Gate ValvesNguyễn Đăng PhúcNo ratings yet

- IFC Series Y125 and Y150 Fabricated Y-Strainers: Design FeaturesDocument2 pagesIFC Series Y125 and Y150 Fabricated Y-Strainers: Design FeaturesPrasanta Kumar Behera100% (1)

- Plug ValveDocument2 pagesPlug ValveFlowBiz Exports Pvt. Ltd.No ratings yet

- Jones MonitorDocument2 pagesJones MonitorHector RamonNo ratings yet

- Safety Relief Valve VSEODocument4 pagesSafety Relief Valve VSEOShashank HNo ratings yet

- OSY Flanged Ends 3299 300 FLF 3 1Document1 pageOSY Flanged Ends 3299 300 FLF 3 1melashry2023No ratings yet

- CI Wafer / DI Lug Butterfly Valves: Series 0160Document2 pagesCI Wafer / DI Lug Butterfly Valves: Series 0160Vignesh NadimuthuNo ratings yet

- Weflo Swing Check Valve F0311-300-Data-SheetDocument1 pageWeflo Swing Check Valve F0311-300-Data-Sheetachmad.zs7827No ratings yet

- ART 1460 Rev1Document1 pageART 1460 Rev1mohdmmedniyaz786No ratings yet

- Combination Flame Arrester & Free VentDocument4 pagesCombination Flame Arrester & Free VentCarlos Andrés BeltránNo ratings yet

- Imi PBM Ansi Double Block & Bleed Valves: AN/TN SERIES 5, Sizes 1/2" - 12"Document2 pagesImi PBM Ansi Double Block & Bleed Valves: AN/TN SERIES 5, Sizes 1/2" - 12"SAM AZNo ratings yet

- Fig Fm463 Fm466 Fa463 Check Cranefs Ds 1702 p95Document1 pageFig Fm463 Fm466 Fa463 Check Cranefs Ds 1702 p95Daniel FloresNo ratings yet

- Shand & Jurs-94160Document5 pagesShand & Jurs-94160jithin.rjn4055No ratings yet

- OSY Flanged X Grooved Ends 3299 300 FXGLFDocument1 pageOSY Flanged X Grooved Ends 3299 300 FXGLFmelashry2023No ratings yet

- V15 Series Needle ValvesDocument4 pagesV15 Series Needle ValvesTran Duc DungNo ratings yet

- Free Float Steam Trap: Model Stainless SteelDocument2 pagesFree Float Steam Trap: Model Stainless SteelJustin GentryNo ratings yet

- Keystone K-Lok 360-370 Data SheetDocument12 pagesKeystone K-Lok 360-370 Data SheetMnttoMecNo ratings yet

- Hol-Sealers™ Hole Seals: Accessories 1Document4 pagesHol-Sealers™ Hole Seals: Accessories 1soayNo ratings yet

- 2017-07-24 Footmaster FR 2Document1 page2017-07-24 Footmaster FR 2Kasia MazurNo ratings yet

- GLT Y StrainerDocument1 pageGLT Y StrainerBagusRekaNo ratings yet

- Dixon HT SeriesDocument2 pagesDixon HT SeriesAngelina JunioNo ratings yet

- Hidrante Seco Mod F0733Document1 pageHidrante Seco Mod F0733Julio FloresNo ratings yet

- A900 - Control HidraulicoDocument14 pagesA900 - Control HidraulicoAnnie De WildeNo ratings yet

- Product Data Sheet: Actuator AssemblyDocument2 pagesProduct Data Sheet: Actuator AssemblylorenzoNo ratings yet

- Ball ValveDocument12 pagesBall ValveToty DzNo ratings yet

- SLds 12 19Document4 pagesSLds 12 19Ha HoangNo ratings yet

- Nowata-A-Series-Spec-Sheet - Media FilterDocument4 pagesNowata-A-Series-Spec-Sheet - Media Filteradewunmi olufemiNo ratings yet

- Ghibson ButterflyHotAirSmoke BrochureDocument5 pagesGhibson ButterflyHotAirSmoke Brochurejhon jairo arangoNo ratings yet

- Scheda Tecnica Bonomi North America 760021V36 V6 V9Document3 pagesScheda Tecnica Bonomi North America 760021V36 V6 V9Miguel Alejandro de León FuentesNo ratings yet

- F0111 300 Data SheetDocument1 pageF0111 300 Data SheetSehoon OhNo ratings yet

- Goulds B AP I3171 LDocument4 pagesGoulds B AP I3171 LwalterNo ratings yet

- Technical Sheet BTM7Document6 pagesTechnical Sheet BTM7Malik DaniyalNo ratings yet

- CAT114 A-Rev.2Document2 pagesCAT114 A-Rev.2Jordi Enjuanes BalaguerNo ratings yet

- Venteo de Emergencia 94200-3FDocument3 pagesVenteo de Emergencia 94200-3FSantiago PeñuelaNo ratings yet

- HERODocument2 pagesHEROozéias salvino cardosoNo ratings yet

- Basket Strainer b150Document4 pagesBasket Strainer b150Rafael UnibioNo ratings yet

- MotorizedisolationvalvesDocument1 pageMotorizedisolationvalves9kkn7rsdm8No ratings yet

- 02 Mech-OS&Y Gate Valve UL FM (XZ41X VALVULAS 290917Document1 page02 Mech-OS&Y Gate Valve UL FM (XZ41X VALVULAS 290917Roman UgarteNo ratings yet

- 111.335.00.5 SpecsheetDocument1 page111.335.00.5 Specsheetsms9869No ratings yet

- Bellows Sealed Globe Valve, Flanged Ends 11.3-G-Fl: 1/2" - 2" Asme 150 - 600 LBDocument4 pagesBellows Sealed Globe Valve, Flanged Ends 11.3-G-Fl: 1/2" - 2" Asme 150 - 600 LBfranznelsonNo ratings yet

- AES BallvalvespecsDocument3 pagesAES Ballvalvespecsclaudio godinezNo ratings yet

- Valvulas Mariposas DorotDocument4 pagesValvulas Mariposas DorotVicenteRojasLeonNo ratings yet

- VB-02 - Bola CS CL600 SW (Apollo 83B-240)Document4 pagesVB-02 - Bola CS CL600 SW (Apollo 83B-240)joseNo ratings yet

- Breather Valve 94020-3HDocument8 pagesBreather Valve 94020-3Hbuzz cmkyNo ratings yet

- OS&Y Resilient Seated Gate Valve, Flanged Ends, 300PSI FIG.F0111-300Document1 pageOS&Y Resilient Seated Gate Valve, Flanged Ends, 300PSI FIG.F0111-300Fight FireNo ratings yet

- ART 6100 PN16: PN16 Float Control ValveDocument2 pagesART 6100 PN16: PN16 Float Control ValverashidNo ratings yet

- Threaded End Ball Valves: Full and Reduced PortDocument4 pagesThreaded End Ball Valves: Full and Reduced PortKok WaiNo ratings yet

- AWWA C-504: Model 3900F & Model 3900MDocument2 pagesAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitNo ratings yet

- NORD SEW Exchange DetailsasdasdaDocument5 pagesNORD SEW Exchange DetailsasdasdaayavuzbvsNo ratings yet

- Aluminium 2014 t6 2014 t651Document3 pagesAluminium 2014 t6 2014 t651Agung Sapto AjiNo ratings yet

- Assignment 2Document6 pagesAssignment 2Ishaan IslamNo ratings yet

- Poly Cell Adhesive: Main ApplicationDocument1 pagePoly Cell Adhesive: Main ApplicationHung Mai VanNo ratings yet

- PU Foam Injection Product BrochureDocument4 pagesPU Foam Injection Product BrochureMiscNo ratings yet

- ME 303 (Manufacturing Engineering) - 08 - Machining IIDocument38 pagesME 303 (Manufacturing Engineering) - 08 - Machining IITt OwnsqqNo ratings yet

- Equipment Supporting Structures and Pipe RackDocument10 pagesEquipment Supporting Structures and Pipe RackSriram KumaranNo ratings yet

- AR Deleuze ElargissementDocument10 pagesAR Deleuze ElargissementMohamad Ali AkbarNo ratings yet

- Masonry and ConcreteDocument10 pagesMasonry and ConcreteMelwin MakalintalNo ratings yet

- Soal PTS Kode DDocument5 pagesSoal PTS Kode DbaeeNo ratings yet

- Maccaferri - Road Mesh Heavy Duty SpecDocument2 pagesMaccaferri - Road Mesh Heavy Duty SpecNguyen HungNo ratings yet

- Microthene F For SMC BMC 9485Document6 pagesMicrothene F For SMC BMC 9485Frank HardyNo ratings yet

- Request For Prior ClearanceDocument2 pagesRequest For Prior ClearanceRyan Melvin NamalataNo ratings yet

- Matweb Carbon SteelDocument1 pageMatweb Carbon SteelSuzy ChenNo ratings yet

- PDS HF09522 Rev0 - EvaleneDocument2 pagesPDS HF09522 Rev0 - EvalenechinchotarngNo ratings yet

- Flo-Grout 2WWADocument2 pagesFlo-Grout 2WWAosama mohNo ratings yet

- 217-CEN Timber Structures - CEN TC 124Document4 pages217-CEN Timber Structures - CEN TC 124Selyun E OnnajNo ratings yet

- Blister Coating - Heat Seal and Cold SealDocument4 pagesBlister Coating - Heat Seal and Cold SealAnujNo ratings yet

- Density of Materials & Comparison of Ss 304 Vs Ss316LDocument4 pagesDensity of Materials & Comparison of Ss 304 Vs Ss316LShino UlahannanNo ratings yet

- Week 6 (1) - CombinedDocument150 pagesWeek 6 (1) - CombinedAdelisa AdrovicNo ratings yet

- Simple Review of Soil ReinforcemementDocument17 pagesSimple Review of Soil Reinforcemementgabriel oliveira100% (1)

- Building Technology ResearchDocument10 pagesBuilding Technology ResearchBlyne ComilangNo ratings yet

- Stycast 2651-40 W1 (2016)Document4 pagesStycast 2651-40 W1 (2016)vishal089No ratings yet

- 10 SteelDocument10 pages10 SteelSahiNo ratings yet

- List of Speakers Singapore2019Document2 pagesList of Speakers Singapore2019Leela WatiNo ratings yet

- Pipe Clamps & Accessories: Chilled Water Clamp LKS 19 (M)Document2 pagesPipe Clamps & Accessories: Chilled Water Clamp LKS 19 (M)rahimi mohamadNo ratings yet

- Rheobuild 2000 PFDocument2 pagesRheobuild 2000 PFFrancois-No ratings yet