Professional Documents

Culture Documents

MG6HFED-WE-0991 - Engine Control System (6HF1 Model)

Uploaded by

vik_md0 ratings0% found this document useful (0 votes)

90 views386 pagesOriginal Title

31. MG6HFED-WE-0991 - Engine Control System (6HF1 Model)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

90 views386 pagesMG6HFED-WE-0991 - Engine Control System (6HF1 Model)

Uploaded by

vik_mdCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 386

ISU2U

2009-2013MY F&G SERIES

WORKSHOP MANUAL

ENGINE CONTROL SYSTEM

(GHF1 model)

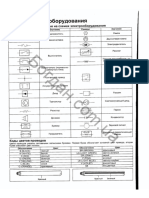

“This Workshop Manual deals only with the scraen toned section(s) in the table balow.

Sention

ENERAL INFORMATION

‘SUSPENSION

DAIVELINEAXLE

“TRANSMISSION/TRANSAXLE

STEERING

HVAC.

RESTRAINTS:

BODY, CAB AND AGCESSORIES

a TROL SYST:

111 [FRAME AND FRAME ACCESSORIES:

Sub Section

eral Information

ine Mechanical

ine Cooling

ino Fuck

ne Electrical

Emission Control

Engine Exhaust

Engine Lubrication

Engine Speed Contral Sysiom

Induction

Pre-Heating Sysiom

Power Take-Off

‘Air Suspension Control Sysiam

Front Suspension

Rear Suspension

‘Wheel and Tire

Front Differential

Rear Differential

Propeller Shaft

Front Axle

Rear Axle

“Transfor Cass)

Brake Control System (Ar Ow

‘Brake Control System (Full Ar

Brake (ir

Brake (Ful Ai

‘Anti-Lock Brake (ABS)

‘Anl-Lock Brake (ABSVAnl-Si

Parking Brake

Hill tart Aid (H

‘Speed Retarder System

“raller Brake

“Transmission Convval System

‘Automatic Transmission

‘Manual Transmission.

Clutch

Power Take-Off

‘Side Power Take-Oft

Power Steerin

Heating and Ventilation

‘Manual Air Condition;

‘Automatic Air Conditioning

‘Seat Bolt

‘Supplemental Restraint System (Ri

‘SBS Control System

Lighting Sysiom

Wiper’Washer System

Entertainment

fring Systers

Instrumentation/Driver Info.

Body Structure

Cab

Seats

Security and Lock

Exteror/interior Trim

(Cabs Mounting

i 7

Frame

Engine Control System (6HF1-CNG)

1A

ENGINE

Engine Control System

(6HF1-CNG)

TABLE OF CONTENTS

Specifications....... 113 DTC P0298 (Flash Code 65).

“Tomporoture vs Resistance. T1A3_—_DTOPO327 (Fash Code 16).

Altitude vs Barometric Pressure . .. 14 DTC P0328 (Flash Code 16}.

Diagnostic Trouble Code (DTC) Type

Definitions... cece

Diagnostic Trouble Code tore) List 16

‘Overview Wirings . :

Overview Wirings

Routing Diagrams...

Fue! System Routing Diagram

‘Component Locator...

Engine Controls Component Views

Engine Control Module (ECM) Connector

End Viaws..

Engine Control Connector End Views... 18-27

Diagnostic Information and Procedures... 18-48

Engine Control System Chock Sheet 1043

Diagnostic Staring Point - Engine Controls. 14-44

Baagosic Sylar Check- Engine Concls «1A?

‘Scan Too! Data List.

‘Sean Tool Data Definitions |

‘Sean Too! Output Controls «

‘Scan Too! Does Not Powsr Up

‘Scan Tool Does Not Communicate with the

Engine Control Modula (ECM) 1as7

DIG POI0S (Flash Code 71) 18.60

DTG PO107 (Flash Code 33). 2.0.2... TAB

DTG PO108 (Flash Code $3) 1n65

DTG Po112 (Flash Goce 23)... S1A70

DTG PO113 (Flash Goce 23). 1873

DTG POIIT (Flash Goce 14)..00.. 002. 1AT?

DTG PO118 (Flash Coce 14) 1n79

DTG P0136 (Fiash Code 48) 1n82

DIG Potat (Fiash Code 65) 1865

DIG P0171 (Flash Code 48) 1889

DTG P0172 (Fiash Code 45) 1h04

DIG PO182 (Flash Code 38) 14-100

DTG Po183 (Fiash Code 34) 1a103

DIG P0102 (Flash Code 32) 14-108

DIG Po1a83 (Fiash Code 32) tani2

DIG Po201 (Fash Code $1) tani?

DTG P0202 (Fiash Code 31) 10-120

DTG P0203 (Fiash Code 31) 10123

DTG P0204 (Flash Code 31) 1h128

DTG P0206 (Fiash Code 31) 1n129

DTG P0206 (Fiash Code 31) 10132

DTG P0207 (Flash Code 31) 14-138

DTG P0208 (Flash Code 31) 14-138

DTG Po234 (Fiash Code 65) tna

DIG Po2A3 (Fiash Code 65) 14146

DTC P0332 (Flash Code 16).

DTG P0388 (Flash Code 16).

DTG P0335 (Flasn Code 41),

DTC PO340 (Flash Code 43).

DIC PO361 (Flash Code 35).

DTC PO362 (Flash Code 35).

DTC P0359 (Flash Code 35).

DTC PO36A (Flash Code 35).

DTG P0356 (Flash Code 36).

DTC P0356 (Flash Code 35).

DTG P0462 (Flash Code 37).

DTG P0453 (Flash Code 37).

DTG P0475 (Flash Code 64).

DTC POSOO (Flash Code 24).

DTC POS02 or P0503 (Flash Code 24)...

DTC PO5OG (Flash Code 53).

OTC POSC7 (Flash Code 53).

DTC POSED (Flash Code 36).

DTG POS62 (Flash Code 86).

DTG P0563 (Flasn Code 86).

DIC P0806 (Flash Code 51).

DIG P1120 (Flash Code 21).

DTG P1125 (Flash Code 52)

DTC P1160 (Flash Code 13).

DTG P1151 (Flash Code 13).

DTC P1162 (Flash Code 13).

DTG P1156 (Flash Code 13).

DTG P1158 (Flash Code 13)...

DTG P1187 (Flash Code 13). :

DTC P1158 (Flash Code 13).

DTG P1220 (Flash Code 21}.

DIG P1224 (Flash Code 21),

DTC P1271 (Flash Code 22}.

DTG P1275 (Flash Code 22),

DTG P1280 (Flash Code 22),

DIC P1200 (Flash Code 21),

DTG P1286 (Flash Code 21},

DTG P1206 (Flash Code 21).

DTC P1514 (Flash Code 21).

DTG P1515 (Flash Code 21).

DTC P1516 (Flash Code 21),

DTG P1828 (Flash Code 21}.

DTC P1686 (Flash Code 21),

DTG P1638 (Flash Code 22}.

DTG P2125 (Flash Code 25).

heck Engine Waring Light humination

Circuit System Check

= 18148,

218-154

218-186,

21-158,

= 18-160

1ai62

1A165

1a68

4Ai71

1ai74

477

aa180

10183

Caate8

1n488

= 18181

195

10198

10-208

218-208,

W210

218218

1w221

18223

1225

18229

14231

10233

18235

18237

1a241

1a243

10265

1n287

14251

18253

18256

18-260

18264

10-268

18-268

1A270

1277

10282

19.287

10290

1A.292

1A294

1A297

4A-2_Engine Control System (GHF1-CNG)

‘Chock Engine Warning Light Blinking Circuit,

‘System Check.

Starting Systam Check |. 2

Fuel System Check.

Ignition System Check --- 2

Exhaust System Check

‘Symptoms - Engine Controls

Diagnosis By Symotom. .- :

Intermittent Conditions o

‘Abnormal Combustion Noise

Poor Fue! Economy.

Hard Siar -

Rough, Unstable, or Incorrect Iele and

Staling...- i

High Idle Speed

Pulsing in Engine Speed

Surges. ee :

Lack of Power, Slugaishness or Sponginess

‘Abnormal Sound! Abnormal Smel\.

Repair instructions

Engine Contvol Module (ECM) Replacement

Fuel Compensation Rate Lea

Engine Driver Unit (EDU) Replacement

Description and Operation

Engine Control Module (ECM) Description

Engine Control Component Descrotion

Ati Fual Ratio Control System Description

Fuel Injection System Description. .

Fuel Injection Sysiem Component

Description -...........+-+

Ignition Systam Description.

‘Throttle Valve Control Description...

“Turbacharger Control System Description

Exhaust Brake Control Description.

‘Spacial Tools and Equipment :

‘Special Tools anc Equipment

14209

1a301

14303

1a3i2

1a314

10316

14316

10318

14321

1323

14.326

14329

14332

10.335

14338

1A34t

1A344

1347

17

1348

1a348

14351

14361

10356

14362

14363

14366

1A375

1a379

14381

1382

10382

Engine Control System (6HF1-CNG) 1A-3.

Specifications

‘Temperature vs Resistance co oF Ohms

Engine Coolant Tempereture vs. Resistance Torpeatina ve, Gopraximatety)

© F Chen 30 ze 25108

“Temperature vs. Resistance Value (Approximately)

7 aaa 55 Intake Air Tomporature vs. Resistance

i) 230 180 c = Steve

500 a 750 “Temperature vs. Resistance Value (Approximately)

30 14 2a 9 198 240

30 176 320 80 176 $20

70 138 30 0 188 450

0 140 500 8 vo 850

[so | mw ‘| 810) a0 12 oe)

0 104 1150 aa i ae

30 6 1660 ad Ld am

20 6 2450 ae 5 3a80

0 50 3700 19) =” sate:

0 @ 600 ° aa s77o

x0 az 00 =10 “4 16810

20 4 15480 7 “ 26560

30 B 26700

Fuel Temperature vs. Resistance

c F ‘Onms

“Tamporature vs. Resistance Value (Aparoximately)

720 248 12

110 230 a

700 212 188

30 14 28

80 176 322

70 158 85

0 140 295

50 2 333

0 104 14

30 3 1706

2 6 298

10 20 3701

0 a2 696

“0 14 9308

20 4 15458

4A-4_Engine Control System (6HF1-CNG)

Altitude vs Barometric Pressure

Barometic

Altitude Altitude Pregsure

Measured in | Measurec in | Measured in

‘Meters (mm) Feet (f) Kilopascals

(Pe)

Determine your altude by contacting @ local weather

station or by using another rforonco source.

4267 14000 56-64

3962 13000, 56-65

3656 12000, 6769

3358 71000 e472

3048 10000 66-74

2as ‘9000 COT

BEd 2000 779

2s 7000 7482

1828 6000 77-85

1524 ‘5000 80-38

[tas | 4000] aor |

oe 3000 87-95

610 2000 90-98

305 7000 34-102

a 0 Sea Level 96-104

“305 1000 101-108

Engine Control System (6HF1-CNG) 1A-5

Diagnostic Trouble Code (DTC) Type Definitions

Emission Related DIC

‘Action Taken When the DTC Sets - Type A

+ Tho ECM illuminates the malfunction indicator

lamp (MIL) when the diagnostic runs ard fais

+ The ECM records the operating conditions at the

‘ime the diagnostic fais. The ECM stores this

information inthe Frooze Frame.

‘Action Taken When the DTC Sets - Type B

+ The ECM illuminates the MIL on the second

‘consecutive driving cycle when the diagnostic runs.

and fails

+ The ECM records the operating conditions at the

‘ime the diagnostic falls. I the diagnostic reports a

failure on the second consecutive:

ECM records the operating condi

of falure and stores tis information in the Freeze

Frame.

Conditions for Clearing the MILIDTC - Type A or

Type B

+ The ECM tums OFF the MIL aller 3 consecutive

driving eycles when the diagnostic runs and doos

nol fal

+ Acurrent DTC clear when the diagnostic runs and

passes.

+ Abhistory DTC and the Freeze Frame clears after

40 consecutive warm-up cycles, If no failures are.

reported.

‘+ Use a scan tool or memory clear switch function to

clear the MIL and the DTC.

Non-Emissions Rolated DTCs

Action Taken When the DTC Sets - Type D

+ The ECM wil not iluminate the MIL,

Conditions for Clearing the DTC - Type D

+ Acurtent OTC clear when the diagnostic runs and

passes.

+ Ahistory DTC clears after 40 consecutive warm-up.

cycles, ifno failures are reported.

+ Use a scan tool or memory clear switch function to

lear the DTC.

4A-6 Engine Control System (GHF1-CNG)

Diagnostic Trouble Code (DTC) List

oe | ae] BE B16 bene

PoROE | Tt |_| Barats rose Sonor Crow Ear

ona [3 [ A nih AF Peso Sea a iam WTS

P0108 33 A [Intake Air Pressure Sensor Circuit High Voltage

PON2 23. A |Intake Air Temperature (IAT) Sensor Circuit Low Voltage

oie | 29 | A [nate Ae Tanpra(n Sersor Grit igh ago

oii? | 1¢ | A [Emin Covent enperare Coo hou

POE 14 A __ | Engine Coolant Temperature Circuit High Input

Ne

PaTai [86 | JO SrsrHelr Creu Ope Gr San To Gnd

Pair 3 [East jie Pers son

Pore [8 [ [ava St Pas Reh

pois | 31 | a [Fa Torpertur (7) Sensor Croton Voge

Fores [94 [A [Ret epee Sosa Gral ih Voge

Se

pore | 82 | A [Pel Press Sons Cut Fgh Vans

Foaoi | at | A [histor eed Open Gra Shot Grado Gd

‘P0202 34 A [Injector #5 Load Open Circuit or Short Circuit to Ground:

‘P0203 31 A |Injector #3 Load Open Circuit or Short Cireuit to Grounc

P0204 3t A [Injector #6 Load Open Circuit or Short Circuit to Ground:

poaos-| 81 | Ancor nes Open Geto Shot Gra ond

Faroe [at [A [ndor i asd Gpen Gra or Sho Grado Gnd

Faa67 [G1 [ A [orl aed Open Gao Shot Grado Gnd

‘0208 3 A [Injector #8 Load Open Circuit or Short Circuit to Ground:

razor | 65 | A [Tuoatrcer tig Boon condon

pazas | 66 | A [Tuto Chair Conte VaV eer

oaaa_[ 65 | Troster nw Bow Gorton

poser [18 [ 8 [Rowe Serer Gres ow hod GaN OF Srge SORAT

Pog28 16 D__ | Knock Sensor 1 Circuit High Input (Bank 1 Or Single Sensor}

Posse | 16 D | Knock Sensor 2 Gireult Low Input (Bank 2)

Passe [6 [ [Ree Senor 2 Gra ah a ane)

posse [ Ai | A] hat Poston Senso ret

pei | 18 |» | Cama Poston Sersr Ct Wanefon

a CL

oe Ce

pease | a6 | A fanson3 Corl Cit

pease [a6 | A fanton 6 Coe cre

Engine Control System (6HF1-CNG) _1A-7

ore | Oem | oe DTC Descriptor

P0385 | 35 | A |lgniion 2 Control Ciraut

poses | 35 | A [tention 4 Control Creut

poss2 | 37 | A _ | Fuel Tank Pressure Sensor Low Voltege

P0453 | 87 | A _ | Fuel Tank Pressure Sensor High Voltage

Pod7s | 64 | A _ | Exhaust Brake VSV Open Circuit or Short Gircuit

Posto | 24 | A _ | Vehicle Spood Sensor

Pos02 | 24 | A _| Vehicle Speed Sensor Circult Low Input

P0503 | 24 | A _|Vehicle Speed Sensor Gircult High Input

Posos | 53 | 0 _ | idle Speed Control RPM Too Low

P0507 | 83 | 0 _ | Idle Speed Control RPM too High

P0560 | 36 | A _ | Ignition Power Source Error

Poséz | 66 | 0 | SyslemVolage tow

posés | 66 | 6 | System Voltage Hich

P0606 | 81 | A _ | Goniol Module intemal Performance

Piz [21 | A _ | Throlte Postion Sensor 1 Gieut

Pitz | _82_| A _| Electronic Throttle Contol Linked Performance Mode

Pits) | 13 | A _|AirFuel Ratio Sensor AFC (Base Voliage) Or AFV (Supply Voliage) Oven

Pitst_| 13 | A _ |AirFuol Ratio Sensor AFV (Supply Vollage) Grault Shorted

Pits2 | 13_| A _ |AirFuel Ratio Sensor AFC (Base Vollage) Gireut Shorted

Pit85 | 13 | A _ |AlrFuel Ratio Sensor, Release of Heater Output

Pit56 | 18 | A _ |AirFuel Ratio Sensor, Short Grout of Heater Output

Pits7 | 13 | A _|Air Fuel Ratio Sensor Heater Error

P1158 | _13_| A _|AirFuel Ratio Sensor Protection Circuit Operation

Piz20 | 21 | A _| Throlle Postion Sensor 2 Girut

Pigei_ | 21 | 0 _|TPS1 and TPS2 Comparison Error

Pieri | 22 | A _ |APStand APS2 Comparison Eror

Pia? | 22 | A _ | Accelerator Pedal Position Sensor 1 Gircuit

Pi280 | 22 | A _ | Accelerator Pedal Position Sensor 2 Grcut

P1290 | 21 | A _ [Electronic Throtle Contol Forced Idle Mode

P1295 | 21 | A _ | Electronic Thratle Control Power Management Mode

P7209 | 21 | A _ | Electronic Throtle Coniol Forced Engine Shuldown Mods

pista | 21 | A |TPSand MAF Comparison Emor

Pisi5 | 21 | A _ | Gommand irom ECU and TPS Comparison Error

Pis16 | 21 | A _ | Gommand rom EOU and TPS2 Comparison Error

Pie23 | 21 | _D _| Thvolle Acuator Control Retum Performance

Press | 21 | 0 _|SV Reference #1 Girout

Pies | 22 | 0 _|6V Reference #2 Grout

P2125 | 25 | A _ |PTO Accelerator Sensor Error

448 _Engine Control System (6HF1-CNG)

Overview Wirings

Overview Wirings

12

dr Gn sae E04

oo

et Bae Mat ae

ancy

7

i

ec eanymace cay

sgt tt

ie Seer

Se

Engine Control System (6HF1-CNG) _1A-9

esis

Sm increta Tile 1L2)

macnn, 2 a

comenl, Sees

[ cxeeel? “| —cnvearen =

eee =

| eee al fee

we uc | | — ener

Tom Maar ‘p[ se tewercn ome] sg eure Coe

sxmuenl, Ef cerrecmreot| SS Hey] Seepeneon

2c {Se “he. 7

sysen ox {i ieaerercmanewerst| Ba t ste ete

ee oe? eS (er,

ce FS ce

sano

sas ndsly

FP? faenacncisnoae |. gy fran B |eorsenn

Se ed

Gos inet $7 LF ‘ce Ga roca 2000] mi Bi | cee sero

[ese rw cua Mews 5g vos fia Ne a

cannons), "Sean

[ sees eee

Teemeeeees|

sense), Some

7 A

Se eel

ee eae

sah «| —SSoae

4A-410__Engine Control System (6HF1-CNG)

Routing Diagrams

Fuel System Routing Diagram

FTR model for Thailand equipped with a high pressure gas filter,

yo

eyes

Legend

CNG container (CNG cylinder)

Manuel cylinder valve

High pressure rigid fuel line

Filing uit

‘Check valve

Manifold ascembly

Fuol tank (CNG container) pressure sensor

Purge valve

CNG pressure stop valve

Gas filter (high pressure side)

Magnes valve (bore roguater)

Pressre reguelor

Wid pressure ng fue ne

Gas filter (Jaw pressure side)

Magno valve (bofore engine)

Flexi uel ino

To engine (to main gas rail)

Engine Control System (GHF1-CNG) _1A-11

FTR model for Thailand not equipped with a high pressure gas filter

NI

;

\

Legend

‘CNG container (CNG cylinder)

Automatic valve

High pressure rigid fuel line

Filing unit

‘Check valve

Manifold assombly

Fuel tank {CNG container) pressure sensor

Purge valve

‘CNG pressure stop valve

Pressure regulator

Middle pressure rigid fue ite

Gas fiter (law pressure side)

Magneic valve (before engine)

Floxible fue ine

To-engine (to main gas rail)

4A-412_Engine Control System (6HF1-CNG)

FVM model for Thailand equipped with a high pressure gas filter

hn

Legend

‘CNG container (CNG cylinder)

Manuel cylinder valve

High pressure rigid fuel line

Filing unit,

‘Check valve

Manifold assembly

Fue! tank (CNG container) pressure sensor

Purge valve

(CNG pressure stop valve

40

1".

2

a

4

6

6

7.

Gas fiter (high pressure side)

Magnetic valve (betore requaater)

Pressure regulator

Midale pressure rigid fue line

Gas fiter(jow pressure side)

Magneic valve (before engine)

Flexible fuel ine

To engine (to main gas ral)

Engine Control System (6HF1-CNG)_1A-13

FVM model for Thailand not equipped with a high pressure gas filter

Legend

‘CNG container (CNG cylinder)

‘Automatic valve

High pressure rigid fuel line

Filing unit,

‘Check valve

Manifold assembly

Fue! tank (CNG container) pressure sensor

Purge valve

8

0.

11

2

2

4

8

‘CNG pressure stop valve

Pressure regulator

Midale pressure rigid fue line

Gas fter(jow pressure side)

Magnetic valve (before engine)

Flexible fuel ine

To engine (to main gas ral)

4A-14_Engine Control System (6HF1-CNG)

‘GVR model for Thailand equipped with a high pressure gas filter

Legend

‘CNG container (CNG cylinder)

Manuel cylinder valve

High pressure rigid fuel line

Filing unit

‘Check valve

Manifold assombly

Fuel tank {CNG container) pressure sensor

Purge valve

CNG pressure stop valve

10

1"

2

6

4

16

6

7

Gas fiter (high pressure side)

Magnetic valve (before requiator)

Pressure regulator

Midalo pressure rigid fue line

Gas fiter (low pressure side)

Magnetic valve (before engine)

Flexible fuel ine

‘To engine (to main gas ral)

‘GVR model for Thailand not equipped with a high prossure gas fitor

Engine Control System (6HF1-CNG) _1A-15

Legend

‘CNG container (CNG cylinder)

Automatic valve

High pressure rigid fuel line

Filing unit

‘Check valve

Manifold assombly

Fuel tank {CNG container) pressure sensor

Purge valve

‘CNG pressure stop valve

Pressure regulator

Middle pressure rigid fue ite

Gas fiter (law pressure side)

Magneic valve (before engine)

Floxible fue ine

To-engine (to main gas rail)

4A-416 Engine Control System (6HF1-CNG)

For Australia

Legend

4. Engine control module 45. Airfuel ratio sensor

2. Accelerator pedal position sensor 16. Sub-ges rail

3, GNG container (CNG cylinder) 17. Camshatt position sensor

4. For inlet manifold 48. Ignition coi

5, Magnetic valve (at tank) 19. Gas injector

8. Magnetic valve (integrated manifold) 20. Crankshaft position sensor

7. Pressure regulator 21. Engine coolant temperature sensor

8. ONG temperature sensor 22. Knock sensor

8. Main gas ra 23. Manifold absolute pressure (MAP) & intake air

10. Sub-gas injector femperature (IAT) sensor

11. CNG pressure sensor 24. To main gas rail

42, Exhaust ges, 25. Three valve

13, O, Sensor 26. Intake alr

14, Exhaust rake magnetic valve 27. Engine criver unit

Engine Control System (6HF1-CNG)_1A-17

Component Locator

Engine Controls Component Views

Legend

11. Accelerator pedal position (APP) sensor

Legend

1. DC-DG converter

4A18 Engine Control System (6HF1-CNG)

For Thailand

Legend

11 Intake alr temperature (IAT) sensor 6. CNG pressure! temperature sensor

2. Thratle valve 7. Crankshaft position (CKP) sensor

3. Manifold absolute pressure (MAP) sensor 8 Sub-gas injector 2

4. Gas injoctor 8. Sub-gas injector 1

5. Main gas rail

Engine Control System (6HF1-CNG)_1A-19

For Australia

Legend

“1. Manifold absolute pressure (MAP) & intake air 5. Main gas rail

temperature (1AT) sensor 8. CNG pressure sensor

2. Throttle valve 7. Crankshaft position (CKP) sensor

3. Gas injector 8 Sub-gas injector 2

4. CNG temperaiure sensor 9, Sub-gas injector 1

Legend

41. Knock sensor 1

2. Knock sensor 2

44-20 _Engine Control System (6HF1-CNG)

Legend

1. Alrfuel ratio (A/F) sensor 6. Ignition cot 4

2. Camshaft position (CMP) sansor 7. Ignition call 3

3. Wastegate contrl solenoid valve 8. Ignition coll 2

4: Ignition coll 6 9. Ignition eal ¢

5. Igntion coll 5

Engine Control System (SHF1-CNG)_1A-21

Modols for Thailand equipped with a high pressure gas filter

Legend

41, Fuel pressure indicator 4, Gas filler (high pressure side)

2. Manual cylinder valve 5. Gas filler (low pressure sido)

3, Magnetic valve (before engine) 6, Magnetic valve (before regulator)

Models for Thailand not equipped with a high pressure gas filter

end

Fuel pressure indicator 3, Magnetic vaive (before engine)

2. Automatic valve 4. Gas iter (iow pressure side)

4A-22__Engine Control System (6HF1-CNG)

For Australia

Legend

1. Magnetic valve (at tank) 3, Magnetic vaive (integrated manifold)

2, Pressure regulator 4. Fuol tank (CNG container) prossure sonsor

2

3

1

Legend

4. Exhaust brake assembly 3. Sway catalyst integrated silencer

2. 02 sensor

Engine Control System (6HF1-CNG) _1A-23

Legend

1. Exhaust brake assembly 2, Exhaust brake magnetic valve

Legend

1. Sensor caver 2. Vehicle speed sensor (VSS)

4A-24 Engine Control System (6HF1-CNG)

Legend

41. Engine control module (ECM) 3, Engine ¢river unit (EDU) 2

2. Engine criver unit (EDU) 1

Engine Control System (6HF1-CNG) _1A-25

Engine Control Module (ECM) Connector ‘Connector No. FB25

End Views Connector color Black

Engine Control Module (ECM) Pin No. | Wire color Pin function

Check engine warring Ugh

19 | vets aux [Ores

Sahat brake aistor Tah

20 [orn rep |Ehaus

Bi_| RED _ | Starter out relay contol

= | — | Notwsed

= 3B = Not used

steer 24 | LTBLU | Keyword 2000 serial data

Cylinder #2 gas inecior

= ERM, (HIGH)

CGyiner #4 gas inecior

ze | were | ince

27_ | GRN/RED | Sub-ea8 recor + (HIGH)

28 WHT | Sub-gas injector 2 (HIGH)

Sean sa @_[ YELORN | Memory dear request awich

Soman soar — B_|_YEL__| Diagnostorequost awich

Pin No. | Wire color Pin function a —_|Neturet

BLK [ECM power ground 2 —_|Netused

SS 33_|_YEL_ [Parking bake swfion anal

Tr GRW

3 | ET | eatery vote a4 | SEN" | cnauet race sen signal

35 | Wor vEL [PTO switch signal

wT?

4 | WET | pation votage =

5 | BLK/ORN | Ignition voltage Ed BLU [AIC switch signal

6 RED/ BLU | Cylinder #1 ignition coil control 38 — Not used

7 [RED _[Gyinder #5 ention col conor) [29 | WHTFELU| Clutch sion sinal

8 RED/ YEL | Cylinder #3 ignition coil control 40 | BLK/ ORN [Neutral switch signal

© [REDTBLK | Cynder #6 anton coroner] [At] BLRTWHT [niion swt START sonal

70 |[RED/ GAN | Cynder #ignion aot conor] | 4a] gay [APPaensor2

a RED — | Cylinder #4 ignition coil contro! 5 volts nee

TAPP sensor?

2 _| RED/BLK | 0, sensorheater contol () wo | pik [APP sensor

18 [BUX/RED [Exiaust rake magootc vaio | | gq —/auxrwart [cinder #2 ao hear LOW)

4 ORM [ose vatn ty cont 46] BTL [ vind gas CD

75 | BLK RED | Gas valve relay contro! 46 GRN | Sud-gas injector 1 (LOW)

76 | BLU/ WHT | ECM main relay control a RED | Sub-gas injector 2 (LOW)

a @5_| BURTPAK | Knock sensor 1 snat

a Lema |Re srpene ar away] [AO [RTPA enna

contrl BO _| wait _[0; sensor signal

44-26 Engine Control System (6HF1-CNG)

onnecior Ne Faas Connector. Fas

Connector coor Beck Connector color Black

Pin No. | Wire calor Pin function Pin No. | Wire color Pin function

St _ | YELIGRN [AT sensor signal Foal tank (CNG container)

GE [Wit [APE sonra et | euwvet Joressue sensor 5 vets

3 | VEL [APP sersor2 signal

4 BLUTWHT | PTO positon sonsor signal

Fuel tank (CNG container

85 | BLI/PNK |p escure sensor signal

we | RED! [DC-DC converter power

WHT | supply votage monor

‘Vehicie speed sensor lgnal /

57 | YELIGRN | (seed sensor control unt) 0 | eee)

58 =| Netused THRE NET]

ma | Bi loan ora SS

[BLU WHT | CAN Wh signal

or |= [Netused

PTO postion sorsor 6 vols

ad BLU, reference:

‘lin #2 gas Rjocor Grea art

65 [pric war | inde

ce | va [Ofecer Rae eaararean| [Comair Ea

moni ‘Connector color Black

UTGRN |Subgas injector 7 creat) be —

Toa [suo Fin No. | Wire color Pin fone

OR |subgas wear 2 eat] | a2 |aLurmeD|Wesouele cto skreid

RN | montor

BT [ON [RroacsareorTewarrares| [as | veu Ren | ONG Wnpemize tose ow

| ORN [Kreck sensor 2Tow reference a RF

@_ | BLK |, sensor ow erence sensor’ low reference {or

7] ot ase 24 | BLK/RED | Thalanay

CNG _presaure sensor tow

7 | RED APP censor {Tow rterence oe ae ee

72_| BLU [APP sensor 2 Tow rferance we lwees lester

PTO pasion sensor ow

za [auuren [PTO po we) pix [MAP IAT aonsor tow

relerence

Fuel tank (CNG container)

74 | BLK’ RED NG "onion Trike Uwotle posilon sensor

pressure sensor lw ee or | ew [inate thoi

75_ | BUR VEL [ECM system iow reference SS

78] BLCTYEL ECM eysiem tow reference {a

77_ | BLRTYEL [ECM aysiem iow erence sacar ge paar a

7a_[ BLKTYEL [ECM ayetem tow reference GRN | montor

7a} = |Netusea Ge] ETGRNT | Gyincer FS ga pct oreat

a} Tithaece RED | monitor

Engine Control System (6HF1-CNG) 14-27

‘Connector No. Ea ‘Gonnactor No. Ea

Connector color Black Connector eater Black

Pin No. | Wire color Pin function Pin No. | Wire color Pin function

‘Gylinder #5 gas injector circuit ‘Airfuel_ratio (AIF) sensor

8 | YE | monitor “8 | _RED | sional (arv)

‘Gylinder #1 gas injector circuit ‘Airfuel_ratio (NF) sensor

98 [PNK WHT monitor 120 | REDI'YEL | gator (contol

84 | WHT _| MAP sensor signal sax | uurwar| Aue ao (senor

5 | WHT | Intake throttle postion sensor

2 signal

86 | _RED__|CKP sensor signal Engine Control Connector End Views

at _| BLS; [GHP seneoreignal ‘Accelerator Pedal Position (APP) Sensor

98 | RED | Cylinder #5 gas injector LOW)

98 | GN _ | Cylinder #3 gas injector LOW)

100 | BLK/BLU | Cylinder #5 gas injector (LOW)

107_[ BLAT WHT | Cynder #1 gas injector (LOW)

CNG temperature sensor

102 | BLUPRED | SN

103 | WET’ | CNG pressure sensor signal

to4 [caw | Rake ProRS poser sence

105_| RED/BLK | ECT sensor signal

Cylinder #6 gas injector

106 | WATT qHichy

Cylinder #3 gas injector ries

tor JornrReD| (reas

‘Ginger #5 _gas_injector Ssamastor Wo

tos |warvevu | ene ‘Connector Ne Fa

yoo | pan | Cylinder #1 gas injector Connector color Gray

(HIGH) Pin No. | Wire color Pin function

RED! | CNG pressure sensor 5 vols ‘APP sensor

110 | WHT [reference ' GRN [5 vot raterence

Ti | RED _ [MAP sensor vols reference 2 YEL _ [APP sensor? signal

tra | nen [iste ote poston sensor BLU__ [APP sensor? low relerence

ence 1 BLK [APP sensor 1

113 | WHT | CMP sensor 14 voli reference 5 volts reference

1i4_| RED __ | Throttle valve (LOW)2 WHT _ | APP sensor 1 signal

115 | _YEL_| Throtie valve (LOW) 7 © | _RED [APP sensor 1 low reference

118 | _GRN _ | Thratile valve (HIGH) 2

117_| BRN _ | Throtle valve (HIGH) 7

‘Aicfuel ratio (NF) sensor

M8 | SRN | sonal (AFC)

4A-28 Engine Control System (6HF1-CNG)

‘Air-Fue! Ratio (A/F) Sensor ‘Connector No. Fare

Connector eater Black

1 | BLKIYEL | Ground

2 | WHT | Valve control

Automatic valve 2 (Models for Thailand not

‘equipped with a high pressure gas filter)

Connector No. Ei

Gonnecter color Gray

Pin No, | Wire color Pin function

1 _ | REDIYEL | Sensor heater control ()

2_[BLUIWHT | Sensor heater contra (1)

3_[__GRN _ [Sensor signal (AFC) caGEENE ean

¢_[_RED_ [Sensor signal (FV) Connacior lar Black

‘Automatic valve 1 (Models for Thailand not | Pin No. | Wire color Pin function

‘equipped with a high pressure gas fiter) 7] BLKYEL [Ground

2__|_ WHT | Valve control

‘Automatic valve 3 (Models for Thailand not

‘equipped with a high pressure gas filter)

| GonneciorNo. | FB70

Connector color Black

Pin No. | Wire color Pin function

Engine Control System (6HF1-CNG) 14-29

‘Connector No.

B28

Automatic valve 5 (Models for Thailand not

‘equipped with a high pressure gas fiter)

Gannector color

Black

Pino.

Wire color

Pin function

7

BLKIYEL

‘Ground

2

WHT

Valve contol

‘Automatic valve 4 (Models for Thailand not

‘equipped with a high pressure gas filter)

‘Connector No. FBI8T

Connector calor Black

Pin No. | Wiro color Pin function

1 | BLKIYEL | Ground

2 | _WHT__ | Valve contol

Magnetic valve (before regulator) (Models for

CARER ee ‘Thalland equipped with a high pressure gas filter)

‘Cannactor color Black

Pino, | Wire color Pin function

1 _[ BLKIYEL [Ground

2 | WHT _ | Valve contol

‘Connector No. F245

Connector color Light gray

Pin No, | Wire calor Pin function

7

BLKIYEL

‘Ground

4A-30__Engine Control System (6HF1-CNG)

ConneciorNe- FERS

Connector coor Tight rey Tonnes Ne) Fam

Connector oF Gay

RN

2 wat |Yave conto! Pin No. | Wire color Pin function |

7 BUKIVEL [Ground

Magnetic valve (before:

engine) (For Thailane)

GRN/BLK | Suction coll control

WHT _ | Rotention coll control

Camera aa

Conner aay

Fe [ Wis car] Pn

[eu veL | omnd

2 | SRY rave cnne

Magnetic valve (at tank) (For Australia)

» |b)

Magnetic valvo (intograted manifold) (For Australia)

‘Connector No. B26

‘Connector calor Gray

Pin No. | Wire color Pin function

1 | BLKIYEL | Ground

2 _ | GRN/BLK | Suction coll conirel

3__| WHT _ | Relontion coll control

Engine Control System (6HF1-CNG)_1A-31

‘Camshaft Position (CMP) Sensor

‘Connector NO. Eg

‘Connector color Black

Pin No | Wire color Pin function

RED?

1 P| Sensor 5 volts reference

WHT?

2 Tey | Sensor signal

‘3 _ | BLK/RED | Sensor iow roferonco

CNG pressure/ temperature sensor

For Thailand

‘Connecior No. Ea

(Gannector color Black

PinNo. | Wire color Pin function

4_[ BLKFYEL | Shield ground

BLK | Sensor signal

WHT _ | Sensor 14 volis reference

‘Connector No. 30

‘Connector calor Black

Pin No. | Wire color Pin function

T_| BLK/RED | Sensor low reference

2 _ | BLU/RED | GNG sensor signal

g | RED! [ONG pressure sensor5 vols

wt _| reference

4 | WHT TONG pressure sensor signal

RED

4-32 _Engine Control System (6HF1-CNG)

CNG Temperature Sensor Connector No. of

Fos Aust Connector eater Black

Pin No. | Wire color Pin function

3 RED _ | Sensor 5 volts reference

Engine Coolant Temperature (ECT) Sensor

‘Connector No Es

Connector color Black

PinNo. | Wire color Pin function onsen

BLU! RED | Sensor signal

2 _ | YEL/RED | Sensor low reference Cannes Ne: Eee

‘Crankshaft Position (CKP) Sensor Fonnedorieter oak

Pin No, | Wire color Pin function

1 | RED/BLK | Sensor signal

2 _| BLK/RED | Sensor low reference

Engine Driver Unit (EDU) 1

DOSOTO

lsasozooaswsgsooBIOH HUA |

‘Connector No. es

Gannector color lack

Pin No. | Wire color Pin function

RED | Sensor signal

2__|_WHT _ | Sensor low reference

Engine Control System (6HF1-CNG) _1A-33

‘Conneator No. Eze

ConnetzorNa. zs Connector estar Black

Sannéericalor Black Pin No. | Wire color Pin function

PinNo. | Wire color Pin function we Len | Onder #5 gas njector LW)

7 BLK | EDU? power ground (Cutout 9 gas injector)

2 —__ | Net used ze | war | cvinder #5 gas injector Fgh)

(Output io gas injector

a_| = [Baws Sit per

inder #3 gas inject

z —_ | Not used 20 | TERN ee ee econ

5 = _|Netused Cylinder #3 gas injoctor High)

é = [Not used 1 | PLY | utputo gas injector)

7 —__[Netused Gylinder #6 gas injector (Low)

32 | GRY RED | stout :0 gas injector)

: = [Metisse Gyiinder #8 gas injector High)

inder #6 gas nk

® = __[Netusea 33 | YEU RED | output 0 gas injector)

10 = __[Netused m = [Netused

a =| Netused Grinder #1 gas injector (Cow)

2 —__ [Net used 38 | BEKOWHT | (input from ECM)

‘Cylinder #1 gas injactor (High) Ly | Sviinder #8 gas miector (Low)

13° | BRN | (input from ECM) 96 | BLXIBLU | (input from ECM)

‘Cylinder #5 gas injactor (High) RN | Ovinder #8 gas injoctor Low)

14 [WHT/BLU | (input from ECM) x {input rom ECM)

‘Cylinder #8 gas injector (High) Cyjlndar #6 gas Ijector (Low)

15 /orwReD| (Mn eee 8 | RED | cinput from ECM)

“Cylinder 6 gas injector (High) Lt Grn | Cinder #8 gas injoctor crout

16 | WHT | (input from ECM) 39 | SAE” | monitor

(Output 9 Een)

‘Cylinder #1 gas injector ecu

17 |puqrwarr| monitor ‘orn | Svinder #5 aas injector creut

(Output ECM) 40 | Gan |e cay

‘Gylindor #5 gas injector ccat ps

18 | yet | monitor RED | Tite vane Lowy

(Output io Eom) (input from ECM)

Throtle valve (High) 7 | Thvatie valve (Low

18 [BRN | (input trom ECM) 42 | YEE | (input irom ECM)

Throtio valve (High) 2 3 _ | GRN/RED | Battery vollage

2 SEN | dsp tom ECM) “4 BLK | EDUT system ground

21 _[GRN/RED | Battery votage

Z| BLK | EDUT system ground

23_|_BUK | EDUT power around

Throtte valve (Low)

24 | SRN | (output io throitle valve)

Throtio valve (igh)

28 | BLY | Cutputiothratle valve)

Be) WHT | Gyindo- WT gas injector Low)

RED _| (Output to gas injactor)

‘Cylinder #1 gas injector (High)

27 | BLKYRED | (Gutpur to gas injector)

4A-34_Engine Control System (6HF1-CNG)

Engine Driver Unit (EDU) 2 Gonnadier Wo. =

Connector cater Back

Pin No, | Wire color Pin function

Gyliner #4 gas injector creat

te | vet | montor

(Output Ens

Te | — [Notused

aeenieesemNeTe| 20 | _—__|Notused

(Sobsdaaoseussecwanneon! 2i_ | GRN/RED | Battery volage

' 2 BLK | EDU2 system ground

23 | BLK [EDU2 power ground

| — | Notused

| _ [Notusea

vee ae | WHT | Cynder #2 gas iiscior (Lowi

RED _| (Output to gas injector)

nestor No. Gylinder #2 gar injector High)

Connector No ae 27 | BLE RED | (6 tout 20 gas injector)

Senet eer ee 2 | RED | Oviinder #4 gas inlector (Low)

PinNo. | Wire color in fonction (Qutput:0.9a injector)

7 | BLK | EDU? power around Cylinder #4 gas iriscior Fah)

Zz ——T timed 29 | WHT | Cutput 10 gas injector)

= = ‘Sub-gas ijecor ¢ (Law)

s Notused *” LTGRN (Output to gas injector)

x =i | Motuned! Hn Buy _ | Su>-g9s injector + High)

5 = Not used (Output to gas injector)

6 = Not used ‘Sub-gas injector 2 {Low}

7 = Not used m2 GRY RED: (Output to gas injector)

= Sub-gas hjecior2 (Hoh)

B Netiped 23 | YELRED | (6 tout io gas injector)

2} [een B_ |__| Notused

= = (Gylinder #2 gas injactor (Low)

1 = Not used 36 | BLK WHT (Input from ECM)

72 | _— | Notused Cynder #4 gas ijector Cow)

26 | BLKIBLU

va | pan | linda: B gas injector (igh) (input fom ECM)

{input from ECM) ar GRN__ | SUd-988 injector 1 (Low)

Input rom ECM)

44 | werrenu | C¥linder #4 gas injector (High) Ainp

Ainput fom ECM) | Rep | Subgar incor 2 (Low

7 ‘Suegas ecto 7 (High) {input rom ECM)

is | cry

{Input rom ECM) Tranny p88 Injector 1 creult

‘Sub-gas injactor 2 (High) = chit

18 | wnt [inpettorecM) RED [(o-touto Em

‘Cylinder #2 gas injector circuit orn) | Sub-gas Injector 2 circuit

47 |pNkrwet] monitor 40 GRN | monitor

(Output 0 ECM) (Outputio Eon

a) | Notuses

| [Notuses

Engine Control System (6HF1-CNG) 14-35

Connector No. 2

Eonnector bbe aa Gonnector No Foie

Pin No, | Wire calor Pin function ‘Connector color Blank

a [GanvraD | pana age Pin No. | Wire color in function

H_[_BIK _[EDUD aystem ground 1 [BUC RED [ Senor iow reference

BLK PNK | Sensor signal

Exhaust Brake Magnetic Valve BERT VEL | Sensor vats wi

Gas Injoctor #1 Cylinder

1[2

Connector NO. Fez om tet

Connector color Gay

Pin No. | Wire calor in faneton ‘Conneater No. Ese

Connector color White

+ | SRN ignition voltage feed

Pin No. | Wie color Pin function

2__ | BLE RED | Soiencid valve control 1 _| BLK/RED | Gas injoctor contr high side

Fuel tank (CNG container) pressure sensor 2 | RET | Gas injector contraltow side

44-38 Engine Control System (6HF1-CNG)

Gas Injector #2 Cylinder

Gas Injector #4 Cylinder

a=

GE]

‘Connecior No. a2 ‘Connector No. Fag

(Gannector color White “Connector color White

PinNo. | Wire color Pin function Pin No, | Wire color Pin function

4 [ BLKP RED | Gas injector contrat high side 1 WHT _ | Gas injector control high side

2 | WET | as mecorconratiow se 2 RED _ | Gas injecior contrat law side

Gas Injector #5 Cylinder

Gas injector #3 Cylinder

nea,

pea

‘Connector Ne Ea0

Connector color whito

| Pin No. | Wire color | Pin function

BLU _ | Gas injector contral high aide

2__| ETGRN | Gas injector controtiow sige

‘Connoctor No, E3e

Connector color White

Pin No. | Wire calor Pin function

T WHT _ | Gas injector control high side

2 RED

(Gas injector controflow side

Engine Control System (6HF1-CNG) _1A-37

Gas Injector #6 Cylinder

Gas Injector (sub) 2

a=

GE]

‘Connecior No. Eat ‘Connector No. Fes

(Gannector color White “Connector color White

Pin No. | Wire color Pin function Pin No, | Wire color Pin function

4 [ YEUFRED | Gas injector contrat high side 1 | YEURED | Gas injector control high side

2 [GRYPRED | Gas injector control ow sige 2 _ | GRYIRED | Gas injector control iow side

Gas Injector (sub) 4

Ignition Coll Cylinder #1

‘Connector No 62 ‘Connoctor No, E52

Connector color White Connector calor Black

PinNo. | Wire color Pin function Pin No. | Wire calor Pin function

1 BLU | Gas injector coriral high side RED?

ve i 1 REO! | Power supply

2 | ETGRN | Gas injector contrat iow sida

4A-38 Engine Control System (6HF1-CNG)

comedirin. = Ignition Coll Cylinder #8

Gonnector color Black

PinNo. | Wire color Pin function

BLKIYEL | Ground (for Thailand)

BLK _| Ground (for Australia)

3 RED/BLU | lanition coll control

2

Ignition Coil Cylinder #2

=

gen = eaveracinoret

oo) a a

WAYY onnector calor Black

1 | RED | power surety

BLK ‘Ground (for Australia)

=|

Pin No. | Wire color Pin function tanition Cou Cyunder $4

+ | BE power supply

BLKIYEL | Ground (for Thailand)

BLK | Ground (for Australia)

3 _ [RED/GRN | Ignition coil control

ComnecorN ES

Connector calor Bleck

Pinto] Wie cor Finan

7 | RET [power supa

7 BLK’ YEL | Ground {for Thailand)

BLK ‘Ground (for Australia)

3 [RED [nin cot conta

Ignition Coil Cylinder #5

Engine Control System (6HF1-CNG) _1A-39

Ignition Coll Cylindor #6

‘Goanester Ne: 7

Connector calor Black

Pin No, | Wire coor Pin fonction

+ | RET ower supp

a BLK) YEL | Ground {for Thailand)

BLK | Ground (for Australia)

| RED'BLK [Tonton coi contrat

Infake Air Temperature (IAT) Sensor

‘Connector No. E36 For Thailand

Tenmector color Black

Fin No. | Wire color Fin funcion

1 Tat | Powersupply

2 BLK/ YEL | Ground (for Thailand)

BLK | Ground for Australian

3 [RED [anton eo onirot

4A-40__Engine Control System (6HF1-CNG)

‘Connector No. E89 ‘Connector NO. E57

Gannector color Black ‘Connector color Gray

Pino. | Wire color Pin function Pin No | Wire color Pin function

7_ | YEU GRN | Sensor signal T PNK | Sensor signal

2 BLK | Sensor low reference 2 BLU | Sensor iow roforence

Knock Sensor 1 Manifold Absolute Pressure (MAP) Sensor

For Thailand

Connector NO. E56

‘Conneator No. E80

‘Cannector color Gray

Connector calor Brown

Pin No. | Wire color Pin function

Pin No. | Wiro color Pin function

PNK _ | Sensor signal

t BLK | Sensor ow reference

2 BLU _ | Sonsorlow roforence

WHT _ | Sensor signal

Knock Sensor 2 3 RED _ [Sensor 5 volts reference

Engine Control System (6HF1-CNG)_1A-41

Manifold Absolute Pressure (MAP) & Intake Air

‘Temperature (IAT) Sensor

For Australia

‘Connector NO.

FRAT

‘Connector color

Black

Pin No | Wire color

Pin function

7 [BLU WHT

‘Sensor heater control (>)

WHT

‘Sensor signal

BLK

‘Sensor low reference

RED/ BLK

‘Sensor heater control (}

PI Monitor Connector

eae a

Fiano | Wie cobs | Peet

|B] Sonsriw teen

2 | wit | AP srr sa

3 CRED [Wa soa es ae

4 YEU GRN | IAT sensor signal ot

oo serer SaaS a7

ennai lr ie

Fino Wie eor| Pinan

YEU GRW | Nema er ees och

a

=

a

221) 5 BLK | Ground

ay) Seay [Par te oats ad

o | ORM [Romer toron

meen

7a pares

aah looms

8 [omvineo| astern rn

sows eta

3) aR [ome

4A-42_Engine Control System (6HF1-CNG)

‘Throttle Valve

‘Connector NO. a?

‘Connector color Light Gray

Pin No | Wire color Pin function

T GRN _ | Ignition voliage feed

BLK | Sensor low reference

GRY _| Sensor signal

‘Wastogato control solenoid valvo

Connector No. ee7

Connector color wie

PinNo. | Wire color Pin fonction

+ | eo | Palin sensor vols

2 [BLU [Motoreontor

3 _[__GRN [Motor eontor runes

[WHT _ [Postion sensor 2 signal

3 _[_GRN | Postion sensor signal ‘Connecter Ne. E88

[BLU _ [Poston sensor Tow reference Connector olor Gray

Pin No. | Wie cotor Pin function

Vehicle Speed Sensor (VSS) +) RED! | poner upp

wat

2 _ | BLUPRED [ Turbocnarser control

Engine Control System (6HF1-CNG) 14-43,

Diagnostic Information and Procedures

Engine Control System Check Sheet

ENGINE CONTROL SYSTEM CHECK SHEET nepacre Nae

[cusomers None odo & Model Year

Devers Nome eho No

Date Veta Brough Engine No.

conse No locometer Reading rane

1 EGE DO== Ts Enno cee not oare 1 No i combuston| 1 No empl comeusten

1 wentstan | Engine cra slop © omer )

a 7 Ainaral ing eed Wiha eed RPG) owing mod RPT

Et reams [t) Reening

i 1 her 1

i Resttan a, vuneie cy Sue a iar

2 |v Baany [L Lacearoewsr soaenass,scnarose

5 Ober 1

2 Soon ea aaE ira pa aT

1 rain sua] Gung eeaon Aneel pol ceased ©. Shitrg fom Ho

one ,

bare 7 wae ane Paar natearany

1 Oe | Amnemalesreuaton note COP ear emer tener roan

1 DPF ete rogentaton og ae

5 one 1

aa paper cared |

iD cae Temiteriyt tnt — day) 0 Ones

Presmmtmcimey Ie one ,

(cane Be T cesar Ran Tso

Vater 1

[ows Ret eepr Wa Oost Teale

© [Fempeetire | Any ompertne

Eliow erway © sano 3 vara Bupa

5 Cowan Rewghnns 1 omer 1

z Oar pose oe) Tr Nowa

E |lcncoriton | onereepm tom)

5 [frame oa Ewa we a

Eltemeewe |G ome )

i E Sieory E dintatersirg( Min) 2 lng

B [Fore Cpweten 13 necraton E Ne sch Ovo

omar 1

Roatan — [ra Tete Tama Tha ong

tans

nana Tr eraicaty ears On 0 Gone rtm on

rset ce u Re oate ‘

gre otha

oa r0} eeu cove

sty cote Ling u fs ,

Sonn

4A-44_Engine Control System (6HF1-CNG)

Diagnostic Starting Point - Engine Controls,

Bogin the system diagnosis with Diagnostic System

‘Check - Engine Controls. The Diagnostic System

‘Check - Engine Controls will provide the following

information

+ The identification of the control madules which

‘command the system,

+ The abiliy of the control modules to communicate

‘through the serial data circuit.

+ The identiication of any stored diagnostic trouble

‘codes (DTCs) and the thai statuses.

The use of the Diagnostic System Check - Engine

Controls will identify the comect procedure for

legnosing the system and whete the procedure is

located.

Important: Engine Control System Check Sheet must

be used to verify the customer complaint, you need to

know the correct (normal) operating behavior of the

‘system and verify that the customer complaints a valid

{allure of tha system.

Salf-diagnosing function

It thore is a malfunction of a sonsor or actuator, ele, a

trouble code will be stored in the ECM memory, the

‘check engine waming light will illuminate (continually

illuminate), and the system may enter the backup

process, depending on ine trouble code.

The check engine warning light tums off when the

problem is resolved, but the trouble code will remain

Fecorded until you connect pins 1 and § of the Pl

monitor connector and tur the memory clear switch

function to "ON or clear the code using the scan tool

Banery

Dag. Swick ai

Memory Clr Stan

Self-diagnosis control modes

‘You can switch to the self-diagnosis modes by

switching the diagnestic switch function anc: memory

clear switch function. However, the ignition switch

should be left “ON during each mode.

Nanay

Diegness

een | 268 | Engine | cont made

function | function

Lignt neck

co oFe | oFF | stoppea | Lam

@ [OFF _|_OFF | Rannig | Normal made

Trouble code

3) OFF ON ‘Stopped | sear mode

Trouble cada

4) ON OFF | Stopped | display mode

Stopsed | Backup cata

®) oN on Tunning | dear mode:

Light check mode

1, When the ignition switch is tured ON", the check

engine warning light luminates.

2. Ino trouble is detected, the check engine warning

light tus off 4 seconds after starting the engine,

Hany failure is detected, the check engine waming

light remains iluminated stter stating the engine.

anton Sen oF

wgne Stan

atsminaton

‘chock Engine oF}

‘amg Lent

Normal mode

1. If'an emission related (OTC type A or B) code is

detected, the DTC willbe recorded, and the check

{engine warning ight remains iluminatec. (For DTC.

‘ype D, only the DTC is racorded)

2, If after detecting a failure, the vehicle becomes:

normal, and the ignition cycle has been cleared

‘three times, the check engine warning ight will tum

off.

However, the trouble code will remain recorded.

8, If the seme failure does not occur onoe after 40

‘warm up cycles, that trouble code will be cleared.

‘Trouble code clear mode

It you connect pins 1 and 5 of the PI monltor connector

‘and the memory clear switch function stays "ON" for 3

consecutive seconds, or if @ scan tool Is used for

‘clearing, all of the trouble codes recorded in the ECM

willbe cleared,

Engine Control System (6HF1-CNG)

“Trouble code display mode

4. If you connect pins 2 and 5 of the Pl monitor

connestor with the ignition switch turned "ON" (but

the engine stopped), the system vill enter the

trouble code dleplay mode while the diagnostic

sit function is turned "ON"

10-45

4A-48 Engine Control System (6HF1-CNG)

2. Ino trouble codes are recorded, code "12" will be

repeatedly cisplayes three times.

If touble codes are recorded, coda "12" and th

recorded trouble codes wil be repeatedly

displayed thre times.

Example Display of Codes 23,44

Neral Cae, rrowie Cote

= Hee taHeH} |

Digplay of Normal Code 12

onl ot s 2

or!

ojos 42 04 04 08 32 Tre (Sec)

Dicoay rove 2rd Oyo

‘Sate ‘Sate

Example Display of Code 23

f [LI

of!

04/04 04 Od 42 GA Od OA O04 OA 32 Tw (ee)

Dispay one 2nd Oye

eae State nana

Backup data clear mode

1, The system wil enter the backup data clear mode

‘nen you connect pins 1 and 5 of the Pl montor

Connector with tne fgiton switch turned "ON?, tum

‘he memory clear switch function "ON", connect

pins 2 and 5 of the P| monitor connector and tam

‘he diagnosteswiton functon "ON",

2, Alter 3 seconds have elansed, the following values

are retumed to ther intial values.

+ AlF sansor treshold value

+ Airtuel ratio lesrning value

+ Coefficient corected by fuel of diferent kind

+ Throtle ing postion leaming value

+ Leaming value for the throttle fuly closed

postion

+ Loaming value for the accelerator podal

position (APP) sensor fully hosed position

Engine Control System (6HF1-CNG) _1A-47

Diagnostic System Check - Engine Controls

Description

‘The Diagnostic Systam Chack - Engine Controls is an

‘organized eporoach to identiving @ condition that is

‘reated by a malfunction in the electronic engine

‘control system. The Diagnostic System Check must be

the starting point for any riveabilty concern. The

Diagnostic System Check directs the service technician

to the next logical step in order to diagnose the

‘concem. Understanding and correctly using the

agnostic table reduces diagnostic time, and prevents,

the replacement of good parts,

‘Test Description

‘The numbers below refer to the step numbers on the

legnostic table.

2. Lack of communication may be because of a partial

(oF 2 total malfunction of the serial data circuit.

6. The DTC list directs you to the appropriate

clagnostic procedure. If the control module stores

multiple DTCs, diagnese the DTCs In the ‘ollawing

order:

+ Component level DTCs, such as sensor DTCs,

solenoid DTCs, actuator DTCs, and relay DTCs.

Diagnose the multiple DTCs within this catagory in

‘numerical order. Begin with the lowest numbered

DTC, unless the diagnostic table directs you

otherwise,

Diagnostic System Check Engine Controls

Important:

+ DO NOT porform this diagnostic if thore is not a

driveabilty concem, unless another procedure

directs you to this diagnostic.

+ Before you proceed with diagnosis, search for

applicable service bulletins.

+ Unless @ ciagnastic procedure instructs you, DO

NOT cloar the DTCs.

* If there is a condition withthe starting system, refer

a tho Staring System in Section 1E Engino

Electical (GHF1-CNG).

+ Ensure the battery has a full charge,

+ Ensure the battery cables (+) (-) are clean and

Light

+ Ensure the ECM grounds are clean, tight, and in

the corract location.

+ Ensure the ECM hamess connectors are clean

‘and correctly connected. D0 NOT attompt to crank

tha engine with ECM harness connectors

disconnect.

+ Ensure the ECM terminals are clean and correctly

mating

Sep ‘ation Vauors) Yes No

Install eo 100

1 — Goto Scan Too!

Does the scan tol tum ON? Gotosiep2 | Does Nat Power Up

Tum ON he ignition wih the engine OFF.

2. Atternp ta establish commurieation with he Goto Soan Too!

2 CM. a= Does Not

Commuricale with

oes the scan tel communicate with the ECM? Goto Sep3 tho ECM

1._Tum ON the igntion, wit the engine OFF Gow Creek ENgNE

2. Check the chosk engine warning ight. o Waming Light

3 vm mee lRurnaton Cicutt

the check engine warning ightituminate? Gota send ‘System Check

7. Connect pine 2 and 6 of the PI monitor

connector (FLA7), Goto Check Engine

4+ | 2. chock no chock engine warning ight = waming Light

ml ais Blinking Ckcut

id he chack engine warning Kght ink? Gota Sep 5 ‘System Chack

‘Atlemp io sartihe engine

5 " ms os Got Starting

oes the engine start and idle? Goto Sep 8 ‘System Chaok

| Does ihe scan tool display EGM DTCs? ~ Gio ta Applicable

ore. Goto Step 7

1048

Engine Control System (6HF1-CNG)

‘ation

vausts)

Yee

Ne

7. Review the folowing symplore.

2. Refer to the applicable symptom dagnostic

table:

‘Abnormal Combustion Noise

oor Fuel Eaoncmy

Hard Sart

Rough, Unstabie, oF Incorrect Idle and

Stating

High idle Speed

Pulsing n Engine Speed

Surges

Leck of Power, Sluggishness or

‘Sponginess

‘Abnormal Sounc/ Abnormal Sel

ed you fie en comet the condition?

System OK.

{Go to interitiont

‘Constions

Engine Control System (6HF1-CNG) _1A-49

‘Scan Tool Data List

‘Scan tool data reference value

‘The purpose of data lists for chacking the status ofthe

Vohicle condition

+ Air conditioning "OFF™

+ Electrical aocessories all'OFF"

vehicle and each equipment. + Shift position °N"

This dala is used in trouble clagnosis by comparing the No lead to power steering

each venice dala with slanderd values, anc necking ging

whether the vehicle data is temporarily or always

ciflerent from the reference values. (This scan tool data

cispiay menu is subject to change without notice.)

‘Soan Tool Parameter Units Displayed Reference valuo

Vehicle Speed kmh 0

Desired Idling Speed RPM ‘510-610

Engine Speed RPM “460 - 660

Daired Throtla Postion = o- 5

Te aS cae = 1-7

SES Siral(ecelatn Psat = 0-3

WAP Sensor Naniot Asatte Pa 15-45

Ful Praseure Sensor Pa ‘500 - 650 (for Thailand)

400 - 550 (for Australia)

Engine Coolant Temperatura °C 75-100

TAT Sensor (Intake Air Temperature) ce 0-90

Fuel Temperature Sensor c 0-90

‘Ai Fuel Ratio Sensor = 085-118

(O2 Sensor2 mv 0-900

Barometric Pressure Pa 90-110

PTO Accelerator Sensor = 0

Tgrition Vallage Vv 1-15

Systom voles Vv 22-30

Injection Pulse Width ms 2-6

‘Air Fuel Ratio Sensor Threshold = 1

ignition Timing . =

Dwell Angie = 0-25

“Acceleration Pedal Sensor #7 = 0-3

‘Accaloralion Pedal Sensor #2 = 0-3

‘Trrottie Position Sensor #1 * 7

“Trratile Position Sensor #2 1-7

‘Basle of Jetting Pulse Width (Tp) ms a2

FIB (Feed Back) Correction % 20-120,

‘Goaficient to corection Open Loop % =

4A-50__Engine Control System (6HF1-CNG)

‘Soan Too! Parameter ‘Units Displayed Reference value

‘Goeficient in which studied mixture % ‘90-120

rato Is revised

‘Map of Coaffcient in which studied % =

mixture rato is revised

Coeficient conecied by ‘uel of % =

diferent kind

TTening to finish jotting = =

“Trrottie Position Sensor Learning = =

Value

Elecironis Control Throtie Default . e5

Position

‘Commanded Air Fuel Ratio = oa- 44

Injection Control Phase Rater to Table 1 Vares depending on aig

Electronle Thatiie Cantral Phase Rafar to Table 2 Varies depending on driving

‘conditions

Exhaust Brake Switch ‘ONIOFF OFF

Parking Switch ON/OFF ON

PTO ido Switch ONOFF ON

‘Accolorator lle Switch ‘ONIOFF ON

Tale Switch ONIOFF ON

‘Clutch Switch ONIOFF ON

‘Memory Clear Switch ON/OFF OFF

Diagnostic Switch ON/OFF OFF

PTO Switch ON/OFF OFF

Freezer Switch ONIOFF OFF

‘AIG Switch (Air Conditioning) ON/OFF OFF

“Accolorator Podal Switch ON/OFF ON

Noulral Switch ON/OFF OFF

‘Starter Switch ON/OFF OFF

Ignition Switch Status ‘ONIOFF ON

Exhaust Brake VSV (Vacuum ‘ONIOFF OFF

Switehing Valve)

Rotarder relay ON/OFF OFF

(02 Sensor Heator ONIOFF Varios depending on diving

conditions

Warning Lamp ONIOFF OFF

FIC (Fuel Cut) Solenoid ON/OFF OFF

FIG 2 (Fuel Cut 2) Solenoie ON/OFF OFF

EOM Relay ONIOFF ON

‘Acaltional Injector Pulse Width of 7S 0-8

Final Jetting

Engine Control System (6HF1-CNG)

1051

Close Loop {idle}

Table 2

Engine StoppadGrank

NEES Roll Rea

PTO

‘Speed Limiter

Engine Siop Saver,

Docolorate Fuol Cot

Doceleration

Tate(Running)

Tale

‘Soan Too! Parameter ‘Units Displayed Reference value

Cylinder 1 Angle of final = 0-25

Gylinder 2 Angle of final . 0-25

Cylinder 3 Angle of final = 0-25

Cylinder 4 Angle of final : 0-25

Cylinder 5 Angle of final i 0-25

Cylinder 6 Angle of final : 0-25

‘Boost Presaure Ganirol Vaive Final me den

Duty

Fuel Tank Presoure Sensor WPa 0-20

Table 1

‘Open Loop

Fuel Gut

Deceleration

High Load Increase

‘AIF Sensor Error

Powor Management

Closed Loop

4A-52_Engine Control System (6HF1-CNG)

‘Scan Tool Data Definitions

This information will assist in emission or driveability

problems. The displays can be viewed while the vehicle

Is being driven. Aways perform the Diagnostic System

‘Check = Engine Controls first. The Diagnostic System

‘Check will confirm proper system operation.

Vohiole Spoed

This parameter indicates the vehicle speed calculated

by the ECM using the signal from the vehicle speed

‘sensor (VSS). The scan too! will display a low value at

lower vehicle speeds, and a high value at higher

vehicle speeds,

Desired Idling Speed

‘This parameter displays the isle speed requested by

the ECM, The ECM wil change desired idle speed

based on engine coolant temperature and other inputs.

Engine Speed

This paramatar displays the rotational speed of the

‘crankshaft a5 calaulated by the ECM based on inputs

from the crankshaft position (CKP} sensor ar camshaft

position (CMP) sensor.

Dasired Throttle Position

‘This parameter displays trrotle valve position desired

by the EGM based on current driving conditions. This,

‘can be compared to the actual tnrotte valve position to

etermine sensor accuracy or valve control problems,

‘TPS Signal (Throttle Position Sensor)

This parameter displays the angle of the throttle valve

position calculated ay the ECM using the signal from

Intake thrttle postion sensor. The scan tool will display

‘a small angle when the throttle valve is closed, and a

lange angle when the throttle valve is opened.

‘APS Signal (Acceleration Podal Sensor}

This parameter displays the angle of the accelerator

pedal as calculated by the ECM using the signals from

the accelerator pedal position (APP) sensors, The scan

toa! will display Inearly from 0 to 36° according to the

pedal operation,

MAP Sensor (Manifold Absolute Pressure)

This parameter displays the current manifold absolute

pressure detected by the MAP sensor.

Fuel Pressure Sonsor

This parameter displays the current fuel pressure

‘detacted by the CNG pressure sancor.

Engine Coolant Temperature

‘This parameter displays the temperatura of the engine

‘coolant as calculated by the ECM using the signal from

the engine coolant temperatura (ECT) sansor. The

‘scan tool will display a low temperature when the ECT.

sensor signal voltage Is high, and a high temperature

when the ECT sensor signal voltage Is low.

IAT Sensor (Intake Air Temperature)

This parameter displays the temperature of the intake

air as calculated by the ECM using the signal from the

intake air temperature (IAT) sensor. The scan tool will

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Wabco EBS DDocument40 pagesWabco EBS Dvik_md100% (3)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Scania Aps RuDocument12 pagesScania Aps Ruvik_md100% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- LG4JJED-WE-0871 - Engine Control System 4JJ1 N-SeriesDocument389 pagesLG4JJED-WE-0871 - Engine Control System 4JJ1 N-Seriesvik_md100% (1)

- 6SDEED-WE-0325AR - Engine Emmision (6SD1-TC (Common Rail) Model)Document364 pages6SDEED-WE-0325AR - Engine Emmision (6SD1-TC (Common Rail) Model)vik_mdNo ratings yet

- Isuzu Sistema Elektrooborudovaniya 1Document1 pageIsuzu Sistema Elektrooborudovaniya 1vik_mdNo ratings yet

- Lg4jjed-We - 4jj1 Euro 5 With DPDDocument379 pagesLg4jjed-We - 4jj1 Euro 5 With DPDvik_mdNo ratings yet

- 6HSEED-WE-775HK - Emission and Electrical DiagnosisDocument97 pages6HSEED-WE-775HK - Emission and Electrical Diagnosisvik_mdNo ratings yet

- 6heed-We-0001 - Emission and Electrical Diagnosis 6HH1 EVTDocument78 pages6heed-We-0001 - Emission and Electrical Diagnosis 6HH1 EVTvik_mdNo ratings yet

- Тормозное давление Volvo fh12Document5 pagesТормозное давление Volvo fh12vik_mdNo ratings yet

- Gysmi: 64163 8 A4 Fonction: Schema - BlocDocument9 pagesGysmi: 64163 8 A4 Fonction: Schema - Blocvik_mdNo ratings yet

- Lg4hke4wd-Wsp-0851co - 4hk1 Euro 4 With DPDDocument1,230 pagesLg4hke4wd-Wsp-0851co - 4hk1 Euro 4 With DPDvik_md100% (1)

- LG4HG-WE-0871-4HG1 - Engine 4HG1Document519 pagesLG4HG-WE-0871-4HG1 - Engine 4HG1vik_md100% (7)

- In190 Gysmi - Repare 195Document14 pagesIn190 Gysmi - Repare 195vik_mdNo ratings yet

- Spare Parts Catalogue - March 2014Document20 pagesSpare Parts Catalogue - March 2014vik_mdNo ratings yet

- DW 80 ManDocument12 pagesDW 80 Manvik_mdNo ratings yet

- BAXI Eco Four котлы - инструкцияDocument34 pagesBAXI Eco Four котлы - инструкцияvik_mdNo ratings yet

- Eber B3L D3LDocument3 pagesEber B3L D3Lvik_mdNo ratings yet

- Autocom CARS 201700Document2,851 pagesAutocom CARS 201700vik_mdNo ratings yet

- Description: LM2576 SeriesDocument8 pagesDescription: LM2576 Seriesvik_mdNo ratings yet

- Thermo 90Document26 pagesThermo 90vik_mdNo ratings yet

- Taura D McsDocument15 pagesTaura D Mcsvik_mdNo ratings yet

- Automotive Quad Low Side Driver: MC33385 SemiconductorDocument11 pagesAutomotive Quad Low Side Driver: MC33385 Semiconductorvik_mdNo ratings yet

- LAMBORGHINI Manuale Installazione e Manutenzione Caldaia Murale A Gas LAMBY IN 20 24 MTC W TOPDocument140 pagesLAMBORGHINI Manuale Installazione e Manutenzione Caldaia Murale A Gas LAMBY IN 20 24 MTC W TOPvik_mdNo ratings yet