Professional Documents

Culture Documents

Direct Acting Pressure Relief Valve Model: DPR Description: A Polyhydron Group Company

Uploaded by

shamim khanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Direct Acting Pressure Relief Valve Model: DPR Description: A Polyhydron Group Company

Uploaded by

shamim khanCopyright:

Available Formats

Ref. No.

D 04896

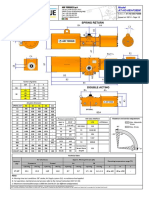

DIRECT ACTING Release: 11 / 2022

PRESSURE RELIEF VALVE

ENGINEERING - 1 of 4

Model : DPR

A Polyhydron Group Company

Description

Direct acting valve.

Guided poppet design.

Cushion arrangement for greater stability and noise control.

Three sizes - 06, 10 and 20.

Three mounting style - Threaded cartridge.

Threaded port body.

Subplate Type (Factory std. and ISO std.)

Six pressure ranges - Up to 25, 50, 100, 200, 315 & 400.

700 bar. ( In size of 06 only.)

Two options for pressure - With set screw and lock nut.

adjustment With hand Knob.

Section Hydraulic Symbol

Unit dimensions

Dimensions in mm.

Cartridge with set screw

pressure adjustment.

Cartridge with hand knob Cartridge cavity machining details.

for pressure adjustment.

Mass 6H 6H ±0.5 ±0.2 ±0.2 ±0.2 Tightening

Size kg A/F1 A/F2 A/F3 M ØD1 ØD2 ØD3 ØD4 L1 L2 L3 L4 L5 L6 L7 L8 L9 torque Nm

06 0.45 19 30 4 M28 x 1.5 43 25 15 6 64 64 65 65 45 35 19 15 55 120

10 0.9 19 36 5 M35 x 1.5 48 32 19 10 77 82 80 80 52 41 23 18 69 140

20 1.6 19 46 5 M45 x 1.5 60 40 24 20 103 85 79 110 70 54 27 21 92 170

Phone : +91-(0)831- 2411001

Fax : +91-(0)831- 2411002

78-80, Machhe Industrial Estate,

E-mail : polyhydron@gmail.com

Machhe, Belgaum - 590 014. INDIA.

Website : www.polyhydron.com

D 04896 - DPR

A Polyhydron Group Company ENGINEERING - 2 of 4

Threaded port body

Mass B1 B2 M A/F1 A/F2 A/F3 L1 L2 L3 L4 L6 H1 H2 T1

Size kg ØD1 ØD2 ØD4

06 1.2 45 60 43 22 G1/4 M6 30 19 4 65 64 35 80 55 40 25 11

10 2.8 60 80 48 30 G1/2 M8 36 19 5 80 82 42 100 69 60 40 15

20 6.2 70 100 60 44 G1 M8 46 19 5 78.5 85 54 135 85 70 50 15

Subplate type Subplate type

(Factory Standard) (ISO Standard) only NG06

ISO valve mounting

interface

ISO valve

Assembly

Size Mass B1 B2 ØD1 ØD2 A/F1 A/F2 A/F3 L1 L2 L3 L4 L5 L6 H1 H2 T1

kg

06 1.1 45 60 43 22 30 19 4 65 64 15 80 55 04 40 25 11

10 2.4 60 80 48 30 36 19 5 80 82 20 100 70 05 60 40 15

20 8 70 100 60 44 46 19 5 78.5 85 20 135 100 05 70 50 15

All rights reserved.

Subject to revision

D 04896 - DPR

A Polyhydron Group Company ENGINEERING - 3 of 4

Subplate

L9 L10

L8

L11

Size Size Mass B1 B2 B3 B4 M ØD1 ØD2 ØD3 ØD4 ØD5 H1 L1 L2 L3 L4 L5

06 1NSR03G02 1.2 45 60 22.5 7.5 M6 11 7 22 G1/4 06 35 25 20 08 55 94

10 1NSR05G03 2.4 60 80 30 10 M8 11 7 25 G3/8 10 42 30 21 10 70 115

10 1NSR05G04 2.4 60 80 30 10 M8 11 7 30 G1/2 10 42 30 21 10 70 115

20 1NSR07G08 5.3 70 100 35 15 M8 17.5 11.5 44 G1 20 54 40 34 15 100 140

Size Size L6 L7 L8 L9 L10 L11 T1 T2 T3 R Valve mounting screws S.H.C.S. Tightning Torque

06 1NSR03G02 1.2 45 60 22.5 7.5 M6 11 7 22 G1/4 06 35 25 20 08 55 94

10 1NSR05G03 2.4 60 80 30 10 M8 11 7 25 G3/8 10 42 30 21 10 70 115

10 1NSR05G04 2.4 60 80 30 10 M8 11 7 30 G1/2 10 42 30 21 10 70 115

20 1NSR07G08 5.3 70 100 35 15 M8 17.5 11.5 44 G1 20 54 40 34 15 100 140

Technical specification

Construction - Direct acting, Poppet type.

Mounting style - Threaded Cartridge, Threaded Port body or Subplate type

(Factory Std. & ISO Std.)

Interface - Factory standard

Note : Subplate mounting valves having interface as per

ISO 6264-03-04 and 6264-06-09 are also

available on request. Please ask for details

Mounting position - Optional.

Flow drication From P to T

Operating pressure for port 400 bar (Std model)

for port P 700 bar max ( for Model DPR06*700-11 only)

for port T 315 bar

Pressure setting range Upto 25, 50, 100, 200, 315, 400 and 700 bar max.

Hydraulic medium Mineral Oil

Viscosity range 10 Cst. to 380 Cst

Fluid temperature range -20°C to + 70°C

Fluid cleanliness requirement As per ISO 16/13 or better.

Mass Refer individual table.

All rights reserved.

Subject to revision

D 04896 - DPR

A Polyhydron Group Company

ENGINEERING - 4 of 4

Ordering code

DPR H 06 T 25 04

Direct operated 01 thru 09, factory Std.

Pressure Relief Valve 04 ( For Subplate Valve only )

10 thru 19, factory Std.

Set screw S 11

( For Threaded Valve only )

Hand knob H

20 thru 29, ISO Std.

21

( for DPR*06S*-21 only )

Size 06, 10 and 20

Design code subject to change.

Cartridge K Installation dimensions remain same.

Threaded T

Subplate S 25, 50, 100, 200

315, 400 & 630 bar

I.S.O. mounting I

Note : Subplate to be ordered seperately

All rights reserved.

Subject to change without notice.

Due to continuous improvement in the design of the product, the actual product supplied may look different than shown above.

For critical apllications, please ask for certified installation drawing.

All rights reserved.

Subject to revision

You might also like

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Double Acting Air Cylinders Technical SpecsDocument7 pagesDouble Acting Air Cylinders Technical SpecskarthikNo ratings yet

- Din en 853 2 SN: Wire Braid Hydraulic Hose Meets EN 853 2 SN, SAE 100R2 and ISO 1436 2SNR2Document1 pageDin en 853 2 SN: Wire Braid Hydraulic Hose Meets EN 853 2 SN, SAE 100R2 and ISO 1436 2SNR2Zoran JankovNo ratings yet

- HDB BreakersDocument88 pagesHDB Breakersmargotsilva96No ratings yet

- HDB BreakersDocument89 pagesHDB BreakersJohn Louie Mazon100% (5)

- PVC Butterfly Valve (Lever)Document4 pagesPVC Butterfly Valve (Lever)Elias SusantoNo ratings yet

- PVC Butterfly Valve (Lever)Document4 pagesPVC Butterfly Valve (Lever)Elias SusantoNo ratings yet

- Operation Manual: Pile Driver DPD 350Document31 pagesOperation Manual: Pile Driver DPD 350Joseph Emmanuel ParedesNo ratings yet

- HDB Breakers ManualDocument89 pagesHDB Breakers ManualJoseph Emmanuel ParedesNo ratings yet

- A51 A52 CylinderDocument6 pagesA51 A52 CylinderBiswanath LenkaNo ratings yet

- Flowcon Ab-Ejust Tech - 2012 AprDocument11 pagesFlowcon Ab-Ejust Tech - 2012 AprJomar BustamanteNo ratings yet

- 421 - 100 Pump Disttibutor Gear 80742042Document1 page421 - 100 Pump Disttibutor Gear 80742042DmitryNo ratings yet

- Pro 787426Document5 pagesPro 787426Mohamed ElmakkyNo ratings yet

- 12E1212E PM Rev B Sep 2021Document229 pages12E1212E PM Rev B Sep 2021mehmetNo ratings yet

- A16 A17 CylinderDocument7 pagesA16 A17 Cylinderjaneesh RNo ratings yet

- Daemo Eng (2ba)Document20 pagesDaemo Eng (2ba)Jairresistenciagt123No ratings yet

- (Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Document16 pages(Eng) DAEMO FULL LINEUP - Catalog - 16p - 140211 (7th)Mahendra Tyre Works RaigarhNo ratings yet

- 602VFM Vortex Flowmeter Installation and Operation ManualDocument32 pages602VFM Vortex Flowmeter Installation and Operation ManualVincent BuensucesoNo ratings yet

- Combibox Program Schedule: AttachmentsDocument8 pagesCombibox Program Schedule: AttachmentsremeenNo ratings yet

- Air Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMDocument4 pagesAir Cylinder: Series A20, A21 Double End Double Acting Cylinders (Square Type) Ø32 - 125 MMBiswanath LenkaNo ratings yet

- Din en 857 2 SC: Compact Hydraulic Hose Construction Acc. To EN 857 2 SCDocument1 pageDin en 857 2 SC: Compact Hydraulic Hose Construction Acc. To EN 857 2 SCZoran JankovNo ratings yet

- 1530SE1930SE1532SE1932SE 0408SE0608SE0408ME0608ME PM Rev C Jun 2021Document204 pages1530SE1930SE1532SE1932SE 0408SE0608SE0408ME0608ME PM Rev C Jun 2021mehmetNo ratings yet

- BBBarBrochure - 2011 05 30 PDFDocument7 pagesBBBarBrochure - 2011 05 30 PDFKS LeeNo ratings yet

- AB Valves Manufacturer Industrial Valves EquipmentsDocument4 pagesAB Valves Manufacturer Industrial Valves EquipmentsRoger Labra LlanoNo ratings yet

- 375 PVC-U ball valve data sheetDocument1 page375 PVC-U ball valve data sheetAhmad RifaiNo ratings yet

- Chariot de Guidage R1651 194 20 RexrothDocument12 pagesChariot de Guidage R1651 194 20 RexrothRedOne KhasmiNo ratings yet

- PVH Sight Glass Data SheetDocument11 pagesPVH Sight Glass Data SheetANIKET PATILNo ratings yet

- SET X Y DA Center of Gravity: ISO 5211 Interface Pressure ConnectionDocument2 pagesSET X Y DA Center of Gravity: ISO 5211 Interface Pressure Connectionhamr01No ratings yet

- VALVES Technical Catalog: Catálogo Técnico ValvoleDocument11 pagesVALVES Technical Catalog: Catálogo Técnico ValvoleMohamed Raafat0% (1)

- GTJZ0608&0808 Parts ManualDocument178 pagesGTJZ0608&0808 Parts ManualHải Đăng PhanNo ratings yet

- Butterfly Valve B7GDocument3 pagesButterfly Valve B7GJorgeCabreraCoronelNo ratings yet

- DP Series Wafer Check Valve CiDocument2 pagesDP Series Wafer Check Valve CiAerox neoNo ratings yet

- Liberty Galati S.A. - Romania: Inspection Certificate 20617901 ACCORDING TO: EN 10204/2004/3.1 DATE: 16.02.2020Document1 pageLiberty Galati S.A. - Romania: Inspection Certificate 20617901 ACCORDING TO: EN 10204/2004/3.1 DATE: 16.02.2020Felicia CioabaNo ratings yet

- Install and operate AAFs silicon compressed air filterDocument10 pagesInstall and operate AAFs silicon compressed air filterMột Lằn QuangNo ratings yet

- Farmi Forest Corporation Ahmolantie 6 FIN-74510 Iisalmi, Finland Tel. +358 (0) 17 83 241 Fax. +358 (0) 17 8324 372 WWW - Farmiforest.fiDocument8 pagesFarmi Forest Corporation Ahmolantie 6 FIN-74510 Iisalmi, Finland Tel. +358 (0) 17 83 241 Fax. +358 (0) 17 8324 372 WWW - Farmiforest.fiacostajorgeluis05No ratings yet

- Extruder Brochure - Old SeriesDocument4 pagesExtruder Brochure - Old SeriesAmirmasoudNo ratings yet

- A51 A52 Cylinder..Document6 pagesA51 A52 Cylinder..Naveenraj SNo ratings yet

- Crosby IPH10EDocument1 pageCrosby IPH10EKonstantinos SynodinosNo ratings yet

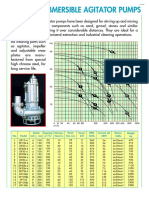

- Submersible Agitator Pumps: Toyo DPDocument2 pagesSubmersible Agitator Pumps: Toyo DPBasit Edu0% (1)

- SEO-Optimized Technical Data Sheet Title for SEVO 1230 Clean Agent CylindersDocument1 pageSEO-Optimized Technical Data Sheet Title for SEVO 1230 Clean Agent Cylinderstribhuvan ShankarNo ratings yet

- Inova Ball Joints JBDocument2 pagesInova Ball Joints JBSympatyagaNo ratings yet

- h07rn F en 50525 2 21 Flexible Rubber CableDocument5 pagesh07rn F en 50525 2 21 Flexible Rubber CableBradNo ratings yet

- 1530S1930S1532M1932M 0408S0608S0408M0608M PM Rev B Mar 2021Document206 pages1530S1930S1532M1932M 0408S0608S0408M0608M PM Rev B Mar 2021mehmetNo ratings yet

- Optimize Air CylinderDocument4 pagesOptimize Air CylinderkarthikNo ratings yet

- Strainer EN558 Serie1Document1 pageStrainer EN558 Serie1Jorge FerrerNo ratings yet

- A25 A26 CylinderDocument5 pagesA25 A26 CylinderBiswanath LenkaNo ratings yet

- Din en 856 4Sh: Multispiral Hydraulic Hose Acc. To EN 856 4SH - MSHA ApprovedDocument1 pageDin en 856 4Sh: Multispiral Hydraulic Hose Acc. To EN 856 4SH - MSHA ApprovedSergio AlbaNo ratings yet

- LINEAR RAIL SBI CATALOGDocument28 pagesLINEAR RAIL SBI CATALOGbách hàNo ratings yet

- Spidex OperatingDocument10 pagesSpidex Operatingwalk001No ratings yet

- HS-901D Technical Data SheetDocument4 pagesHS-901D Technical Data SheetAji SetiawanNo ratings yet

- PHILIPP Lifting Insert With Cross Hole Installation InstructionDocument4 pagesPHILIPP Lifting Insert With Cross Hole Installation InstructionSrdjan KosoricNo ratings yet

- 711 - 100 Climb 14248934Document1 page711 - 100 Climb 14248934DmitryNo ratings yet

- 711 - 100 Climb 14248934Document1 page711 - 100 Climb 14248934DmitryNo ratings yet

- Volvo ABG325 part information for Climb 14248934Document1 pageVolvo ABG325 part information for Climb 14248934DmitryNo ratings yet

- Gate Valve: Engineering AdvantageDocument4 pagesGate Valve: Engineering AdvantageAbderrazek ziedNo ratings yet

- Alfa Laval Unique SSV Standard Product LeafletDocument6 pagesAlfa Laval Unique SSV Standard Product LeafletAnonymous KdnOsd9No ratings yet

- Oilless guide elements buying guideDocument136 pagesOilless guide elements buying guidesansagithNo ratings yet

- Van Can Bang Nhiet ApDocument1 pageVan Can Bang Nhiet ApMaker PhạmNo ratings yet

- Din en 856 4Sp: Multispiral Hydraulic Hose Acc. To EN 856 4SP - MSHA ApprovedDocument1 pageDin en 856 4Sp: Multispiral Hydraulic Hose Acc. To EN 856 4SP - MSHA ApprovedSergio AlbaNo ratings yet

- Electronic Skin PPT 2Document12 pagesElectronic Skin PPT 2Sunitha AteliNo ratings yet

- Gathering Materials: Presentation Skills MPU 2113Document18 pagesGathering Materials: Presentation Skills MPU 2113ila2nabilaNo ratings yet

- Saipem - FdsDocument8 pagesSaipem - FdsWaldemar100% (1)

- CNS Unit IV NotesDocument24 pagesCNS Unit IV NotesJUSTUS KEVIN T 2019-2023 CSENo ratings yet

- Isoefficiency Function A Scalability Metric For PaDocument20 pagesIsoefficiency Function A Scalability Metric For PaDasha PoluninaNo ratings yet

- Counting Discrete Math ChoicesDocument2 pagesCounting Discrete Math ChoicesAfizah NazatulNo ratings yet

- G2 4-G2 4M-2014Document58 pagesG2 4-G2 4M-2014Peter Lopez67% (3)

- Energy Loss in Pipe and Fitting 1.0 ObjectiveDocument5 pagesEnergy Loss in Pipe and Fitting 1.0 Objectivefaku lolipopNo ratings yet

- Code: Final Exam in English: Grade 8Document7 pagesCode: Final Exam in English: Grade 8Luka EradzeNo ratings yet

- Yanmar SMSV15 - SV17Document356 pagesYanmar SMSV15 - SV17kokosik22100% (3)

- 9A01709 Advanced Structural Analysis PDFDocument8 pages9A01709 Advanced Structural Analysis PDFReddy Kiran KDNo ratings yet

- Mestrado Hang GlidingDocument82 pagesMestrado Hang GlidingJuliana Silveira100% (2)

- Tacana Project (15687597)Document1 pageTacana Project (15687597)jesusNo ratings yet

- International ArbitrageDocument24 pagesInternational Arbitrageaadis191No ratings yet

- Referral 9b66451b 9b66451bDocument1 pageReferral 9b66451b 9b66451bleonelale95No ratings yet

- Chapter 2: 19Th Century Philippines As Rizal'S ContextDocument52 pagesChapter 2: 19Th Century Philippines As Rizal'S ContextJorielyn ApostolNo ratings yet

- Odor Out Brochure PDFDocument4 pagesOdor Out Brochure PDFTitas IlekisNo ratings yet

- EVCC Product Specifications-2.1.2Document11 pagesEVCC Product Specifications-2.1.2Windya SaputraNo ratings yet

- Tamil Nadu Govt Form for Testing Lab EMDocument4 pagesTamil Nadu Govt Form for Testing Lab EMPraveenNo ratings yet

- Group5 AssignmentDocument10 pagesGroup5 AssignmentYenew AyenewNo ratings yet

- Partial Molar PropertiesDocument6 pagesPartial Molar PropertiesNISHTHA PANDEYNo ratings yet

- E-Learning - Learning For Smart GenerationZ-Dr.U.S.pandey, Sangita RawalDocument2 pagesE-Learning - Learning For Smart GenerationZ-Dr.U.S.pandey, Sangita RawaleletsonlineNo ratings yet

- Induction Motor StarterDocument5 pagesInduction Motor StarterAnikendu MaitraNo ratings yet

- 5 Ear Disorders of DogsDocument14 pages5 Ear Disorders of DogsKoleen Lopez ÜNo ratings yet

- CSA Recap-8.8 Test 1Document72 pagesCSA Recap-8.8 Test 1Gokul BakkiyarasuNo ratings yet

- ARIA JumpChainDocument52 pagesARIA JumpChainDorothy FeelyNo ratings yet

- Lighthouse Institute Mathematics Cala D 2023Document4 pagesLighthouse Institute Mathematics Cala D 2023Kudakwashe RushwayaNo ratings yet

- Preventing Needlestick Injuries Among Healthcare Workers:: A WHO-ICN CollaborationDocument6 pagesPreventing Needlestick Injuries Among Healthcare Workers:: A WHO-ICN CollaborationWasni TheresiaNo ratings yet

- Law On Other Business Transactions 20181Document365 pagesLaw On Other Business Transactions 20181Leonel King0% (1)

- Firelights PDFDocument2 pagesFirelights PDFEFG EFGNo ratings yet