Professional Documents

Culture Documents

ESAB 8018 Datos

Uploaded by

Elwe Singolo0 ratings0% found this document useful (0 votes)

5 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesESAB 8018 Datos

Uploaded by

Elwe SingoloCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

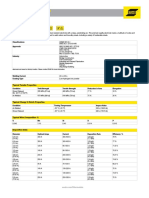

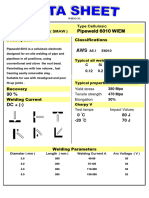

ATOM ARC LOW HYDROGEN LOW ALLOY ELECTRODES

ATOM ARC 8018-B3L AWS A5.5: E8018-B3LH4R

FEATURES TYPICAL MECHANICAL PROPERTIES

Atom Arc 8018-B3L electrodes contain 2.25% Stress Relieved 1 hr. @ 1275°F (691°C)

Cr and 1% Mo alloy additions with low carbon Yield Strength 78 ksi, 538 MPa

content. The electrode is designed for welding

Tensile Strength 93 ksi, 641 MPa

2.25% Cr - 1% Mo steels. The rod operates with

a very stable arc and minimal spatter. The low Elongation in 2” 25%

carbon analysis of the weld metal contributes

to its crack resistance. The addition of Cr and

Mo provide for the excellent creep and stress

rupture properties of weldments subjected to

elevated temperature service.

CLASSIFICATIONS AND APPROVALS WELD METAL ANALYSIS

AWS A5.5: E8018-B3LH4R C 0.04%

ASME SFA 5.5

Mn 0.7%

Si 0.4%

P 0.017%

S 0.015%

Cr 2.3%

Mo 1.1%

WELDING PROCESS

SMAW (Stick)

INDUSTRIES

Mobile Machinery

Pipeline

Power Generation

ESAB Welding & Cutting Products / esabna.com / 1.800.ESAB.123 CEP-10035-A

ATOM ARC LOW HYDROGEN LOW ALLOY ELECTRODES

ATOM ARC 8018-B3L

DEPOSITION TABLE

Diameter Optimal Current Current Range Deposition Rate Efficiency

in (mm) Amps Amps lb/hr (kg/hr) %

3/32 (2.4) 90 70 - 100 1.7 (0.8) 66.3

1/8 (3.2) 120 90 - 160 2.6 (1.2) 71.6

140 90 - 160 2.7 (1.2) 70.9%

5/32 (4.0) 140 130 - 220 3.1 (1.1) 75

170 130 - 220 3.8 (1.7) 73.5

PART NUMBER / PRODUCT INFORMATION

Part Number Description

255173320 AA 8018-B3L 3/32X14X10#HS

255173312 AA 8018-B3L 3/32X14X50#HS

255171829 AA 8018-B3L 1/8X14X10#HS

255171811 AA 8018-B3L 1/8X14X50#HS

255175325 AA 8018-B3L 5/32X14X10#HS

ESAB Welding & Cutting Products / esabna.com / 1.800.ESAB.123 CEP-10035-A

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Low Hydrogen Low Alloy Electrodes for High Strength Steel WeldsDocument2 pagesLow Hydrogen Low Alloy Electrodes for High Strength Steel WeldsFranklin Aranda ChacónNo ratings yet

- Smooth arc stainless steel electrodeDocument1 pageSmooth arc stainless steel electrodeson ambaritaNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- ESB 321M116700 SpecSheetDocument2 pagesESB 321M116700 SpecSheetArthanari VaidyanathanNo ratings yet

- ESB 321M116700 SpecSheetDocument2 pagesESB 321M116700 SpecSheetCitra Adelina SitorusNo ratings yet

- ATOM ARC LOW HYDROGEN ELECTRODESDocument2 pagesATOM ARC LOW HYDROGEN ELECTRODESanupmenon menonNo ratings yet

- Special Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenDocument1 pageSpecial Metal Korea Co., LTD.: Smaw Electrode - Mild Steel, Low HydrogenWelli E SNo ratings yet

- AWS A5.5 E8018-B2 low alloy welding electrodeDocument1 pageAWS A5.5 E8018-B2 low alloy welding electrodeWelli E SNo ratings yet

- Ok 347 AutrodDocument2 pagesOk 347 Autrodjoao guilhermeNo ratings yet

- Atom Arc 7018-B2L: Typical Tensile PropertiesDocument1 pageAtom Arc 7018-B2L: Typical Tensile PropertiesPubcrawlNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- MILD STEEL WIRE PROPERTIESDocument4 pagesMILD STEEL WIRE PROPERTIESPoltak SianiparNo ratings yet

- AWS A5.1 E6010 SC-10 Mild Steel Electrodes SpecificationsDocument56 pagesAWS A5.1 E6010 SC-10 Mild Steel Electrodes SpecificationsFakhar WindratamaNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Weld carbon steel plate with OK FLUX 231 fluxDocument2 pagesWeld carbon steel plate with OK FLUX 231 fluxborovniskiNo ratings yet

- Afrox Alumoid282 30146Document1 pageAfrox Alumoid282 30146Adel AbduoNo ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffNo ratings yet

- Aws Er70sDocument4 pagesAws Er70smanofNo ratings yet

- Exaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel ElectrodesDocument1 pageExaton 383-16: Covered (Stick) Electrodes (Smaw) Stainless Steel Electrodessergio jose morales perazaNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- S-8018 B2Document5 pagesS-8018 B2Abhishek AnandNo ratings yet

- Spoolarc 75: Elite SeriesDocument2 pagesSpoolarc 75: Elite Seriesrajit kumarNo ratings yet

- Atom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesAtom Arc 7018: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesKrishna VachaNo ratings yet

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- OK Flux 281 (F7AO-EM13K) PDFDocument2 pagesOK Flux 281 (F7AO-EM13K) PDFborovniskiNo ratings yet

- Mode of Metal Transfer-Gas Metal Arc Wel PDFDocument5 pagesMode of Metal Transfer-Gas Metal Arc Wel PDFRamesh RNo ratings yet

- Lincoln, TECHALLOY® 606 (c14107)Document2 pagesLincoln, TECHALLOY® 606 (c14107)RodrigoNo ratings yet

- COVERED ELECTRODES FOR MILD STEEL WELDINGDocument1 pageCOVERED ELECTRODES FOR MILD STEEL WELDINGKannan MurugesanNo ratings yet

- FICHADocument2 pagesFICHAadmisecoinperuNo ratings yet

- E8018-B2 E7018-1 H4R: AWS ClassificationsDocument1 pageE8018-B2 E7018-1 H4R: AWS ClassificationsARUNNo ratings yet

- AWS Classification PosterDocument1 pageAWS Classification PosterJorge LunaNo ratings yet

- Low Hydrogen High Tensile Welding RodDocument1 pageLow Hydrogen High Tensile Welding Rodmohamed AdelNo ratings yet

- Delta E8018-B2L Aws A5.5Document1 pageDelta E8018-B2L Aws A5.5Ehab AhmedNo ratings yet

- Description:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless SteelDocument1 pageDescription:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless Steel13421301508No ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- Stainless Steel Welding Consumables GuideDocument3 pagesStainless Steel Welding Consumables GuideBranko FerenčakNo ratings yet

- Ficha Tecnica ER-316LDocument1 pageFicha Tecnica ER-316LOscar ZavaletaNo ratings yet

- BS5308 Part 1 Type 2Document4 pagesBS5308 Part 1 Type 2Anil ChakkadathNo ratings yet

- JIS S45C Steel, TemperedDocument2 pagesJIS S45C Steel, TemperedAnonymous kAday2100% (2)

- Metalcor 1.4571 Aisi 316 TiDocument1 pageMetalcor 1.4571 Aisi 316 TirezaNo ratings yet

- Lincoln6011 AS ES-MX PDFDocument2 pagesLincoln6011 AS ES-MX PDFJuan Novillo RamosNo ratings yet

- Afrox 308L (-196) electrode for cryogenic applicationsDocument4 pagesAfrox 308L (-196) electrode for cryogenic applicationsBranko FerenčakNo ratings yet

- 01112015000000B - Boehler EMK 8 - Solid WireDocument2 pages01112015000000B - Boehler EMK 8 - Solid WirePopa RobertNo ratings yet

- 6010Document1 page6010agrinjoshNo ratings yet

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNo ratings yet

- Laboratory ELCA Laboratories, Plot No. A-444, Road No. 37, Ram Nagar, Wagle Industrial Estate, Thane, MaharashtraDocument56 pagesLaboratory ELCA Laboratories, Plot No. A-444, Road No. 37, Ram Nagar, Wagle Industrial Estate, Thane, MaharashtraProsenjit RoyNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document3 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'bagusrindi2801No ratings yet

- Ama 23ak - enDocument1 pageAma 23ak - enmohamed AdelNo ratings yet

- E7014 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7014 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- S-717XM-12K_engDocument12 pagesS-717XM-12K_engamir bizhehNo ratings yet

- Product Data Sheet: Afrox 7018-1Document2 pagesProduct Data Sheet: Afrox 7018-1Gervasio AndradeNo ratings yet

- 19-CE-023-PMI Report Remaining (Jan 6th 2021)Document14 pages19-CE-023-PMI Report Remaining (Jan 6th 2021)thuctruongNo ratings yet

- Weld Consumable SelectionDocument25 pagesWeld Consumable SelectionNisarg PandyaNo ratings yet

- Universalis: Rutile ElectrodeDocument2 pagesUniversalis: Rutile ElectrodeBeshoy RedaNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

- Lesson 9 - Estimating & Comparing Weld Metal Costs 11Document1 pageLesson 9 - Estimating & Comparing Weld Metal Costs 11Elwe SingoloNo ratings yet

- Lesson 9 - Estimating & Comparing Weld Metal CostsDocument1 pageLesson 9 - Estimating & Comparing Weld Metal CostsElwe SingoloNo ratings yet

- Lesson 9 - Estimating & Comparing Weld Metal Costs 7Document1 pageLesson 9 - Estimating & Comparing Weld Metal Costs 7Elwe SingoloNo ratings yet

- Hazen Williams FormulaDocument1 pageHazen Williams FormulaJR ZunigaNo ratings yet

- Lesson 9 - Estimating & Comparing Weld Metal Costs 6Document1 pageLesson 9 - Estimating & Comparing Weld Metal Costs 6Elwe SingoloNo ratings yet

- Avesta Welding ManualDocument300 pagesAvesta Welding Manual66apenlullenNo ratings yet

- MSG 01283Document4 pagesMSG 01283ariessridharNo ratings yet

- Demag tc1200 SpecificationsDocument14 pagesDemag tc1200 SpecificationsElwe SingoloNo ratings yet

- A 193 - A 193M - 04 Qte5my9bmtkztqDocument12 pagesA 193 - A 193M - 04 Qte5my9bmtkztqfekihassanNo ratings yet

- Amerlock 400Document3 pagesAmerlock 400RafiqKuNo ratings yet

- Astm A 967 - 01 - Chemical Passivation Stainless Steel PDFDocument7 pagesAstm A 967 - 01 - Chemical Passivation Stainless Steel PDFElwe SingoloNo ratings yet

- Starting Torque Values for BoltsDocument6 pagesStarting Torque Values for BoltsHtet Mrak Aung100% (1)

- Lifting Lug CalculationDocument8 pagesLifting Lug CalculationLathesh JanarthananNo ratings yet

- AMIES-A-113 - 2 - Geotechnical Engineering RequirementsDocument21 pagesAMIES-A-113 - 2 - Geotechnical Engineering RequirementsSeungtai JeongNo ratings yet

- A Level Chemistry SolutionsDocument8 pagesA Level Chemistry SolutionsImagreenbucklegirl SGNo ratings yet

- HPLC Nexera PHDocument2 pagesHPLC Nexera PHhectorNo ratings yet

- Mechanical IOCL Technical PYQsDocument19 pagesMechanical IOCL Technical PYQsSANDIP PATELNo ratings yet

- CHEMISTRY - CHEMICAL BONDINGDocument6 pagesCHEMISTRY - CHEMICAL BONDINGChemistry ClassNo ratings yet

- Cossack - Summary Crude Oil Assay Report: Source of Sample Light Hydrocarbon Analysis Assay Summary / TBP DataDocument55 pagesCossack - Summary Crude Oil Assay Report: Source of Sample Light Hydrocarbon Analysis Assay Summary / TBP DataDaniel LautaroNo ratings yet

- Zinc Metal: Copper: Magnesium: Metal R: Zinc IonsDocument2 pagesZinc Metal: Copper: Magnesium: Metal R: Zinc IonstahjsalmonNo ratings yet

- PH of Soils: Standard Test Method ForDocument4 pagesPH of Soils: Standard Test Method ForSenor TodoNo ratings yet

- 25 Words SilicaDocument5 pages25 Words SilicaJahRed FronterasNo ratings yet

- Filter DryerDocument20 pagesFilter Dryermd_taheriNo ratings yet

- Lec 1Document26 pagesLec 1chandrakiranNo ratings yet

- Microstructural Characteristics of A Stainless Steel/Copper Dissimilar Joint Made by Laser WeldingDocument8 pagesMicrostructural Characteristics of A Stainless Steel/Copper Dissimilar Joint Made by Laser WeldingHan Hisyam PratamaNo ratings yet

- Chemistry Module Form 4Document25 pagesChemistry Module Form 4mohd faisol100% (2)

- Theory of Relativity in Quran AssignmentDocument7 pagesTheory of Relativity in Quran Assignmentmuzammalsafdar100% (1)

- Selection of Materials For Prototype Fast Breeder Reactor S.L.Mannan, S.C.Chetal, Baldev Raj and S.B.BhojeDocument35 pagesSelection of Materials For Prototype Fast Breeder Reactor S.L.Mannan, S.C.Chetal, Baldev Raj and S.B.BhojeSatish Kumar GautamNo ratings yet

- ThesisDocument214 pagesThesisWill BlackNo ratings yet

- Ap4073 Sensors and Actuators L T P CDocument1 pageAp4073 Sensors and Actuators L T P Cjames RNo ratings yet

- Chapter 7 33Document9 pagesChapter 7 33ayushNo ratings yet

- Engg Thermodynamics PDFDocument44 pagesEngg Thermodynamics PDFBrandon FunaNo ratings yet

- Magnetism Sub SheetDocument18 pagesMagnetism Sub SheetVipul VermaNo ratings yet

- Fundamentals of Process Intensification: A Process Systems Engineering ViewDocument28 pagesFundamentals of Process Intensification: A Process Systems Engineering Viewkumar_chemicalNo ratings yet

- Extraction and Characterization of Nigeria Shea Butter OilDocument7 pagesExtraction and Characterization of Nigeria Shea Butter OilJordon AlvaradoNo ratings yet

- FerromagnetismDocument48 pagesFerromagnetismkawtherahmedNo ratings yet

- Chapter 2 - Sample Problem SolutionDocument7 pagesChapter 2 - Sample Problem SolutiondiamantechennieNo ratings yet

- Redox Potential Presentation)Document8 pagesRedox Potential Presentation)api-27589736No ratings yet

- Bracker RoNo RBS Folleto PDFDocument2 pagesBracker RoNo RBS Folleto PDFLardys RodrìguezNo ratings yet

- Allen Practice Test Series - (2021-22)Document1 pageAllen Practice Test Series - (2021-22)Raghav KaranNo ratings yet

- Fundamentals of Thermal RadiationDocument14 pagesFundamentals of Thermal Radiationbommareddy akashreddyNo ratings yet

- Unit 1 CH 07 Exergy Analysis - ReidDocument31 pagesUnit 1 CH 07 Exergy Analysis - ReidLorenzo Galindo Jr.No ratings yet

- KRUPA SINDU 6000 LPH Fully Automatic Two LineDocument31 pagesKRUPA SINDU 6000 LPH Fully Automatic Two LineVinod DadannavarNo ratings yet