Professional Documents

Culture Documents

6SDEED-WE-0325AR - Engine Emmision (6SD1-TC (Common Rail) Model)

Uploaded by

vik_md0 ratings0% found this document useful (0 votes)

103 views364 pagesIsuzu Engine Emmision (6SD1-TC (Common Rail) model)

Original Title

33. 6SDEED-WE-0325AR - Engine Emmision (6SD1-TC (Common Rail) model)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIsuzu Engine Emmision (6SD1-TC (Common Rail) model)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

103 views364 pages6SDEED-WE-0325AR - Engine Emmision (6SD1-TC (Common Rail) Model)

Uploaded by

vik_mdIsuzu Engine Emmision (6SD1-TC (Common Rail) model)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 364

WORKSHOP MANUAL

F&G-SERIES

ENGINE EMISSION

6SD1-TC (COMMON RAIL)

SECTION 6E

iSU2U

1suzu

rd

NOTICE

Betoro using this Workshop Manual to assist you in performing

vehicle service and maintenance operations, it is recommended

that you caretully read and thoroughly understand the

information contained in Section 0A under the headings

“GENERAL REPAIR INSTRUCTIONS” and “HOW TO USE THIS

MANUAL",

{All material contained in this Manual is besed on the latest

product information available at the timo of publication.

All rights are reserved to make changes at any time without

prior notice.

Applicable Model : FVR, FVD, GVR, GVD, FVM, FVL, FVZ, FVY

‘This Manual is applicable to 2003 year model and later vehicles.

Contents

Chapter 1 Overview of IE system

[Overview and specifications of IE system... 1-2

Overview of IE system. sevens

Specifications of IE system . ld

Electronically controlled fuel injection system

(ommon-rail type). - cere LB

GS (Variable Geometry Turbo System) | 3

(Output of ide position signal to brake intensive

control unit. 7

Ourpurof engine rotations to tachometer. 1-7

Speed Limiter (SLD) .......+ 18

External view of en lg

Engine contol unit inpuvourput ist... 1-10

2. TE system schematic connection diagram .. 1-12

3. Control wnit’sesoriswitch installing positon. 1-14

4, Functions of inputioatput and vehicle behavior

‘upon failure influence) E19

S. Others... sees seve EAL

Object and procedure for aceclerterlearaing

lcarning of accelerator pedal idling position

and full-thrortle position) 1-21

Qadjusiment data... ee. eee eee P22

Chapter 2 Failure Diagnosis

1.Self-diagnosis of IE system...

“Metod of choeking the di

‘by SERVICE ENGINE SOON lamp... . 2-2

Erasing the diagnostic trouble code by memory

clear switch (connector) 123

Tech 2 Operation manual... 26

2. Vehicle diagnostic procedure 216

3. Diagnostic trouble codes list. 219

Chapter 3 Functional diagnosis

Checking of SERVICE ENGINE SOON lamp

ighting circuit system (SERVICE ENGINE

‘SOON lamp docs not turn ON). BD

(Checking the SERVICE ENGINE SOON lamp

‘lashing control system (SERVICE ENGINE,

SOON lamp does not flashing) . 239

(Checking the Tech I ce TS

Checking the engine starting system 37

Checking the power supply cirevit........3-20

(Cheeking the fuel system eee. cece eee 324

Checking the intake system 3.26

(Checking the staring system... 00.22, 3-28

‘Checking the exhaust system 332

Checking the parking switeh ......2.....3-36

Idling speed cannot be adjusted 2341

ling speed cannot be decreased 3.43

Chapter 4 Checking procedure for each

diagnostic trouble code

1 CMP sensor system trouble 43

13 CKP sensor system trouble... b8

2 Atmospheric temperatize sensor system

twoubie 413

39 Waceremperature scasor system woul. 4-19

© Accelerator sensor sytem touble «4-25

23 Vehicle speed sensor system trouble... . 4-31

5 Boos: sensor system trouble 4.38

9 CPU monitoring IC trouble. we Gad

3 A/D conversion error/charger

sirouittrovble sees 6

£9 High boost trouble... . . a FAB

£2 Low boos trouble 456

Di Atmospheric presse sesor trouble «460

U3 Fuel pressure sensor output fixed ..... 4-62

4S Common sail pressure rouble, «1.1467

Common rl presstre trouble

(pump excessive pressare feed)... 4.74

Injector power system trouble (Common 1

“Injector 1, 3, 5 Systems"). ..... 4-81

159 Injector power system trouble (Common 2

injector 2,46 Systoms"). 21s. -86

Sl Fuel temperate sensor trouble |... 491

214 PCVI system short cireuit (battery and

power supply ciel

E18 PCV2 system short circuit batery and

495

power supply circuit) trouble... -.4.99

Supply pump no presture feed ar

mein pend. 103

527 Pump no pressure feed

(Fel outfhoW) svc eeseeeeveeses 4108

BH Accelerator switch of rouble... 4-113

id Accelerator switch on trouble... 4-118

Fic pressure sonsor Buble... 4-128

EEE PCV system haces, shor

(GND circuit) trouble me 4128

PCV2 system hamess, short

(GND circuit) trouble . see 18S

ZI No.! eylinder No. injector drive

syscm wouble sede

No.2 eylinder No injector dive

system iroube aor

No3 cylinder No3 injector dive

SYStem HOU evo eceseseves ee A150

Contents

0.4 cylinder No.6 injstor drive

system trouble. ass

25 No.5 cylinder No.? injector drive

system trouble oe 160

B37 Nos oplinder No.t injector drive

system trouble 4-168

55) Magnetic valve "AP dive

system trouble 4168

13 Magnetic valve "3" drive

system trouble . corres

13 Magnetic valve "C* drive

system MOUbIC a 24182

{08 Main relay system io ar)

Starter switch trouble. 2196

AS Pai-sfe (Mametc vave eu)

relay "A" system rouble 4.199

PCY relay system trouble 14-208

18 BOL data eror... 4-208

53 Excessive high revolution enor... 4-210

Chapter 8, Checking Mothod for Symptom

Engine stall. . 52

Engine hunting, rough idle... 55

Lack output power of engine, insufficieat

blow up, pulsating combustion 58

White smoke (lange)... ses. S12

Black smoke (large) 55

Chapter 6 Wiring check

1. Preface 62

Wentfication of wites 6.2.2... .2 se 62

Wiring specifications 62

Fuse . : 63

Relay. ....-.- ro 63,

Handling of connectors and hamess.. 6-4

2. Vehicle wiring harness 610

3. Wiring check... - ell

Engine control unit power source,

GND cireuit. cell

NE, G and fuel pressure sensor cireuit. |. 6-12

‘Boos, all speod accelerator sensor eieuit.. 6-13

Accelerator sensor and accelerator

switch circuit old

‘Water temperature, fuel temperature and

atmospheric temperature sensor circuit. 6-15

PCY (pump coatrol valve),

PCV relay circuit... 616

Injector (TWV) circuit... 2... ..2..1617

Magnetic valve, magnetic valve fail safe

relay circuit...

Vehicle speod sensor eet

Starting cizeuit (key switch,

slow blow fuse and fuse circuit)

os

619

= 6-20

‘Moter eireuit (SERVICE ENGINE SOON

lamp, tachometer output)

Self-diagnosis circuit (diagnosis switch,

‘memory clear switeh and Tech IL

connector circtit)

"Neutral circuit (Except automatic

transmission vehicles)

Clutch switch circuit

Brake switeh circuit

Reverse circuit .

Idling control switeh and idling control

selector switch eirenit

Exlaaust brake cizuit .

621

62

623

2624

625

626

627

6-28

Chapter 7 How to use IE System Inspection

Tools

1. Tech IL,

Tech I.

Chapter 8 Others

Inspection item chart for IE system

condition .

Abbreviation list

Programming / upload / download fuel

delivery rate data... 2...

72

72

82

83

85

How to read this Manual

‘This IE System Troubleshooting Mannal describes the inspection procedure for the IE System (an electronically

controlled fuel injection system (common-rail))

‘This maaual will help you in correct and speedy service operation for the TE System,

Chapter 1 Overview of IE system

‘© Specifications of IE system

‘© Control mechanism of TE system

‘© Inpatioutput of IE system

‘+ Sensor & actuator insalling postion of each engine

Chapter 2 Failure diagnosis

‘© View of diagnostic trouble codes

‘* TE lamp does not light ON, or the diagnosis monitor displays no data,

‘© Contents of diagnostic trouble codes

Chapter 3 Functional diagnosis

‘* Checking method for proper operation of IE System or its funetions

Chapter 4 Checking procedure for each diagnostic trouble code

‘© Checking method when a diagnostic trouble is displayed

Chapter 5 Checking method for symptom (when no trouble code lights ON)

'* When no diagnostic trouble cod is displayed, how to know the position to be checked based on

the failure condition

Chapter 6 Wiring check

‘+ Wiring connection condition

‘+ Connector inspection method

‘© Wire arrangement

Chapter 7 How to use IE system inspection tools

‘¢ How to use the wiring harness for checking the witing hamess checker, Teel Il, and voltage

Chapter 8 Others

‘© Check sheet of IE system and simplified troubleshooting

Chapter 1

Overview of IE system

Chapter 1 Overview of IE system

1. Overview and specifications of IE system

Overview of IE system

‘The LE system is un clectronie control system which controls the engine combustion condition optimally

according to tae traveling requirements ofthe vehicle. ‘The IE system comprises the following components:

1. Electronically controlled fue! injection system (eommon-rail type)

2. VGS turbo control

3. Idle coal

‘Tae IE system Ins other functions as follows in addition to the engine control function,

‘A, Engine speed output to tachometer

B. Self-diagnosis function

Specifications of IE system

List of IE system specications

st

Engine model | Oust SES vg

riasls

228) |€

ets) (2

Bs) lz

2] [8

kW iPS} *

faa] _68D7-TC _|aoeKw za0PS}| _O | 0] 0

(O- Standard equipment

Overview and specifications of IE system

Electronically controlled fuel injection system (common-rail type)

‘Tho engine control unit (ECU) acquires information (signals fom many sensors) such as eagine speed,

vine load and others. Based on such information, BCU sends electric signals to the supply pump, injector,

to control the fuel injection rate und injection timing properly For each cylinder.»

© Injection rate controt

‘The two-way valve (TWV) inthe injector is controlled based on the signals mainly fom the engine speed

and accelerator opening to control the fuel injection rate properly.

© Injection pressure control

By controlling the fuel pressure in the common-rail, the injection pressure is controlled. Proper pressure

in the common-rail is calculated based on the engine specd, fuel injection rate, and other conditions. By

fing the supply pump (PCV: Pump Coattol Valve), fuel ina proper quantity is discharged and fed

10 the common-rail under controlled pressure

© Injection timing control

‘Tho injoction timing control substitutes for the timer, Proper fuel injection timing is ealeulated based oa

the engine speed and fuel injection rate 1o control the TW (two-way valve) inthe injector

© Injection rate control

In order to improve the combustion in the cylinder, a sipall quantity of fuel i injected (pilot injection) first

and ignited, and then the second injection (main injection) follows. The injection timing and the injection

quantity are controlled by controlling the TWY (ts0-way valve) in the injector,

‘System schematic diagram

13

Overview and specifications of IE system

‘System control schematic diagram

i

i

|

i

i

i

|

i

i

i

|

|

i

i

|

L

14

Engine canal unit (£CU)

‘002! eencor input —a

CHP engine speea)

uUPeyindor écinion) 9

Fuel proseure sansot

‘Gam pensation

[Bate hue inaction ra

Pov

opening|cocing

‘scsion

Injotor (TW) pow supply ume,

timing decision

Fuel pressure sensor

Vabice

‘luton switeh signal ste.

Gonmonal

‘

normally high prezsure)

ume

STS] rast tac

S

oosisrator sencoringut

‘or soitehinpat

ASR demand signal (uol cu gna)

sensor input

ww

(hee Way valve)

JN

Overview and specifications of IE system

IE VGS (Variable Geometry Turbo System)

Air eylindor stroke distance (No. of stops of magnctio valve) is obtained from the engine speod, which is

‘compensated according to information from various inputs to obtain the final stroke distance (No. of stages

‘of magnetic valve) for the air eylindst.

The VGS magnetic valve is operated by thc number of steps decided and the air cylinder is moved under air

‘pressnse to contol the nozzle vane angle in the turbine housing.

soestes,

Engine sposd—

pte

Input tom

‘wien of.

‘Magnes vave cv erst

Engine contol unit

15

Overview and specifications of IE system

© Idling control switch

The iding speed can be adjusted by operating the idling contol switch. The upper limit of speed varies

depencing onthe engine model, vehicle specifications an engine warming vp contion.

uP

4 While the UP side of the switch is pushed, the engine speed

———————— _inereases and te iting spood is incresed necondingy.

DOWN

While the DOWN side ofthe switch is pushod, te engine speed

decreases andthe idling speed can be deceased, only dow tthe

lower limit

16

Overview and specifications of IE system

Output of idle position signal to brake intensive control

‘Tho engine eontral unit issues the “accelerator pedal stepping condition (stepped not stepped)” to the brake

integrated control unit as idle position signal output.

The brake intensive control unit operates or releases the exhaust brake according to the “accelerator pedal

stepping condition" sent from the engine control unit and the operating condition of the exhaust brake I

clutch pedal, ete. which is directly detected

POWER SUPPLYIKEY ON)

Exh Brake SW.

-G—{_ engine control Unit mv

Output of engine rotations to tachometer

‘The engine control unit sends the “engine speed pulse (4 pulses per spoed of engine)" 1 the tachometer and

the tachometer onrpet.

‘The tachometer indicates the engine speed. according to the "engine speed pulse” sent from the engine

control unit

NE sensor

sti | orem SET

| eco

Geonser saan

17

Overview and specifications of IE system

Speed Limiter (SLD)

‘The speed limiter (SLD) is control ia the ECM which limits vehicle specd not to exceed a setting value.

‘Tae limit of vehicle speed is performed by fuel rate control in the ECM. Fuel rate is controlled based on

‘chicks specd signal and engine specd signal.

Vehicle speed signal is inputted tothe spoed meter control unit (VSS control uni), The VSS contro] unit

tectifies vehicle speed signal according to vehicles and oxtputs the signal to ECM and mete.

Engine spced is compured by the ECM based on the crank position (CKP) sensor.

18

Meier

Giher civ

<——_

com be] ves ow

Fu

Injection Contra!

lcrank Position (CkPy|

f

pySensor

wr

Vehicle SpeedSensor

(ss)

Overview and specifications of IE system

External view of engine control unit

sSpecccoocoow

wWovoscoEEonM

g@eeeseseasan

Note: Operate the control unit suited to the vehicle according to the "Commment" and “Applicable engine

identication name" described on the label

Ifa control unit not fitted for the vehicle is use, fallure may result

19

ications of IE system

Engine control unit inputfoutput list

110

cnet < Uae Cnt a ph tit

Overview and specifications of IE system

Chapter 1 Overview of IE system

(varview and specifistons of IE system

2. IE system schematic connection diagram

5 |

Stoo

Chapter 1 Overview of IE system

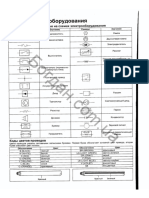

3. Control unit/sensor/switch installing position

114

Control unit/sensor/swite!

FUSEBOX ——_—RELAYEOX EXHAUST BRAKE SWITCH * IOLEUP SWITCH

“IDLE DOWN GvnTeH

ACCELERATOR SENSOR

+ ACCELERATOR SWITCH

Diagnectie Swit (White)

Memory Clear Switch (Bice)

* Date Link Connector

[Neticls eavippee with no mult warning]

sevice

Control unit/sensor/switch installing position

1-16

Control unit/sensor/switch installing position

Cab rear member

Legend

Ouv co)

@uve)

@MV(A)

Control unit/sensor/switch installing position

Engine (6801-70)

od oa snet

\ LY e

ee ge

LS SP

o a

vom) Le PES =

A, | L1/|

sage pom

Sa ance

Mt nperaure censor

- “\

\

Ie

2

at“ ae

1-18

Chapter 1 Overview of IE system

4. Functions of input/output and vehicle behavior upon failure (influence)

reson

ieee oe a

oa

lest tf iteteeniasiid, §— saint ug

iam Te | dail eur erence i

co 77 Sara cee :

[SP I

vas sr [onc tunoae tthe a

i = ae Lae |

* Check by SERVICE ENGINE SOON lamp

‘© Chock by Tech Il (with the Tech II connected)

‘= Check by diagnosis monitor (with the diagnosis monitor connected)

} | a °

sea | Tater | fee | came | trator ene e ™

Tater | Tiler | Stet | came | tater mene e jon °

set [ee [set [oe [amare [oe [on °

Sot | ter | set | ate, [Semvasvamises |e [ae [ene ©

Set | see | set | bey [srmieyaein=| 0 | os [nw .

smal | Seth | Sat | esa. | srmsitayvamisem | @ | as Jew °

Sel | ser | set | be, [Smieeamism | 0 | a [ae °

set | Sot | et | comtany_| Srv | 276 [rw °

a °

set | tet by [Suet att, [peas

Moet | tr | Stet | cate = 2

2.20

Diagnostic trouble codes list

fa trance |Get | ee cone, | mhntnteng tn

a permease Beer | aepenmsene

ees Eagar esntnneta

Sn Hote iepnarmcennnnee |

tn tr man a

lnc] SO Leo veces Sener)

Jen Zager (RPM | Taine tits [enna betaine

= oo

Se Eanes

[andre [I TANCae |e

ee 7 ee

Lc a Ye eV renr

roars ae aioe

ee oe

= eaate oh RRS aa mrataene

a eo

aa PaO

= fone SSE [ae eee!

@ fanaa (EERE |e

221

Diagnostic trouble codes list

tx | ter | ee Seeseegmeetes st e

‘cant at sat oun anda & « °

set] ee | ae aatcinmior | @ | #2 °

eer | aie net * °

vor [ver | se | oe, [Beer eh ©

Saet_[ Ber colt, [anartat ” f

ee ee °

set | Set | ez | atm, [peeemmsuse | @ | a

EC] TA | at feowmnwere fe [ee °

a °

Se |e | ee [ome me [eae *

vont [ter [sem [amt [amnesia [oe [ae °

See [er Ba a rere e

ser [ees [ast [cr pnw [| °

Se [Se [ee [ete [amen es °

cot | Gam | ot | eatin is °

2.22

Chapter 3

Functional diagnosis

Preface

For the purpose of keeping engine operation normal or to restore the engine operation to normal condition,

functional diagnosis is made. If some engine control functions are not properiy working, the engine control unit

diagnoses erroneously o7 some error showing 10 diagnostic trouble code occurs so that dingnosis cannot be made

correctly.

Follow ihe inspection procedure described on the following pages for diagnosis (check or repeir) of functions.

(Checking of SERVICE ENGINE SOON lamp

lighting circuit system (SERVICE ENGINE SOON lamp dos not turn ON)

‘Checking the SERVICE ENGINE SOON lamp flashing coatrol system

(SERVICE ENGINE SOON lap das ot aig

(Checking the Tech It 0

Checking te engine stating system... 2...

Checking the power supply circuit

‘Checking the foe! system a 3

Checking the intake system. :

Checking the staring system

CCheeking the exhaust system

Checking the parking switeh

Tdling speed cannot he adjusted

ling speed cannot be deercased

Chapter 3 Functional diagnosis

Checking of SERVICE ENGINE SOON lamp lighting circuit

system (SERVICE ENGINE SOON lamp does not turn ON)

ll SERVICE ENGINE SOON lamp circuit

ENGINE CONTROL UNIT CONNECTO!

OU HARNESS

INSTRUMENT {LOWER} INSTRUMENT (UPPER) HARNESS

HANES

D Ey ono

S39 cAseOND

a2

Checking of service engine soon lamp lighting circuit system

nd OU SERVICE ENGINE SOON lamp does not turn ON)

Engine control unit power source, GND circuit

ENGINE CONTROL UNIT CONNECTOR

EGU HAFNESS SDE.

Le

FET

DIAG CONNECTOR

TONTOONNECTOR

INSTRUMENT

(LOWER) HARNESS

33

Checking of service engine soon lamp lighting circuit system

(SERVICE ENGINE SOON lamp does nof turn ON)

Connection of meter connector

SERVICE ENGINE SOON Lame

CONNECTOR © CONNECTORD (CONNECTOR E

‘CAUTION

Euse box USE FUBE W/TH THE SPECIFED CAPACITY

Jeo nts TS]

rel Elmo

ee [imc

ay I gl ts

Blaecowmny lee eton [| [GB lsu re (se |esreraa ||

Es el

[ee fe ee at

Bae [Ble m (S| B[unsew [Blemenom [S|

eI Kein fs \eiwone

[Blows [ane na ISB ree wrccmreard © |

ae ome [Siero

[Blewwruarven [| [B]ocorwecn [|

eke be a

Checking of service engine soon lamp lighting circuit system

nd OU SERVICE ENGINE SOON lamp dovs not turn ON)

Circuit description

Power to opecate the meter (SERVICE ENGINE SOON lamp) is supplied through the fuse.

Lighting up and going out of the lamp are controlled with the engine contro] unit. (The engine contol unit

is Tocated in the cireuit between the power source and GND (ground) circuit to gperate the lamp control

‘switeh in the control unit and light up or extinguish the lamp.)

Possible causes

Faulty power supply circuit (starter switch circuit, ct.)

Faulty main unit (indicator, communication circuit)

SERVICE ENGINE SOON lamp (bulb) burnt out

Faulty meter main assembly (including circuits)

Disconnected wire of meter power source cireuit

Discoanected wire of lamp driving cireuit

Faulty engiae control unit

Faulty engine control unit power circuit (key ON)

Faulty engine control unit power source circuit (main relay eieuit)

Faulty engine control unit GND eizeuit

35

Checking of service engine soon lamp lighting circuit system

GBERUICE ENGINE SOON any Goss hotturn BN?

Troubleshooting (Checking steps and corrective actions)

Perform the checking and corrective actions following the steps shown below.

Siena] ‘Ghacking and Carredtive Actions Result YES [NO

1 | Check the fises Fuses are nanmal | Step3 | Step?

(Check ithe fuse far meter power anu dhe fases for Engine Control

Unit (No. 17 forkey ON signal and No. 45 for main relzy power) are

normal

| Replace the ses, and check ifthe SERVICE ENGINE SOON amp] Lamp ON (operated) |) Step? Step

ums on (operated) when the starter switch is turned on again.

| Check the voltage is applied to fses for need ECU. Batty voliage | Step 4 | Giecin|

1 Remove the fases No.L1, 17, and 45. te

2, Torn tho starter switch o. power

3, Measure the voltage at each fise siounting place. source

Is the voltage normal valin teat

[1 Disconnect the harness from the Engine Control Ua Tarp ON (operated) | Step? | Step

2.Ground (GND) the connector (No. 105 pin) ofthe Engine Control

Unit.

3.Turm the starter switch on

S| Check the connector and harness of the miler eireul Wo faultistound | Stsp7 | Steps

1. Disconnect the harness from he meter,

2, Disconnect the harness from the Engine Control Unit

3, Check the eonncetors for corrsion, looscncss, opening, or iting

conditions of pins,

4. Rofering tothe circuit diagrams, check the following circuits

Between power source and meter

1) Fuse No.17 to instrument (upper) harness eenncetor

2) Motoew instrument (ower) hers connoctor

‘Betwoon Engine Control Unit end meter

1) Engine Contro! Unit to instrument (lower harness eonncetor

2)ECU hamess connector to instrument (upper) hamest|

3) Meter to instrument (lower) harmess connector

Are the harnesses and connectors normal?

36

Checking of service engine soon lat

9 OU SERVICE ENGINE SOON t

lighting circuit system

amp does not turn ON)

‘Checking and Corrective Actions

Result

YES

NO

Repair Tauly pats (coanectors and hamesses) in the meter zou,

| After repai, check if the lamps other than SERVICE ENGINE

/SCON lamp tum on (operate) when the starter switch is tuned on

again

‘Lamp ON (operated)

Siep 1

Step 7

[Check ths METER lamp bal

is the bull broken?

Bulb i nomad

Supe

Spe

Replace the METER lamp bulb

After repair, cheok if the SERVICE ENGINE SOON Trp turns on]

(operates) when the starter site is turned on again,

Did the meter (Lamp) operate’)

Tamp ON (operated)

Sep

sepa

[Check the power source forthe Eagine Control Uni

1. Diseuomect the harness from the Engine Control Unit,

2, Turn the starter switch on.

3, Measure the voltage at the connector of Engine Control Unit

(80.13 and 23 pins),

Is the voltage normal value?

Battery voltae

Slept

Sept

Reni the hamess between fs No.1 and Engine Control Unit

[After repair, check if the Tamps ether than SERVICE ENGINE|

]SOON tamp tur on (operate) when the starter switch is tumed on]

again

Lamp ON (operated)

Step 17

Step 11

7

[Check the wiain relay cireuie (hamesses and connestor) and the|

relays,

1. Disconnoet the harness from the Engine Contra Unit,

2, Remove the main relay.

3. Check the connectors for corrosion, looseness, opening, ot fitting

conditions of pins.

4. Referiag tothe circuit diagrams, check the following circuits

‘Fngine Control Unit to instrusent (lower) harness connector

FECT hamest comncetor to main relay

Fuse Nod§ to main relay

Fuso No.4S fo frame (FI) hamess connoetor

Instrument (lowe) hamess connector to ground paint

5, Cheek the relay for fmetion.

Are the hamesses, connectors, and relays normal

No fas found

Step 3

Step 12

a7

Checking of s

(SERVICI

ENGINE SOON lamp does not IN)

ce engine soon lamp lighting crcult system

t turn

(Checking and Corrective Actions:

Result

YES |_NO

12

[Repair faulty harness, connector, or relay inthe main relay circuit

[After repair, chock if the lamps other than SERVICE ENGINE

SOON lamp turn om (operate) when the starter switch is turned ca

agin

TLaaip ON (oparaied)

‘Step 17 | Sep 13

3B

[Chook the GND for Engine Control Unit

L. Diseonneet the harness from the Engine Control Uait,

2. Check the connoeters for corrosion, looseness, opening, of fing

conditions of pins.

3. Referring to the citeuit disgrams, chock the folowing circuits:

‘Engine Contol Unit to instrument (lower) hamess counector

[BCU hamess comuector to frame (F#) hamess connector

+ Instrument (lower) harness connector to ground point

Aso the harnesses and connectors uot?

No foul is Found

‘Sep 15 | Step 4

rr

"Ropar Faulty harnesses and connectors in ts grond clcuit for ths

‘Engine Contol Unit.

[After repeir, chock if the lamps other than SERVICE ENGINE

SOON lamp tur on (operate) when the starter switch is turned on

again,

Lamp ON (operated)

Sep 17 | Step 15

Replave the meter anerbly,

[After repair, check if the lamps other than SERVICE ENGINE|

SOON lamp turn on (operate) when the starter switch is turned on

again

amp ON (operated)

Step 17 | Step 16

16

Replace the Engine Control Unit

After the Engine Control Unit was replaced, perform the

accelerator learning,

Did corrective actions complete?

‘Seep 17

7

Restore the vehicle, and perform the repair check.

Cheak |

38

Checking the SERVICE ENGINE SOON lamp flashing control system

(SERVICE ENGINE SOON lamp does not flashing)

lH SERVICE ENGINE SOON lamp circuit

ENGINE GONTAOL UNIT GONNEGTOR:

fo

ruse2

nsTRUWENT (LOWER) INSTRUMENT (UPPER) HARNESS

HARNESS

5 DAG SWITCH

cca Lies ca ona

‘aa cl | Yeaunect33 Lo arseano

[MEMORY LEAR GWiTEN |

39

Checking the SERVICE ENGINE SOON lamp flashing control system

(SERVICE ENGINE SOON lamp does not flashing)

Connection of meter connector

SERVICE ENGINE SOON Lame

CONNECTOR © CONNECTORD (CONNECTOR E

‘CAUTION

Euse box USE FUBE W/TH THE SPECIFED CAPACITY

Jeo nts TS]

rel Elmo

Ez plead

ay I gl ts

Blaecowmny lee eton [| [GB lsu re (se |esreraa ||

Es el

[ee fe ee at

Bae [Ble m (S| B[unsew [Blemenom [S|

eI Kein fs \eiwone

[Blows [ane na ISB ree wrccmreard © |

ae ome [Siero

[Blewwruarven [| [B]ocorwecn [|

eke be a

340

Checking the SERVICE ENGINE SOON lamp flashing control eystom

(SERVICE ENGINE SOON lamp does not flashing)

Circuit description

Power 10 operate the meter (SERVICE ENGINE SOON lamp) is supplicd through the fuse No.11

Lighting up and going out of the lamp lashing are controlled with the engine contral unit, (The engine

‘control unit is locatsd inthe circuit between the power souree and (GND), to operate the lamp control switch

jn the engine control unit and lighting up or extinguish the lamp flashing.)

Possible causes

Faulty meter main assembly (including cireuits)

Shorted lamp driving circuit,

Faulty diagnostic switch circuit

Faulty engiae contol unit

|B Troubleshooting (Checking steps and corrective actions)

Perform the checising and corrective actions following the steps shown below.

sions ‘Checking and Corrective Actons Recut Yes | NO

1 | Check the diagnostic switch (connector) eieuit. No faultis found | Step3 | Step?

1. Disconnect the harness from the Engine Couttal Unit

2. Check the connectors for corrosion, looseness, opening, ot iting

conditions of pias.

3. Refering tothe circuit diagrams, check the following ercuits

Between Engine Control Unit and diagnostic switch (connector)

1) Engine Control Unit to instrument (lower) harness connector

2) BCU hamess connector to diagnostic switch (connector)

‘Between diagnostic switch (connector) and ground (GND)

1) Diagnostic switch (connector) to frame (F#) harness eonnoctr|

2} Instrument (lower) harness connector and ground (GND)

Are the harnesses and connectors normal?

2 [Repair fully hamesses and conncetors ia the Gaguowic switch] flashing (operat) | Sep® | Sep

(connector circuit,

att

Checking the SERVICE ENGINE SOON lamp flashing control system

(SERVICI

ENGINE SOON lamp does not flashing)

‘Checking and Corrective Actions

Rest

Yes

‘Check the connector snd haness ofthe meter cient

1. Disconnect the barness ftom the meter

2, Disconnect the harness from the Engine Control Unit

3, Cheek the eonncetors for corrosion, looseness, opening, or fitting

concitions of pins

4, Refering tothe circuit diagrams, check the following circuits

Engine Control Unit to instrument lower) aess connector

ECU hamess connector to instrument (upper) harness connector

Meter to instrument (lower) hamess comeetor

Are the harnesses and connectors normal?

TNo fas found

Step &

Step

Repair faulty parts (connectors and hamesses) inthe meter rca

‘asking (operated)

Sepe

Seps

[Replace the mister assembly, and connect al harnesses Tor the Fagine

Control Unit, ee

‘Sarier swiich ON:

Lamp ON

‘Starter switch OFF:

Lamp OFF

‘Sup

Bene

ATTSe vopair, chook Whe Tampe thor Than’ SERVICE: ENGINE

‘SOON lamp Mashing (operate) whon tho starter switch is tured on]

again

Tasking (oporaiod)

Tepe

SapT

Replace the Bagine Control Unit

“After the Engine Control Unitis replaced, perform the seesterator

Teaming,

Did corrective action complete?

sepe

estore the vehicle, and perform the repair heck

Check

342

Checking the Tech Il

I Self-diagnosis circuit (Engine control unit)

|HeINE CONTROL UNIT CONNECTOR [ETAR]

343

hocking the Tech Il

atd

Circuit description

‘There are Two Tech Il communication circuits provided; one in the signal communication cireuit from the

engine control unit tothe Tec IT and other in the signal received cireit from the Tech I to the engine control

unit,

‘The signal from the transmission side is used for the "monitor" mode to read the self-diagnosis codes or

engine data with the Tech I

‘The signal from the reception sie is used for the "communication mad” to erase the self-diagnosis codes,

cte., or for the "inspeetion mode" to cheek the accelerator learning or switches.

Possible causes

Faulty cizouit from the engine contvel unit connector to Tech IL councetor (disconnected wire, shoxtcireuit,

cic.)

Eaulty engine control unit

Eaulty Tech LI connector power souree

Checking the Tech It

Troubleshooting (Checking steps and corrective actions)

Perform the checising and corrective actions following the steps shown below.

Sens]

‘Checking and Correctve Actons

Reso

(Check the fise

Is the power fuse for Tech I normal?

Fise is normal

Seep} | Step?

Replace the fuse, and turn the starter switch ow epain to check the|

Tech for function,

Dax the Tech I aperate?

Tamp ON [aperated)

Siep 15 | Step 3

[Check the Tech TT power supply.

[Check ifthe voltage is applied tothe Tech I when the tater swith

is turned on.

Is the voltage applied?

Battery voltage

Sep7 | Steps

[Check ithe voltage is applied to the fuse when the starter switch is

turned on.

Is the voltage applied?

Batiery voltage

SepT | Sapo

Repair the power supply circuit forthe Tech TE

After repair, check the Tech TT operation when che starter switch is

cured on again

Does the Tech M operate?

Tech l opertee

Bepls | Sepe

3

Repair or replace the power supply eeu

(See Section 6, Wiring chock "powce supply circuit")

Affe ropair, check the Tech IT operation when the starter switch is

turned on again

Does the Tech I operate?

"Tech I operates

Siep 15 | Siop 7

(Check the Tech I connector Cea

1. Diseouneet the harness from the Engine Coutrol Unit.

2, Check the comectors for corrosion, looseness, opening, ¢ Siting

conditions of pins.

5. Referring tothe circuit diagrams, check the following citevits

Between Engine Contol Unit and Tech Il connector

1) Engine Conteol Unit instrument (laser) hamcss connector

2)ECU hamess connector to Tech Il connector

Are the hamesses and connectors normal?

No faults Found

Siep 1S | Siep ®

[Repair Taully harnesses and eomnectars the Teoh M1 connector

ict

After repair, check the Tech IL operation when the starter switch is

turned on again,

Does the Tech Il operate?

Tech operates

Sep lS] Sep

[Cheek the fise @A) inside the Teoh I

Is te fuse (2A) normal?

No faults Found

Siep 1S | Sep 10

[Replace the fase (ZA) inside the Tech I

After repair, check the Tech IL operation when the starter switch is

turned on nit

ows the Tech M1 operate?

Tech aperater

Sep ls | Sep

345

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Wabco EBS DDocument40 pagesWabco EBS Dvik_md100% (3)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Scania Aps RuDocument12 pagesScania Aps Ruvik_md100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- LG4JJED-WE-0871 - Engine Control System 4JJ1 N-SeriesDocument389 pagesLG4JJED-WE-0871 - Engine Control System 4JJ1 N-Seriesvik_md100% (1)

- MG6HFED-WE-0991 - Engine Control System (6HF1 Model)Document386 pagesMG6HFED-WE-0991 - Engine Control System (6HF1 Model)vik_mdNo ratings yet

- Isuzu Sistema Elektrooborudovaniya 1Document1 pageIsuzu Sistema Elektrooborudovaniya 1vik_mdNo ratings yet

- Lg4jjed-We - 4jj1 Euro 5 With DPDDocument379 pagesLg4jjed-We - 4jj1 Euro 5 With DPDvik_mdNo ratings yet

- 6HSEED-WE-775HK - Emission and Electrical DiagnosisDocument97 pages6HSEED-WE-775HK - Emission and Electrical Diagnosisvik_mdNo ratings yet

- 6heed-We-0001 - Emission and Electrical Diagnosis 6HH1 EVTDocument78 pages6heed-We-0001 - Emission and Electrical Diagnosis 6HH1 EVTvik_mdNo ratings yet

- Тормозное давление Volvo fh12Document5 pagesТормозное давление Volvo fh12vik_mdNo ratings yet

- Gysmi: 64163 8 A4 Fonction: Schema - BlocDocument9 pagesGysmi: 64163 8 A4 Fonction: Schema - Blocvik_mdNo ratings yet

- Lg4hke4wd-Wsp-0851co - 4hk1 Euro 4 With DPDDocument1,230 pagesLg4hke4wd-Wsp-0851co - 4hk1 Euro 4 With DPDvik_md100% (1)

- LG4HG-WE-0871-4HG1 - Engine 4HG1Document519 pagesLG4HG-WE-0871-4HG1 - Engine 4HG1vik_md100% (7)

- In190 Gysmi - Repare 195Document14 pagesIn190 Gysmi - Repare 195vik_mdNo ratings yet

- Spare Parts Catalogue - March 2014Document20 pagesSpare Parts Catalogue - March 2014vik_mdNo ratings yet

- DW 80 ManDocument12 pagesDW 80 Manvik_mdNo ratings yet

- BAXI Eco Four котлы - инструкцияDocument34 pagesBAXI Eco Four котлы - инструкцияvik_mdNo ratings yet

- Eber B3L D3LDocument3 pagesEber B3L D3Lvik_mdNo ratings yet

- Autocom CARS 201700Document2,851 pagesAutocom CARS 201700vik_mdNo ratings yet

- Description: LM2576 SeriesDocument8 pagesDescription: LM2576 Seriesvik_mdNo ratings yet

- Thermo 90Document26 pagesThermo 90vik_mdNo ratings yet

- Taura D McsDocument15 pagesTaura D Mcsvik_mdNo ratings yet

- Automotive Quad Low Side Driver: MC33385 SemiconductorDocument11 pagesAutomotive Quad Low Side Driver: MC33385 Semiconductorvik_mdNo ratings yet

- LAMBORGHINI Manuale Installazione e Manutenzione Caldaia Murale A Gas LAMBY IN 20 24 MTC W TOPDocument140 pagesLAMBORGHINI Manuale Installazione e Manutenzione Caldaia Murale A Gas LAMBY IN 20 24 MTC W TOPvik_mdNo ratings yet