Professional Documents

Culture Documents

ATOM ARC LOW HYDROGEN ELECTRODES

Uploaded by

anupmenon menonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ATOM ARC LOW HYDROGEN ELECTRODES

Uploaded by

anupmenon menonCopyright:

Available Formats

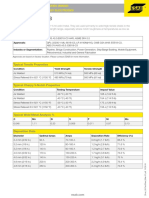

ATOM ARC LOW HYDROGEN LOW ALLOY ELECTRODES

ATOM ARC 8018-CM AWS A5.5: E8018-B2H4R

FEATURES TYPICAL MECHANICAL PROPERTIES

Atom Arc 8018-CM electrodes contain 1.25% Stress Relieved 8 hrs @ 1150°F (620°C)

Cr and 0.50% Mo as alloy addition. They are Yield Strength 88 ksi, 607 MPa

used for the welding of such steels as 0.5% Tensile Strength 102 ksi, 704 MPa

Cr - 0.5% Mo, 1% Cr - 0.5% Mo, and 1.25% Cr

- 0.5% Mo, which are used principally in power Elongation% in 2” 24%

piping and boiler work for the fabrication of Stress Relieved 1 hr @ 1275°F (690°C)

plates, pipes, tubes, castings, and forgings.

Yield Strength 84 ksi, 580 MPa

Tensile Strength 97 ksi, 669 MPa

Elongation% in 2” 25%

CLASSIFICATIONS AND APPROVALS Stress Relieved 8 hrs @ 1275°F (690°C)

AWS A5.5: E8018-B2H4R Yield Strength 82 ksi, 566 MPa

MILITARY-MIL-E-22200/8; MIL-8018-B2

Tensile Strength 96 ksi, 662 MPa

A.B.S.- AWS A5.5: E8018-B2

ASME SFA 5.5 Elongation% in 2” 26%

Stress Relieved 1 hr @ 1300°F (705°C)

Yield Strength 90 ksi, 621 MPa

WELDING PROCESS Tensile Strength 93 ksi, 642 MPa

SMAW (Stick) Elongation% in 2” 25%

INDUSTRIES

Power Generation CHARPY V-NOTCH PROPERTIES

Pipeline

Testing Temperature @ 30°F (0°C)

Pressure Vessels

Stress Relieved 8 hrs. @ 1125°F (607°C)

80 ft-lb, 108 J

WELD METAL ANALYSIS Testing Temperature @ 30°F (0°C)

C 0.06% Stress Relieved 8 hrs. @ 1150°F (620°C)

Mn 0.8% 83 ft-lb, 113 J

Si 0.5% Testing Temperature @ 30°F (0°C)

P 0.011% Stress Relieved 8 hrs. @ 1250°F (677°C)

S 0.008% 98 ft-lb, 133 J

Cr 1.3%

Mo 0.57%

X-Factor < 15

ESAB Welding & Cutting Products / esabna.com / 1.800.ESAB.123 CEP-10033-B

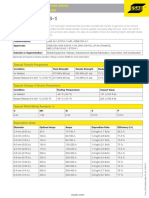

ATOM ARC LOW HYDROGEN LOW ALLOY ELECTRODES

ATOM ARC 8018-CM

DEPOSITION TABLE

Diameter Optimal Current Current Range Deposition Rate Efficiency

in (mm) Amps Amps lb/hr (kg/hr) %

3/32 (2.4) 90 70 - 100 1.7 (0.8) 66.3

1/8 (3.2) 120 90 - 160 2.6 (1.2) 71.6

140 90 - 160 2.7 (1.2) 70.9

5/32 (4.0) 140 130 - 220 3.1 (1.1) 75

170 130 - 220 3.8 (1.7) 73.5

3/16 (4.8) 200 200 - 300 4.9 (2.2) 76.4

250 200 - 300 5.4 (2.4) 74.6

7/32 (5.6) 250 250 - 350 6.5 (2.9) 75

300 250 - 350 7.2 (3.3) 74

1/4 (6.4) 300 300 - 400 7.7 (3.5) 78

350 300 - 400 8.7 (3.9) 77

PART NUMBER / PRODUCT INFORMATION

Part Number Description

255053324 AA 8018-CM 3/32X14X10#HS

255053316 AA 8018-CM 3/32X14X50#HS

255051823 AA 8018-CM 1/8X14X10#HS

255051815 AA 8018-CM 1/8X14X50#HS

255055311 AA 8018-CM 5/32X14X50#HS

255053118 AA 8018-CM 3/16X14X50#HS

ESAB Welding & Cutting Products / esabna.com / 1.800.ESAB.123 CEP-10033-B

You might also like

- Low Hydrogen Low Alloy Electrodes for High Strength Steel WeldsDocument2 pagesLow Hydrogen Low Alloy Electrodes for High Strength Steel WeldsFranklin Aranda ChacónNo ratings yet

- Accendo GloGreen Digital HID (DHID) Ballast B600W-277M Electrical Test ReportDocument1 pageAccendo GloGreen Digital HID (DHID) Ballast B600W-277M Electrical Test ReportAnthony BorgesNo ratings yet

- Metal-Cored: Gmaw-CDocument16 pagesMetal-Cored: Gmaw-CChandrajeet ShelkeNo ratings yet

- Product Data Sheet: Afrox 7018-1Document2 pagesProduct Data Sheet: Afrox 7018-1Gervasio AndradeNo ratings yet

- MILD STEEL WIRE PROPERTIESDocument4 pagesMILD STEEL WIRE PROPERTIESPoltak SianiparNo ratings yet

- Atom Arc 8018Document2 pagesAtom Arc 8018Jagan TnNo ratings yet

- Compacted Graphite Iron Material Data Sheet PDFDocument2 pagesCompacted Graphite Iron Material Data Sheet PDFDewang KambreNo ratings yet

- Dual Shield II 80-Ni1 h4 Data SheetDocument3 pagesDual Shield II 80-Ni1 h4 Data SheetNicolas MaximilianoNo ratings yet

- Low HydrogenDocument3 pagesLow Hydrogenseeralan balakrishnanNo ratings yet

- FICHADocument2 pagesFICHAadmisecoinperuNo ratings yet

- SUPERDUPLEXDocument7 pagesSUPERDUPLEXM RNo ratings yet

- PL NB301Document5 pagesPL NB301Alaa ElsisiNo ratings yet

- Esab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)Document1 pageEsab, Atom Arc 8018 (26-En - US-FactSheet - Main-01, 2016.10.26)RodrigoNo ratings yet

- Low Hydrogen Electrode Atom Arc 7018-1Document1 pageLow Hydrogen Electrode Atom Arc 7018-1HORACIONo ratings yet

- Spoolarc 75: Elite SeriesDocument2 pagesSpoolarc 75: Elite Seriesrajit kumarNo ratings yet

- FabCO 811N1Document2 pagesFabCO 811N1Sleyda MunozNo ratings yet

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelDocument2 pagesChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanNo ratings yet

- Nec B310-9Document2 pagesNec B310-9Mohamed MahrousNo ratings yet

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Document2 pagesAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNo ratings yet

- TT - Electronics 898 3 R100K Datasheet PDFDocument4 pagesTT - Electronics 898 3 R100K Datasheet PDFelnegritoheberNo ratings yet

- Lexan™ Copolymer 943X: Region AmericasDocument3 pagesLexan™ Copolymer 943X: Region AmericasAdirSchoierNo ratings yet

- EV Woofer Data SummaryDocument1 pageEV Woofer Data SummaryRafRouf SehiliNo ratings yet

- 6A05 THRU 6A10: Axial Silastic Guard Junction Standard RectifierDocument2 pages6A05 THRU 6A10: Axial Silastic Guard Junction Standard RectifiercuickNo ratings yet

- Adjust Circuit Breaker Curves for Ambient TemperaturesDocument1 pageAdjust Circuit Breaker Curves for Ambient TemperaturesThameemul BuhariNo ratings yet

- ESAB 8018 DatosDocument2 pagesESAB 8018 DatosElwe SingoloNo ratings yet

- 100 CR 62Document4 pages100 CR 62dadNo ratings yet

- E9018 M Specifications PDFDocument2 pagesE9018 M Specifications PDFMohamed MostafaNo ratings yet

- PC - Trinseo Emerge 8701HH GF10Document3 pagesPC - Trinseo Emerge 8701HH GF10armandoNo ratings yet

- Products Welding Consumables OK 76.28Document1 pageProducts Welding Consumables OK 76.28Saravanan KcNo ratings yet

- High-alloy creep resistant stick electrode for 9% Cr steelsDocument1 pageHigh-alloy creep resistant stick electrode for 9% Cr steelsmisthahNo ratings yet

- FR-PA66 PRODUCT INFORMATION AND TEST RESULTSDocument1 pageFR-PA66 PRODUCT INFORMATION AND TEST RESULTSSơn Nguyễn ĐắcNo ratings yet

- The Wear-Resistant SteelDocument16 pagesThe Wear-Resistant SteelredNo ratings yet

- Metalshield MC - 90 SuiteDocument1 pageMetalshield MC - 90 SuiteH_DEBIANENo ratings yet

- Datasheet Sandvik Saf 2507 en PDFDocument15 pagesDatasheet Sandvik Saf 2507 en PDFShesharam Chouhan100% (1)

- (TSC) ss32-ss315Document2 pages(TSC) ss32-ss315Gut Besser WasserNo ratings yet

- Dual Shiel Ii 101Document2 pagesDual Shiel Ii 101Robin carcamoNo ratings yet

- Superarc LA-75: Conformances Key FeaturesDocument2 pagesSuperarc LA-75: Conformances Key Featuressattar12345No ratings yet

- Propriedades Das Matrizes PolimericasDocument7 pagesPropriedades Das Matrizes PolimericasllepsterlNo ratings yet

- Ebitt Motor Katalog R01Document9 pagesEbitt Motor Katalog R01mani_208eeNo ratings yet

- CSF-71T Technical Report EN - V2Document7 pagesCSF-71T Technical Report EN - V2Miroslav ThôngNo ratings yet

- LEXAN FST3403tDocument3 pagesLEXAN FST3403tJose Ramon Florez OrdizNo ratings yet

- ESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root GapDocument1 pageESAB Welding & Cu Ing Products: A515 516 4 In. Thick 2 In. Root Gapalok987No ratings yet

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrleNo ratings yet

- P6KE6.8-440 TVS specsDocument3 pagesP6KE6.8-440 TVS specsAnonymous DjTnqWXUNo ratings yet

- Dual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresDocument2 pagesDual Shield T-115: Gas-Shielded Flux-Cored Wires (Fcaw) Low Alloy WiresPEPITO GRILLO2No ratings yet

- ESB 321M116700 SpecSheetDocument2 pagesESB 321M116700 SpecSheetArthanari VaidyanathanNo ratings yet

- ESB 321M116700 SpecSheetDocument2 pagesESB 321M116700 SpecSheetCitra Adelina SitorusNo ratings yet

- STAR Aromatic Amine Line Pipe High Pressure API 15HR Design Data SheetDocument4 pagesSTAR Aromatic Amine Line Pipe High Pressure API 15HR Design Data SheetFirasNo ratings yet

- Product Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet OK Autrod 12.51: G 'Gas-Shielded Metal-Arc Welding'Filipe CordeiroNo ratings yet

- W22 Smoke Extraction: Motor For Smoke Exhaustion African MarketDocument60 pagesW22 Smoke Extraction: Motor For Smoke Exhaustion African MarketAgustynho MagimbaNo ratings yet

- Hoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsDocument2 pagesHoballoy 8018B2: AWS E8018-B2 H4R Elding OsitionsJuanNo ratings yet

- Fiches Full Power Katana enDocument1 pageFiches Full Power Katana enZeljko AcimovicNo ratings yet

- 278 en US FactSheet Main 01Document1 page278 en US FactSheet Main 01Jorge Manuel GuillermoNo ratings yet

- CLC4003 HardnessDocument5 pagesCLC4003 Hardnessarif.haddieNo ratings yet

- Dual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresDocument2 pagesDual Shield II 70T-12H4: Gas-Shielded Flux-Cored Wires (Fcaw) Mild Steel WiresPhilippe TrudelNo ratings yet

- Generators Brochure 1Document4 pagesGenerators Brochure 1Victor SihombingNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- F7az Em12kDocument1 pageF7az Em12kKara WhiteNo ratings yet

- Joints in Steel Construction - Simple Connections - Part 22 PDFDocument1 pageJoints in Steel Construction - Simple Connections - Part 22 PDFkakem61No ratings yet

- The Nature of MaterialsDocument11 pagesThe Nature of MaterialscdymlkNo ratings yet

- Load Calculation and Design of PurlinsDocument23 pagesLoad Calculation and Design of Purlinssabah morsiNo ratings yet

- Chennai BOQDocument8 pagesChennai BOQDharmendra SharmaNo ratings yet

- METROLOGY & MEASUREMENTSDocument12 pagesMETROLOGY & MEASUREMENTSmirztrNo ratings yet

- S50 Valve Status Monitor 04-05 (Metric) - 2Document1 pageS50 Valve Status Monitor 04-05 (Metric) - 2Victor AlvarezNo ratings yet

- Tricocat PDFDocument44 pagesTricocat PDFJuan PabloNo ratings yet

- FraceDocument12 pagesFraceIra MejiaNo ratings yet

- Introduction To Properties of Materials: Badi 1 John Errington MSCDocument42 pagesIntroduction To Properties of Materials: Badi 1 John Errington MSCgereNo ratings yet

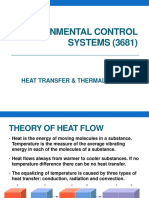

- ENVIRONMENTAL CONTROL SYSTEMS (3681) Lec 2-3Document73 pagesENVIRONMENTAL CONTROL SYSTEMS (3681) Lec 2-3shariq talatNo ratings yet

- 12.0 Moment and Shear Coefficient For Solid Slab: L Effective Span F Total Ultimate Load 1.35gDocument1 page12.0 Moment and Shear Coefficient For Solid Slab: L Effective Span F Total Ultimate Load 1.35gKumaresvaranNo ratings yet

- Chemical Engineering Test QuestionsDocument1 pageChemical Engineering Test Questionsjake dionisioNo ratings yet

- Truss Design DocumentationDocument2 pagesTruss Design DocumentationNiroj MaharjanNo ratings yet

- Nonlinear Material Properties of StructuralDocument9 pagesNonlinear Material Properties of Structuralkhawaja AliNo ratings yet

- ME 323 Homework 2 ProblemsDocument4 pagesME 323 Homework 2 ProblemsPotatoes123No ratings yet

- Surface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Document7 pagesSurface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Carlos Gonzalez100% (1)

- Climatology (Unit-7)Document12 pagesClimatology (Unit-7)SaakshiNo ratings yet

- Thermomechanical Treatment CorrosionDocument8 pagesThermomechanical Treatment CorrosionbharatNo ratings yet

- Plastering Checklist PDFDocument1 pagePlastering Checklist PDFabdelmjidNo ratings yet

- Astm A451Document4 pagesAstm A451Đoàn Thoại Đông TriềuNo ratings yet

- Dedicated Outdoor Air SystemsDocument5 pagesDedicated Outdoor Air SystemseduardofemecNo ratings yet

- X-Roc Epoxybond: Technical Data SheetDocument2 pagesX-Roc Epoxybond: Technical Data SheetJanaka Dinesh100% (1)

- Overtime AccomplishmentDocument9 pagesOvertime AccomplishmentKate PerezNo ratings yet

- Project Report Group 4Document28 pagesProject Report Group 4Akame TakashitaNo ratings yet

- Detailed Plan: Scale 1: 50 @A3 (Foyer Ground Block C)Document1 pageDetailed Plan: Scale 1: 50 @A3 (Foyer Ground Block C)Richard LeongNo ratings yet

- Corosion Assignment FullDocument104 pagesCorosion Assignment FullVelavan KNo ratings yet

- 1) Design A Large Building WITHOUT Expansion JointDocument7 pages1) Design A Large Building WITHOUT Expansion JointSubinDesarNo ratings yet

- Concrete Strength Testing ExplainedDocument32 pagesConcrete Strength Testing ExplainedMinn LwinNo ratings yet

- Amex Seals Product Data SheetsDocument13 pagesAmex Seals Product Data SheetscloantafNo ratings yet