Professional Documents

Culture Documents

Porque Sobran 3 Hilos SDDS

Uploaded by

Carlos FloresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Porque Sobran 3 Hilos SDDS

Uploaded by

Carlos FloresCopyright:

Available Formats

2010 SECTION II, PART A SA-325

size and length produced consecutively at the initial opera- Table 6 shall be applied. During rotation, the bolt head shall

tion from a single mill heat of material and processed at be restrained from turning. After the tightening rotation

one time, by the same process, in the same manner so that has been applied, the assembly shall be taken apart and

statistical sampling is valid. The identity of the lot and lot examined for compliance with 6.3.3.

integrity shall be maintained throughout all subsequent

NOTE 5 — Rotational capacity tests shall apply only to matched assembly

operations and packaging. lots that contain one A 325 bolt, one A 563 lubricated nut, and one F 436

9.5 Number of Tests — The minimum number of tests washer that have been zinc coated in accordance with either Specifications

F 2329 or B 695. Both the bolt and nut components of the matched

from each lot for the tests specified below shall be as assembly shall be zinc coated using the same process.

follows:

Number of Tests in

Tests Accordance With 11. Inspection

Hardness, tensile strength, proof Guide F 1470 11.1 If the inspection described in 11.2 is required by

load, and rotational capacity the purchaser, it shall be specified in the inquiry and con-

Coating weight/thickness The referenced coating tract or order.

specificationA

Surface discontinuities Specification 11.2 The purchaser’s representative shall have free

F 788/F 788M entry to all parts of the manufacturer’s works, or supplier’s

Dimensions and thread fit ASME B18.2.6 place of business, that concern the manufacture or supply

A

of the material ordered. The manufacturer or supplier shall

Guide F 1470 applies if the coating specification does not specify a

testing frequency.

afford the purchaser’s representative all reasonable facili-

ties to satisfy him that the material is being furnished in

accordance with this specification. All tests and inspections

required by the specification that are requested by the pur-

10. Test Methods chaser’s representative shall be made before shipment, and

10.1 Tensile, Proof Load, and Hardness: shall be conducted as not to interfere unnecessarily with

10.1.1 Tensile, proof load, and hardness tests shall the operation of the manufacturer’s works or supplier’s

be conducted in accordance with Test Methods F 606. place of business.

10.1.2 Tensile strength shall be determined using

the Wedge or Axial Tension Testing Method of Full Size 12. Rejection and Rehearing

Product Method or the Machined Test Specimens Method

12.1 Disposition of nonconforming bolts shall be in

depending on size and length as specified in 6.2.1-6.2.4.

accordance with the Guide F 1470 section titled “Disposi-

Fracture on full-size tests shall be in the body or threads

tion of Nonconforming Lots.”

of the bolt without a fracture at the junction of the head

and body.

10.1.3 Proof load shall be determined using Method 13. Certification

1, Length Measurement, or Method 2, Yield Strength, at 13.1 When specified on the purchase order, the manu-

the option of the manufacturer. facturer or supplier, whichever is the responsible party as

10.2 Rotational Capacity — The zinc-coated bolt shall defined in Section 14, shall furnish the purchaser a test

be placed in a steel joint or tension measuring device and reports that includes the following:

assembled with a zinc-coated washer and a zinc-coated 13.1.1 Heat analysis, heat number, and a statement

and lubricated nut with which the bolt is intended to be certifying that heats having the elements listed in 5.4 inten-

used (see Note 5). The nut shall have been provided with tionally added were not used to produce the bolts,

the lubricant described in the last paragraph of the Manu- 13.1.2 Results of hardness, tensile, and proof load

facturing Processes section of Specification A 563. The tests,

joint shall be one or more flat structural steel plates or

13.1.3 Results of rotational capacity tests. This shall

fixture stack up with a total thickness, including the washer,

include the test method used (solid plate or tension measur-

such that 3 to 5 full threads of the bolt are located between

ing device); and the statement “Nuts lubricated” for zinc-

the bearing surfaces of the bolt head and nut. The hole in

coated nuts when shipped with zinc-coated bolts,

the joint shall have the same nominal diameter as the hole

in the washer. The initial tightening of the nut shall produce 13.1.4 Zinc coating measured coating weight/thick-

a load in the bolt not less than 10% of the specified proof ness for coated bolts,

load. After initial tightening, the nut position shall be 13.1.5 Statement of compliance of visual inspection

marked relative to the bolt, and the rotation shown in for surface discontinuities (Section 8),

513

--``,`,`,`,,,,```,,,,,,,,`,,`,``-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME Licensee=Korea Power Engineering Co Inc ( KOPEC ) /3289500001

No reproduction or networking permitted without license from IHS Not for Resale, 07/11/2010 18:51:11 MDT

ESTA LONGITUD

ES ESTANDAR

ASME B18.2.6-2010 SIEMPRE TRAEN

2 DIAMETROS DE

CUERDA

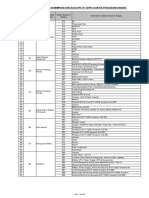

Table 1 Dimensions of Heavy Hex Structural Bolts

Para. 2.1.6 A Para. 2.1.6 A Para. 2.1.5 M A M

A A

H H F

R – Para. 2.1.12 M R – Para. 2.1.12 M

See para. 2.1.11 See para. 2.1.11

E E G

Y (Ref.) LT (Ref.) Y (Ref.) LT (Ref.)

+0⬚ LB LB

ESTO SE LE LLAMA AGARRE

30⬚ –15⬚ 30⬚

+0⬚

–15⬚ Y SEGUN A 325 MENSIONA

LG LG

See L See para. 2.1.6 L

ARRIBA, QUE DEBEN

para. 2.1.6 QUEDAR DE 3 A 5 CUERDAS

Cut Thread Rolled Thread

ENTRE TUERCA Y CABEZA DE

TORNILLO Maximum

Total

Transition

Runout

Nominal Size Width Thread Thread of

or Basic Body Width Across Flats, Across Head Height, Radius of Length, Length, Bearing

Product Diameter, F Corners, H Fillet, LT Y Surface

E [Note (2)] G [Note (3)] R [Note (4)] [Note (4)]

Diameter FIM

[Note (1)] Max. Min. Nominal Max. Min. Max. Min. Nominal Max. Min. Max. Min. Ref. Ref. [Note (5)]

1 7 5

⁄2 0.500 0.515 0.482 ⁄8 0.875 0.850 1.010 0.969 ⁄16 0.323 0.302 0.031 0.009 1.00 0.19 0.016

5

⁄8 0.625 0.642 0.605 11⁄16 1.062 1.031 1.227 1.175 25

⁄64 0.403 0.378 0.062 0.021 1.25 0.22 0.019

3

⁄4 0.750 0.768 0.729 11⁄4 1.250 1.212 1.443 1.383 15

⁄32 0.483 0.455 0.062 0.021 1.38 0.25 0.022

7

⁄8 0.875 0.895 0.852 17⁄16 1.438 1.394 1.660 1.589 35

⁄64 0.563 0.531 0.062 0.031 1.50 0.28 0.025

1 1.000 1.022 0.976 15⁄8 1.625 1.575 1.876 1.796 39

⁄64 0.627 0.591 0.093 0.062 1.75 0.31 0.028

11⁄8 1.125 1.149 1.098 113⁄16 1.812 1.756 2.093 2.002 11

⁄16 0.718 0.658 0.093 0.062 2.00 0.34 0.032

11⁄4 1.250 1.277 1.223 2 2.000 1.938 2.309 2.209 25

⁄32 0.813 0.749 0.093 0.062 2.00 0.38 0.035

13⁄8 1.375 1.404 1.345 23⁄16 2.188 2.119 2.526 2.416 27

⁄32 0.878 0.810 0.093 0.062 2.25 0.44 0.038

11⁄2 1.500 1.531 1.470 23⁄8 2.375 2.300 2.742 2.622 15

⁄16 0.974 0.902 0.093 0.062 2.25 0.44 0.041

GENERAL NOTE: See additional requirements in section 2.

NOTES:

(1) See para. 2.4.1.

(2) See paras. 2.1.2 and 2.1.3.

(3) See para. 2.1.4.

(4) See para. 2.1.10.2.

(5) See para. 2.1.6.

Publisher: American Society for Testing and Materials width across flats within a tolerance of −15% of the

(ASTM International), 100 Barr Harbor Drive, P.O. Box maximum across flats dimension.

C700, West Conshohocken, PA 19428-2959

(www.astm.org) 2.1.2 Width Across Flats. The width across flats of

heads shall be the distance measured perpendicular to

the axis of the overall product between the two opposite

2 HEAVY HEX STRUCTURAL BOLTS: ASTM A 325 sides of the head.

AND ASTM A 490

2.1.3 Head Taper. The maximum width across flats

2.1 Heavy Hex Structural Bolt Dimensions shall not be exceeded. No transverse section through

Bolts shall conform to the dimensions given in Table 1. the head between 25% and 75% of actual head height,

Formulas for heavy hex structural bolts are given in the as measured from the bearing surface, shall be less than

Appendix of ASME B18.2.1. the minimum width across flats.

2.1.1 Top of Head. Top of head shall be full form 2.1.4 Head Height. The head height shall be that

and chamfered or rounded with the diameter of chamfer overall distance measured parallel to the axis of the

circle, or start of rounding being equal to the maximum product from the top of the head to the bearing surface

You might also like

- ER288-Rebar Test PlanDocument4 pagesER288-Rebar Test PlanalfieNo ratings yet

- Acoustic Emission Monitoring During Resistance Spot-WeldingDocument6 pagesAcoustic Emission Monitoring During Resistance Spot-WeldingROHITNo ratings yet

- 03 38 16 - Post-Tensioned ConcreteDocument9 pages03 38 16 - Post-Tensioned ConcreteAnonymous swFolM3gXNo ratings yet

- Section II Par T A Fer Rous Material Specifications Sa 451 To End 2019 Asme Boiler and Pressure Vessel Code An International Code PDF Free - 64Document1 pageSection II Par T A Fer Rous Material Specifications Sa 451 To End 2019 Asme Boiler and Pressure Vessel Code An International Code PDF Free - 64洛霖No ratings yet

- Tendernotice 12Document1,500 pagesTendernotice 12pankajmay100% (1)

- Measuring Compressive Properties of Thermal Insulations: Standard Test Method ForDocument5 pagesMeasuring Compressive Properties of Thermal Insulations: Standard Test Method ForNada KhlifNo ratings yet

- A1045Document5 pagesA1045Marcelo LacerdaNo ratings yet

- E529-04 (2011) Standard Guide For Conducting Flexural Tests On Beams and Girders For Building ConstructionDocument3 pagesE529-04 (2011) Standard Guide For Conducting Flexural Tests On Beams and Girders For Building ConstructionMuhammad SalmanNo ratings yet

- ASTM A 66 - 87 (Reapproved 1995)Document2 pagesASTM A 66 - 87 (Reapproved 1995)geraldo leoncioNo ratings yet

- Sealability of Enveloped Gaskets: Standard Test Method ForDocument4 pagesSealability of Enveloped Gaskets: Standard Test Method Formonica andrea suarezNo ratings yet

- N0ndestructiv3 Ass5y 5Document1 pageN0ndestructiv3 Ass5y 5JOSE CANTERONo ratings yet

- Changes/Amendments in Astm E309-95 and E309-11 Along With Relevant Bpi In-Practice/Corrective ActionsDocument2 pagesChanges/Amendments in Astm E309-95 and E309-11 Along With Relevant Bpi In-Practice/Corrective ActionsMahmood KhanNo ratings yet

- Clause Wise CommentsDocument1 pageClause Wise Commentsrajitkumar.3005No ratings yet

- Inspection of Underground Precast Concrete Utility StructuresDocument2 pagesInspection of Underground Precast Concrete Utility Structuresmohammed ;arasnehNo ratings yet

- C 557 - 03 - Qzu1nw - PDFDocument9 pagesC 557 - 03 - Qzu1nw - PDFSamuelNo ratings yet

- Astm D2095 PDFDocument3 pagesAstm D2095 PDFTaher Hama AmeenNo ratings yet

- OSHA Technical Manual PDFDocument102 pagesOSHA Technical Manual PDFAshish PatelNo ratings yet

- Standard Practice For Ultrasonic Examination of Austenitic Steel ForgingsDocument6 pagesStandard Practice For Ultrasonic Examination of Austenitic Steel ForgingssyyouNo ratings yet

- E987-88 (2009) Standard Test Methods For Deglazing Force of Fenestration ProductsDocument3 pagesE987-88 (2009) Standard Test Methods For Deglazing Force of Fenestration ProductsAlabbas FadhelNo ratings yet

- Ranking Resistance of Materials To Sliding Wear Using Block-on-Ring Wear TestDocument11 pagesRanking Resistance of Materials To Sliding Wear Using Block-on-Ring Wear TestNav Talukdar100% (1)

- Aws D1.1 D1.1M-2010 VTDocument7 pagesAws D1.1 D1.1M-2010 VTCristian Alejandro Huerta HernandezNo ratings yet

- D 1635 - 00 Rde2mzu - PDFDocument3 pagesD 1635 - 00 Rde2mzu - PDFLupita CarelyNo ratings yet

- ASTM G14 - 04 (Reapproved 2010)Document6 pagesASTM G14 - 04 (Reapproved 2010)Sofia YuliNo ratings yet

- Astm-F 711Document8 pagesAstm-F 711IngJGMNo ratings yet

- 1 0 ITP Pole Inspection and Test Plan R1Document7 pages1 0 ITP Pole Inspection and Test Plan R1omarqasimNo ratings yet

- Fixed Anchorages Installed On Structures Used For Rope Rescue TrainingDocument2 pagesFixed Anchorages Installed On Structures Used For Rope Rescue TrainingAhmad Zubair RasulyNo ratings yet

- Flexural Strength of Soil-Cement Using Simple Beam With Third-Point LoadingDocument3 pagesFlexural Strength of Soil-Cement Using Simple Beam With Third-Point LoadingsamerNo ratings yet

- Ranking Resistance of Materials To Sliding Wear Using Block-on-Ring Wear TestDocument14 pagesRanking Resistance of Materials To Sliding Wear Using Block-on-Ring Wear Testvuqar0979No ratings yet

- D 903 - 98 - Rdkwmy05oa - PDFDocument3 pagesD 903 - 98 - Rdkwmy05oa - PDFPatricioArrienNo ratings yet

- Inorganic Underlayment For Use With Steep Slope Roofing ProductsDocument2 pagesInorganic Underlayment For Use With Steep Slope Roofing ProductsMohammad YaseenNo ratings yet

- Chapter 13 Load Hooks: DOE-STD-1090-2007Document16 pagesChapter 13 Load Hooks: DOE-STD-1090-2007Keng LengNo ratings yet

- Ultrasonic Contact Examination of Weldments: Standard Practice ForDocument23 pagesUltrasonic Contact Examination of Weldments: Standard Practice ForDiego GamarraNo ratings yet

- Inspection and Test ProceduresDocument17 pagesInspection and Test ProceduressatishmuggulaNo ratings yet

- ASTM E987 - DeglazingDocument3 pagesASTM E987 - DeglazingphilipNo ratings yet

- F3096-14 (Edition 2014.10.01)Document2 pagesF3096-14 (Edition 2014.10.01)Nguyen PhatNo ratings yet

- Expansion (Pin Test) of Copper and Copper-Alloy Pipe and TubingDocument2 pagesExpansion (Pin Test) of Copper and Copper-Alloy Pipe and TubingmahfuzNo ratings yet

- C 1135 00 Sellantes Adhesion TensionDocument3 pagesC 1135 00 Sellantes Adhesion TensionMariano Bonum DieNo ratings yet

- API Spec 11D1 - Packers and Bridge PlugsDocument2 pagesAPI Spec 11D1 - Packers and Bridge Plugsali50% (2)

- Joints For Drain and Sewer Plastic Pipes Using Flexible Elastomeric SealsDocument3 pagesJoints For Drain and Sewer Plastic Pipes Using Flexible Elastomeric Sealsastewayb_964354182No ratings yet

- Anybus Modbus To Bacnet Gateway DatasheetDocument5 pagesAnybus Modbus To Bacnet Gateway DatasheetmohannadNo ratings yet

- Vitrified Clay Pipe: Standard Test Methods ForDocument4 pagesVitrified Clay Pipe: Standard Test Methods Fornisha_khanNo ratings yet

- Astm A66Document3 pagesAstm A66Darwin DarmawanNo ratings yet

- E 1925 - 01 - Rte5mjuDocument12 pagesE 1925 - 01 - Rte5mjuMauricio Antonio SalgadoNo ratings yet

- Astm C794Document7 pagesAstm C794CPA BTKNo ratings yet

- Astm A66 07 PDFDocument3 pagesAstm A66 07 PDFJavier Ricardo Romero BohorquezNo ratings yet

- Damage Prevention of Bearings, and Bearing Components Through Proper Handling TechniquesDocument10 pagesDamage Prevention of Bearings, and Bearing Components Through Proper Handling TechniquesDarwin DarmawanNo ratings yet

- F 1362 - 97 R03 RjeznjiDocument5 pagesF 1362 - 97 R03 RjeznjiJuanNo ratings yet

- Asme2a Sa-667Document2 pagesAsme2a Sa-667cgmoralesNo ratings yet

- Annex A Series Construction Supervision of Pleasure Craft: I - Part 3 GL 2003 Page A-1Document3 pagesAnnex A Series Construction Supervision of Pleasure Craft: I - Part 3 GL 2003 Page A-1J T Mendonça SantosNo ratings yet

- F 1117Document2 pagesF 1117Gelver Torres RodríguezNo ratings yet

- C 932 - 03 PDFDocument5 pagesC 932 - 03 PDFTarek FennicheNo ratings yet

- Part TPDocument6 pagesPart TPMARCIONo ratings yet

- 9.5 Installation Criteria: Dhofar Power Company SAOGDocument1 page9.5 Installation Criteria: Dhofar Power Company SAOG54045114No ratings yet

- C497MDocument14 pagesC497MCnel RyanNo ratings yet

- Design and Testing of Fixed-Pitch or Ground Adjustable Light Sport Aircraft PropellersDocument4 pagesDesign and Testing of Fixed-Pitch or Ground Adjustable Light Sport Aircraft PropellersAhmad Zubair RasulyNo ratings yet

- ASTM D 903 - 98 (Reapproved 2004)Document3 pagesASTM D 903 - 98 (Reapproved 2004)y2kareinNo ratings yet

- ASTM D3963 & D3963M-01 - Epoxy Coated Steel Reinforcing BarsDocument5 pagesASTM D3963 & D3963M-01 - Epoxy Coated Steel Reinforcing BarsKitNo ratings yet

- Steel Screw Spikes: Standard Specification ForDocument3 pagesSteel Screw Spikes: Standard Specification ForVivi VargasNo ratings yet

- BS 750-1984 - Specification For Underground Fire Hydrants & Surface Box Frames & Covers PDFDocument28 pagesBS 750-1984 - Specification For Underground Fire Hydrants & Surface Box Frames & Covers PDFambition1340cn100% (2)

- The Electronic Experimenter's Manual FindlayDocument176 pagesThe Electronic Experimenter's Manual FindlayTEDY-RNo ratings yet

- A4-80 - A2-80 Material ClassDocument3 pagesA4-80 - A2-80 Material Classcwfh779No ratings yet

- Bollhoff Helicoil Plus Kits and Inserts CatalogueDocument49 pagesBollhoff Helicoil Plus Kits and Inserts CatalogueThor InternationalNo ratings yet

- BB URC V3 Parts ListDocument2 pagesBB URC V3 Parts ListxxaudioxxNo ratings yet

- Joist Installation-GuideDocument4 pagesJoist Installation-GuideDoble EmeNo ratings yet

- Tablas Del Manual Aisc 360-11Document220 pagesTablas Del Manual Aisc 360-11Ykr Calderón ChiroqueNo ratings yet

- For Construction: MAX. DIST. 0.5EDocument1 pageFor Construction: MAX. DIST. 0.5EHimal Nilanka RathnayakaNo ratings yet

- Bolt Depot - Bolt Grade Markings and Strength ChartDocument3 pagesBolt Depot - Bolt Grade Markings and Strength ChartcopcopNo ratings yet

- Resumen MaterialesDocument20 pagesResumen MaterialesLorenzoNo ratings yet

- Rep 24Document330 pagesRep 24ArturNo ratings yet

- Catalogo 01Document128 pagesCatalogo 01Joao EspadaNo ratings yet

- Structural FPD P.sanchezDocument9 pagesStructural FPD P.sanchezHailley DensonNo ratings yet

- Bombas Caterpillar 3208 y OtrosDocument32 pagesBombas Caterpillar 3208 y OtrosJuan Gabriel Ochoa100% (1)

- Mercedes Benz OM906LA OM926LA PDFDocument294 pagesMercedes Benz OM906LA OM926LA PDFAnonymous koCz1k92% (26)

- Chinese Centrifuge LW450x1000 Centrifuge ManualDocument34 pagesChinese Centrifuge LW450x1000 Centrifuge ManualNurlan Valiyev100% (1)

- Daftar Bidang Kemampuan Suplai (Scope of Supply) Untuk Pengadaan BarangDocument6 pagesDaftar Bidang Kemampuan Suplai (Scope of Supply) Untuk Pengadaan BarangAdhiezNo ratings yet

- Honda XL600R 1983 1984 Service ManualDocument254 pagesHonda XL600R 1983 1984 Service Manualjølle jølle100% (1)

- InspireYourBusiness Bro-00253 EN PDFDocument32 pagesInspireYourBusiness Bro-00253 EN PDFAravind VishweshwaraNo ratings yet

- Gantrex b17Document2 pagesGantrex b17martin100% (1)

- Structural Design of Steel StructuresDocument43 pagesStructural Design of Steel Structureskiran sreekumarNo ratings yet

- ABS 2014 Steel Vessel Rules - Propellers, SVR - Part - 4 - E-Feb14Document14 pagesABS 2014 Steel Vessel Rules - Propellers, SVR - Part - 4 - E-Feb14cupidkhhNo ratings yet

- Catalogue3 2003 EngDocument22 pagesCatalogue3 2003 EngMouchartStéphanieNo ratings yet

- Genie GS-2668/3268 RT Parts ManualDocument238 pagesGenie GS-2668/3268 RT Parts ManualAnonymous Pk3VzhXUGBNo ratings yet

- Mainstays Classic 5 Drawer Dresser, WhiteDocument32 pagesMainstays Classic 5 Drawer Dresser, WhiteAut BeatNo ratings yet

- B737 Ch70 STD PracticesDocument21 pagesB737 Ch70 STD PracticesAhmed Abdoul ZaherNo ratings yet

- Plastic Rivets and ScrewsDocument23 pagesPlastic Rivets and ScrewsMV Research & Development TRSNo ratings yet

- Tightening Torque of BoltsDocument3 pagesTightening Torque of BoltsMohamed el attarNo ratings yet

- Sampa Axle Rod CatalogueDocument189 pagesSampa Axle Rod CatalogueFabio OchoaNo ratings yet

- Cycloid Instructions WebDocument16 pagesCycloid Instructions Webanil100% (4)