Professional Documents

Culture Documents

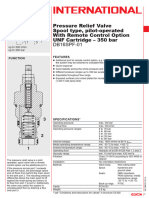

8674UK Parker Hydrolic

Uploaded by

samuel dion0 ratings0% found this document useful (0 votes)

4 views4 pagesThis document summarizes a 2-way fast response solenoid valve called the Lucifer 2-way fast response and long life solenoid valve. The valve is used for air control or air pulsing applications requiring extremely short response times and long life expectancy, with flow rates up to 40 Nm3/h. Key features include a high performance plunger with low residual magnetic effect and long life, as well as a PUR seat disc that provides a magnalift effect. The valve has a response time of 9.5-12 ms for switching on and 4-8 ms for switching off, and a life expectancy of over 500 million cycles.

Original Description:

Parker hydraulic 8674uk

Original Title

8674UK parker hydrolic

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document summarizes a 2-way fast response solenoid valve called the Lucifer 2-way fast response and long life solenoid valve. The valve is used for air control or air pulsing applications requiring extremely short response times and long life expectancy, with flow rates up to 40 Nm3/h. Key features include a high performance plunger with low residual magnetic effect and long life, as well as a PUR seat disc that provides a magnalift effect. The valve has a response time of 9.5-12 ms for switching on and 4-8 ms for switching off, and a life expectancy of over 500 million cycles.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views4 pages8674UK Parker Hydrolic

Uploaded by

samuel dionThis document summarizes a 2-way fast response solenoid valve called the Lucifer 2-way fast response and long life solenoid valve. The valve is used for air control or air pulsing applications requiring extremely short response times and long life expectancy, with flow rates up to 40 Nm3/h. Key features include a high performance plunger with low residual magnetic effect and long life, as well as a PUR seat disc that provides a magnalift effect. The valve has a response time of 9.5-12 ms for switching on and 4-8 ms for switching off, and a life expectancy of over 500 million cycles.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

aerospace

climate control

electromechanical

filtration

fluid & gas handling

hydraulics

pneumatics

process control

sealing & shielding

© abcdefghijklmn

Fast Switching Valve

Lucifer 2-way fast response

and long life solenoid valves

Applications Technical Data

2/2 magnalift solenoid valve used for air control or air pulsing in all applications where extremely short response

time and/or long life expectancy are required. Function: 2/2 solenoid valve closed when de-energized.

Flow rate up to 40 Nm3/h (subsonic flow only) like: textile weaving looms, printing machines, sorting machines, Design: Pilot operated poppet valve with magnalift.

bank note counting machines. Mounting: For direct pipe mounting or with the help of M5x6 mm screw (see dimensions).

Mounting position: Indifferent.

Material specifications: Forged brass body. Internal parts in stainless steel. Sealing material in PUR.

Features Range of admissible

pressure drop:

∆p min. = 0 bar

∆p max. = 7 bar

Response time (see p. 2): Conditions: voltage 24 VDC nominal, flow 34 Nm3/h.

Torque 20 Nm for 299560 housing Torque 10 Nm for 2994 & 2995 housing Reference pressure dynamic (orifice 2): 4.5 bar.

(self locking nut 492681) (nut 484018) Response times are increasing above starting from 300 millions cycles.

Switching on: TE on: 9.5 - 12 ms

• 2P+E DIN 43650A plug • High performance plunger with • PUR seat disc provides Electrical response time until the plunger is in fully attracted position.

connection low residual magnetic effect and magnalift effect T on: 10-14 ms

long life Filling time until the pressure has reached 50% of output pressure P2

• Degree of protection IP65

(own volume of the valve, outlet port plugged.)

• Shock absorber improves life

• Guide rings assure high life Switching off: TD off: 4 - 8 ms

expectamcy of the valve

expectancy Closing time until the plunger is in the rest position.

T off: 5,5 - 9,5 ms

Emptying time until the pressure has dropped to 50% of P2 pressure.

This response time is depending on user at the outlet port.

Cycling rate: Up to 30 Hz.

Section drawing Life expectancy: > 500 millions cycles

Conditions: Instrumentation dryed and filtered air at 20 µm, (dew point +2°C).

of the 221 J 3311 Typical reponse times

At 20 Hz (40% on) Media:

P max. 5 bar nominal voltage 24 VDC vibrations 5 to 500 Hz.

Instrumentation air (dryed and unlubricated) filtered at 20 µm.

Fluid temperature: Min. 0°C. Max. + 40°C.

Ambient temperature: 0°C to +50°C.

Vibrations: Up to 1500 Hz, max. shocks 10 g.

At max. vibration rating, life expectancy will decrease.

Electrical part: 32 mm coil 483816 (14W DC) encapsulated in synthetic material.

Connection with 3 pin DIN 43650 type A plug connector, degree of protection IP 65.

Solenoid duty: Relative duty time:

80% max. for cycle 30 Hz (33ms).

70% max. for cycle 20 Hz (50ms).

55% max. for cycle 10 Hz (100ms).

25% max. for cycle 1 hour (this valve can not work at ED 100%).

x % = Energized time ÷ 100

Cycle time

Housing: 3 possibilities 2994/2995/299560.

Voltage: 24 V DC.

Voltage tolerance: ±10%.

Flow rate (valve on 100%) Class of insulation material: Class F (155 °C).

Part kit: Nothing available

Port Size: G 3/8

Orifice: mm 8

Qmax: Nm³/ h 40

Admissible differential min. 0

pressure: bar Max. 7

Maximum admissible Air 40

fluid temperature: C°

References N°: Valve 221 J 3311

Housing 2994 2995 299560

Coil 483816

Power consumption: W 14

Weight: g 360

Applications Technical Data

2/2 magnalift solenoid valve used for air control or air pulsing in all applications where extremely short response

time and/or long life expectancy are required. Function: 2/2 solenoid valve closed when de-energized.

Flow rate up to 40 Nm3/h (subsonic flow only) like: textile weaving looms, printing machines, sorting machines, Design: Pilot operated poppet valve with magnalift.

bank note counting machines. Mounting: For direct pipe mounting or with the help of M5x6 mm screw (see dimensions).

Mounting position: Indifferent.

Material specifications: Forged brass body. Internal parts in stainless steel. Sealing material in PUR.

Features Range of admissible

pressure drop:

∆p min. = 0 bar

∆p max. = 7 bar

Response time (see p. 2): Conditions: voltage 24 VDC nominal, flow 34 Nm3/h.

Torque 20 Nm for 299560 housing Torque 10 Nm for 2994 & 2995 housing Reference pressure dynamic (orifice 2): 4.5 bar.

(self locking nut 492681) (nut 484018) Response times are increasing above starting from 300 millions cycles.

Switching on: TE on: 9.5 - 12 ms

• 2P+E DIN 43650A plug • High performance plunger with • PUR seat disc provides Electrical response time until the plunger is in fully attracted position.

connection low residual magnetic effect and magnalift effect T on: 10-14 ms

long life Filling time until the pressure has reached 50% of output pressure P2

• Degree of protection IP65

(own volume of the valve, outlet port plugged.)

• Shock absorber improves life

• Guide rings assure high life Switching off: TD off: 4 - 8 ms

expectamcy of the valve

expectancy Closing time until the plunger is in the rest position.

T off: 5,5 - 9,5 ms

Emptying time until the pressure has dropped to 50% of P2 pressure.

This response time is depending on user at the outlet port.

Cycling rate: Up to 30 Hz.

Section drawing Life expectancy: > 500 millions cycles

Conditions: Instrumentation dryed and filtered air at 20 µm, (dew point +2°C).

of the 221 J 3311 Typical reponse times

At 20 Hz (40% on) Media:

P max. 5 bar nominal voltage 24 VDC vibrations 5 to 500 Hz.

Instrumentation air (dryed and unlubricated) filtered at 20 µm.

Fluid temperature: Min. 0°C. Max. + 40°C.

Ambient temperature: 0°C to +50°C.

Vibrations: Up to 1500 Hz, max. shocks 10 g.

At max. vibration rating, life expectancy will decrease.

Electrical part: 32 mm coil 483816 (14W DC) encapsulated in synthetic material.

Connection with 3 pin DIN 43650 type A plug connector, degree of protection IP 65.

Solenoid duty: Relative duty time:

80% max. for cycle 30 Hz (33ms).

70% max. for cycle 20 Hz (50ms).

55% max. for cycle 10 Hz (100ms).

25% max. for cycle 1 hour (this valve can not work at ED 100%).

x % = Energized time ÷ 100

Cycle time

Housing: 3 possibilities 2994/2995/299560.

Voltage: 24 V DC.

Voltage tolerance: ±10%.

Flow rate (valve on 100%) Class of insulation material: Class F (155 °C).

Part kit: Nothing available

Port Size: G 3/8

Orifice: mm 8

Qmax: Nm³/ h 40

Admissible differential min. 0

pressure: bar Max. 7

Maximum admissible Air 40

fluid temperature: C°

References N°: Valve 221 J 3311

Housing 2994 2995 299560

Coil 483816

Power consumption: W 14

Weight: g 360

Worldwide division headquarters

Parker Lucifer SA

Fluid Control Division Europe

16 Ch. Faubourg-de-Cruseilles

CH - 1227 Carouge / Geneva

Tel.: +41 22 30 77 111

Fax: +41 22 30 77 110

www.parker.com/fcde

infolucifer@parker.com

Parker Hannifin S.p.A

Fluid Control Division Europe

Via E. Fermi, 5

IT - 20060 Gessate (Milan)

Tel.: + 39 02 95 125 1

Fax: + 39 02 95 382 051

www.parker.com/fcde

cicgessate@parker.com

Parker Hannifin Corporation

Fluid Control Division

95 Edgewood Ave.

USA - New Britain,

CT 06051-4100

Tel.: +1 (860) 827 2300

Fax: +1 (860) 827 2384

www.parker.com/fcd

skinnervalve@parker.com

Parker Hannifin Corporation

Fluid Control Division

147 West Hoy Road

USA - Madison,

MS 39110-9357

Tel.: +1 (601) 856 4123

Fax: +1 (601) 853 7250

www.parker.com/fcd

skinnervalve@parker.com

Parker Korea Ltd.

777 Jungri, Dongtanmyeon,

KR - Hwasungsi, Kyunggido,

445-813

Tel.: +(82) 31 379 2200

Fax: +(82) 31 377 9710

www.parker.com

© 2007 Parker Lucifer SA - 12/2007 8674/UK

Parker Lucifer SA

Fluid Control Division Europe

16 Ch. Faubourg-de-Cruseilles

CH - 1227 Carouge / Geneva

Tel.: +41 22 30 77 111

Fax: +41 22 30 77 110

www.parker.com/fcde

infolucifer@parker.com

You might also like

- Ezekiel The End Time Prophet - Gerald Flurry PDFDocument162 pagesEzekiel The End Time Prophet - Gerald Flurry PDFNeilGWilsonNo ratings yet

- Fanuc NCGuide PMC Simulation FunctionDocument121 pagesFanuc NCGuide PMC Simulation FunctionkenNo ratings yet

- Oxylog Ve300Document134 pagesOxylog Ve300davidNo ratings yet

- Capacitor Information (PT 2) PDFDocument18 pagesCapacitor Information (PT 2) PDFwillchamNo ratings yet

- Media MetricsDocument28 pagesMedia MetricsPulkit ChhabraNo ratings yet

- Sir Syed Ahmed Khan and Two Nation TheoryDocument11 pagesSir Syed Ahmed Khan and Two Nation TheoryZeeshan Saeed100% (5)

- Teaching Listening and Speaking in Second and Foreign Language Contexts (Kathleen M. Bailey)Document226 pagesTeaching Listening and Speaking in Second and Foreign Language Contexts (Kathleen M. Bailey)iamhsuv100% (1)

- Islamic ArchitectureDocument84 pagesIslamic ArchitecturesidNo ratings yet

- Facilities 2013 SG - Full Time, 2nd YearDocument49 pagesFacilities 2013 SG - Full Time, 2nd Yearsaifasad100% (2)

- Brand Awareness Questionnaire SampleDocument2 pagesBrand Awareness Questionnaire SampleYogesh Sangani77% (13)

- Vasuanand Bba ProjectDocument66 pagesVasuanand Bba ProjectMaster PrintersNo ratings yet

- Construction ProjectsDocument13 pagesConstruction ProjectsMuhammad SafdarNo ratings yet

- BYPASSDocument2 pagesBYPASSSting DâuNo ratings yet

- Dosing PumpDocument2 pagesDosing PumpIbrahimNo ratings yet

- 4-2 Directional Spool Valve 4WE6DDocument2 pages4-2 Directional Spool Valve 4WE6DRaphael SasdelliNo ratings yet

- 4-3 Directional Spool Valve 4WE6EDocument2 pages4-3 Directional Spool Valve 4WE6ERaphael SasdelliNo ratings yet

- Danfoss RTDocument12 pagesDanfoss RTSerge Yannick MimboeNo ratings yet

- 3-Way Proportional Pressure Reducing Valve Spool Type, Direct-Acting UNF Cartridge - 350 BarDocument4 pages3-Way Proportional Pressure Reducing Valve Spool Type, Direct-Acting UNF Cartridge - 350 BarFloNo ratings yet

- GQR Spa2019Document4 pagesGQR Spa2019Hidroterm Plantas Electricas-Bombas De Agua-Maquinaria PesadaNo ratings yet

- Argo Hytos e 453Document6 pagesArgo Hytos e 453Raúl FigueroaNo ratings yet

- HD 049 HD 069: High Pressure Filters - Worldline 100Document6 pagesHD 049 HD 069: High Pressure Filters - Worldline 100Susmit patelNo ratings yet

- 3/2-Way Solenoid Valve, Direct-Acting: Type 743Document4 pages3/2-Way Solenoid Valve, Direct-Acting: Type 743Francisco Mones RuizNo ratings yet

- Pressure Switch: Data SheetDocument4 pagesPressure Switch: Data SheettauNo ratings yet

- Solenoid Valve - Pneumatic: Direct Acting, Pressure Relieved NamurDocument4 pagesSolenoid Valve - Pneumatic: Direct Acting, Pressure Relieved NamurFrancisco Mones RuizNo ratings yet

- Flipper Solenoid Valve With Isolating Diaphragm For Analytical ApplicationsDocument4 pagesFlipper Solenoid Valve With Isolating Diaphragm For Analytical ApplicationsFrancisco Mones RuizNo ratings yet

- Hydac dr10p Pressure Reducing ValveDocument2 pagesHydac dr10p Pressure Reducing ValveAhmad Y. AbughaushNo ratings yet

- 4-3 Directional Spool Valve 4WE 6 HDocument2 pages4-3 Directional Spool Valve 4WE 6 HRaphael SasdelliNo ratings yet

- 2/2 Solenoid Directional Valve Poppet Type, Pilot Operated Normally Closed Metric Cartridge Valve - 350 BarDocument2 pages2/2 Solenoid Directional Valve Poppet Type, Pilot Operated Normally Closed Metric Cartridge Valve - 350 BarDyna ClementeNo ratings yet

- 5/2-Directional Valve, Series HF03-LG: Technical RemarksDocument2 pages5/2-Directional Valve, Series HF03-LG: Technical RemarksTOny OlivenciaNo ratings yet

- Torrent - Sales Flyer - English - HighDocument2 pagesTorrent - Sales Flyer - English - HighgiampaoloNo ratings yet

- 3/2-Way Solenoid Valve, Direct-Acting: Type 744Document4 pages3/2-Way Solenoid Valve, Direct-Acting: Type 744Francisco Mones RuizNo ratings yet

- Torrent Brochure PDFDocument2 pagesTorrent Brochure PDFMauricio ChavezNo ratings yet

- Construction: Submersible Drainage PumpDocument2 pagesConstruction: Submersible Drainage PumpAya Abd-ElghafarNo ratings yet

- Pressure Relief Valve Poppet Type, Direct-Acting Cartridge - 350 Bar DB10-01Document4 pagesPressure Relief Valve Poppet Type, Direct-Acting Cartridge - 350 Bar DB10-01markoNo ratings yet

- 3-Way Valve DN 20 PDFDocument4 pages3-Way Valve DN 20 PDFEng MidoNo ratings yet

- pRESSURE REDUCING VALVEDocument2 pagespRESSURE REDUCING VALVESamad A BakarNo ratings yet

- 4-3 Directional Spool Valve 4WE-6-GDocument2 pages4-3 Directional Spool Valve 4WE-6-GRaphael SasdelliNo ratings yet

- Valvula Proporcional Norgren Vp50sDocument1 pageValvula Proporcional Norgren Vp50sBase SistemasNo ratings yet

- Pressure Reducing Valve Spool Type, Pilot-Operated SAE-8 Cartridge - 350 BarDocument2 pagesPressure Reducing Valve Spool Type, Pilot-Operated SAE-8 Cartridge - 350 BarYazad DoctorrNo ratings yet

- 1.0 en-US 2020-01 TS.3127Document48 pages1.0 en-US 2020-01 TS.3127ruben estebanNo ratings yet

- En5922-5 DB16SPFDocument2 pagesEn5922-5 DB16SPFarq.clavijobNo ratings yet

- En5919 1 0 09 20 - WK08X 01RDocument4 pagesEn5919 1 0 09 20 - WK08X 01RAyman AlhalfawyNo ratings yet

- Relief, Bi-Directional CR10-28Document2 pagesRelief, Bi-Directional CR10-28tungNo ratings yet

- Pressure Sensor, Series PE6: Technical RemarksDocument4 pagesPressure Sensor, Series PE6: Technical Remarksกฤษดา ปินะสาNo ratings yet

- E5991-8 pwk12120wpDocument2 pagesE5991-8 pwk12120wpMarius MihaescuNo ratings yet

- SelectCatalog 2015 EU PDFDocument452 pagesSelectCatalog 2015 EU PDFTrương Văn TàiNo ratings yet

- HydacDocument4 pagesHydacmarkoNo ratings yet

- EuroswimDocument7 pagesEuroswimRizky Tri UtomoNo ratings yet

- Fluidcontrol Unit Fcu 2000 Series: Description Technical DetailsDocument4 pagesFluidcontrol Unit Fcu 2000 Series: Description Technical Detailsjulya julyaNo ratings yet

- 771, 772, 773 Series ServovalvesDocument8 pages771, 772, 773 Series Servovalvesrafik1995No ratings yet

- dp15 Variable Reluctance Pressure Sensor Capable of Range ChangesDocument2 pagesdp15 Variable Reluctance Pressure Sensor Capable of Range ChangesGuillaume HaddadNo ratings yet

- En5978-5 PDMC04S30DDocument4 pagesEn5978-5 PDMC04S30DRonald BosNo ratings yet

- Sika VHDocument9 pagesSika VHmichelonkoNo ratings yet

- Durant ManualDocument4 pagesDurant ManualDavid Perea Perea MorenoNo ratings yet

- Pt5 Pressure Transmitters en Us 1734302Document1 pagePt5 Pressure Transmitters en Us 1734302Mamdooh AbdallahNo ratings yet

- Pressure Compensator, Upstream, Spool Type, Direct-Acting Normally Open Metric Cartridge - 250 BarDocument2 pagesPressure Compensator, Upstream, Spool Type, Direct-Acting Normally Open Metric Cartridge - 250 BarAlaa saidNo ratings yet

- Flygt 3152 50 LDocument32 pagesFlygt 3152 50 LDiego MayorgaNo ratings yet

- En5922 Db08a-01Document2 pagesEn5922 Db08a-01markoNo ratings yet

- DMDAMNN224-ECT en Us LetterDocument2 pagesDMDAMNN224-ECT en Us LetterLUIS SANCHEZ SANZCHEZNo ratings yet

- SNS Series Specifications・How to Order・Dimensions (0.6MB)Document5 pagesSNS Series Specifications・How to Order・Dimensions (0.6MB)Fasta DriveNo ratings yet

- Model Normally Closed, Balanced Poppet, Logic Element - Pilot-To-OpenDocument2 pagesModel Normally Closed, Balanced Poppet, Logic Element - Pilot-To-OpenjuampacervantesNo ratings yet

- Calpeda - GQSM PumpDocument4 pagesCalpeda - GQSM PumpkuraimundNo ratings yet

- Pressure Compensator Spool Valve, Direct-Acting Normally Closed Metric Cartridge - 350 BarDocument4 pagesPressure Compensator Spool Valve, Direct-Acting Normally Closed Metric Cartridge - 350 BarPaulo ArrudaNo ratings yet

- E5194-1 DW12P PDFDocument2 pagesE5194-1 DW12P PDFhelderfgmNo ratings yet

- Technical Data Sheet C2..QPT-..: Type OverviewDocument5 pagesTechnical Data Sheet C2..QPT-..: Type OverviewJNo ratings yet

- Solenoid Valve - Pneumatic: Direct Acting, Pressure RelievedDocument4 pagesSolenoid Valve - Pneumatic: Direct Acting, Pressure RelievedFrancisco Mones RuizNo ratings yet

- AC2056R 35 Data SheetDocument9 pagesAC2056R 35 Data SheetIslem LiliyaneNo ratings yet

- Prop. Pressure-Reducing/Relieving Cartridge, Size SAE 08Document6 pagesProp. Pressure-Reducing/Relieving Cartridge, Size SAE 08galih kalokaNo ratings yet

- Flow Switch BWTSDocument5 pagesFlow Switch BWTSIvo MozaraNo ratings yet

- Wuolah Free Use of EnglishDocument20 pagesWuolah Free Use of EnglishCristina CórcolesNo ratings yet

- Penjelasan IMRAD StructureDocument2 pagesPenjelasan IMRAD Structureaji bondesNo ratings yet

- Cept FinalDocument14 pagesCept FinalVighnesh MalagiNo ratings yet

- 22661-RET Notes-UNIT 02Document25 pages22661-RET Notes-UNIT 02jayeshdeore398No ratings yet

- Civil Engineering MCQ'sDocument1 pageCivil Engineering MCQ'sNISHIKANTA MONDALNo ratings yet

- Smart Test Series: Q.1 Circle The Correct Answers. (6x1 6)Document1 pageSmart Test Series: Q.1 Circle The Correct Answers. (6x1 6)Eeman AkbarNo ratings yet

- Agitated Thin Film Dryer ClaculationDocument12 pagesAgitated Thin Film Dryer ClaculationakaashNo ratings yet

- Clamp Selection Guide - Rev.12 - 3.24.2016 PDFDocument32 pagesClamp Selection Guide - Rev.12 - 3.24.2016 PDFgoran muhamdNo ratings yet

- Antenna Mini ProjectDocument65 pagesAntenna Mini ProjectHassan MehsenNo ratings yet

- 1.1.DeFacto Academy enDocument7 pages1.1.DeFacto Academy enYahya AçafNo ratings yet

- Cybersecurity in Operational Technology: Special ReportDocument15 pagesCybersecurity in Operational Technology: Special ReportAdrian ReyesNo ratings yet

- Tripwire Is An Intrusion Detection SystemDocument28 pagesTripwire Is An Intrusion Detection SystempoornimaNo ratings yet

- Pakistan: Nation-State, State-Nation or Multinational State?Document12 pagesPakistan: Nation-State, State-Nation or Multinational State?Asif KhanNo ratings yet

- 900 MCQs Ancient IndiaDocument189 pages900 MCQs Ancient IndiaZahaab AlimNo ratings yet

- Cynara FoliumDocument37 pagesCynara Foliumshuvvro dhaNo ratings yet

- Ol7 SecurityDocument84 pagesOl7 Securityneaman_ahmedNo ratings yet

- Inter-Bank Fund Transfer: Case Study 6Document5 pagesInter-Bank Fund Transfer: Case Study 6Ravi RanjanNo ratings yet

- Ferrites For Linear Appl - Properties - SnellingDocument10 pagesFerrites For Linear Appl - Properties - SnellingTom SebastianNo ratings yet