Professional Documents

Culture Documents

6D1l 5

Uploaded by

Jasm LiuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6D1l 5

Uploaded by

Jasm LiuCopyright:

Available Formats

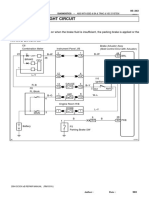

ON-VEHICLE INSPECTION AND ADJUSTMENT

1. Measuring Compression Pressure

Service standards

Location Maintenance item Standard value Limit Remedy

- Compression Each cylinder {26-30 kgf/cm2} 2940 1960 kPa {20 kgf/cm2} Inspect

pressure (at 200 rpm)

Cylinder-to-cylinder pressure difference - 390 kPa {4 k�f/cm2} Inspect

lf] Special tools Unit: mm

Location Tool name and shape Part No. Application

Compression MH061461 Measuring compression pressure

Gauge Adapter

Centre distance 46 01942

Reductions in compression pressure should be used as a guide in determining the timing of engine overhauls. Take mea

surements regularly and keep track of changes; an overview of pressure variations can be useful in fault diagnosis.

During the engine's run-in period and after parts have been replaced, the compression pressure will increase slightly as

piston rings, valve seats,- and other parts fit snugly in position. T he pressure will then normalize as parts wear.

• Before inspections, check that the engine oil, starter, and battery are normal.

• Warm up the engine until the coolant temperature reaches 75 to 85°C.

• Turn off all lights and auxiliary devices.

• To prevent injection of fuel while cranking the engine by the starter, perform the following steps.

• Set the stop lever of the injection pump governor to the stop position. <Mechanical governor>

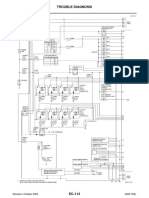

• Remove fuse 1 shown in the diagram below. For the terminal arrangement of the engine ECU, refer to Gr. 13E. <Elec

tronic governor>

Starter SW

OFF

ACC 1

ON

START

Engine ECU

STARTER SW S 03

STARTER SW(M)-1

CB

ECU main power relay STARTER SW(Ml-2

C?

l--- 1 MAIN RELAY-1

DB

MAIN RELAY-2

013

Battery ECU POWE +VB -1

::!J

Dl

relay I•.

ECU POWER +VB)-2

02

Battery

®47396

11-8

You might also like

- DTC 14 Timing Control System Malfunction: Circuit DescriptionDocument3 pagesDTC 14 Timing Control System Malfunction: Circuit DescriptionFerry DarmawanNo ratings yet

- Starting Ignition SystemDocument20 pagesStarting Ignition SystemkavehNo ratings yet

- Hino Engine Harness For Test RunDocument5 pagesHino Engine Harness For Test RunPHÁT NGUYỄN THẾNo ratings yet

- M Di 0145 PDFDocument4 pagesM Di 0145 PDFJuanCarlosCastilloNo ratings yet

- Codigo de FallaDocument5 pagesCodigo de FallaMarco Yarasca RomeroNo ratings yet

- Charging System PDFDocument19 pagesCharging System PDFSSEVERAiTJUGANo ratings yet

- Trouble Diagnosis Circuit Diagram: Revision: October 2004 2005 TitanDocument10 pagesTrouble Diagnosis Circuit Diagram: Revision: October 2004 2005 TitanDavid QuispeNo ratings yet

- ECU Common Rail System For HINO Dutro-ToYOTA Dyna N04C-TDocument7 pagesECU Common Rail System For HINO Dutro-ToYOTA Dyna N04C-Tkidskung75% (8)

- f24 English 406 Ec 0549Document1 pagef24 English 406 Ec 0549Arkady GrandsonNo ratings yet

- Esquema InversorDocument18 pagesEsquema Inversorx3roNo ratings yet

- F. 99500-92J00-01E - DF115A - DF140A (SN. 61000 - ) - Engine ControlDocument27 pagesF. 99500-92J00-01E - DF115A - DF140A (SN. 61000 - ) - Engine ControlAlan PriceNo ratings yet

- Service Bulletin: Limited DistributionDocument7 pagesService Bulletin: Limited DistributionFabri Di MonacoNo ratings yet

- M1507: 2014-2020 Sportster - Low/No Charging Diagnostics: Reason For Revision Motorcycles AffectedDocument3 pagesM1507: 2014-2020 Sportster - Low/No Charging Diagnostics: Reason For Revision Motorcycles AffectedIgor LukNo ratings yet

- DTC P0505 Idle Control System Malfunction: Circuit DescriptionDocument5 pagesDTC P0505 Idle Control System Malfunction: Circuit DescriptionwilliamNo ratings yet

- Laptek Breaker MCCDocument2 pagesLaptek Breaker MCCenergiprimer.sintangNo ratings yet

- Electrical: Section 2C - Timing, Synchronizing & AdjustingDocument4 pagesElectrical: Section 2C - Timing, Synchronizing & AdjustingDr. Centelha Mecânica NaúticaNo ratings yet

- B11 Starting System/Charging System: To IndexDocument6 pagesB11 Starting System/Charging System: To Indexwei fooNo ratings yet

- Application Tip: Using 2 Paralleling OptionDocument3 pagesApplication Tip: Using 2 Paralleling OptionMohamed MeeranNo ratings yet

- DTC 32 Injection Pump Correction System Malfunc-Tion: Circuit DescriptionDocument2 pagesDTC 32 Injection Pump Correction System Malfunc-Tion: Circuit DescriptionsundarNo ratings yet

- Engine ControlDocument2 pagesEngine ControlKale GuleNo ratings yet

- TCD4281DNDDocument14 pagesTCD4281DNDPierina AstudilloNo ratings yet

- Date: Experiment - 2 To Study The Operation of Controlled Rectifier Fed Separately Excited DC Motor DriveDocument5 pagesDate: Experiment - 2 To Study The Operation of Controlled Rectifier Fed Separately Excited DC Motor DriveDaksh SharmaNo ratings yet

- Yaskawa L1000ADocument247 pagesYaskawa L1000Arendy kurniawanNo ratings yet

- Acs 01Document12 pagesAcs 01satya prakashNo ratings yet

- CMP Sensor-01-01Document3 pagesCMP Sensor-01-01oretuertoyanapaNo ratings yet

- Technical Service Information: Lincoln Ls 5R55SDocument6 pagesTechnical Service Information: Lincoln Ls 5R55SPlanta Damiana2No ratings yet

- Fuel Pressure ControlDocument4 pagesFuel Pressure ControlSirleh SalehNo ratings yet

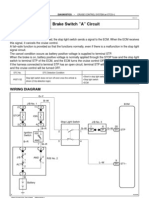

- DTC P0571/52 Brake Switch "A" CircuitDocument4 pagesDTC P0571/52 Brake Switch "A" CircuitErln LimaNo ratings yet

- Service Bulletin: Fuel Injection PumpDocument14 pagesService Bulletin: Fuel Injection PumpKrunoslav100% (1)

- P 200 eDocument65 pagesP 200 eRafael ZuletaNo ratings yet

- DTC 14 Timing Control System Malfunction: Circuit DescriptionDocument3 pagesDTC 14 Timing Control System Malfunction: Circuit DescriptionFerry Darmawan100% (1)

- Skoda Workshop Manuals Fabia Mk2 Engine 1-6-77 KW MPI Engine Engine CyliDocument6 pagesSkoda Workshop Manuals Fabia Mk2 Engine 1-6-77 KW MPI Engine Engine CyliBezzaouya MustaphaNo ratings yet

- Power Steering Pressure SensorDocument2 pagesPower Steering Pressure SensorDaniel Mamani ParedezNo ratings yet

- ၄၆၀engine control systemDocument14 pages၄၆၀engine control systemkogyi.tty987No ratings yet

- Motor Operated Valve List, Datasheet and Drawings: Enersur S.ADocument50 pagesMotor Operated Valve List, Datasheet and Drawings: Enersur S.AJuan ShunaNo ratings yet

- As Shipped 9KS Prefix (Starboard)Document3 pagesAs Shipped 9KS Prefix (Starboard)Muhammad Ary safartaNo ratings yet

- Consew CSM1000 Motor ControllerDocument3 pagesConsew CSM1000 Motor ControllerJose Eduardo Vargas AngaritaNo ratings yet

- StarterDocument1 pageStarterDuy KhaNo ratings yet

- EV1 SCR Motor ControllerDocument32 pagesEV1 SCR Motor ControllerJShearer95% (20)

- Starting System: Differ From The Above Listed ManualDocument6 pagesStarting System: Differ From The Above Listed ManualDavid QuispeNo ratings yet

- C 7 ENGINE APU (ATA 49,71,72,73,74,75,76,77,79,80) MumbaiDocument2 pagesC 7 ENGINE APU (ATA 49,71,72,73,74,75,76,77,79,80) Mumbaiarun RajannaNo ratings yet

- Yd AcceleratorDocument5 pagesYd AcceleratorRomeo HinogNo ratings yet

- New Holland Engines F4be0454b F4be0484d F4be0484e F4be0684b Repair ManualDocument20 pagesNew Holland Engines F4be0454b F4be0484d F4be0484e F4be0684b Repair Manualpatricia100% (35)

- Ergo Mover 600AC Service Manual 212892-040Document50 pagesErgo Mover 600AC Service Manual 212892-040TotalNo ratings yet

- SM F4BE-IVECO EN PDFDocument209 pagesSM F4BE-IVECO EN PDFjulianmata67% (3)

- Power Factor Corrector: 1 FeaturesDocument13 pagesPower Factor Corrector: 1 Featuresdeilyn rivasNo ratings yet

- ST PDFDocument23 pagesST PDFzeroNo ratings yet

- Addendum For L1000A Technical Manual: Yaskawa Europe GMBH 1Document89 pagesAddendum For L1000A Technical Manual: Yaskawa Europe GMBH 1m.alfarez87gmail.comNo ratings yet

- Trans-Amf Eng Short V48Document29 pagesTrans-Amf Eng Short V48ABMOHENo ratings yet

- Final Consolidated Expts-18eel46Document55 pagesFinal Consolidated Expts-18eel46AshwiniNo ratings yet

- Ecm 1 CDocument1 pageEcm 1 CJim LiebNo ratings yet

- Service Bulletin: Fuel Injection PumpDocument15 pagesService Bulletin: Fuel Injection PumpKrunoslavNo ratings yet

- Light Control Switch Circuit: Wiring DiagramDocument3 pagesLight Control Switch Circuit: Wiring DiagramPhang KumwingNo ratings yet

- TLE4905L Siemens Elenota - PLDocument15 pagesTLE4905L Siemens Elenota - PLボロウスキ グジェゴジNo ratings yet

- Bullet Classic EfiDocument220 pagesBullet Classic EfiGS MeenaNo ratings yet

- Brake Warning Light CircuitDocument4 pagesBrake Warning Light CircuitDannyDDannyDNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 6D1l 6Document1 page6D1l 6Jasm LiuNo ratings yet

- 6D1l 2Document1 page6D1l 2Jasm LiuNo ratings yet

- Allison Transmission HD4060 Operator Manual 24Document1 pageAllison Transmission HD4060 Operator Manual 24Jasm LiuNo ratings yet

- Allison Transmission HD4060 Operator Manual 23Document1 pageAllison Transmission HD4060 Operator Manual 23Jasm LiuNo ratings yet

- Lec 17Document27 pagesLec 17durgesh patelNo ratings yet

- Pressure Test Plan FormDocument1 pagePressure Test Plan FormAsia BelmontNo ratings yet

- Steam Tables PDFDocument16 pagesSteam Tables PDFMarcus Clarke100% (2)

- Edward Cudahy and Stephen Parvin - The Effects of Underwater Blast On DiversDocument64 pagesEdward Cudahy and Stephen Parvin - The Effects of Underwater Blast On DiversMallamaxNo ratings yet

- 3PBO-M: Oil-Lubricated Rotary Vane Vacuum PumpDocument2 pages3PBO-M: Oil-Lubricated Rotary Vane Vacuum PumpAir-center CompresoresNo ratings yet

- Calculation of A Box Culvert: Data Ǿ (Ton/m )Document5 pagesCalculation of A Box Culvert: Data Ǿ (Ton/m )sidiq7No ratings yet

- Fluidized BedDocument10 pagesFluidized BedRafique Ahmed AbroNo ratings yet

- Thermal Stress Analysis For A Disk Brake of Railway Vehicles With Consideration of The Pressure Distribution On A Frictional SurfaceDocument4 pagesThermal Stress Analysis For A Disk Brake of Railway Vehicles With Consideration of The Pressure Distribution On A Frictional SurfaceÖmer Faruk TürkNo ratings yet

- Pressure Relief System DesignDocument6 pagesPressure Relief System Designahsan8880% (1)

- Anemometrul Testo 425-EnDocument30 pagesAnemometrul Testo 425-EnLuca CristianNo ratings yet

- Gce o Level Physics Questions Faq 2013Document12 pagesGce o Level Physics Questions Faq 2013api-235555080No ratings yet

- Best Practice For Isolation - Hydrocarbon EquipmentDocument45 pagesBest Practice For Isolation - Hydrocarbon EquipmentvictorvikramNo ratings yet

- Operation Manual: For XP2i Digital Test Gauge (Standard and Dual-Display (DD) )Document42 pagesOperation Manual: For XP2i Digital Test Gauge (Standard and Dual-Display (DD) )Jaime Antonio Cruz RojasNo ratings yet

- Chemical and Petroleum Engineering DepartmentDocument55 pagesChemical and Petroleum Engineering DepartmentSiraj AL sharifNo ratings yet

- Skirt Support DesignDocument8 pagesSkirt Support Designimrancenakk100% (2)

- Orifice Bore Calculation Specification Form: Orifice Plate Data SheetDocument1 pageOrifice Bore Calculation Specification Form: Orifice Plate Data Sheetsmartaps123No ratings yet

- Submarine DesignDocument70 pagesSubmarine DesignMohd Idris MohiuddinNo ratings yet

- Atlantis Product CatalogDocument9 pagesAtlantis Product CatalogNeo DacanayNo ratings yet

- Corrosiveness To Copper From Petroleum Products by Copper Strip TestDocument10 pagesCorrosiveness To Copper From Petroleum Products by Copper Strip TesteliiiiiiNo ratings yet

- Saep 57 PDFDocument30 pagesSaep 57 PDFRami ElloumiNo ratings yet

- Asme PTC 1986Document4 pagesAsme PTC 1986AmalAhmed0% (1)

- CMMV 301121 F1976 01Document4 pagesCMMV 301121 F1976 01MarcosRyloNo ratings yet

- Reservoir Eng Labsheet - 2019Document39 pagesReservoir Eng Labsheet - 2019Albert ChongNo ratings yet

- Engineering Action Request Form EPSDocument5 pagesEngineering Action Request Form EPSDomingo DiazNo ratings yet

- Sealing Tubular ConnectionsDocument11 pagesSealing Tubular Connectionssufregs100% (2)

- Lec.2 Mass Transfer PDFDocument18 pagesLec.2 Mass Transfer PDFاحمد حمید کارسول عزیزNo ratings yet

- En-DTR CMK-02Document51 pagesEn-DTR CMK-02Henry MaedaNo ratings yet

- UL-142 R912 Installation InstructionsDocument4 pagesUL-142 R912 Installation InstructionsRodrigoNo ratings yet

- Instructions: Each Question Is Followed by Four Possible Answers A, B, C and D. Choose The Correct AnswerDocument8 pagesInstructions: Each Question Is Followed by Four Possible Answers A, B, C and D. Choose The Correct AnswerZ'karia Al Ayi-zNo ratings yet

- 2010 1053 r05 Summary ReportDocument42 pages2010 1053 r05 Summary ReportNguyễn Văn BanNo ratings yet