Professional Documents

Culture Documents

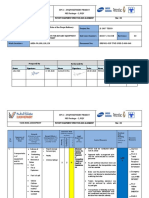

Load Out Hazid

Uploaded by

Shirley G. LeónOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Load Out Hazid

Uploaded by

Shirley G. LeónCopyright:

Available Formats

RECOMMENDED

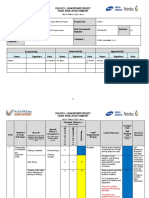

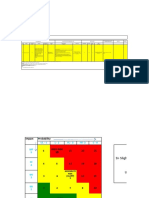

RESIDUAL

HAZARD CURRENT CONTROL INITIAL CONTROL DUE Action Action Action

Node # Task GUIDEWORDS ID# CAUSAL FACTORS POTENTIAL CONSEQUENCE RISK COMMENTS

DESCRIPTION MEASURES RISK (Use HAZARD Control DATE Group Owner Closed

Hierarchy)

a).- Bad weather conditions (Lightning,

Lack of weather forecast monitoring

hurricanes) b).-

Personal Injury / illness

Flying debris c).- 1. Daily monitoring of the weather forecast by

Wheater 1 Personnel not informed (lack of awareness)

Strong wind d).- the SMN (National Meteorological System)

Property Damage

High temperatures

Lack of housekeeping

e).- Rise or fall in sea level

Lack of maintenance program 1. Review in advance the maintenance

program carried out on the equipment to be

Lack of Program Maintenance

2.1 Pre-Operations ( Preparations )

Inadequate spare parts Personal Injury/Illness used.

Maintenance of Strand Jack

2

Set's Lack of completion and inspection

Previous repairs without spare parts and/or Damage to own property and third parties 2. Physically check the equipment through the

before use.

adequate equipment check list both in Fagioli facilities and in the

field.

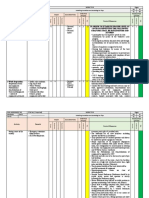

Personnel not trained for such tasks 1. A safety exclusion zone must be defined

Lack of competence/experience of personal

for any maneuver to prevent unauthorized

entry and minimize the risk of personnel

Lack of spotters when needed

exposure.

2. Staff competency certificates

Unauthorized personnel in the unloading area

3. Trained observers available

4. Drug and alcohol detection test for

Violation of Drug and Alcohol Policy

personnel to intervene in each of the

Inexperienced/non-competent staff

maneuvers before starting the load. (verify

Unreported health condition

test availability)

substance abuse Personal Injury/Illness

5. Operators must report any health condition

Personnel 3 Inadequate Communication

or existing medical treatment.

Pre-existing health condition Damage to own property and third parties

6. Carry out the daily Tool Box Meeting before

distracted staff

starting operations

Injury to oneself and/or to third parties

7. Stop Work Authority Policy

Personnel carrying out activities outside their work

8. On-site medical assistance

area

9. Emergency Response Man

10. Barricade in the Barge

Lack of attention to the activity carried out

11. The maneuver supervisor is always

present to formalize the operations

Staff playing games or pranks on other

12. Personnel committed to the company and

colleagues

to the security objectives of the company and

1. Application of Environmental Practices

2. Documented inspections at all times by a

person in charge of the ecological area.

3. Updated maintenance schedule

4. Ethically responsible personnel

Lack of communication

Liquid spill contamination Personnel Injury 5. Specialized personnel for the proper

Operation and Maintenance of Mechanical

Lack of environmental deforestation and

Pollution from environmental Property Damage Equipment and Machinery (Various)

reforestation program

Environmental Damage 1 deforestation 6. Daily Check List in each activity.

Downtime 7. Use of radios between crane operators and

Lack of maintenance program

Damage to terrestrial and marine riggers

wildlife Environmental 8. Analysis of the bearing capacity of the area

Lack of human awareness

9. SPMT back-up and spill kits available on

site

10. Established program for affectation of

green areas and recovery of local flora and

fauna.

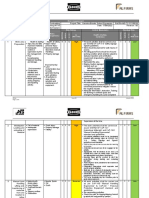

1. A safety exclusion zone must be defined

Lack of competence/experience of operator and for any maneuver to prevent unauthorized

riggers entry and minimize the risk of personnel

exposure.

Lack of spotters when needed 2. Staff competency certificates

3. Trained observers available

2.2 Assembly of Strand Jack Set's Equipment

Unauthorized personnel in the unloading area 4. Drug and alcohol detection test for

personnel to intervene in each of the

Violation of Drug and Alcohol Policy maneuvers before starting the load. (verify

Inexperienced/non-competent staff

test availability)

Unreported health condition 5. Operators must report any health condition

substance abuse Personal Injury/Illness

or existing medical treatment.

Personnel 2

Inadequate Communication 6. Carry out the daily Tool Box Meeting before

Pre-existing health condition Damage to own property and third parties

starting operations

distracted staff 7. Stop Work Authority Policy

Injury to oneself and/or to third parties

8. On-site medical assistance

Personnel carrying out activities outside their work 9. Emergency Response Man

area 10. Barricade in the Barge

11. The maneuver supervisor is always

Lack of attention to the activity carried out present to formalize the operations

12. Personnel committed to the company and

Staff playing games or pranks on other to the security objectives of the company and

colleagues the client.

13. Pay full attention to the activities to be

1. A safety exclusion zone must be defined

for any maneuver to prevent unauthorized

entry and minimize the risk of personnel

exposure.

2. Certificates of competence of certified

personnel and equipment

3. Trained observers available

4. Drug and alcohol detection test for the

personnel that will intervene in each of the

Equipment and spare parts in poor

maneuvers before starting the load. (check

condition Lack of maintenance program

test availability)

5. Operators must report any existing health

damaged equipment Lack of documentation such as the certification

condition or medical treatment.

issued

6. Hold the daily Tool Box Meeting before

Equipment, spare parts and material Personal Injury/Illness

starting operations

Equipment 3 not suitable for operations Lack of human conscience.

7. Stop Work Authority Policy

Damage to own property and third parties

8. On-site medical assistance

non-certified equipment Lack of trained personnel

9. Emergency Response Man

10. Workplace Barricade

Misaligned Strand Jack Assembly Lack of engineering for the Strand jack assembly

11. The maneuver supervisor is always

at its bases

present to formalize the operations

Unsuitable Strand Jack base structure

12. Personnel committed to the company and

to the security objectives of the company and

the client.

13. Current maintenance schedule

14. Daily and available check list

15. Immediate attention to any mechanical,

hydraulic, electrical and/or electronic failure.

16. Safe handling of materials and equipment

17. All the structural bases for the assembly

1. Application of Environmental Practices

2. Documented inspections at all times by a

person in charge of the ecological area.

2.- JACKET LOAD OUT ( STRAND JACK )

3. Updated maintenance schedule

Lack of communication 4. Ethically responsible personnel

Liquid spill contamination Personnel Injury

5. Specialized personnel for the proper

Lack of environmental deforestation and Operation and Maintenance of Mechanical

Pollution from environmental Property Damage

reforestation program Equipment and Machinery (Various)

Environmental Damage 1 deforestation

6. Daily Check List in each activity.

Downtime

Lack of maintenance program 7. Use of radios between crane operators and

Damage to terrestrial and marine

riggers

wildlife Environmental

Lack of human awareness 8. Analysis of the bearing capacity of the area

9. Sspill kits available on site

10. Established program for affectation of

green areas and recovery of local flora and

fauna.

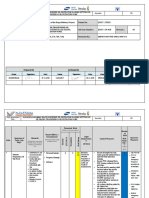

Lack of competence/experience of operator and 1. A safety exclusion zone must be defined

riggers for any maneuver to prevent unauthorized

entry and minimize the risk of personnel

Lack of spotters when needed exposure.

2. Staff competency certificates

Unauthorized personnel in the unloading area 3. Trained observers available

4. Drug and alcohol detection test for

Violation of Drug and Alcohol Policy personnel to intervene in each of the

maneuvers before starting the load. (verify

Inexperienced/non-competent staff

Unreported health condition Personal injuries / test availability)

disease 5. Operators must report any health condition

substance abuse

Inadequate Communication or existing medical treatment.

Personnel 2

Damage to own property and third parties 6. Carry out the daily Tool Box Meeting before

Pre-existing health condition

distracted staff starting operations

2.3 Operations

delayed programming 7. Stop Work Authority Policy

Injury to oneself and/or to third parties

Personnel carrying out activities outside their work 8. On-site medical assistance

area 9. Emergency Response Man

10. Barricade in the Barge

Lack of attention and planning to the activity 11. The maneuver supervisor is always

carried out present to formalize the operations

12. Personnel committed to the company and

Staff playing games or pranks on other to the security objectives of the company and

colleagues the client.

13. Pay full attention to the activities to be

1. A safety exclusion zone must be defined

for any maneuver to prevent unauthorized

entry and minimize the risk of personnel

exposure.

2. Certificates of competence of certified

personnel and equipment

3. Trained observers available

4. Drug and alcohol detection test for the

Equipment and spare parts in poor personnel that will intervene in each of the

Lack of maintenance program

condition maneuvers before starting the load. (check

test availability)

Lack of documentation such as the certification

Damaged equipment Personal injuries / 5. Operators must report any existing health

issued

disease condition or medical treatment.

Equipment, spare parts and material 6. Hold the daily Tool Box Meeting before

Equipment 3 Lack of human conscience.

not suitable for operations Damage to own property and third parties starting operations

7. Stop Work Authority Policy

Lack of trained personnel

non-certified equipment delayed programming 8. On-site medical assistance

9. Emergency Response Man

Radio communication equipment in poor

Blind spots unknown 10. Barricade at the job site

condition

poor communication 11. The maneuver supervisor is always

present to formalize the operations

12. Personnel committed to the company and

to the security objectives of the company and

the client.

13. Current maintenance schedule

14. Daily and available check list

15. Immediate attention to any mechanical,

hydraulic, electrical and/or electronic failure.

1. Application of Environmental Practices

2. Documented inspections at all times by a

person in charge of the ecological area.

3. Updated maintenance schedule

4. Ethically responsible personnel

Lack of communication

Liquid spill contamination Personnel Injury 5. Specialized personnel for the proper

Operation and Maintenance of Mechanical

Lack of environmental deforestation and

Pollution from environmental Property Damage Equipment and Machinery (Various)

reforestation program

Environmental Damage 1 deforestation 6. Daily Check List in each activity.

Downtime 7. Use of radios between crane operators and

Lack of maintenance program

Damage to terrestrial and marine riggers

wildlife Environmental 8. Analysis of the bearing capacity of the area

Lack of human awareness

9. SPMT back-up and spill kits available on

site

10. Established program for affectation of

green areas and recovery of local flora and

fauna.

1. A safety exclusion zone must be defined

Lack of competence/experience of operator and for any maneuver to prevent unauthorized

riggers entry and minimize the risk of personnel

exposure.

2.4 Disassembly of Strand Jack Set's Equipment

Lack of spotters when needed 2. Staff competency certificates

3. Trained observers available

Unauthorized personnel in the unloading area 4. Drug and alcohol detection test for

personnel to intervene in each of the

Violation of Drug and Alcohol Policy maneuvers before starting the load. (verify

Inexperienced/non-competent staff

test availability)

Unreported health condition 5. Operators must report any health condition

substance abuse Personal Injury/Illness

or existing medical treatment.

Personnel 2

Inadequate Communication 6. Carry out the daily Tool Box Meeting before

Pre-existing health condition Damage to own property and third parties

starting operations

distracted staff 7. Stop Work Authority Policy

Injury to oneself and/or to third parties

8. On-site medical assistance

Personnel carrying out activities outside their work 9. Emergency Response Man

area 10. Barricade in the Barge

11. The maneuver supervisor is always

Lack of attention to the activity carried out present to formalize the operations

12. Personnel committed to the company and

Staff playing games or pranks on other to the security objectives of the company and

colleagues the client.

13. Pay full attention to the activities to be

1. A safety exclusion zone must be defined

for any maneuver to prevent unauthorized

entry and minimize the risk of personnel

exposure.

2. Certificates of competence of certified

personnel and equipment

3. Trained observers available

4. Drug and alcohol detection test for the

personnel that will intervene in each of the

Equipment and spare parts in poor maneuvers before starting the load. (check

Lack of Maintenance Program

condition test availability)

5. Operators must report any existing health

Lack of documentation such as the released

Damaged equipment Personal Injury/Illness condition or medical treatment.

certification

Equipment 3 6. Hold the daily Tool Box Meeting before

Equipment, spare parts and material Damage to own property and third parties starting operations

Lack of human awareness

not suitable for operations 7. Stop Work Authority Policy

8. On-site medical assistance

Lack of trained personnel

non-certified equipment 9. Emergency Response Man

10. Barricade at the job site

11. The maneuver supervisor is always

present to formalize the operations

12. Personnel committed to the company and

to the security objectives of the company and

the client.

13. Current maintenance schedule

14. Daily and available check list

15. Immediate attention to any mechanical,

You might also like

- Prepared HIRA for reference, Coke Oven, BPPDocument8 pagesPrepared HIRA for reference, Coke Oven, BPPvikram.knNo ratings yet

- HIRA FormatDocument7 pagesHIRA Formatvikram.knNo ratings yet

- Important Risk Assessment of Wind FarmDocument3 pagesImportant Risk Assessment of Wind FarmRaza Muhammad SoomroNo ratings yet

- COVID-19 Risk Assesment For NCCCLDocument3 pagesCOVID-19 Risk Assesment For NCCCLmohit100% (2)

- HIRA WORK SHEET Blasting and Painting.Document10 pagesHIRA WORK SHEET Blasting and Painting.Madhu Electricals & Engineering100% (2)

- 2.1_RISK_ASSESMENT_TABLE_ELE-LPS_and_Earthing[1]Document3 pages2.1_RISK_ASSESMENT_TABLE_ELE-LPS_and_Earthing[1]nanthan06No ratings yet

- Aspect-Impact/ Hira Registry: Ccbpi Davao Plant EnvironmentDocument4 pagesAspect-Impact/ Hira Registry: Ccbpi Davao Plant EnvironmentRafhael EspinosaNo ratings yet

- Hazards Identification and Risk Assessment - New FormatDocument2 pagesHazards Identification and Risk Assessment - New FormatBIIS QAQC Babu Siva100% (1)

- TRA FOR FRT - Rev.S2-2 (Recovered)Document31 pagesTRA FOR FRT - Rev.S2-2 (Recovered)rodman823No ratings yet

- Risk Assessment and Prevention Plan for COVID-19Document3 pagesRisk Assessment and Prevention Plan for COVID-19Adhavan M AnnathuraiNo ratings yet

- Risk Assessment: Camp and Site Activities Affected by Covid-19 OutbreakDocument7 pagesRisk Assessment: Camp and Site Activities Affected by Covid-19 OutbreakJay PrasanthNo ratings yet

- ACTIVITY DESCRIPTION: TRANSITION DUCT LIFTINGDocument3 pagesACTIVITY DESCRIPTION: TRANSITION DUCT LIFTINGAnıl AKÇANo ratings yet

- 4.HIRARC Cable Trench-Rev0.4Document5 pages4.HIRARC Cable Trench-Rev0.4fatimah beluhiNo ratings yet

- Task Risk Assessment For Sandblasting and Painting of Sheets SpoolsDocument3 pagesTask Risk Assessment For Sandblasting and Painting of Sheets SpoolsAftab Qadir100% (1)

- Hazard Identification Risk Assessment Risk Control (HIRARC) - Lighting InstallationDocument3 pagesHazard Identification Risk Assessment Risk Control (HIRARC) - Lighting InstallationYasHie PwincsZaNo ratings yet

- Hiradc ProduksiDocument156 pagesHiradc ProduksiNur AisyahNo ratings yet

- Drilling & Blasting: Format No.: F 01 15 01, Rev. 05, Rev. Date:-10. 02. 2009 4Document4 pagesDrilling & Blasting: Format No.: F 01 15 01, Rev. 05, Rev. Date:-10. 02. 2009 4Bhagat DeepakNo ratings yet

- Risk Assessment For InsulationDocument9 pagesRisk Assessment For InsulationSaleem Akhtar75% (8)

- RA - SandblastingDocument2 pagesRA - Sandblasting721917114 47No ratings yet

- Bow Tie - CTW and Isolation Failure 6.6.17Document15 pagesBow Tie - CTW and Isolation Failure 6.6.17joseNo ratings yet

- Hse Risk Assessment For Civil Works, Isolators and Duct InstallationDocument6 pagesHse Risk Assessment For Civil Works, Isolators and Duct Installationvenkatesh snkNo ratings yet

- Risk Assessment - Fire Pump SetDocument8 pagesRisk Assessment - Fire Pump SetJhOichriz Reginaldo CuevasNo ratings yet

- HIRA For Mech Work SalcompDocument3 pagesHIRA For Mech Work SalcompNaveenNo ratings yet

- Transformer Oil Filtration Risk AssessmentDocument21 pagesTransformer Oil Filtration Risk AssessmentBenasher IbrahimNo ratings yet

- HIRADC - 004 - Temporary Facilities & Site CabinDocument4 pagesHIRADC - 004 - Temporary Facilities & Site CabinZhafri SyazwiNo ratings yet

- EHS JSA Form for ContractorsDocument1 pageEHS JSA Form for ContractorsIwan RayaNo ratings yet

- Final HiraDocument39 pagesFinal HiraAnsari HarisNo ratings yet

- Copper 09 Winter Trail MapDocument2 pagesCopper 09 Winter Trail Mapapi-12697835No ratings yet

- Risk Assessment - Plumbing Pump SetDocument8 pagesRisk Assessment - Plumbing Pump SetJhOichriz Reginaldo Cuevas100% (1)

- HSE Risk Assessment To The Activity of Welding Cutting & GrindingDocument2 pagesHSE Risk Assessment To The Activity of Welding Cutting & GrindingAbid Rehman100% (1)

- Hira Interior Activities - RevisedDocument148 pagesHira Interior Activities - Revisedassac5741No ratings yet

- Living in Camp Accommodation RA-R9-01-010-01Document1 pageLiving in Camp Accommodation RA-R9-01-010-01cmrig74No ratings yet

- Risk Assessment - Installation of Air-Cooled ChillersDocument4 pagesRisk Assessment - Installation of Air-Cooled ChillersBabar ShehzadNo ratings yet

- HSE risk assessment for deluge foam systemDocument7 pagesHSE risk assessment for deluge foam systemnathisonsNo ratings yet

- CM00-CS03-CEG-ARC-DWG-030001-COVER PAGE (Life Safety)Document1 pageCM00-CS03-CEG-ARC-DWG-030001-COVER PAGE (Life Safety)AjmeerNo ratings yet

- Risk AssessmentDocument3 pagesRisk Assessmentsecretthing.6No ratings yet

- Risk Assessment - Hvac SystemDocument8 pagesRisk Assessment - Hvac SystemJhOichriz Reginaldo CuevasNo ratings yet

- HIRA - Hydro TestDocument3 pagesHIRA - Hydro TestHiralal PattanayakNo ratings yet

- HSE Risk Assessment To The Activity of Welding Cutting & Grinding Inside Storage TanDocument3 pagesHSE Risk Assessment To The Activity of Welding Cutting & Grinding Inside Storage TanAndi BuswanNo ratings yet

- JohanDocument1 pageJohanEstmarg EstmargNo ratings yet

- Risk Assessment SummaryDocument8 pagesRisk Assessment SummaryJhOichriz Reginaldo CuevasNo ratings yet

- Job Safety Analysis (Jsa) N2.Document5 pagesJob Safety Analysis (Jsa) N2.Joseph Paul IlaganNo ratings yet

- Provision of Hoists Services Risk AssessmentDocument4 pagesProvision of Hoists Services Risk AssessmentBlister PatchNo ratings yet

- TRA - Rotary Equipment ErectionDocument29 pagesTRA - Rotary Equipment ErectionBenasher IbrahimNo ratings yet

- 1726 Beyond Resiliency Fitzgerald DNV-GLDocument15 pages1726 Beyond Resiliency Fitzgerald DNV-GLYasmein OkourNo ratings yet

- Standing operation process disaster response diagramDocument3 pagesStanding operation process disaster response diagramXuyen LeNgocNo ratings yet

- Risk assessment and control measures for work at height operationsDocument1 pageRisk assessment and control measures for work at height operationsdnmuleNo ratings yet

- Ergonomics Risk MatrixDocument31 pagesErgonomics Risk Matrixvacky77No ratings yet

- Hazard Identification, Risk Assessment and Risk Control FormDocument1 pageHazard Identification, Risk Assessment and Risk Control Formusman4428No ratings yet

- RISK ASSESSMENT COVID-19 - Edit - 1645265605593 - Edit - 1645265644305Document11 pagesRISK ASSESSMENT COVID-19 - Edit - 1645265605593 - Edit - 1645265644305Ansar0% (1)

- Excavation Trenching & Pipe Laying R-ADocument18 pagesExcavation Trenching & Pipe Laying R-ANabil Abdelsamea100% (1)

- HiraDocument44 pagesHirasuresh kumarNo ratings yet

- Lim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMDocument2 pagesLim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMVaradaraju ThirunavukkarasanNo ratings yet

- Inform Epidemic p2p Risk Index 2020Document183 pagesInform Epidemic p2p Risk Index 2020Vadim Koz Jr.No ratings yet

- Insulation Works For Heat ExchangerDocument3 pagesInsulation Works For Heat ExchangerVenodaren VelusamyNo ratings yet

- Conducting Drop Object Inspection - RA-R9-01-017-01Document1 pageConducting Drop Object Inspection - RA-R9-01-017-01cmrig74No ratings yet

- Risk Assessment - SanitarywaresDocument9 pagesRisk Assessment - SanitarywaresJhOichriz Reginaldo CuevasNo ratings yet

- Hira HousekeepingDocument1 pageHira Housekeepingspst03792No ratings yet

- Kalokal Barangay Highway HillsDocument35 pagesKalokal Barangay Highway HillsDixie MirandaNo ratings yet

- Preface: What Is Financial Intelligence?Document4 pagesPreface: What Is Financial Intelligence?Iuliana GondosNo ratings yet

- Toaz - Info Module in Ergonomics and Planning Facilities For The Hospitality Industry PRDocument33 pagesToaz - Info Module in Ergonomics and Planning Facilities For The Hospitality Industry PRma celine villoNo ratings yet

- CIO Executive SummaryDocument8 pagesCIO Executive SummaryResumeBearNo ratings yet

- Fatigue Analysis of Sundry I.C Engine Connecting Rods: SciencedirectDocument7 pagesFatigue Analysis of Sundry I.C Engine Connecting Rods: SciencedirectAshwin MisraNo ratings yet

- GitHub TrainingDocument21 pagesGitHub Trainingcyberfox786No ratings yet

- George Washington's Presidency NotesDocument5 pagesGeorge Washington's Presidency Notesf kNo ratings yet

- PSE Archery2015 RecurveDocument10 pagesPSE Archery2015 RecurvecarlheindlNo ratings yet

- IC Release Management Checklist TemplateDocument5 pagesIC Release Management Checklist Templatepasc colcheteNo ratings yet

- Houghton Mifflin Harcourt Sap Document of UnderstandingDocument10 pagesHoughton Mifflin Harcourt Sap Document of UnderstandingSunil KumarNo ratings yet

- Acute AppendicitisDocument51 pagesAcute AppendicitisPauloCostaNo ratings yet

- Modern History Notes (Sample Notes For JPSC Mains Exam)Document21 pagesModern History Notes (Sample Notes For JPSC Mains Exam)Ijhar AhmadNo ratings yet

- Zara Marketing Mix Four PsDocument3 pagesZara Marketing Mix Four PsHaniyeh ShojaeiNo ratings yet

- Land Sale Dispute Interest Rate CaseDocument3 pagesLand Sale Dispute Interest Rate CaseAnne MiguelNo ratings yet

- Table 141: India'S Overall Balance of Payments - RupeesDocument2 pagesTable 141: India'S Overall Balance of Payments - Rupeesmahbobullah rahmaniNo ratings yet

- SatconDocument18 pagesSatconBADRI VENKATESHNo ratings yet

- AI Writing Tools For Social Media Marketing Creating Compelling PostsDocument5 pagesAI Writing Tools For Social Media Marketing Creating Compelling PostsJames DanielsNo ratings yet

- Automatic Transfer Switch (ATS) : I. History and BackgroundDocument3 pagesAutomatic Transfer Switch (ATS) : I. History and BackgroundJon Lorde BolivarNo ratings yet

- Laboratory Testing of Oilwell CementsDocument41 pagesLaboratory Testing of Oilwell Cementsbillel ameuriNo ratings yet

- PRINCIPLES OF MANAGEMENT Model Questions - ADocument4 pagesPRINCIPLES OF MANAGEMENT Model Questions - ALionel MintsaNo ratings yet

- The Role of Molecular Testing in The Differential Diagnosis of Salivary Gland CarcinomasDocument17 pagesThe Role of Molecular Testing in The Differential Diagnosis of Salivary Gland CarcinomasMariela Judith UCNo ratings yet

- Vodacom Fibre - Application Form CPD - 23 August 2018Document8 pagesVodacom Fibre - Application Form CPD - 23 August 2018Mla Emmanuel ZondoNo ratings yet

- Production AnalysisDocument15 pagesProduction AnalysisAman -BCOMNo ratings yet

- Manual ZappyDocument9 pagesManual Zappyapi-45129352No ratings yet

- Theory of Planned Behaviour (TPB)Document18 pagesTheory of Planned Behaviour (TPB)Afiq Wahyu AjiNo ratings yet

- How Chips Are DesignedDocument46 pagesHow Chips Are DesignedAli AhmadNo ratings yet

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetandrew rachmanNo ratings yet

- Honeywell 393690 Inlet Outlet Flange Kits 69-0256Document2 pagesHoneywell 393690 Inlet Outlet Flange Kits 69-0256Alfredo Castro FernándezNo ratings yet

- OriginalDocument4 pagesOriginalJob ValleNo ratings yet

- 11 - Surrogate Constraints 1968Document9 pages11 - Surrogate Constraints 1968asistensi pakNo ratings yet

![2.1_RISK_ASSESMENT_TABLE_ELE-LPS_and_Earthing[1]](https://imgv2-1-f.scribdassets.com/img/document/724127514/149x198/0b47d53301/1713403434?v=1)