Professional Documents

Culture Documents

Jsa For Installation of Cyclone Rev 4

Uploaded by

WilsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jsa For Installation of Cyclone Rev 4

Uploaded by

WilsonCopyright:

Available Formats

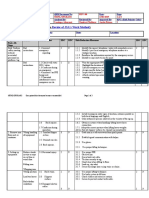

JSA FOR INSTALLATION OF CYCLONE, BLOWER, DUCT INSTALLATION

22Aug 2023

Name Company Sign Date

Prepared by: Elisha Alex SECO ___________________ ____________________

Reviewed by: ENI ___________________ ____________________

___________________ ____________________

Description of task:

Installation of cyclone, blower & duct installation at the main plant building according to the scope of work while performing the

following:

1. Working at height 5. Use of slip chain block

2. Use of electric drill & grinder 6. Use of welding machine

3. Use of cherry picker 7. Canvas two in numbers

4. Use of scaffolding with toe board (ensure availability)

8. Safety harness (with double

lanyard)

1 | P a g e DOC NO: SECO/0104/2023/JSA-03

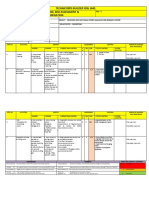

NO TASK HAZARD Associated Risk P S Ris Control Measure P S Residual Respon

k Risk

Rat rating

ing

1. Mobilization of New/ Incidents 3 2 med Personnel shall undergo safety 2 2 low Site EH

tools, inexperienced resulting from ium induction and the scope of work

equipment, and staff ignorance and discussed

staff lack of

knowledge

Damaged/ faulty Oil spillage 3 2 med Inspection of tools and equipment 1 2 Low Site EH

tools and Hand and finger ium

equipment injuries

Poor Trip and fall 2 3 med Continuous housekeeping to be 1 3 Low Site EH

housekeeping hazards ium observed. (Before, during , and

after)

2 | P a g e DOC NO: SECO/0104/2023/JSA-03

Inadequate site Injury risk to 3 4 Me The project supervisor shall ensure 2 1 Low Site EH

supervision workers diu an adequate number and

m distribution of workers with

competent supervisory figure.

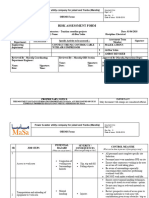

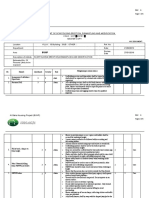

2 Marking out for Sharp edges Cuts, lacerations 2 3 Me Grind off all the sharp edges and 2 1 Low Site

the cable tray and bruises diu use cut-resistant gloves 2 1 Site En

and re-routing m & Super

of electrical

cables

3 Routing of the Dust Eye and throat 3 2 low All workers will be issued with a 2 1 Low Site

cable and cable irritation dust mask (N95) Enginee

tray Site

installation. supervis

Site EH

Faulty Electrical shocks 2 4 Inspect all tools and equipment for Site

Med

equipment. damage using a checklist before 2 1 Low supervis

ium

use. Site EH

med

Use of safety harness, Competent

Work at height/

Falling from 2 work at height personnel to be 1 2 Low

use of cherry ium

height 4 engaged

picker

Site

Tether tools, use tool bag and Enginee

3 | P a g e DOC NO: SECO/0104/2023/JSA-03

Falling objects 2 Med barricade the working area 2 1 Low Site

ium Supervi

3

Site EH

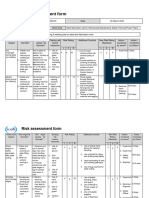

4 Measuring and Falling objects Hit and injure 3 2 Me All equipment’s should be secured 2 2 Low Site EH

cutting of the nearby people diu during working at height. Site

cable and cable Eye throat m Supervi

tray installation. irritation

Dust and flying Eye & respiratory 3 3 Me All workers will be issued with 2 2 Low Site EH

particles. irritation diu N95 face mask Site

m Supervi

Awkward Musculoskeletal 3 2 Me Avoid bending your back or over 2 2

posture injuries diu stretching for long periods of time Low Site EH

m that can lead to musculoskeletal

disorder

Sharp edges Cuts and 4 3 Grind off sharp edges using a

Lacerations grinder and provide workers with 2

cut resistant hand gloves (EN388) 2

4 | P a g e DOC NO: SECO/0104/2023/JSA-03

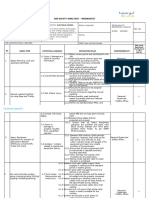

Poor fastening of Third party 4 3 Me All loads should be safely secured Low Site EH

materials during injures diu before lifting and double checked 2

2

installation and m by the rigger ie the work area to be

routing of cable demarcated by using a warning

tape

2 2

incompetent Property damage 4 4 Me Low Site EH

operator diu Cherry picker operators must have Site

m competent certificates Supervi

Overloading

the equipment Equipment failure 3 3 Me 2 Low Site EH

diu Ensure SWL is not exceeded. 2 Site

m supervis

2

Swinging load Crushed by 3 3 Me 3 2 Low Site EH

machine diu Barricading cherry picker radius

area to prevent access by 2

m 2

unauthorized personnel.

2

1

2 Low Site

Sudden Tip over 3 2 Me 2 supervis

movement of diu Barricade to avoid walking or Site EH

equipment m working under suspended

hydraulic equipment’s and

loads

5 | P a g e DOC NO: SECO/0104/2023/JSA-03

Faulty lifting Property damage 3 2 Me 1 Low Site

equipment diu 2 supervis

m Equipment should be rigged on site EHS

a stable firm ground before any

lifting activities commences.

5 Electrical Death 3 Make sure before any electrical 2 1 Low Site

connection to Electrocution 2 3 Me connections are done the

the distribution diu engineer and technician

board m should liaise with ENI

electrical team for coordination

on lockout and tag out

procedure on the distribution

board.

6 Fabrication of Manual Back pain 3 3 Me SMART lifting techniques 2 2 Low Site

the ducts and Handling diu

supports Cuts & bruise m Site

Sharp edges 3 3 Me Grind sharp edges and use cut- 2 2 Low

diu resistant gloves

m

Naked cables Electrocution Site

3 3 Me

diu Ensure cables are well insulated 2 2 Low

m

Site

Extra expenses on

Faulty tools and replacement 3 4 Me Inspection of tools and equipment

6 | P a g e DOC NO: SECO/0104/2023/JSA-03

equipment (drill diu before use 2 2 Low

machines m Site

Me Proper cable management and

Falls and bruises 3 3 diu ensuring good housekeeping at 2 2 Low

Trip and fall m the work location

HAZARD SEVERITY

1 2 3 4

Negligible Slight Moderate High Very

injury no absence Minor injury requiring Injury leading to a Involving a Multip

from work first aid treatment lost time accident single death or

serious injury

1

Very Unlikely Medium

A freak combination of factors would be required Low Low Low Medium

LIKELIHOOD OF

for an incident to result

2

Unlikely

A rare combination of factors would be required Low Medium medium Medium Medium

for an incident to result

3

Possible

Could happen when additional factors are present Low Medium Medium Medium High

but otherwise unlikely to occur

7 | P a g e DOC NO: SECO/0104/2023/JSA-03

4

OCCURRENCE

Likely Medium Medium Medium

Not certain to happen but an additional factor High High

may result in an accident

5

Very Likely Medium Medium High High High

Almost inevitable that an incident would result

SECO EMERGENCY RESCUE PLAN

ACTIVITY ACTION

Communication Fire Alarm Telephone

Personnel to evacuate to Assembly point. 1. Authorised personnel will contact ENI representatives in

case of emergency through number (07)

2. Seek assistance through KK Security guards at the gate

Method of Stretcher Handling of the victim

conveying victims For conveying Only trained first Aiders are allowed to handle injured persons.

to safety and for victims from the Casualties will be referred to infirmary for further treatment or referrals

treatment accident scene

A stretcher is

available at the

infirmary.

Modes of conveying victims from various locations

On a working plat Use stand by personnel to lift and lower down the 1. Stand by man should be aware of all the persons

8 | P a g e DOC NO: SECO/0104/2023/JSA-03

form IP from the working plat form using a stretcher working at height There must be enough personnel to

and make sure the IP is safely strapped on the form a rescue team before start of the work

stretcher before lowering him down to safety 2. Rescue exercise must be rehearsed by the team

Under the weight Try to remove the object manually and if too whenever there is a new member of the team and as a

of an object heavy use lifting equipment, without causing more matter of refreshing the team.

injury to the victim.

In a steam Rescue the victim 1. . Evacuate the victim using the stretcher

atmosphere using a stretcher 2. Personnel who are not involved in the emergency to walk to the assembly point.

3. Inform the ENI team of the accident and let all casualties be handled with trained

competent first aiders take charge of the rescue of casualties using a stretcher.

JSA discussion/review attendance list

No Name Company Sign Date

.

1. Elisha Alex SECO

2.

3.

4.

9 | P a g e DOC NO: SECO/0104/2023/JSA-03

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

10 | P a g e DOC NO: SECO/0104/2023/JSA-03

You might also like

- 08 Cable Termination Risk AssessmentDocument2 pages08 Cable Termination Risk AssessmentBaranidaranRavi72% (18)

- Risk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)Document3 pagesRisk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)AmeerHamzaWarraichNo ratings yet

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Document11 pages012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanNo ratings yet

- Job Safety Analysis For: Hcu & Lobs Revamp ProjectDocument6 pagesJob Safety Analysis For: Hcu & Lobs Revamp ProjectShilpiengg SafetyNo ratings yet

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyDocument9 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- Concrete Pouring JSaDocument12 pagesConcrete Pouring JSaTheo Vidallon BautistaNo ratings yet

- Cable TestingDocument2 pagesCable Testinglalmani bhusalNo ratings yet

- JSA - For Trays ErectionDocument1 pageJSA - For Trays ErectionAvinash RaiNo ratings yet

- RA For HydrotestDocument26 pagesRA For HydrotestSandeep kumarNo ratings yet

- Work Method Statement PDFDocument8 pagesWork Method Statement PDFUsiwo Abed Soteria Otowa100% (3)

- Sheikh Jaber Causeway Subcontract No.: KUSC-SC-S-0600: Activity/Task: Installation of Cable TrayDocument7 pagesSheikh Jaber Causeway Subcontract No.: KUSC-SC-S-0600: Activity/Task: Installation of Cable Traywaseem kausarNo ratings yet

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 pagesRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Document5 pages012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- 007 Risk Assessment For Precast Construction & Installation of Street Lighting FoundationDocument5 pages007 Risk Assessment For Precast Construction & Installation of Street Lighting FoundationJahan Zaib50% (2)

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- JSA Install Automatic Parking GateDocument6 pagesJSA Install Automatic Parking GateMarhendraNo ratings yet

- Generic TPL JsaDocument83 pagesGeneric TPL JsaSanjay Kumar GhadaiNo ratings yet

- Ergonomics Principles and GuidelinesDocument18 pagesErgonomics Principles and GuidelinesMohamed AdelNo ratings yet

- Iss Nebosh Igc02Document60 pagesIss Nebosh Igc02Sean Yeo100% (4)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDocument7 pagesRisk Assessment For Installation of Automatic Revolving Door InstallationTECHCOM100% (1)

- English For Physiotherapists 2Document117 pagesEnglish For Physiotherapists 2Artur PacekNo ratings yet

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Document6 pages012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- Falih Falih SDN SDN BHD BHD JOB Job Safety Safety Analysis Analysis Jsa/Piling Jsa/Piling 1 1 of OF5 5 Doc. Doc. No. NO. Page No. NODocument9 pagesFalih Falih SDN SDN BHD BHD JOB Job Safety Safety Analysis Analysis Jsa/Piling Jsa/Piling 1 1 of OF5 5 Doc. Doc. No. NO. Page No. NOSreejith SureshNo ratings yet

- Wireless Communications Design Handbook: Space Interference: Aspects of Noise, Interference and Environmental ConcernsFrom EverandWireless Communications Design Handbook: Space Interference: Aspects of Noise, Interference and Environmental ConcernsRating: 5 out of 5 stars5/5 (1)

- Elements of Ergonomics ProgramsDocument57 pagesElements of Ergonomics ProgramsMuhammed Mohsin100% (1)

- Occupational Hazards and ErgonomicsDocument68 pagesOccupational Hazards and ErgonomicsNaveen KumarNo ratings yet

- Template Advanced ERA ReportDocument20 pagesTemplate Advanced ERA ReportIma Hisham100% (1)

- Electrical Work: Phase Hazard AnalysisDocument10 pagesElectrical Work: Phase Hazard AnalysisBNCHNo ratings yet

- Risk Assessment For Installation of BMS M Tower PDFDocument15 pagesRisk Assessment For Installation of BMS M Tower PDFAndrew HivNo ratings yet

- Osha StandardsDocument18 pagesOsha StandardsAnsarMahmoodNo ratings yet

- (McCauley-Bush, Pamela) Ergonomics Foundational (Book4You) PDFDocument347 pages(McCauley-Bush, Pamela) Ergonomics Foundational (Book4You) PDFmikiNo ratings yet

- TLE-TE 9 - Q1 - W5 - Mod5 - ICT CSSDocument31 pagesTLE-TE 9 - Q1 - W5 - Mod5 - ICT CSSrose arianne nadayao100% (3)

- JSA For Childrens RoomDocument3 pagesJSA For Childrens Roomkalai selvanNo ratings yet

- Ra - Floor Box Ins - QCSD - Rev 0Document7 pagesRa - Floor Box Ins - QCSD - Rev 0irfan vpNo ratings yet

- Work Method Statement For Coring Works A PDFDocument3 pagesWork Method Statement For Coring Works A PDFmichelleNo ratings yet

- Earth Pit Making and Fixing of G.I Flat - JEIMDocument6 pagesEarth Pit Making and Fixing of G.I Flat - JEIMsapat309No ratings yet

- UntitledDocument5 pagesUntitledPranayNo ratings yet

- Jha Lighting ArrestorDocument3 pagesJha Lighting ArrestorRavi thokalNo ratings yet

- JSA-pumping Lines Rig Up.Document3 pagesJSA-pumping Lines Rig Up.Aniekan AkpaidiokNo ratings yet

- Temporary Sheds JSA HSE ProfessionalsDocument1 pageTemporary Sheds JSA HSE ProfessionalsAli KaziNo ratings yet

- Ground Works - Laying Kerbs Llandrindod WellsDocument1 pageGround Works - Laying Kerbs Llandrindod WellsMarkNo ratings yet

- Ra - Electrcial - Testing & CommissioningDocument7 pagesRa - Electrcial - Testing & Commissioningirfan vpNo ratings yet

- Job Safety AnalysisiDocument7 pagesJob Safety AnalysisiHARSHADNo ratings yet

- Risk Assessement For AAES ProductsDocument4 pagesRisk Assessement For AAES ProductsAzhar Shaikh100% (1)

- Electrical Work: Phase Hazard AnalysisDocument11 pagesElectrical Work: Phase Hazard AnalysisazerNo ratings yet

- OH Crane OverhaulingDocument2 pagesOH Crane OverhaulingSharjeel AhmedNo ratings yet

- Concrete Placing by Using Mobile Crane Through Concrete Bucket JSA HSE ProfessionalsDocument1 pageConcrete Placing by Using Mobile Crane Through Concrete Bucket JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Connect The PLC Control Cable With Air CompressorDocument5 pagesConnect The PLC Control Cable With Air CompressorAmrou Ben RjebNo ratings yet

- RA INSTALLATION Electrical PannelDocument7 pagesRA INSTALLATION Electrical PannelAmrou Ben RjebNo ratings yet

- Builder Hoist Erection JSA HSE ProfessionalsDocument2 pagesBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDONo ratings yet

- JSA 03 Electrical WorksDocument9 pagesJSA 03 Electrical WorkssalmankhanehsNo ratings yet

- Jsa For - SRPDocument3 pagesJsa For - SRPVijay chauhanNo ratings yet

- Cement Pipe Loading Unloading and Shifting Erection by Using Hydra JSA HSE ProfessionalsDocument1 pageCement Pipe Loading Unloading and Shifting Erection by Using Hydra JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Angle GrinderDocument1 pageAngle GrinderAshraf Bin Abdul KadirNo ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- Mobile Tower Crane Erection JSA HSE ProfessionalsDocument2 pagesMobile Tower Crane Erection JSA HSE ProfessionalsNoval FebriNo ratings yet

- Grouting of Bolts - Pockets JSA HSE ProfessionalsDocument1 pageGrouting of Bolts - Pockets JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- SWMS (Cable Glanding and Termination )Document6 pagesSWMS (Cable Glanding and Termination )PRIYESH . K. PRIYANNo ratings yet

- Bolts - Template Fixing JSA HSE ProfessionalsDocument1 pageBolts - Template Fixing JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Hirard ConcretingDocument3 pagesHirard ConcretingJames JoviNo ratings yet

- Risk Assessment Project Iosh - Ms PDF Welding Construction PDFDocument1 pageRisk Assessment Project Iosh - Ms PDF Welding Construction PDFMustafa FlayyihNo ratings yet

- ScaffoldingDocument6 pagesScaffoldingMuhammed yahiyaNo ratings yet

- JSA - 003 - Tripod Rig Erection, Operation and DismantlingDocument2 pagesJSA - 003 - Tripod Rig Erection, Operation and DismantlingAbhijit JanaNo ratings yet

- Expansion Joints in Columns JSA HSE ProfessionalsDocument1 pageExpansion Joints in Columns JSA HSE ProfessionalsSamadov 13No ratings yet

- Pipe Spool Replacement by Mobile CraneDocument8 pagesPipe Spool Replacement by Mobile CraneManikandanNo ratings yet

- Cutting & Welding Job JSADocument1 pageCutting & Welding Job JSADeepak PatelNo ratings yet

- 14 - Method Statements For Erection of Steel PDFDocument1 page14 - Method Statements For Erection of Steel PDFAbdul RahmanNo ratings yet

- JSA CABLE TaggingDocument5 pagesJSA CABLE TaggingthennarasuNo ratings yet

- IOSH Risk Assessment Project - AJEET KUMAR SINGHDocument2 pagesIOSH Risk Assessment Project - AJEET KUMAR SINGHajeet singhNo ratings yet

- Priyanka Arien Dr.Document5 pagesPriyanka Arien Dr.barcimNo ratings yet

- HSE List of PublicationsDocument12 pagesHSE List of PublicationsDanijel PindrićNo ratings yet

- OSHA & Safety in Pallet WrappingDocument5 pagesOSHA & Safety in Pallet WrappingscribdjuiceNo ratings yet

- Osh 6301Document4 pagesOsh 6301Hassan ShahzadNo ratings yet

- JHA Petronas Juru Layby Northbound.Document12 pagesJHA Petronas Juru Layby Northbound.Abdullah ZakariaNo ratings yet

- MusculoskeletalPain FinalDocument2 pagesMusculoskeletalPain FinalCarlos CardenasNo ratings yet

- Original Xbox Manual User GuideDocument56 pagesOriginal Xbox Manual User GuideManuel Yagui0% (1)

- Healthy Workplaces Campaign 2020-22 Lighten The Load: Risk Assessment For Musculoskeletal Disorders (MSDS)Document19 pagesHealthy Workplaces Campaign 2020-22 Lighten The Load: Risk Assessment For Musculoskeletal Disorders (MSDS)Khlalid SHahNo ratings yet

- Assignment HIRARCDocument11 pagesAssignment HIRARC2022467678No ratings yet

- Work Related Musculoskeletal Disorders in Physiotherapists Challenges and Coping Strategies WRMSDs in PhysiotherapistsDocument5 pagesWork Related Musculoskeletal Disorders in Physiotherapists Challenges and Coping Strategies WRMSDs in PhysiotherapistsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 15-Article Text-185-1-10-20220826Document10 pages15-Article Text-185-1-10-20220826Muhammad Elfatih RaushanfiqrNo ratings yet

- Nurul Husna Binti ZakariaDocument41 pagesNurul Husna Binti ZakariaHenry Cardenas BedonNo ratings yet

- Academic Compare and Contrast Essay TopicsDocument53 pagesAcademic Compare and Contrast Essay Topicszzcpllaeg100% (3)

- Hse Business PlanDocument45 pagesHse Business PlanSalman AlNo ratings yet

- TransformYourHabits EditedDocument60 pagesTransformYourHabits EditedGowtham GanesanNo ratings yet

- Prolonged StandingDocument2 pagesProlonged StandingMadalena CrespoNo ratings yet

- Xbox 360 Important InformationDocument68 pagesXbox 360 Important InformationPavel Mendez LNo ratings yet

- Medip, IJCMPH-4552 ODocument4 pagesMedip, IJCMPH-4552 OSumanth KaiwarNo ratings yet