Professional Documents

Culture Documents

2925-Machining Simple Connecting Rods

Uploaded by

Ali ZamaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2925-Machining Simple Connecting Rods

Uploaded by

Ali ZamaniCopyright:

Available Formats

By GEOMETER

Machining simple connecting rods

A

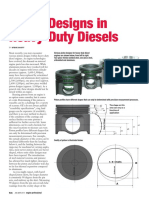

A D V A N T A G E of the single-

N pin may be a fixture in the small end Then the centres of small and big

web crankshaft with open and oscillate in the piston bosses. ends are marked, and these bores

crankpin-and of certain Brass or bronze may also be used machined, clampmg the bar to the

built-up types-is that the con- for the connecting rods of simple lathe faceplate-preferably leaving

engines, of moderate speed and power, the bores undersize for final finishing

necting rod can have a solid big- and both are heavier than steel, later by machining or reaming.

end eye, which simplifies its con- though neither requires bushing ex- For machining the web, the bar is

struction, makes for strength, and pressly, but only to facilitate overhaul centralised and clamped, and facing

reduces bulk and weight-all im- when wear occurs, thus avoiding cuts taken across. Final smoothing

portant factors, and particularly renewal of the whole connecting rod. may be done with a file, with the bar

so for high-speed engines and for The simplest section for the length removed ; and for machining the

two-stroke engines where dead of a connecting rod is a rectangular opposite side of it, a piece of packing

space in the crankcase should be one with rounded sides; and on a of appropriate thickness should be

kept to a minimum. weight/strength basis it lacks little clamped against the faceplate, as at

beside the familiar I-section, which is A, to provide support for the web.

In the interest of reducing the milled each side to leave a narrow

weight of the connecting rod, while central web. The connecting rod of

retaining a high degree of strength, rectangular section, however, can be Removing surplus material

duralumin is often used in model entirely finished by turning methods The small-end and big-end bosses,

petrol engines, and in itself provides and some handwork-without the which will be circular, can be pro-

a good bearing on soft-steel or hard- need for milling where there are no duced partly by sawmg and filing,

steel gudgeon pins and crankpins. facilities for this. partly by machining. Sawing and

-wj

Steel may be used, but it is heavier, Using a piece of suitable flat bar filing are recommended for removing

and the eyes require bushing with to make the comecting rod, it is the surplus material; and for holding.

bronze, brass, or duralumin-except faced flat one side by filing or machin- the connecting rod securely in the

in some instances where the gudgeon ing a light cut, in the four-jaw chuck. vice. without risk of damage, suitable

hardened steel plugs should be made

for each end, as at B. Following

.CLAMP

this, the connecting rod is mounted

4

- _- on a mandrel in the chuck (one

-- I mandrel for each end), and the bosses

- l .

are turned back to the web-slightly

CONNECTING

tapering them towards the outside

0 C if required.

Surplus material along the edges of

the web can also be removed by care-

fully sawing and filing; and eventually

there will remain only material on the

bosses in line with the web. Plugs

MOUNTING can then be used as filing guides-

particularly where the outside edges

of the bosses are tapered, as with

larger plugs, the file will clear except

at the centre.

Alternatively, material in line with

the web can be milled or “ turned ”

off. For milling, as at C, the mill is

TOOL

run in the chuck, and the connecting

rod mounted on a bracket on the

topslide. A stop prevents the cutter

gathering on to the web; with a light

IREL

-7- feed, the connecting rod is pulled

round by hand. For “turning,” as

at D, the connecting rod is on a

mandrel in the chuck, which is pulled

round by hand for each cut.

Connecting rod centres may be

accurately obtained, a s at E, using a

plug Y in one bore, for dimension X

to be measured over a hollow “button”

Z, which is then set to run truly for

machining the other bore.

13 JUNE 1957 847 MODEL ENGINEER

You might also like

- Steam Engine PlansDocument20 pagesSteam Engine Planstszabi26100% (2)

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- CutoffsawDocument4 pagesCutoffsawFrenchwolf420No ratings yet

- Yamaha Grizzly 550 700 Service Manual PDFDocument447 pagesYamaha Grizzly 550 700 Service Manual PDFRobert TNo ratings yet

- Lathe Design ADocument3 pagesLathe Design AFrenchwolf420100% (1)

- Flying CloudDocument14 pagesFlying CloudJim96% (27)

- Quorn: Tool and Cutter GrinderDocument4 pagesQuorn: Tool and Cutter GrinderDan HendersonNo ratings yet

- 4ZD1 MTDocument117 pages4ZD1 MTArsenio Cordones CarrilloNo ratings yet

- Belt SanderDocument2 pagesBelt SanderFrenchwolf420No ratings yet

- Quorn: Tool and D Cutter GrinderDocument5 pagesQuorn: Tool and D Cutter GrinderDan HendersonNo ratings yet

- Grinder AutoDocument3 pagesGrinder AutoMike NichlosNo ratings yet

- EMS, Diagnostic Trouble CodesDocument9 pagesEMS, Diagnostic Trouble CodesTri wibowoNo ratings yet

- FFLB Engine Nlde-3Document81 pagesFFLB Engine Nlde-3Stefas DimitriosNo ratings yet

- Lapping BoresDocument10 pagesLapping BoreshortenivNo ratings yet

- Power Rasp, Build Your OwnDocument6 pagesPower Rasp, Build Your OwnJim100% (1)

- Weld Consideration For Tubular JointsDocument4 pagesWeld Consideration For Tubular JointssnipertombNo ratings yet

- Electrical Machine Important 25 MCQ PDFDocument3 pagesElectrical Machine Important 25 MCQ PDFsamyalarunNo ratings yet

- CF34 10EBSIJune09Document51 pagesCF34 10EBSIJune09ArturoACE75% (4)

- Star Lite SailboatDocument13 pagesStar Lite SailboatJim100% (8)

- Dodge 5.7 Service InformationDocument243 pagesDodge 5.7 Service InformationNay Linn Htet100% (1)

- Oxford Octane Formula Student ReportDocument188 pagesOxford Octane Formula Student Reportsome3148100% (2)

- Simple Boring BarDocument3 pagesSimple Boring BarMike Nichlos100% (1)

- Moment Connection TipsDocument7 pagesMoment Connection TipsManoj JaiswalNo ratings yet

- Maintanence (J T057 - En)Document376 pagesMaintanence (J T057 - En)Md.Mominul IslamNo ratings yet

- Perkins 4-154 Shop ManualDocument108 pagesPerkins 4-154 Shop ManualDoug Stuart75% (4)

- CAT - G3516H Intake Manifold Air Temperature Is High PDFDocument5 pagesCAT - G3516H Intake Manifold Air Temperature Is High PDFwagner_guimarães_1No ratings yet

- Alternator Frame: Turbine DiameterDocument4 pagesAlternator Frame: Turbine DiameterDennyHalim.com50% (2)

- Southwire Cable in Conduit Product CatalogDocument65 pagesSouthwire Cable in Conduit Product Catalogjtb12No ratings yet

- Metal Deck and Cast in ChannelsDocument8 pagesMetal Deck and Cast in ChannelsrealdarossNo ratings yet

- Complete Guide To Cable LacingDocument83 pagesComplete Guide To Cable LacingfulltrackproductionsNo ratings yet

- ACTOM OUTDOOR DISCONNECTORS Ver 1.cdrDocument8 pagesACTOM OUTDOOR DISCONNECTORS Ver 1.cdrbrianNo ratings yet

- Connectors PDFDocument8 pagesConnectors PDFhossinmaaNo ratings yet

- Weandc 2019 3 198Document7 pagesWeandc 2019 3 198shahidrazzaqNo ratings yet

- Tri Star MB SeriesDocument1 pageTri Star MB SerieschuranjitNo ratings yet

- HG Manhat2 PDFDocument11 pagesHG Manhat2 PDFNikola DulgiarovNo ratings yet

- Repair Welding of A Rotating Electrical Machine's Broken ShaftDocument7 pagesRepair Welding of A Rotating Electrical Machine's Broken ShaftLargyla Torres MendesNo ratings yet

- Repair Welding of A Rotating Electrical Machine's Broken ShaftDocument7 pagesRepair Welding of A Rotating Electrical Machine's Broken ShaftkanosriNo ratings yet

- ADSS Tab 3 - HDWR Assembly InstructionsDocument9 pagesADSS Tab 3 - HDWR Assembly InstructionsramsesiNo ratings yet

- DiplomaDocument5 pagesDiplomaBHALAJI BIRLANo ratings yet

- LP7 Fixings and AdhesivesDocument6 pagesLP7 Fixings and Adhesivesglenn salandananNo ratings yet

- LP7 Fixings and AdhesivesDocument6 pagesLP7 Fixings and Adhesivesglenn salandananNo ratings yet

- WaterBug Paddle BoatDocument5 pagesWaterBug Paddle BoatJim100% (1)

- PORTABLE Mag Loop For 40m-10m - G8ODEDocument4 pagesPORTABLE Mag Loop For 40m-10m - G8ODEAnonymous XoW23y58ONo ratings yet

- 3077-Cutting Keyways in ShaftsDocument1 page3077-Cutting Keyways in ShaftsS280RILEYNo ratings yet

- Turn Buckle Safety WireDocument1 pageTurn Buckle Safety WireJohn Adrian RoceroNo ratings yet

- Mini Dobrador de Tubos DIYDocument4 pagesMini Dobrador de Tubos DIYw4rh4ck3r-scribdNo ratings yet

- Piston Designs in Heavy-Duty Diesels: by Steve ScottDocument3 pagesPiston Designs in Heavy-Duty Diesels: by Steve ScottSatyabrat GaanNo ratings yet

- Electrical Skills (Eepw2241) : DC MotorsDocument6 pagesElectrical Skills (Eepw2241) : DC MotorsVenkata Rajkumar ChNo ratings yet

- Small Workshop CompressorDocument2 pagesSmall Workshop Compressorw4rh4ck3r-scribdNo ratings yet

- E-Z Splice Connector: ApplicationsDocument1 pageE-Z Splice Connector: ApplicationsFabio ParceroNo ratings yet

- 3d Open Source Foam CutterDocument22 pages3d Open Source Foam CutterOtto GonzalezNo ratings yet

- 2845-Bending & FormingDocument1 page2845-Bending & FormingJim MarnochNo ratings yet

- Simpson ConnectionDocument3 pagesSimpson ConnectionIac Cyp Capobianco IngenieroNo ratings yet

- Fc-s8 Designing With Planar Ferrite CoresDocument12 pagesFc-s8 Designing With Planar Ferrite CoresemilfrancuNo ratings yet

- Pipe Thread Primer - Why Is LeakingDocument5 pagesPipe Thread Primer - Why Is LeakingCarlos Cesar FerranteNo ratings yet

- Chapter 3a Riveted JointDocument20 pagesChapter 3a Riveted JointAdugna GosaNo ratings yet

- 1987 - ASCE - Polyzois, Dimos - Sag Rods As Lateral Supports For Girts and PurlinsDocument11 pages1987 - ASCE - Polyzois, Dimos - Sag Rods As Lateral Supports For Girts and PurlinsRobert Vochescu100% (1)

- Pages From Applied Process Design C Hemical Petrochemical Plants1Document1 pagePages From Applied Process Design C Hemical Petrochemical Plants1ashrafNo ratings yet

- Hightpowerbar 1000-6300A PDFDocument48 pagesHightpowerbar 1000-6300A PDFGopa KumarNo ratings yet

- 149-Workshop Hints & Tips PDFDocument1 page149-Workshop Hints & Tips PDFsyllavethyjimNo ratings yet

- Flex Design Machine Design January 2010 With Cover 1Document5 pagesFlex Design Machine Design January 2010 With Cover 1clipclapNo ratings yet

- Kick CatamaranDocument2 pagesKick CatamaranFrenchwolf420100% (1)

- Foot CatamaranDocument2 pagesFoot CatamaranАндрей КовальчукNo ratings yet

- Horizontal Split Case LN TypeDocument38 pagesHorizontal Split Case LN TypeprojashNo ratings yet

- Zero Fugitive EmissionsDocument2 pagesZero Fugitive EmissionsDebelmeNo ratings yet

- Applied SciencesDocument11 pagesApplied Sciencesafshin dadvarNo ratings yet

- How Two Boys Made Their Own Electrical Apparatus Containing Complete Directions for Making All Kinds of Simple Apparatus for the Study of Elementary ElectricityFrom EverandHow Two Boys Made Their Own Electrical Apparatus Containing Complete Directions for Making All Kinds of Simple Apparatus for the Study of Elementary ElectricityNo ratings yet

- Info Map EDC15C2Document2 pagesInfo Map EDC15C2Mathys Le GranchéNo ratings yet

- Everest Blowers M5125 Technical Specs GADrawingw FiltraDocument4 pagesEverest Blowers M5125 Technical Specs GADrawingw FiltraKELVIN TECHNOLOGIESNo ratings yet

- S Hydraulic Turbine - (1) Sheet:) Pelton (Document3 pagesS Hydraulic Turbine - (1) Sheet:) Pelton (Hazem MohamedNo ratings yet

- Vit SystemDocument10 pagesVit SystemVijeeshNo ratings yet

- LNS125 ValveDocument1 pageLNS125 ValvesahawaeNo ratings yet

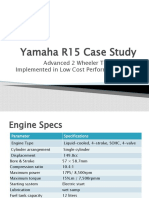

- Yamaha R15 Case Study: Advanced 2 Wheeler Technologies Implemented in Low Cost Performance BikesDocument10 pagesYamaha R15 Case Study: Advanced 2 Wheeler Technologies Implemented in Low Cost Performance BikesAdinath UpadhyeNo ratings yet

- AU2DCD21Document1 pageAU2DCD21Costel BuradaNo ratings yet

- Man v51 60g EngDocument2 pagesMan v51 60g EngGhaza UlfikriNo ratings yet

- Hornet 1955Document292 pagesHornet 1955try AGAINNo ratings yet

- B160CDocument2 pagesB160CedholminNo ratings yet

- Hitchcock Crusader RebuildDocument11 pagesHitchcock Crusader RebuildcarphoneNo ratings yet

- Hydraulic Turbine-1Document6 pagesHydraulic Turbine-1Suman Kumar DashNo ratings yet

- Engine: S6D125-1C-FW S/N 10001-UPDocument2 pagesEngine: S6D125-1C-FW S/N 10001-UPeshopmanual limaNo ratings yet

- MTU 20V4000 DS4000: Diesel Generator SetDocument6 pagesMTU 20V4000 DS4000: Diesel Generator SetMarioyfernanda Guerra Murua100% (1)

- 015 - 2023-10-10 Lista de Precios Castrol Octubre 2023Document89 pages015 - 2023-10-10 Lista de Precios Castrol Octubre 2023Gabriel ZucchiNo ratings yet

- Mining Excavator RH 120-E: Service TrainingDocument9 pagesMining Excavator RH 120-E: Service TrainingJHONNYS ALFONSO MANJARREZ GUTIERREZNo ratings yet

- ALT Series Service Parts List: 24 Volt AlternatorDocument4 pagesALT Series Service Parts List: 24 Volt AlternatorJacksonNo ratings yet

- A003E1Document6 pagesA003E1Ahmer CamdzicNo ratings yet

- Td5 Engine Diagnostic Function-3Document4 pagesTd5 Engine Diagnostic Function-3Paul JacobsonNo ratings yet