Professional Documents

Culture Documents

Course File - Introduction To Composite Materials

Uploaded by

AmarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Course File - Introduction To Composite Materials

Uploaded by

AmarCopyright:

Available Formats

AIT/IQAC/Aca/20-21/CFS

ACHARYA INSTITUTE OF TECHNOLOGY,

BENGALURU 560107

Course File: Students

Department: Aeronautical Engineering

A) Course Administrator Details

Course Title Course Code Core/Elective Semester Year

INTRODUCTION TO COMPOSITE 18AE54 Core 5 2021-22

MATERIALS

Contact Hours/ week Lecture Tutorials Practical

3hr/week 3 0 0

Name of the faculty PRASHANT

Designation and mail ID Assistant Professor G-III

prashant@acharya.ac.in

Department Aeronautical Engineering

B) Course Related Specifics

Prerequisites for the Course Complete Knowledge of Mechanics of Materials and Aircraft

(Exemption from the prerequisites isMaterial Science, Manufacturing Processes.

provided only in exceptional

circumstances)

1.Understand the advantages of composite materials compared to conventional

materials

Course Objectives 2.Evaluate the properties of polymer matrix composites with fiber

reinforcements

3. Explain the manufacturing process and applications of composite materials

Department of Aeronautical Engineering, Acharya Institute of Technology.

AIT/IQAC/Aca/20-21/CFS

ACHARYA INSTITUTE OF TECHNOLOGY,

BENGALURU 560107

Recommended Text Books

1. “Composite Materials- Science and Engineering” K.K Chawla, Springer Verlag, II

edition,1998.

2. “Mechanics of Composites” Autar Kaw, CRC Press, II edition,2006.

Recommended Reference Materials

1. “Composite Materials Handbook” Mein Schwartz, Department of Defense, USA, 2002.

2. “Non-Destructive Testing of Composite Materials” Ajay Kapadia, TWI Publications, 2006.

3. “Mechanics of Composite Materials” R M Jones, Taylor & Francis, 2ndEdn,2015.

Course Outcomes

CO1: Explain the advantages of using composite materials as an alternative to conventional

materials for specific applications

CO2: Describe the advanced fabrication and processing for producing composite parts.

CO3: Evaluate the micro- and macro-mechanical behavior of composite laminates

Department of Aeronautical Engineering, Acharya Institute of Technology.

AIT/IQAC/Aca/20-21/CFS

ACHARYA INSTITUTE OF TECHNOLOGY,

BENGALURU 560107

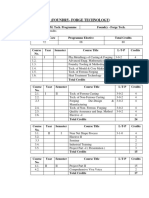

Lesson Plan

Teaching Skills &

Hr.

Unit Content Aid and Competency COs addressed

No.

Methodology developed

1 1 Introduction to Composite Materials: Chalk and 1

Definition, classification of composite materials Talk

2 1 classification of reinforcement - particulate, short Chalk and 1

fiber, whiskers, long fibers composites Talk

3 1 matrix materials – metals, ceramics, polymers Chalk and 1

(including thermoplastics and thermosets) Talk

4 1 Carbon-Carbon Composites Chalk and 1

Talk

5 1 Metal Matrix Composites: Chalk and 1

MMC with particulate and short fiber Talk

reinforcement

6 1 liquid and solid state processing of MMC – stir Chalk and 2

casting, squeeze casting Talk

7 1 Properties of MMCs, Applications of Al, Mg, Ti Chalk and 1

based MMC Talk

8 2 Processing of Polymer Matrix Composites: Chalk and 2

Thermoset Polymers Talk

9 2 Hand layup Process, Vacuum Bagging Process Chalk and 2

Department of Aeronautical Engineering, Acharya Institute of Technology.

AIT/IQAC/Aca/20-21/CFS

ACHARYA INSTITUTE OF TECHNOLOGY,

BENGALURU 560107

Talk

10 2 Post Curing Process, Filament winding Chalk and 2

Talk

11 2 Pultrusion, Pulforming, Autoclave Process Chalk and 2

Talk

12 2 Processing of Polymer Matrix Composites: Chalk and 2

Thermoplastic Polymers Talk

13 2 Extrusion process, Injection Moulding Process, Chalk and 2

Thermo-forming process. Talk

14 2 Post Processing of Composites: Adhesive bonding Chalk and 2

Talk

15 2 drilling, cutting processes Chalk and 2

Talk

16 3 Micro-Mechanical Behavior of a Lamina: Chalk and 3

Determination of elastic constants-Rule of Talk

mixtures

17 3 transformation of coordinates Chalk and 3

Talk

18 3 micro-mechanics based analysis Chalk and 3

Talk

19 3 experimental determination of material constants Chalk and 3

Talk

Department of Aeronautical Engineering, Acharya Institute of Technology.

AIT/IQAC/Aca/20-21/CFS

ACHARYA INSTITUTE OF TECHNOLOGY,

BENGALURU 560107

20 3 Macro-Mechanical Behavior of a Lamina: Chalk and 3

Global and local axis for angle lamina Talk

21 3 determination of global and local stresses and Chalk and 3

moduli Talk

22 3 for 2D-UD lamina with different fiber orientation Chalk and 3

Talk

23 3 different fiber materials glass Chalk and 3

Talk

24 3 carbon and aramid fiber reinforcement Chalk and 3

Talk

25 3 Problems Chalk and 3

Talk

26 3 Problems Chalk and 3

Talk

27 4 Failure Theory : Tsai-Hill Chalk and 1

Talk

28 4 Tsai-Wu Chalk and 1

Talk

29 4 Max Stress and Max Strain Chalk and 1

Talk

30 4 Classical plate theory- Stress and strain variation Chalk and 1

in a laminate Talk

Department of Aeronautical Engineering, Acharya Institute of Technology.

AIT/IQAC/Aca/20-21/CFS

ACHARYA INSTITUTE OF TECHNOLOGY,

BENGALURU 560107

31 4 Resultant forces Chalk and 1

Talk

32 4 moments Chalk and 1

Talk

33 4 A B & D matrices Chalk and 1

Talk

34 4 Strength analysis of a laminate Chalk and 1

Talk

35 4 Problems Chalk and 1

Talk

36 4 Problems Chalk and 1

Talk

37 5 Inspection & Quality Control: Destructive & Non- Chalk and 1

Destructive Testing Talk

38 5 Tensile, Compression, Flexural, Shear, Hardness Chalk and 1

Talk

39 5 ultrasonic testing – A-B-C scan Chalk and 1

Talk

40 5 Applications of Composites Materials: Chalk and 1

Automobile, Aircrafts, missiles, Space hardware Talk

Department of Aeronautical Engineering, Acharya Institute of Technology.

AIT/IQAC/Aca/20-21/CFS

ACHARYA INSTITUTE OF TECHNOLOGY,

BENGALURU 560107

41 5 Electrical and electronics, marine, recreational and Chalk and 1

Sports equipment, future potential of composites. Talk

C) Course Assessment Procedure

Procedure for Internal Assessment average of 3 Tests

Maximum Marks for Internal Assessment 30+10=40

Maximum Marks for Final Exam 60/100

Programme Outcomes (student outcomes):

1. Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering

specialization to the solution of complex engineering problems.

2. Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated

conclusions using first principles of mathematics, natural sciences, and engineering sciences.

3. Design/development of solutions: Design solutions for complex engineering problems and design system components or processes

that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and

environmental considerations.

4. Conduct investigations of complex problems: Use research-based knowledge and research methods including design of

experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

5. Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including

prediction and modeling to complex engineering activities with an understanding of the limitations.

6. The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and

cultural issues and the consequent responsibilities relevant to the professional engineering practice.

7. Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental

contexts, and demonstrate the knowledge of, and need for sustainable development.

8. Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

Department of Aeronautical Engineering, Acharya Institute of Technology.

AIT/IQAC/Aca/20-21/CFS

ACHARYA INSTITUTE OF TECHNOLOGY,

BENGALURU 560107

9. Individual and team work: Function effectively as an individual, and as a member or leader in diverse teams, and in

multidisciplinary settings.

10. Communication: Communicate effectively on complex engineering activities with the engineering community and with society at

large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give

and receive clear instructions.

11. Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and

apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

12. Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in

the broadest context of technological change.

Course Outcomes-Program Outcomes mapping

Department of Aeronautical Engineering, Acharya Institute of Technology.

AIT/IQAC/Aca/20-21/CFS

ACHARYA INSTITUTE OF TECHNOLOGY,

BENGALURU 560107

COs Program Outcomes Total

a b c d e F g h i j k l

CO1 1 1 1 1 4

CO2 1 1 2

CO3 1 1 2

CO4

CO5

Total 2 3 1 2 8

Department of Aeronautical Engineering, Acharya Institute of Technology.

You might also like

- Hindusthan College of Engineering and Technology: AircraftDocument12 pagesHindusthan College of Engineering and Technology: AircraftKathirvel KNo ratings yet

- Finite Element Analysis of High Pressure Composite Vessels: in Cad-CamDocument11 pagesFinite Element Analysis of High Pressure Composite Vessels: in Cad-CamTanuj JoshiNo ratings yet

- Finite Element Analysis of High Pressure Composite Vessels: in Cad-CamDocument11 pagesFinite Element Analysis of High Pressure Composite Vessels: in Cad-CamTanuj JoshiNo ratings yet

- 1d and 2d Ablation Code ReportDocument45 pages1d and 2d Ablation Code ReportVenkata AlluriNo ratings yet

- DTE MATERIAL EnggDocument8 pagesDTE MATERIAL EnggramptechNo ratings yet

- Production TechniquesDocument2 pagesProduction TechniquesVELUGUBANTLA AALAPNo ratings yet

- Syllabus-PULP & PAPER TECHNOLOGYDocument5 pagesSyllabus-PULP & PAPER TECHNOLOGYVijai B RaghavanNo ratings yet

- Methods For Improving Seismic Performances of BridgesDocument71 pagesMethods For Improving Seismic Performances of BridgesCamila HernandezNo ratings yet

- All PDFDocument77 pagesAll PDFmrcopy xeroxNo ratings yet

- Production Syllabus 2017-18-1Document71 pagesProduction Syllabus 2017-18-1Akankshya MishraNo ratings yet

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum Chemical Process Technology-I (Code: 3330505)Document5 pagesGujarat Technological University, Ahmedabad, Gujarat Course Curriculum Chemical Process Technology-I (Code: 3330505)joshi madhavNo ratings yet

- Ae 8603 Composite Materials and StructuresDocument7 pagesAe 8603 Composite Materials and StructuresDURLAB DASNo ratings yet

- Strength Studies On Geo-Polymer Concrete by Using Fly Ash and Quarry Dust"Document51 pagesStrength Studies On Geo-Polymer Concrete by Using Fly Ash and Quarry Dust"PratikNo ratings yet

- 18ME653 - Syllabus - CO - PODocument4 pages18ME653 - Syllabus - CO - PORameshkumarNo ratings yet

- M.Tech (Foundry-Forge Technology)Document8 pagesM.Tech (Foundry-Forge Technology)JagdishNo ratings yet

- ME363 Composite Materials and MechanicsDocument3 pagesME363 Composite Materials and Mechanicsnandan144No ratings yet

- 7th Sem SyllabusDocument6 pages7th Sem SyllabusAshwit KumarNo ratings yet

- Construction and MaterialDocument39 pagesConstruction and Material11-CD2 Mohamed ASIFNo ratings yet

- Inclusion Control Model in The Ladle Metallurgy FurnaceDocument152 pagesInclusion Control Model in The Ladle Metallurgy Furnaceabhijit kumarNo ratings yet

- Project - Bit-Final 8-05-15 PrintDocument39 pagesProject - Bit-Final 8-05-15 PrintchiragdbeckNo ratings yet

- Composite Fabrication and Machining: Lecture Notes ONDocument87 pagesComposite Fabrication and Machining: Lecture Notes ONMadhulaalasa KurmaNo ratings yet

- Nptel: Introduction To Composites - Web CourseDocument3 pagesNptel: Introduction To Composites - Web CourseAnu PriyaNo ratings yet

- CE F230 - Civil Engineering Materials (2019)Document3 pagesCE F230 - Civil Engineering Materials (2019)jacklickmydickNo ratings yet

- Hydraulic Bearing Puller ReportDocument23 pagesHydraulic Bearing Puller ReportAman sharmaNo ratings yet

- Project ReportDocument85 pagesProject Reportmurali thathaNo ratings yet

- UntitledDocument68 pagesUntitledAnanthika MaheswaranNo ratings yet

- 22CH101-Unit IV - Smart MaterialsDocument92 pages22CH101-Unit IV - Smart MaterialsshebajeyasevliNo ratings yet

- Iit Rurkela SugarcaneDocument36 pagesIit Rurkela SugarcaneshivaNo ratings yet

- Basic Maths II for Diploma in Rubber TechnologyDocument4 pagesBasic Maths II for Diploma in Rubber TechnologyAbhishekNo ratings yet

- Concrete Technology HandoutDocument21 pagesConcrete Technology HandoutsainathNo ratings yet

- Assignment Questions UNIT 4Document1 pageAssignment Questions UNIT 4manoj1316kumar_63152No ratings yet

- 3350602Document7 pages3350602draqbhattiNo ratings yet

- 20ME403 Engineering Materials and Metallurgy Unit - 1 Digital MaterialDocument55 pages20ME403 Engineering Materials and Metallurgy Unit - 1 Digital MaterialDark ranger YtNo ratings yet

- Academic Content: Engineering ChemistryDocument218 pagesAcademic Content: Engineering ChemistryVIVEK SINGHNo ratings yet

- Investigationof Mechanical Propertiesof Coconut Shell Dust Epoxyand Fly-Ash CompositesDocument36 pagesInvestigationof Mechanical Propertiesof Coconut Shell Dust Epoxyand Fly-Ash CompositesTeja shivraj DandeNo ratings yet

- Investigationof Mechanical Propertiesof Coconut Shell Dust Epoxyand Fly-Ash CompositesDocument36 pagesInvestigationof Mechanical Propertiesof Coconut Shell Dust Epoxyand Fly-Ash CompositesTeja shivraj DandeNo ratings yet

- Abhishek ThesisDocument62 pagesAbhishek ThesisPiyushNo ratings yet

- Nanosciense LectureplanDocument7 pagesNanosciense Lectureplanarahul sctengNo ratings yet

- PROJECT2018 FullReportDocument94 pagesPROJECT2018 FullReportTEAM LUASKARTNo ratings yet

- Chemical Process Materials PropertiesDocument13 pagesChemical Process Materials PropertiesMann OjhaNo ratings yet

- Final Thesis IpsaDocument73 pagesFinal Thesis IpsaVasu RajaNo ratings yet

- Inductrial Training Report FormatDocument5 pagesInductrial Training Report FormatAyush VishwakarmaNo ratings yet

- Materials For Engg-20ME11T INTERNAL-IDocument4 pagesMaterials For Engg-20ME11T INTERNAL-IPrasad Kumar CMNo ratings yet

- Ceramics and Glasses Course OverviewDocument44 pagesCeramics and Glasses Course OverviewNawaz KhanNo ratings yet

- 19CH1161 NT SchemeDocument4 pages19CH1161 NT SchemeMr. G. Naga ChaitanyaNo ratings yet

- Powder Metallurgy Processing of Aluminum Matrix Reinforced With Carbon NanotubesDocument53 pagesPowder Metallurgy Processing of Aluminum Matrix Reinforced With Carbon NanotubesTRNADEWNo ratings yet

- St. Michael College of Engineering & Technology: Course Plan (Theory)Document5 pagesSt. Michael College of Engineering & Technology: Course Plan (Theory)MECHANICAL SMCETNo ratings yet

- Nehru Institute of Engineering and Technology: T.M.Palayam, Coimbatore-105 Department of Mechanical EngineeringDocument12 pagesNehru Institute of Engineering and Technology: T.M.Palayam, Coimbatore-105 Department of Mechanical EngineeringRamkumar CNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityDev IndustriesNo ratings yet

- A New Generation of High Stiffness Rotational Moulding Materials - Hashim BhabhaDocument259 pagesA New Generation of High Stiffness Rotational Moulding Materials - Hashim BhabhaSK SahooNo ratings yet

- For Peer ReviewDocument17 pagesFor Peer ReviewParth VaswaniNo ratings yet

- Chapter 01 IntroductionDocument36 pagesChapter 01 IntroductionMario WNo ratings yet

- PMT Cie1 Jan 2018Document1 pagePMT Cie1 Jan 2018Suchetha RajuNo ratings yet

- Man Made Fiber Technology Course Code 3352901Document6 pagesMan Made Fiber Technology Course Code 3352901Sher Hai HamNo ratings yet

- AO208 Aircraft Materials and Processes PDFDocument2 pagesAO208 Aircraft Materials and Processes PDFVIGNESH RAJNo ratings yet

- Emg 4102 CN 1Document3 pagesEmg 4102 CN 1MaxwellNo ratings yet

- Development of Low-Cost Water Purification TechniquesDocument48 pagesDevelopment of Low-Cost Water Purification TechniquesRudra narayan sahooNo ratings yet

- A Practical Guide to the Selection of High-Temperature Engineering ThermoplasticsFrom EverandA Practical Guide to the Selection of High-Temperature Engineering ThermoplasticsNo ratings yet

- Computational Mesomechanics of Composites: Numerical Analysis of the Effect of Microstructures of Composites of Strength and Damage ResistanceFrom EverandComputational Mesomechanics of Composites: Numerical Analysis of the Effect of Microstructures of Composites of Strength and Damage ResistanceNo ratings yet

- A - One Polar LimitedDocument20 pagesA - One Polar LimitedinfoNo ratings yet

- UNIT 10 Organic ChemistryDocument51 pagesUNIT 10 Organic ChemistryTristan PereyNo ratings yet

- MATS Mod 3 Lec 4Document27 pagesMATS Mod 3 Lec 4Tim WuNo ratings yet

- (Andreas Öchsner, Holm Altenbach (Eds.) ) Properti (B-Ok - Xyz)Document450 pages(Andreas Öchsner, Holm Altenbach (Eds.) ) Properti (B-Ok - Xyz)Cristian Xavier Avendaño Bello0% (1)

- Bonderite NT-1 (14825190)Document6 pagesBonderite NT-1 (14825190)Nikolas Kolasni Lakenir Ckerde DockosNo ratings yet

- U-Bolt Range: Technical Information SheetDocument2 pagesU-Bolt Range: Technical Information SheetBrian VisserNo ratings yet

- Guide For The Repairs Excavator Structures by Welding: Print No. 604.07.189.01 - EnglishDocument32 pagesGuide For The Repairs Excavator Structures by Welding: Print No. 604.07.189.01 - EnglishАнатолій ГуменюкNo ratings yet

- Mto Civil ArsitekturDocument1 pageMto Civil Arsitekturkoko srihandokoNo ratings yet

- Grade 7 Science Test Item PDFDocument208 pagesGrade 7 Science Test Item PDFISABEL GASESNo ratings yet

- BM 1Document13 pagesBM 120 - 65 perla saisreeNo ratings yet

- N-Propanol M5579 2016 05Document4 pagesN-Propanol M5579 2016 05Syukri ZainuddinNo ratings yet

- Bangsar Rising - M&E ChecklistDocument13 pagesBangsar Rising - M&E ChecklistchanjunkaiNo ratings yet

- Es23 12Document2 pagesEs23 12yeng botzNo ratings yet

- OBJECTIVESDocument5 pagesOBJECTIVESlaila100% (1)

- Characterization of Refractory Behaviour of Complex Gold/silver Ore by Diagnostic LeachingDocument7 pagesCharacterization of Refractory Behaviour of Complex Gold/silver Ore by Diagnostic Leachingdavid mNo ratings yet

- CATALOUGEDocument154 pagesCATALOUGEArokiaraj AmalrajNo ratings yet

- Polymer Flooding ReportDocument17 pagesPolymer Flooding ReporthkaqlqNo ratings yet

- The Mechanical Properties and Creep Behavior of Epoxy Polymer Under TheDocument12 pagesThe Mechanical Properties and Creep Behavior of Epoxy Polymer Under TheAbhiraj MeenaNo ratings yet

- Drying & Cleanning SpecificationDocument5 pagesDrying & Cleanning SpecificationAnant Rubade100% (1)

- Omega Secondary School Form Three Holiday Package - May 2010 Chemistry Set 01Document3 pagesOmega Secondary School Form Three Holiday Package - May 2010 Chemistry Set 01umuchero danielNo ratings yet

- Resistance of Compacted Bituminous Mixtures to Moisture DamageDocument6 pagesResistance of Compacted Bituminous Mixtures to Moisture DamageAnonymous sSNLqweXgNo ratings yet

- Glass-Fibre Reinforced Plastic Pipeline and Piping SystemsDocument10 pagesGlass-Fibre Reinforced Plastic Pipeline and Piping SystemsTurbo Snail RNo ratings yet

- Astm D2321 (2000) PDFDocument10 pagesAstm D2321 (2000) PDFMohammad Rawoof100% (1)

- Post-Top Pole DesignDocument1 pagePost-Top Pole DesignManoranjan ONo ratings yet

- 0620 Chemistry: MARK SCHEME For The May/June 2010 Question Paper For The Guidance of TeachersDocument6 pages0620 Chemistry: MARK SCHEME For The May/June 2010 Question Paper For The Guidance of TeachersVarun PanickerNo ratings yet

- Barfell Catalogue 2016Document28 pagesBarfell Catalogue 2016Luke FosterNo ratings yet

- Astm B695 - 2021Document6 pagesAstm B695 - 2021Danny TriwibowoNo ratings yet

- Hydrogen Reduction of Metals: Thermodynamic PossibilitiesDocument6 pagesHydrogen Reduction of Metals: Thermodynamic PossibilitiesGus AcevedoNo ratings yet

- Adobe Scan Aug 17, 2023Document3 pagesAdobe Scan Aug 17, 2023gulatisrishti15No ratings yet

- VDF flooring technical specificationDocument9 pagesVDF flooring technical specificationBasava NNo ratings yet