Professional Documents

Culture Documents

4.500 in 18.90 PPF 0.430 in SM2535-125 VAM HTF-NR Ref. 27-11-17

Uploaded by

Ahmed ElwanyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.500 in 18.90 PPF 0.430 in SM2535-125 VAM HTF-NR Ref. 27-11-17

Uploaded by

Ahmed ElwanyCopyright:

Available Formats

Nov 27, 2017

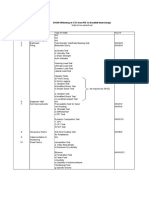

CDS 2180 Rev.1

Connection Data Sheet

OD Weight Wall Th. Grade API Drift Connection

4 1/2 18.9 0.430 SM2535- 3.515

VAM® HTF-NR

in. lb/ft in. 125 in.

PIPE PROPERTIES CONNECTION PROPERTIES

Nominal OD 4.500 in. Connection Type Premium Integral Flush

Nominal ID 3.640 in. Connection OD (nom) 4.545 in.

Nominal Cross Section Area 5.498 sqin. Connection ID (nom) 3.546 in.

Grade Type Ni Base Alloys Make-up Loss 5.687 in.

Min. Yield Strength 125 ksi Critical Cross Section 3.432 sqin.

Max. Yield Strength 145 ksi Tension Efficiency 62 % of pipe

Min. Ultimate Tensile Strength 130 ksi Structual Compression Efficiency 71 % of pipe

Compression Efficiency 37 % of pipe

Compression Yield Strength (CRA) 100 ksi Internal Pressure Efficiency 100 % of pipe

External Pressure Efficiency 100 % of pipe

JOINT LOADING PERFORMANCES TORQUE VALUES

Tensile Yield Strength 429 klb Min. Make-up torque 10600 ft.lb

Structual Compression Resistance 391 klb Opti. Make-up torque 12500 ft.lb

Compression Resistance 206 klb Max. Make-up torque 14400 ft.lb

Internal Yield Pressure 20900 psi

External Pressure Resistance 21600 psi

Max. bending with sealability 30 °/100 ft

VAM® HTF™ (High Torque Flush) is a flush OD integral connection providing maximum clearance along with extreme

torque strength for challenging applications such as extended reach and slim hole wells, drilling with liner / casing, liner

rotation to achieve better cementation in highly deviated and critical High Pressure / High Temperature wells.

Looking ahead on the outcoming testing industry standards, VAM® decided to create an upgraded design and launch on the

market the VAM® HTF-NR as the new standard version of VAM® extreme high torque flush connection. The VAM® HTF-NR

has extensive tests as per API RP 5C5:2017 CAL II which include the gas sealability having load points with bending,

internal pressure and high temperature at 135° C.

Prepared by Checked by Approved by

Sadao DOUCHI 2017.11.27 2017.11.27

2017.11.27

19:46:41 +09'00' 20:07:00 +09'00'

15:28:28 +09'00'

http://www.tubular.nssmc.com/

© 2017 NIPPON STEEL & SUMITOMO METAL CORPORATION All Rights Reserved.

You might also like

- Innovative Exploration Methods for Minerals, Oil, Gas, and Groundwater for Sustainable DevelopmentFrom EverandInnovative Exploration Methods for Minerals, Oil, Gas, and Groundwater for Sustainable DevelopmentA. K. MoitraNo ratings yet

- How the dual activity drill floor is expected to operateDocument8 pagesHow the dual activity drill floor is expected to operateWILLIANS HERNANDEZNo ratings yet

- Formation Testing: Supercharge, Pressure Testing, and Contamination ModelsFrom EverandFormation Testing: Supercharge, Pressure Testing, and Contamination ModelsNo ratings yet

- 003 - Presentation From Nabors Drilling PDFDocument16 pages003 - Presentation From Nabors Drilling PDFVi Et100% (1)

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- 14P220 Triplex Mud Pump Spec SheetDocument1 page14P220 Triplex Mud Pump Spec SheetWHWENNo ratings yet

- Specialty Connectors PipeDocument19 pagesSpecialty Connectors PipeBhai RamaNo ratings yet

- Heavy Duty Jackup Rigs Are Versatile and Capable: Application RangeDocument2 pagesHeavy Duty Jackup Rigs Are Versatile and Capable: Application RangeMILADNo ratings yet

- Slot RecoveryDocument49 pagesSlot RecoveryIslam MazeedNo ratings yet

- CDS Crown Mounted Compensator SpecDocument1 pageCDS Crown Mounted Compensator SpecMarcos SobreiroNo ratings yet

- Sprint CTU ContigencyPlanDocument32 pagesSprint CTU ContigencyPlanJawad Khan100% (1)

- Brochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedDocument8 pagesBrochure - NCS Multistage-Unlimited-Pin-point Fracturing - CompressedNightNo ratings yet

- Parker Drilling Company Rig 257: Submersible Shallow Water - Barge Drilling Rig - Caspian Sea (ABS & RMRS Certified)Document2 pagesParker Drilling Company Rig 257: Submersible Shallow Water - Barge Drilling Rig - Caspian Sea (ABS & RMRS Certified)Seyedeh Roghayeh SeyediNo ratings yet

- 01-Primary Cementing OverviewDocument42 pages01-Primary Cementing OverviewAmina Mekkakia100% (1)

- Skid Off DrillingDocument2 pagesSkid Off DrillingKeithbNo ratings yet

- Cameron Hydraulic Gate Valves Type F & FCDocument3 pagesCameron Hydraulic Gate Valves Type F & FCJuan Sebastian Diaz CuadrosNo ratings yet

- Wellhead - Manual S2100559Document47 pagesWellhead - Manual S2100559Parag PadoleNo ratings yet

- Tomax AST Tool User ManualDocument4 pagesTomax AST Tool User ManualChinyere NkereNo ratings yet

- Varel Mining CatalogDocument24 pagesVarel Mining CatalogEmerson Phocco Yauli100% (1)

- Advanced Subsea Engineer Program (ASSEP) : Lloyd's Register Energy - Drilling Training AcademyDocument2 pagesAdvanced Subsea Engineer Program (ASSEP) : Lloyd's Register Energy - Drilling Training AcademyShraddhanand More100% (1)

- CF Diverter Product Line: Diverter Solutions For Jackups and FloatersDocument4 pagesCF Diverter Product Line: Diverter Solutions For Jackups and FloatersiswantmachooNo ratings yet

- PoliopDocument32 pagesPoliopRamani KevinNo ratings yet

- Kahraman C-181 (ST-1)Document3 pagesKahraman C-181 (ST-1)Islam AtifNo ratings yet

- Pipe Body Performance PropertiesDocument118 pagesPipe Body Performance Propertieshamid nobakhtNo ratings yet

- PPS Catalogue 2016v4 (English)Document44 pagesPPS Catalogue 2016v4 (English)Kamry AhmadNo ratings yet

- Detail Specification of Rig Sagar Gaurav: Ongc Videsh Ltd. Out Line Drilling Unit SpecificationDocument25 pagesDetail Specification of Rig Sagar Gaurav: Ongc Videsh Ltd. Out Line Drilling Unit SpecificationMohitNo ratings yet

- Advances in Oil & Gas DrillingDocument35 pagesAdvances in Oil & Gas DrillingKhanzzNo ratings yet

- 5 - Bit Hydraulic OptimizationDocument31 pages5 - Bit Hydraulic OptimizationFarouq EngNo ratings yet

- D392005428-MKT-001 6012 Bop PDFDocument2 pagesD392005428-MKT-001 6012 Bop PDFMitul PatelNo ratings yet

- WWC Technical Data BookDocument73 pagesWWC Technical Data BookSylvan BorgNo ratings yet

- 50006034-SSW - 30 - Manual #107BDocument62 pages50006034-SSW - 30 - Manual #107BVictor Hugo Andrade100% (1)

- RigSpecs R1 Rev11 PDFDocument2 pagesRigSpecs R1 Rev11 PDFjiokoijiko100% (1)

- 2mm Vs 8mm Charpy Striker Edge RadiusDocument26 pages2mm Vs 8mm Charpy Striker Edge RadiusErick EaxNo ratings yet

- CJ46-X100-D: Platform ParticularsDocument3 pagesCJ46-X100-D: Platform ParticularsAshwani YadavNo ratings yet

- Drilling SupervisorDocument2 pagesDrilling Supervisoreng7mohamed7hashimNo ratings yet

- SPE 88446 Making Steerable Bits: Separating Side-Force From Side-CuttingDocument7 pagesSPE 88446 Making Steerable Bits: Separating Side-Force From Side-CuttingmsmsoftNo ratings yet

- Directional Drilling PDFDocument2 pagesDirectional Drilling PDFArpan BiswasNo ratings yet

- NCS SpotFrac Saves Troubled Flossie Lake Horizontal CompletionDocument9 pagesNCS SpotFrac Saves Troubled Flossie Lake Horizontal CompletionMauro LozanoNo ratings yet

- 11 - Compass For DD - Data Structure Exercise - 061005Document7 pages11 - Compass For DD - Data Structure Exercise - 061005ebrahimNo ratings yet

- 3 - Arenas Curables y ActivadoresDocument52 pages3 - Arenas Curables y ActivadoresPablo SotoNo ratings yet

- Powerstroke Drilling Jar: Instruction Manual 4250Document24 pagesPowerstroke Drilling Jar: Instruction Manual 4250Foros IscNo ratings yet

- 7in 29ppf 13Cr-80 JFE BearDocument1 page7in 29ppf 13Cr-80 JFE BearYeit HauNo ratings yet

- Reservoir SimulationDocument3 pagesReservoir SimulationEuler MendozaNo ratings yet

- Successful Installation of The First Dual Concentric Completion System On 9 5 8inch Casing ESP ESP Type in ColombiaDocument18 pagesSuccessful Installation of The First Dual Concentric Completion System On 9 5 8inch Casing ESP ESP Type in ColombiaAbe RmNo ratings yet

- Wireline Rig Up On Bails For Deepwater Rig Correlation PDFDocument1 pageWireline Rig Up On Bails For Deepwater Rig Correlation PDFgugal KumarNo ratings yet

- IWCF Surface Vertical Kill Sheet - API Field Units - Revised July 2010Document4 pagesIWCF Surface Vertical Kill Sheet - API Field Units - Revised July 2010rverretNo ratings yet

- Hydraulic Set Packer Rev0Document1 pageHydraulic Set Packer Rev0JasonNo ratings yet

- Laser DrillingDocument19 pagesLaser Drillingmts1234100% (1)

- LandRig PosterDocument1 pageLandRig PosterRaúl MárquezNo ratings yet

- Causes of Oil Well Blowout and Methods of Prevention and ControlDocument23 pagesCauses of Oil Well Blowout and Methods of Prevention and ControlAli KakiNo ratings yet

- Santrol Pocket Guide InternationalDocument2 pagesSantrol Pocket Guide Internationalintoyou2007No ratings yet

- Maersk Developer PDFDocument12 pagesMaersk Developer PDFmuhammad rivaiNo ratings yet

- 2 February - Onshore Vs Offshore DrillingDocument2 pages2 February - Onshore Vs Offshore DrillingHanly MauriceNo ratings yet

- TotcoDocument13 pagesTotcoObdulioNo ratings yet

- TDF DISPAROS HLBDocument88 pagesTDF DISPAROS HLBDanielStiglitzNo ratings yet

- Top CO - Catalog February 2015 - R6 PDFDocument36 pagesTop CO - Catalog February 2015 - R6 PDFzapspazNo ratings yet

- 1.1. Daftar Spek. Peralatan RigDocument61 pages1.1. Daftar Spek. Peralatan RigLavayrter100% (1)

- Subsea Tree design considerationsDocument47 pagesSubsea Tree design considerationsWilliam EvansNo ratings yet

- TDS 93 1 Pib PDFDocument6 pagesTDS 93 1 Pib PDFMohamed HashemNo ratings yet

- Petroleum Drilling Technology: Chang-Hong GaoDocument159 pagesPetroleum Drilling Technology: Chang-Hong GaoRe FunayNo ratings yet

- Biomechanics of CartilageDocument14 pagesBiomechanics of CartilageEric Urbina SantibañezNo ratings yet

- Mean Stress Effects in Stress-Life and Strain-Life Fatigue-DowlingBrasilPaperDocument14 pagesMean Stress Effects in Stress-Life and Strain-Life Fatigue-DowlingBrasilPaperRadwan HazimeNo ratings yet

- 010 Subsea Hose PDFDocument16 pages010 Subsea Hose PDFJhonatan FerreiraNo ratings yet

- Mec - Mes 121 - 2-1Document64 pagesMec - Mes 121 - 2-1ZAINAB MOFFATNo ratings yet

- Experiment 7: Tension Test of Steel: School of Civil, Environmental, and Geological EngineeringDocument7 pagesExperiment 7: Tension Test of Steel: School of Civil, Environmental, and Geological EngineeringJoash SalamancaNo ratings yet

- 1969 - The Coupling of Shear WallsDocument462 pages1969 - The Coupling of Shear Wallssobah assidqiNo ratings yet

- Corso Di Metallurgia E Saldatura Testo IngDocument124 pagesCorso Di Metallurgia E Saldatura Testo IngpropeneNo ratings yet

- Mechanical Characteristic of Austenitic Stainless Steel 316LN Weldment at Cryogenic TemperatureDocument4 pagesMechanical Characteristic of Austenitic Stainless Steel 316LN Weldment at Cryogenic TemperatureRobin GuNo ratings yet

- Astm F2882F2882M-17Document7 pagesAstm F2882F2882M-17Gabriel Perez CruzNo ratings yet

- Ageing Effect On The Properties of CuCrZr AlloyDocument5 pagesAgeing Effect On The Properties of CuCrZr AlloyPankaj SahlotNo ratings yet

- Elements of Structural Anbalysis1 PDFDocument513 pagesElements of Structural Anbalysis1 PDFoptimum it solutionsNo ratings yet

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechNo ratings yet

- Sae J1397-1992 PDFDocument11 pagesSae J1397-1992 PDFAdam GordonNo ratings yet

- ISRM-EUROCK-2010-012 - Determination of Direct Tensile Strength and Stiffness of Intact RocksDocument4 pagesISRM-EUROCK-2010-012 - Determination of Direct Tensile Strength and Stiffness of Intact Rocksamy75No ratings yet

- Effect of Different Sand Grading On Strength Properties of Cement Grout PDFDocument8 pagesEffect of Different Sand Grading On Strength Properties of Cement Grout PDFyoussefNo ratings yet

- Civil Engineering Interview Questions and Answers Guide.: Global GuidelineDocument18 pagesCivil Engineering Interview Questions and Answers Guide.: Global GuidelineNagesh SinghNo ratings yet

- PP VirginDocument2 pagesPP Virginapi-343230598No ratings yet

- Concrete Structures Interview QuestionsDocument26 pagesConcrete Structures Interview QuestionsBala GopalNo ratings yet

- Astm A753Document6 pagesAstm A753Cristian Otivo100% (1)

- Minor Project Report Unified Wheel OpenerDocument50 pagesMinor Project Report Unified Wheel Openerapi-3757722100% (17)

- Astm A 228Document4 pagesAstm A 228Joselinn LoaezaNo ratings yet

- NORSOK M 710 Ed 2001 Qualification of Non Metallic Sealing Materials and ManufacturesDocument26 pagesNORSOK M 710 Ed 2001 Qualification of Non Metallic Sealing Materials and ManufacturesChairul AnwarNo ratings yet

- Porque Sobran 3 Hilos SDDSDocument2 pagesPorque Sobran 3 Hilos SDDSCarlos FloresNo ratings yet

- Maruichi Gi PipeDocument6 pagesMaruichi Gi Pipeasif4u91No ratings yet

- Two-Stage Concrete As A Sustainable Production: CMSS-2017Document7 pagesTwo-Stage Concrete As A Sustainable Production: CMSS-2017Bishowkumar ShresthaNo ratings yet

- Activity 1Document18 pagesActivity 1zyx xyzNo ratings yet

- Magnesium-Alloy Forgings: Standard Specification ForDocument4 pagesMagnesium-Alloy Forgings: Standard Specification Formalika_00No ratings yet

- Solutions manual for textbook on failure, fracture and fatigueDocument152 pagesSolutions manual for textbook on failure, fracture and fatigueSerawit TadesseNo ratings yet

- Done - SSAB - 64 TechSupport Static Strength in Joints of Strenx Grades en PDFDocument5 pagesDone - SSAB - 64 TechSupport Static Strength in Joints of Strenx Grades en PDFMONo ratings yet

- Tests for CTE Widening ProjectDocument3 pagesTests for CTE Widening ProjectalfieNo ratings yet