Professional Documents

Culture Documents

Leviat Ancon Keybox Reinforcement Continuity Systems (1) 10

Uploaded by

Anonymous 0x2pwMCWgjOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Leviat Ancon Keybox Reinforcement Continuity Systems (1) 10

Uploaded by

Anonymous 0x2pwMCWgjCopyright:

Available Formats

Reinforcement Continuity Systems

Installation Bar Straightening

1 4 The bars must be straightened using the

appropriate sized Ancon Keybox re-bending

tool. This is a steel tube designed to fit over

the bar, the internal diameter being slightly

larger than the maximum dimension of the ribs

on the bar. One end of the tube has a section

cut away; this provides support to the outside

of the bend during straightening of the bar and

limits the point contact of the tube on the bar.

Nail the Keybox through the casing to the Straighten the bars using a Keybox re-bending

formwork or alternatively securely tie the tool. The bars should be straightened only

projecting anchorage reinforcing bars back once. To avoid damage to adjacent concrete,

to the main reinforcement. In both cases the it is prudent to allow a concrete curing period

Keybox box should be securely fixed to avoid of seven days. See ‘Bar Straightening’ for

displacement during concreting. The casing more information.

should be tight against the formwork. Pour

concrete. Use of the tool allows the re-bending process

to be carried out in a smooth continuous

2 5 action (avoiding jerky action), the tube being

moved along the bar and around the bend as

it is straightened.

To enable the re-bending tool to be fitted onto

the bar, the bar should be pulled the minimum

distance from the Keybox steel casing.

The re-bending tool should then be slid along

the bar to the start of the bend radius.

The bar straightening process should be

smooth and progressive with the tube allowed

to move along the bend towards the metal

casing as it is straightened. The tool should

Strike the formwork to reveal the steel cover. Once the bars are straightened and aligned

contact the Keybox steel casing at the

they are ready for lapping.

3 completion of the straightening process.

The tube is then removed and the straightened

bar checked for alignment and cover with the

adjoining reinforcement.

Keybox reinforcing bars should not be

straightened when the temperature of the steel

is below 5°C. Where straightening is necessary

below 5°C, indirect warming of the steel to a

temperature not exceeding 100°C is permitted.

Scaffold tubes or similar must not be used to

straighten bar. Inappropriate tools will result

Remove the steel cover to expose the in excessive kinks in the region of the bar

pre-bent bars. bend and result in undesirable work hardening

which may damage the bar and affect the

strength. Bending the bar in excess of the

recommendations will also result in work

hardening of the rebar and should therefore be

avoided.

10 Tel: 1300 304 320 www.ancon.com.au

You might also like

- Model Steam TurbineDocument2 pagesModel Steam TurbineJim100% (8)

- Outland Build Your Own CabinDocument5 pagesOutland Build Your Own CabinJerryNo ratings yet

- Auto Spring CrossbowDocument4 pagesAuto Spring CrossbowFacundo Gomez100% (1)

- Parting The PipeDocument9 pagesParting The Pipephucbm bmNo ratings yet

- Plate and Screw TraumaDocument45 pagesPlate and Screw TraumaRichard 151289No ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 21Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 21Anonymous 0x2pwMCWgjNo ratings yet

- Cook Compression PackingDocument2 pagesCook Compression PackingMuhammad Imran100% (1)

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 23Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 23Anonymous 0x2pwMCWgjNo ratings yet

- Assignment 1 (Screw Production)Document11 pagesAssignment 1 (Screw Production)Ariff AziziNo ratings yet

- Tubebender GsbatesDocument4 pagesTubebender GsbatesFrenchwolf420No ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Single Conductor Re Head InstructionsDocument14 pagesSingle Conductor Re Head Instructionsanksri07No ratings yet

- Section 4 Conveyor Chain Designer GuideDocument41 pagesSection 4 Conveyor Chain Designer GuidesgtNo ratings yet

- Drawing 10 (4.18)Document1 pageDrawing 10 (4.18)Reddie BlueNo ratings yet

- 1.2 Architectural Bar Systems Brochure - Industrial Applications 25 07 2017Document4 pages1.2 Architectural Bar Systems Brochure - Industrial Applications 25 07 2017VenNo ratings yet

- Safety Precautions: Assembling The CraneDocument1 pageSafety Precautions: Assembling The CraneNotnow CalmNo ratings yet

- IPCO B Service-Instructions-Steel-Belts 2018 LOW-RESDocument7 pagesIPCO B Service-Instructions-Steel-Belts 2018 LOW-RESCarlos NeyNo ratings yet

- Large WM Live Tap InstructionsDocument2 pagesLarge WM Live Tap InstructionswaleeedNo ratings yet

- Perawatan Kolom GCDocument12 pagesPerawatan Kolom GCRafi Pratama SetiawanNo ratings yet

- Concrete Construction Article PDF - Slickline For Pumping ConcreteDocument3 pagesConcrete Construction Article PDF - Slickline For Pumping Concreteshen fredNo ratings yet

- Section 4: Conveyor Chain Designer GuideDocument39 pagesSection 4: Conveyor Chain Designer GuideRobin HoodNo ratings yet

- Spiral Dividing ChuckDocument3 pagesSpiral Dividing Chuckneko222No ratings yet

- FTS 425 InstallDocument2 pagesFTS 425 InstalldedypunyaNo ratings yet

- 422en Bending of StrenxDocument8 pages422en Bending of StrenxJoe FlaniganNo ratings yet

- Joanne Karla Jimenez - ENSC 234-LABORATORY NO.2Document8 pagesJoanne Karla Jimenez - ENSC 234-LABORATORY NO.2Joanne JimenezNo ratings yet

- IEEE Cable Plowing GuideDocument9 pagesIEEE Cable Plowing GuideAlexander ToyoNo ratings yet

- Some Bands Including Metal Ones Are Easily Removable. Following The Instructions Below You Can Detach and Attach The BandDocument1 pageSome Bands Including Metal Ones Are Easily Removable. Following The Instructions Below You Can Detach and Attach The BandyikyongNo ratings yet

- (Doi 10.4043/7730-MS) Lane, M. McNamara, J.F. Gibson, R. Tyrer, A.Document10 pages(Doi 10.4043/7730-MS) Lane, M. McNamara, J.F. Gibson, R. Tyrer, A.thlim19078656No ratings yet

- WIR7.5 38 Publication 19396 Mooring Buoy Installation InstructionsDocument2 pagesWIR7.5 38 Publication 19396 Mooring Buoy Installation Instructionsray9699No ratings yet

- Mason Industries, Inc.: ND MountsDocument2 pagesMason Industries, Inc.: ND MountsErwin MaldoNo ratings yet

- Toggle Bolt: Installation ProceduresDocument2 pagesToggle Bolt: Installation ProceduresRajed MaglinteNo ratings yet

- Fertil Dispenser InstructionsDocument1 pageFertil Dispenser InstructionsJesus TorgarNo ratings yet

- Fertil Dispenser Instructions PDFDocument1 pageFertil Dispenser Instructions PDFJesus TorgarNo ratings yet

- KnotDocument1 pageKnotMazin KCNo ratings yet

- Mounting Adjusting Pump UnitDocument2 pagesMounting Adjusting Pump UnitRalf JonesNo ratings yet

- © Plumbers and Pipefitters Union, Alton, ILDocument8 pages© Plumbers and Pipefitters Union, Alton, ILWilly UioNo ratings yet

- Coupler 3Document1 pageCoupler 3m_mahfuz118187No ratings yet

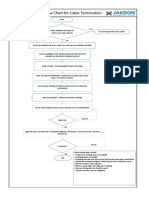

- Flow Chart For Cable Termination: Not OkDocument1 pageFlow Chart For Cable Termination: Not Okpushpanath reddyNo ratings yet

- Ridgid Precision Flaring Tools ManualDocument1 pageRidgid Precision Flaring Tools ManualmaftmutoNo ratings yet

- Design Considerations in Cable Stayed RoDocument7 pagesDesign Considerations in Cable Stayed RoJen AgabinNo ratings yet

- Replacement Plumb Bobs Manual ME 9868ADocument3 pagesReplacement Plumb Bobs Manual ME 9868A이지민No ratings yet

- Snap On Pipe Installation Methodology Foil FacedDocument2 pagesSnap On Pipe Installation Methodology Foil FacedNoah MusundiNo ratings yet

- Wire Rope Gen InfoDocument5 pagesWire Rope Gen InfobugseNo ratings yet

- Soporte AntivibratorioDocument2 pagesSoporte AntivibratorioGerman GinesNo ratings yet

- Grinder WeldingDocument2 pagesGrinder WeldingbobNo ratings yet

- Fin TigerDocument3 pagesFin TigerAlexej PietruszakNo ratings yet

- OrthodonticDocument3 pagesOrthodonticMarcelinoFernandezNo ratings yet

- Fy Smcs-1 Q. Bank Sem 1 2023-24Document12 pagesFy Smcs-1 Q. Bank Sem 1 2023-24raju.sharmqNo ratings yet

- Cable Bolt Anchors Performance PDFDocument8 pagesCable Bolt Anchors Performance PDFwilmerlanceNo ratings yet

- Kameda TechniqueDocument14 pagesKameda TechniqueSuseela Lakshmanan100% (2)

- Design Considerations in Cable-Stayed Roof StructuresDocument7 pagesDesign Considerations in Cable-Stayed Roof StructuresSunil PulikkalNo ratings yet

- Tubing and Casing Rollers: Instruction Manual 6200Document9 pagesTubing and Casing Rollers: Instruction Manual 6200Aderobaki GbengaNo ratings yet

- Connections Precast Girder Cap (Caltrans)Document27 pagesConnections Precast Girder Cap (Caltrans)Anderson UrreaNo ratings yet

- RSID2008-Lapuz Etal-RevDocument6 pagesRSID2008-Lapuz Etal-RevAndy OretaNo ratings yet

- Cable Tool DrillingDocument13 pagesCable Tool DrillingAHMED100% (2)

- Phu Luc Cable of Drain Solution Instructions V1 - 10082017w32Document8 pagesPhu Luc Cable of Drain Solution Instructions V1 - 10082017w32KHOA NGUYEN DANGNo ratings yet

- A: Flex Hard Folding B: Side Mounting C: Hardware Bag &Document4 pagesA: Flex Hard Folding B: Side Mounting C: Hardware Bag &Adrian Salinas AldereteNo ratings yet

- Novices'Corner: Using The D-BitDocument3 pagesNovices'Corner: Using The D-BitBob RossNo ratings yet

- Toilet Seat Fitting Instructions & Product CareDocument2 pagesToilet Seat Fitting Instructions & Product CareDAVENo ratings yet

- ROMAC AlphaDocument12 pagesROMAC AlphaRogNo ratings yet

- BANDO-Belt TensionDocument1 pageBANDO-Belt TensionTeerachai PruksapitakulNo ratings yet

- Leviat Ancon Keybox Reinforcement Continuity Systems (1) 1Document1 pageLeviat Ancon Keybox Reinforcement Continuity Systems (1) 1Anonymous 0x2pwMCWgjNo ratings yet

- 2AISC - Design Capacity Tables For Structural Steel - Open SectionsDocument1 page2AISC - Design Capacity Tables For Structural Steel - Open SectionsAnonymous 0x2pwMCWgjNo ratings yet

- 5AISC - Design Capacity Tables For Structural Steel - Open SectionsDocument1 page5AISC - Design Capacity Tables For Structural Steel - Open SectionsAnonymous 0x2pwMCWgjNo ratings yet

- 1AISC - Design Capacity Tables For Structural Steel - Open SectionsDocument1 page1AISC - Design Capacity Tables For Structural Steel - Open SectionsAnonymous 0x2pwMCWgjNo ratings yet

- 3AISC - Design Capacity Tables For Structural Steel - Open SectionsDocument1 page3AISC - Design Capacity Tables For Structural Steel - Open SectionsAnonymous 0x2pwMCWgjNo ratings yet

- 4AISC - Design Capacity Tables For Structural Steel - Open SectionsDocument1 page4AISC - Design Capacity Tables For Structural Steel - Open SectionsAnonymous 0x2pwMCWgjNo ratings yet

- ACEGrid Brochure HR Final 6Document1 pageACEGrid Brochure HR Final 6Anonymous 0x2pwMCWgjNo ratings yet

- Volume 2 - Hollow Sections Second Edition 4Document1 pageVolume 2 - Hollow Sections Second Edition 4Anonymous 0x2pwMCWgjNo ratings yet

- Unit 10Document3 pagesUnit 10Anonymous 0x2pwMCWgjNo ratings yet

- Displacement-Based - Seismic - Design - of - Structures 22Document1 pageDisplacement-Based - Seismic - Design - of - Structures 22Anonymous 0x2pwMCWgjNo ratings yet

- ACEGrid Brochure HR Final 4Document1 pageACEGrid Brochure HR Final 4Anonymous 0x2pwMCWgjNo ratings yet

- ACEGrid-Brochure-HR-final 3Document1 pageACEGrid-Brochure-HR-final 3Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 18Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 18Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 22Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 22Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 19Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 19Anonymous 0x2pwMCWgjNo ratings yet

- 4-T-Tij H - . - : Design Guide 10: Bolted Moment End Plate Beam Splice Connection. First EditionDocument1 page4-T-Tij H - . - : Design Guide 10: Bolted Moment End Plate Beam Splice Connection. First EditionAnonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 20Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 20Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 17Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 17Anonymous 0x2pwMCWgjNo ratings yet

- Design Guide 10: Bolted Moment End Plate Beam Splice Connection, First EditionDocument1 pageDesign Guide 10: Bolted Moment End Plate Beam Splice Connection, First EditionAnonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 12Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 12Anonymous 0x2pwMCWgjNo ratings yet

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 11Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 11Anonymous 0x2pwMCWgjNo ratings yet