Professional Documents

Culture Documents

Flow Chart For Cable Termination: Not Ok

Uploaded by

pushpanath reddyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flow Chart For Cable Termination: Not Ok

Uploaded by

pushpanath reddyCopyright:

Available Formats

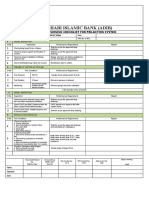

Flow Chart for Cable Termination

Start

Not ok

Check Insulation Resitance of

Rework/Repair/Return to vendor

cable as per cable capacity

ok

Ensure termination kits as per cable sizes and type are available and Cable

Ensure availability of all required tools and material as per

manufacture instruction /standard practice

Fixing of cable : Must be glanded /fixed with clamps

Mark the Phase identification on both side of cable using colored

tapes / Permanent markers

Ensure proper shaping of cable to remove stress on cable after

termination

Match the lug face with bus bars before crimping

Ensure the Complete process as per manufacturer recommendation

Not Ok

Inspection

Ok

Tight the bolts and check the termination tightness with torque wrench as per force required

for bolt size

Not Ok

Inspection

Please ensure below points:

Ok 1.Proper Size crimping tools are available

2.Cramping paste is available

End

3.Crimping must be done from top to bottom and proper gap is maintained

4.Rotate the criming tool slightly while doing the next crimp after one to

make firm contact with conductor

5.Remove sharp edges from lugs after crimping

6.Sleeves of adequate size should be used

7.Torque wrenches must be calibrated

You might also like

- (TM) Jeep Manual de Taller Jeep Grand Cherokee 2011Document6,318 pages(TM) Jeep Manual de Taller Jeep Grand Cherokee 2011Pedro Arrieta100% (1)

- Industrial Machine and ControlsDocument31 pagesIndustrial Machine and ControlsCarol Soi100% (4)

- Jsa-Ht & LT Panel InstallationDocument1 pageJsa-Ht & LT Panel Installationpushpanath reddy100% (1)

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- Main Switch Panel IntakeDocument4 pagesMain Switch Panel IntakeMohammed Sayeeduddin100% (1)

- Cable LayingDocument6 pagesCable LayingSourav RanaNo ratings yet

- Sample Electrical PlanDocument6 pagesSample Electrical PlanDelphine Katrien CesarNo ratings yet

- JSA Cable Trench Excavtion, Cable Laying, Cable TerminationDocument1 pageJSA Cable Trench Excavtion, Cable Laying, Cable Terminationpushpanath reddyNo ratings yet

- CHECKLIST For Installation of Wires & Cable For Lighting, Small Power and ELV CircuitsDocument1 pageCHECKLIST For Installation of Wires & Cable For Lighting, Small Power and ELV CircuitsTHEOPHILUS ATO FLETCHER0% (1)

- Service Training 2530D 35DN 9V v1.2Document157 pagesService Training 2530D 35DN 9V v1.2Gogu Ilie0% (1)

- Transformer Failure AnalysisDocument12 pagesTransformer Failure AnalysisABHINAV SAURAVNo ratings yet

- SOP of UPS Battery ReplacementDocument7 pagesSOP of UPS Battery ReplacementYe Kyaw SwarNo ratings yet

- Electrical Inspections ChecklistDocument6 pagesElectrical Inspections Checklistasyraf azaharyNo ratings yet

- CHECKLIST For Installation & Testing of Fire Fighting Pipe WorkDocument1 pageCHECKLIST For Installation & Testing of Fire Fighting Pipe WorkTHEOPHILUS ATO FLETCHER50% (2)

- Maintenance of Sub Station EquipmentDocument57 pagesMaintenance of Sub Station Equipmentsofyan_shah100% (2)

- 31504647-Antenna System (On Tower) Installation Standard ModelDocument27 pages31504647-Antenna System (On Tower) Installation Standard ModelBadr AmerNo ratings yet

- CHECKLIST For Installation of Power CablesDocument1 pageCHECKLIST For Installation of Power CablesTHEOPHILUS ATO FLETCHER100% (5)

- CHECKLIST For Installation of MICC CableDocument2 pagesCHECKLIST For Installation of MICC CableTHEOPHILUS ATO FLETCHERNo ratings yet

- Method Statement For Installation of High Voltage HV Cables Above & Under Ground - Safe Work Method of StatementDocument4 pagesMethod Statement For Installation of High Voltage HV Cables Above & Under Ground - Safe Work Method of StatementMohammed K. HayderNo ratings yet

- SJW-H Leak Clamp Installation InstructionDocument2 pagesSJW-H Leak Clamp Installation InstructionSarwat Naim SiddiquiNo ratings yet

- NippledownDocument4 pagesNippledownali abbasNo ratings yet

- TF100-75 - Rynglok R5 Fittings AS-Cross ReferenceDocument4 pagesTF100-75 - Rynglok R5 Fittings AS-Cross ReferenceLorenzoTanNo ratings yet

- Work Instructions For Arc Welding Machine: ReferenceDocument1 pageWork Instructions For Arc Welding Machine: Referencevivek sureshNo ratings yet

- Perawatan Kolom GCDocument12 pagesPerawatan Kolom GCRafi Pratama SetiawanNo ratings yet

- Electrofusion Jointing ProceduresDocument12 pagesElectrofusion Jointing ProcedureslfpachecoNo ratings yet

- SMI - BBSR - OPN - WI 02.01, Hardness, Conductivity & TC Hole InspectionDocument1 pageSMI - BBSR - OPN - WI 02.01, Hardness, Conductivity & TC Hole InspectionImmalatulhusnaNo ratings yet

- SSE-QC-ELE-525-Cable LayingDocument3 pagesSSE-QC-ELE-525-Cable LayingBhalsingh JangraNo ratings yet

- PHYSICAL INSTALLATION and MAINTENANCE CHECKLISTsDocument3 pagesPHYSICAL INSTALLATION and MAINTENANCE CHECKLISTsmohsin abbas Abba'sNo ratings yet

- Accesory Eqipment TabulationDocument11 pagesAccesory Eqipment TabulationNER CARLO SANTOSNo ratings yet

- Strainers Hattersley IOM 0221Document8 pagesStrainers Hattersley IOM 0221Qatar Mega Building DrillingNo ratings yet

- Superlok CA Tube FittingsDocument60 pagesSuperlok CA Tube FittingsAjdinNo ratings yet

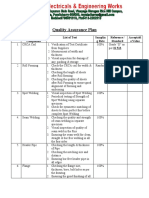

- SAN-Quality Assurance PlanDocument3 pagesSAN-Quality Assurance PlanAdhavan ThamizhanNo ratings yet

- Strainers Crane FS IOM 0221Document8 pagesStrainers Crane FS IOM 0221TripleOffsetNo ratings yet

- API RP 687-2001 (2015) Ut BabbitpdfDocument1 pageAPI RP 687-2001 (2015) Ut BabbitpdfudomNo ratings yet

- CCB Sleeve Weld ProcedureDocument2 pagesCCB Sleeve Weld ProcedureIME SOLUTIONSNo ratings yet

- Ridgid Precision Flaring Tools ManualDocument1 pageRidgid Precision Flaring Tools ManualmaftmutoNo ratings yet

- Quality Assurance Plan SL - No Item / Component List of Test Sampling Rate Reference / Standard Acceptable ValueDocument2 pagesQuality Assurance Plan SL - No Item / Component List of Test Sampling Rate Reference / Standard Acceptable ValueAdhavan ThamizhanNo ratings yet

- System and Work Methodology For Casting Final 2Document6 pagesSystem and Work Methodology For Casting Final 2Dan GoNo ratings yet

- How To Inspect Your Wire Ropes: Focus On Your Rope'S Critical PointsDocument2 pagesHow To Inspect Your Wire Ropes: Focus On Your Rope'S Critical PointskaloordenisNo ratings yet

- Astm d6230 - Part 2Document4 pagesAstm d6230 - Part 2leegoon82No ratings yet

- 5.19 JSP Power Transformer High Voltage TestDocument4 pages5.19 JSP Power Transformer High Voltage Testmuhammad.younisNo ratings yet

- Swagelok Quick GuideDocument2 pagesSwagelok Quick GuideAqib SiddiqueNo ratings yet

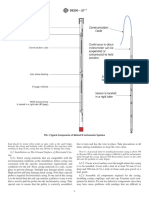

- Field Monitoring Instrumentation of Embankment ConstructionDocument32 pagesField Monitoring Instrumentation of Embankment ConstructionAprilia N PrettyalinNo ratings yet

- TRANZX INSTALL MANUAL 2x INTERNAL v0Document5 pagesTRANZX INSTALL MANUAL 2x INTERNAL v0dan nadNo ratings yet

- Throttle Cable Kit ProcedureDocument3 pagesThrottle Cable Kit ProcedureKitti JoeNo ratings yet

- Acrow Prop GuideDocument3 pagesAcrow Prop Guidecristi stefanNo ratings yet

- Location: Date of InspectionDocument1 pageLocation: Date of InspectionMohan VadiveluNo ratings yet

- Quality Assembly Plan: If This Is A Paper Copy, It Is Uncontrolled. You Must Verify The On-Line Revision Before UsingDocument2 pagesQuality Assembly Plan: If This Is A Paper Copy, It Is Uncontrolled. You Must Verify The On-Line Revision Before UsingvinothNo ratings yet

- MFL40322181Sapience 23inch CSA - Service Manual - 131014Document58 pagesMFL40322181Sapience 23inch CSA - Service Manual - 131014Cesar Calderon Gr100% (1)

- Material Handling Equipment Test Method Rev. 2 (Dood)Document8 pagesMaterial Handling Equipment Test Method Rev. 2 (Dood)ThomasNo ratings yet

- How To Install Formica LifeSeal Worktops Step by StepDocument4 pagesHow To Install Formica LifeSeal Worktops Step by StepwitwatersrandNo ratings yet

- 6606 Issue 3 Cathodic Protection Potential SurveyDocument4 pages6606 Issue 3 Cathodic Protection Potential SurveyFethi BELOUISNo ratings yet

- PHMSA 2017 0158 0001 - Attachment - 41Document7 pagesPHMSA 2017 0158 0001 - Attachment - 41mscpm22113418No ratings yet

- Mechanical Signalling Maintenance Schedule NewDocument3 pagesMechanical Signalling Maintenance Schedule NewSaurabh MoharirNo ratings yet

- Workscope Unit 3 Work OH 2021: Install Axial Seal A&BDocument1 pageWorkscope Unit 3 Work OH 2021: Install Axial Seal A&BAnu MuNo ratings yet

- Is Hc1909flDocument1 pageIs Hc1909fldayshift5No ratings yet

- Banquets SOP - Stage SetupDocument2 pagesBanquets SOP - Stage SetupVivekanand SinghNo ratings yet

- Shield Expansion Anchors.: Sample Method StatementDocument2 pagesShield Expansion Anchors.: Sample Method StatementMauricio SosaNo ratings yet

- Leviat Ancon Keybox Reinforcement Continuity Systems (1) 10Document1 pageLeviat Ancon Keybox Reinforcement Continuity Systems (1) 10Anonymous 0x2pwMCWgjNo ratings yet

- 200A 15 and 25Kv Class Deadbreak Elbow Installation & Operating InstructionsDocument4 pages200A 15 and 25Kv Class Deadbreak Elbow Installation & Operating InstructionsCesar PreciadoNo ratings yet

- Pre-Pre-Commissioning ChecklistDocument1 pagePre-Pre-Commissioning Checklistsundar giscoNo ratings yet

- Qc-Qcr-Ele-24 Power CircuitDocument1 pageQc-Qcr-Ele-24 Power CircuitRoderick HipolNo ratings yet

- MK Tron Auto Part: Procedure of Leak TestingDocument1 pageMK Tron Auto Part: Procedure of Leak Testingsachin kadamNo ratings yet

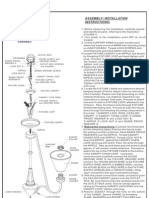

- Assembly / Installation Instructions:: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .Document1 pageAssembly / Installation Instructions:: 6 Corporate Parkway Goose Creek SC 29445 WWW Quoizel Com, - .dayshift5No ratings yet

- SAN Radiators-Manufacturing ProcessDocument6 pagesSAN Radiators-Manufacturing ProcessAdhavan ThamizhanNo ratings yet

- SAN Radiators-Manufacturing Process PDFDocument6 pagesSAN Radiators-Manufacturing Process PDFAdhavan ThamizhanNo ratings yet

- Object:-Job Safety Analysis For PDB InstallationDocument1 pageObject:-Job Safety Analysis For PDB Installationpushpanath reddyNo ratings yet

- Object:-Job Safety Analysis For Module InstallationDocument1 pageObject:-Job Safety Analysis For Module Installationpushpanath reddyNo ratings yet

- Object:-Job Safety Analysis For LA InstallationDocument1 pageObject:-Job Safety Analysis For LA Installationpushpanath reddyNo ratings yet

- Valvula de Freio L50Document4 pagesValvula de Freio L50adelmomouraNo ratings yet

- 8501CT0901AQ21Document12 pages8501CT0901AQ21ecolomboeNo ratings yet

- Functions: Ihc Combined Ove, Cu,,ent Digita N Oprocesso Advance Cal Tec Qu SDocument4 pagesFunctions: Ihc Combined Ove, Cu,,ent Digita N Oprocesso Advance Cal Tec Qu Stalha0703097No ratings yet

- Presentation On Waterjet CuttingDocument24 pagesPresentation On Waterjet Cuttingsonu_saurabhNo ratings yet

- Lucide 2Document232 pagesLucide 2Elma SomunNo ratings yet

- Types of ComputerDocument8 pagesTypes of Computerapi-321074746No ratings yet

- Crouse Hinds If1229 Instruction SheetDocument5 pagesCrouse Hinds If1229 Instruction Sheethector-moraNo ratings yet

- ABUS Product Overview PDFDocument15 pagesABUS Product Overview PDFNguyen Duc CuongNo ratings yet

- Roomba 500 Series Servicing and Repair Guide: Chapter 3: How To Open Up RoombaDocument25 pagesRoomba 500 Series Servicing and Repair Guide: Chapter 3: How To Open Up RoombajulioNo ratings yet

- Anly Floatless Relay: Aln / Al2NDocument2 pagesAnly Floatless Relay: Aln / Al2NduleepabowatteNo ratings yet

- 881NXDocument12 pages881NXYogesh RamdasiNo ratings yet

- BGP-APR Series 50HzDocument6 pagesBGP-APR Series 50HzAriel SaáNo ratings yet

- Room Air Conditioner: Service ManualDocument68 pagesRoom Air Conditioner: Service ManualjhonnyNo ratings yet

- Owner'S Manual: Stellar Air Conditioning Unit Split-System Cooling With Environmentally Friendly R-410ADocument4 pagesOwner'S Manual: Stellar Air Conditioning Unit Split-System Cooling With Environmentally Friendly R-410Aramon5356No ratings yet

- Aqua Electrical Equipment PDFDocument14 pagesAqua Electrical Equipment PDFBambang YuwonoNo ratings yet

- User Manual of YKD-9122-2022.6Document18 pagesUser Manual of YKD-9122-2022.6Dr Ibrahima BaldeNo ratings yet

- HYVA Spare PartsDocument97 pagesHYVA Spare PartsduocNo ratings yet

- Wall Hung Electric BoilerDocument2 pagesWall Hung Electric BoilerDaxom NavidensNo ratings yet

- Panasonic KX-TD500 - Function GuideDocument1,574 pagesPanasonic KX-TD500 - Function GuideJuan Rivera100% (1)

- Jetcon 1301 / 1301-Mw / 1301-Sw: Industrial Fast Ethernet To Fiber Media ConverterDocument6 pagesJetcon 1301 / 1301-Mw / 1301-Sw: Industrial Fast Ethernet To Fiber Media ConverterSoyManuNo ratings yet

- Lathe: A Lathe in Building 35Document32 pagesLathe: A Lathe in Building 35srajubasavaNo ratings yet

- WD 1409 RDDocument51 pagesWD 1409 RDJhonatan K LieblNo ratings yet

- Optisplice One Handheld Fusion Splicer: ApplicationsDocument6 pagesOptisplice One Handheld Fusion Splicer: ApplicationsAlan Abdiel RuizNo ratings yet

- Model Main Unit Package Cash Price: Without The PumpDocument7 pagesModel Main Unit Package Cash Price: Without The PumpKassapa GamlathNo ratings yet

- DataSheet KX-DT543Document3 pagesDataSheet KX-DT543Haris AnsariNo ratings yet