Professional Documents

Culture Documents

BM Safe Use of Chemicals

BM Safe Use of Chemicals

Uploaded by

Swidwell Kataya0 ratings0% found this document useful (0 votes)

3 views48 pagesThe document discusses guidelines for safely using chemicals at work. It outlines key objectives like protecting workers from chemical hazards. It describes major routes of chemical exposure like inhalation and absorption. It also defines hazardous substances and explains how chemicals can affect the body through acute, chronic, local and systemic effects. The document recommends technical and organization measures to minimize risks, like substitution, ventilation systems, safety committees and training workers.

Original Description:

Original Title

Bm Safe Use of Chemicals

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses guidelines for safely using chemicals at work. It outlines key objectives like protecting workers from chemical hazards. It describes major routes of chemical exposure like inhalation and absorption. It also defines hazardous substances and explains how chemicals can affect the body through acute, chronic, local and systemic effects. The document recommends technical and organization measures to minimize risks, like substitution, ventilation systems, safety committees and training workers.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views48 pagesBM Safe Use of Chemicals

BM Safe Use of Chemicals

Uploaded by

Swidwell KatayaThe document discusses guidelines for safely using chemicals at work. It outlines key objectives like protecting workers from chemical hazards. It describes major routes of chemical exposure like inhalation and absorption. It also defines hazardous substances and explains how chemicals can affect the body through acute, chronic, local and systemic effects. The document recommends technical and organization measures to minimize risks, like substitution, ventilation systems, safety committees and training workers.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 48

SAFE USE OF

CHEMICALS AT

WORK

by

Benjamin Mutetwa

NATIONAL SOCIAL SECURITY AUTHORITY

Chemical Safety: Mutetwa B 1

INTRODUCTION & OBJECTIVES

• Whole life cycle of a chemical should be

considered when assessing its dangers

and benefits i.e. production, storage,

handling and disposal of chemicals.

• Key objective of subject include

- To protect workers from the hazards of

chemicals.

- To reduce or prevent the incidence of

chemicals at work.

Chemical Safety: Mutetwa B 2

INTRODUCTION & OBJECTIVES -

CONT

- Provision of guidelines for ensuring that all

chemicals for use at work, including impurities

by-products and wastes that may be formed are

evaluated to determine their hazards.

- Ensuring that employers are provided with a

mechanism for obtaining from their suppliers

information about the chemicals used at work to

enable them to implement effective programmes

to protect workers from chemicals hazards.

- .

Chemical Safety: Mutetwa B 3

INTRODUCTION &

OBJECTIVES - CONT

- Provision to workers with information

about the chemicals at their workplace and

about appropriate preventive measures to

enable them to participate effectively in

safety programmes.

- Establishing principles for programmes to

ensure that chemicals are used safely.

Chemical Safety: Mutetwa B 4

ROUTES OF EXPOSURE

• No chemical substance can cause

adverse effects without first entering the

body or coming to contact with it.

• 4 major routes

- Inhalation (breathing in)

- Absorption (through the skin or eyes)

- Injection (eating, swallowing).

- Transfer across the placenta of a pregnant

woman to the unborn baby.

Chemical Safety: Mutetwa B 5

ROUTES OF EXPOSURE –CONT.

- Most chemicals can be dispersed into the air

to form dust, mists, fumes, gas or vapour.

- Skin absorption is, after inhalation, the second

most common route through which

occupational exposure may take place.

- Eyes can also absorb chemical substances,

either from splashes or from vapours.

Chemical Safety: Mutetwa B 6

WHAT IS A HAZARDOUS

SUBSTANCE?

• A health risk

- Toxic or very toxic

- Corrosive

- Harmful

- Irritant

- Sensitizing

- Cancer causing

- Effects on reproduction

Chemical Safety: Mutetwa B 7

WHAT IS A HAZARDOUS

SUBSTANCE? – CONT.

• Fire and explosion hazard

- Explosive

- Oxidizing

- Flammable

• Dangerous for the Environment

- Toxic to living organisms

- persists in the environment

- Bioaccumulation

Chemical Safety: Mutetwa B 8

HOW CHEMICALS AFFECTS US

• Harmful effects of chemical substances depends

on the toxicity of chemical and exposure to it.

• Level of exposure: concentration and exposure

duration.

• Acute and Chronic Effects

- Acute: effects that occur immediately after a short

exposure; can occur inside 24 hours.

- Chronic: effects usually require repeated exposure

and a delay is observed between the first exposure

and appearance of adverse effects.

Chemical Safety: Mutetwa B 9

HOW CHEMICALS AFFECTS US

– CONT.

• Local and Systemic Effects

- Acute local effects:

- Corrosive injuries.

- Lung injuries from inhaled gases e.g. Phosgene, nitrogen

oxides.

- Systemic effects

- Chemicals, which are absorbed from site of administration, end

up in the blood stream and may produce toxic effects in remote

tissues, cells or organs e.g. skin irritation, dermatitis, skin itching,

watery/teary eyes, sneezing (nasal effects)

- Effects on blood.

- Effects on organs/tissues such as liver, kidney and lungs.

Chemical Safety: Mutetwa B 10

HOW CHEMICALS AFFECTS US

– CONT.

• Target Organs

- Organs affected by chemical agents.

- e.g. CNS usually involved in systemic effects.

Other target organs include liver, lung, and

skin.

- Also to a lesser extent muscles and bones.

- Male and female reproductive systems

vulnerable to many substances.

- NB: Many substances can penetrate the skin

and enter blood circulation, e.g. phenol.

Chemical Safety: Mutetwa B 11

HOW CHEMICALS AFFECTS US

– CONT.

• Allergic Reactions

- Allergic reaction, or sensitization may appear after

repeated contact with a substance.

- Small doses of a substance can provoke a reaction.

- Skin and eyes common areas in humans which

respond to allergic reactions.

• Interactions

- Additive effects of chemicals

e.g. Solvents

Asbestos and cigarette smoking

Chemical Safety: Mutetwa B 12

COMMON CHEMICAL GROUPS

THAT CAUSE HEALTH RISKS.

• Dust, fumes and gases

- pneumoconiosis

- asbestosis

- metal fume fever

- irritation to the respiratory system

• Solvents

- Narcotic effects

- Dizziness

- Headache

- Reduced comprehension

- Tiredness

- Damage to liver, kidney, bone marrow, cns.

Chemical Safety: Mutetwa B 13

Common Chemical Groups That

Cause Health Risks- Cont

• Metals

- CNS effects

- Sensitization

- Cancer

- Allergic reactions

• Acids and Bases

- Corrosive

- Irritation

• Pesticides

- CNS

- Headache

- Convulsions

- Unconsciousness

- Difficulty in breathing

Chemical Safety: Mutetwa B 14

HOW TO MINIMISE THE RISKS

CAUSED BY CHEMICALS

• Technical Measures

- Such measures can be used to prevent chemical hazards at the

source.

• Substitution

- Effective method where a hazardous chemical is replaced with a

less hazardous one.

- Quite important when dealing with cancer causing substances.

- e.g. use of pellets or paste instead of powdered substances

which readily produces high levels of dangerous dusts.

- Water based paints and adhesives instead of products

containing solvents.

- Ensure all possible information is available before changing so

that new choice does not create unexpected new dangers and

risks.

Chemical Safety: Mutetwa B 15

• Technical Measures – Cont.

• Engineering Controls

- Closed system

- If hazardous chemicals cannot be replaced by less

dangerous ones, exposure must be prevented by

protecting the worker through enclosing the

hazardous process or chemical.

- e.g. use of sealed pipes to transfer solvents and other

liquids instead of pouring them in the open air.

Vapours and gases caused by spray painting or

produced in pickling and hardening baths in the metal

industry should be controlled, ventilated and not

allowed to enter the workplace atmosphere.

Chemical Safety: Mutetwa B 16

• Technical Measures – Cont.

• Local Exhaust Ventilation

➢ Enclosure of all dangerous operation may not be

possible.

➢ Need for local exhaust ventilation system which

consists of hood, ducts or pipes, a system to collect

and separate the pollutants from the clean air and an

efficient fan to create enough such force.

➢ Hazardous gases, fumes and dust should not be

discharged untreated to pollute surroundings of the

factory and environment.

➢ Inspection proper maintenance regular cleaning and

changing of filters are essential to protect the workers

against hazardous contaminants.

Chemical Safety: Mutetwa B 17

• General Ventilation

➢When it is difficult or impossible to prevent

hazardous chemicals, fumes, dusts, mists or

particles from entering the workplace air at

the source, a general dilution ventilation can

be installed.

➢This should be designed to meet the needs of

the specific work process and workplace.

➢At its best it should consist of an inflow of

clean air and an outflow of exhaust forced by

fans at the right places.

➢It can also be used with other preventive

measures.

Chemical Safety: Mutetwa B 18

ORGANIZATION MEASURES

• Establishment of properly constituted safety and

health committees.

• Identify chemicals in use.

• Obtain information on their hazards.

• Collect these data and make an inventory list of

all chemicals used in the factory: create a

Register for Workplace Chemicals.

• Assess chemical hazards and set priorities

concerning the safety in the organization.

• Create emergency plans for the assessed

hazards.

Chemical Safety: Mutetwa B 19

ORGANIZATION MEASURES –

CONT.

• Organize occupational health care and regular surveys

as needed.

• Organize contacts with authorities/ laboratories to create

a monitoring system for chemical hazards, and to reliably

measure and/or estimate occupational exposure to

chemicals when needed.

• Start collecting case studies of accidents and sickness

records in the enterprise to create a basis for priority

measures in the control of hazards.

• Involve workers in safety organizations, such as the

system of Safety Representatives, and Safety

Committees.

Chemical Safety: Mutetwa B 20

ORGANIZATION MEASURES –

CONT.

• Do regular inspection using checklists

made for the particular chemicals and

chemical processes in use.

• Mark and label all chemicals.

• Keep at hand an inventory list of all

chemicals handled in the place of work

together with a collection of Chemical

Safety Data Sheets for these chemicals.

Chemical Safety: Mutetwa B 21

ORGANIZATION MEASURES –

CONT.

• Train workers to read and understand the

Chemical Safety Information, including the

health hazards and routes of exposure;

train them to handle dangerous chemicals

and processes with caution.

• Plan, develop and choose the safe

working procedures.

• Reduce the number of people coming into

contact with dangerous chemicals.

Chemical Safety: Mutetwa B 22

PERSONAL PROTECTIVE

EQUIPMENT

• Correct equipment

- Respirators designed to protect against dust are

useless against hazardous gases.

- Many solvents rapidly penetrate natural rubber

gloves.

• Training and follow-up training must be given to

workers required to use the equipment.

• Maintenance programme, including regular

cleaning, inspection and replacement of items,

such as gloves and respiratory filters, must be

planned.

Chemical Safety: Mutetwa B 23

PERSONAL PROTECTIVE

EQUIPMENT - CONT

• Tests to ensure the good condition of

equipment are necessary. It is especially

important to check the face masks and

respirators.

• Responsible person should be indicated to

take care of the equipment.

• An individual set of equipment must be

given to each worker, and a secure, clean

place where to store the equipment.

Chemical Safety: Mutetwa B 24

STORAGE

• Planning and proper maintenance of storage

areas is relevant for users of chemicals in order

to avoid material losses, accidents and

disasters.

• Hazardous substances can leak, cause a fire or

give off dangerous fumes and vapours.

• When two substances come into contact with

one another, they may react violently.

• The reaction products may be much more

dangerous than the original chemicals.

Chemical Safety: Mutetwa B 25

STORAGE – CONT.

• Special attention should be paid to

incompatible substances, suitable location

of products within the storage area and

proper arrangements and climatic

conditions.

• For example, cylinders should be fixed

with chains to upright position; the acids in

the area or cupboard meant only for them.

Chemical Safety: Mutetwa B 26

STORAGE – CONT.

• The acid fumes or splashes should never

reach the area where cylinders are kept.

• Written instructions of storage practices

should be provided, and Chemical Safety

Data Sheets of dangerous substances

kept in the stock should be available in the

storage area.

Chemical Safety: Mutetwa B 27

ROLE AND OBLIGATIONS OF THE

COMPETENT AUTHORITY

• Formulate coherent policy in consultation with social

partners.

• Review of national measures and practice in consultation

with social partners.

• Compliance with laws and regulations concerning safety

in the use of chemicals at work.

• Competent authority should have the power if justified on

safety and health grounds to;

– Prohibit or restrict the use of certain hazardous chemicals or

– Require advance notification and authorisation before such

chemicals are used.

Chemical Safety: Mutetwa B 28

GENERAL RESPONSIBILITIES OF

EMPLOYERS

• Employers should set out in writing their policy and

arrangements on safety in the use of chemicals as part

of their general policy and arrangements in the field of

occupational safety and health.

• Employers should ensure that all chemicals used at work

are labelled or marked in accordance with the provisions

of code of practice on safe use of chemicals and that

chemical safety data sheet (CSDS) have been provided

in respect of all hazardous chemicals used at work.

• CSDS and all relevant information are made available to

workers and their representatives.

Chemical Safety: Mutetwa B 29

GENERAL RESPONSIBILITIES OF

EMPLOYERS – CONT.

• Employers receiving chemicals which have not

been labelled or marked or provided with CSDS

should not use the chemicals until the relevant

information has been obtained from the supplier,

or other reasonable available source.

• Employers should maintain a record of

hazardous chemicals at the workplace.

• Record of chemicals should be accessible to all

workers who might be affected by use of the

chemicals.

• Employers should institute risk assessment of

chemicals at work.

Chemical Safety: Mutetwa B 30

GENERAL RESPONSIBILITIES OF

EMPLOYERS – CONT.

• Employers should comply with guidelines

standards, laws and regulations

formulated, approved and recognised by

the competent authority.

• Employers should make arrangements to

deal with incidents and accidents involving

chemicals.

• Employers should provide, workers with

necessary appropriate and regular

training on chemical safety.

Chemical Safety: Mutetwa B 31

DUTIES AND RIGHTS OF

WORKERS

• Workers should take all reasonable steps

to eliminate or minimize risk to themselves

and to others from use of chemicals.

• Workers should take care of their own

safety and health and that of other

persons who may be affected by acts or

omissions at work.

• Workers should make proper use of all

devices provided for their protection or the

protection of others.

Chemical Safety: Mutetwa B 32

DUTIES AND RIGHTS OF

WORKERS – CONT.

• Workers should report to their supervisors any

situation which they believe could present a risk.

• Workers have the right to information on identity

of chemicals used at work, the hazardous

properties of such chemical and precautionary

measures and information on the risks which

may arise from the use of hazardous chemicals.

• Workers have right to information contained in

labels and markings, CSDS.

Chemical Safety: Mutetwa B 33

DUTIES AND RIGHTS OF

WORKERS – CONT.

• Workers should receive training in the

methods which are available for the

prevention and control of and protection

against such risks.

• Workers and their representative have the

right to request and participate in an

investigation by the employer or

competent authority of possible risks

resulting from the use of chemicals at

work.

Chemical Safety: Mutetwa B 34

DUTIES AND RIGHTS OF

WORKERS – CONT.

• Workers have the right to remove themselves

from danger resulting from the use of chemicals

when they have reasonable justification to

believe that there is an imminent and serious

risk to their safety and health.

• Workers who remove themselves from danger or

exercise their right to adequate protection in

regard to exposure to hazardous chemicals

should be protected against undue

consequences.

Chemical Safety: Mutetwa B 35

GENERAL RESPONSIBILITIES OF

SUPPLIERS

• Suppliers of chemicals, manufacturers,

importers, or distributors should ensure

that:

- Chemicals are classified

- Hazardous chemicals are labelled.

- CSDS for hazardous chemicals are prepared

and provided to employers.

- Chemicals are marked indicating place of

origin and destination.

Chemical Safety: Mutetwa B 36

CLASSIFICATION SYSTEMS

• Major basis for classification of chemicals is the

assessment of exposure levels and

environmental impact (water, air and soil).

• Classification of chemicals should be based

upon their intrinsic health and physical hazards

which include:

- Toxic properties, including both acute and chronic

health effects in all parts of the body.

- Chemical or physical characteristics including

flammable explosive, oxidising and dangerously

reactive properties.

- Corrosive and irritant properties.

Chemical Safety: Mutetwa B 37

CLASSIFICATION SYSTEMS –

CONT.

- All organic and sensitising effects.

- Carcinogenic effects.

- Teratogenic or mutagenic effects.

- Effects on the reproductive system

• United Nations Environmental Programme – UN

Recommendation on the Transport of

Dangerous Goods (UNRTDG).

• WHO Recommended Classification of pesticides

by hazard and guidelines to classification, which

classifies pesticides by degree of toxicity only

and principally by acute risks to health.

Chemical Safety: Mutetwa B 38

CLASSIFICATION SYSTEMS –

CONT.

• Most wide spread criteria used in chemical

classification are values of LD50.

• EU system uses 3 – level acute toxicity scale

[very toxic, toxic and harmful].

• US OSHA applies two acute toxicity levels

(highly toxic and toxic).

• Zimbabwe applies a 4 level acute toxicity scale

namely;

- Purple triangle label – very dangerous poison.

- Red triangle label –dangerous poison.

- Orange triangle label –poison.

- Green triangle label – harmful if swallowed.

Chemical Safety: Mutetwa B 39

UNRTDG

• Is generally on issues such as notification, identification

and hazard communication.

• Scope restricted to the transport of hazardous

substances in packaged form.

• Recommendation does not apply to exposed hazardous

chemicals or to transport in bulk.

• System now extended to include substances hazardous

to the environment.

• UNRTDG focus on hazard communication based on

labels which include a combination of graphic symbols,

colours, warning words and classification codes and

provide key data for emergency response teams.

Chemical Safety: Mutetwa B 40

UNRTDG – CONT.

• UN classification subdivides chemicals into 9

classes of hazards namely:

- 1st class – exposure substance

- 2nd class – compressed liquefied, dissolved under

pressure or deeply condensed gases

- 3rd class – condensed gases

- 4th class – easily flammable solid substance

- 5th class – oxidising substances , organic peroxides

- 6th class – poisonous (toxic) and infectious substance

- 7th class – radioactive substance

- 8th class – corrosive substance

- 9th class – other dangerous substance

Chemical Safety: Mutetwa B 41

LABELLING AND MARKING

• Labelling should consists of phrases, graphics and color

symbols applied directly on the product, package, label

or tag

• Labels on containers of hazardous chemicals provide the

first alert that a chemical is hazardous.

• Labelling should be generally cover the following:

- Trade names

- Identify of the chemical

- Name, address and telephone numbers of the supplier

- Hazard symbols

- Nature of special risks associated with the use of the chemical.

- Safety precautions

Chemical Safety: Mutetwa B 42

LABELLING AND MARKING –

CONT.

• Marking should be clear, comprehensive

and able to withstand adverse climatic

conditions.

- Statement that a CSDS giving additional

information is available from the employer.

- Legibility, durability and size of the label.

- Uniformity of labels and symbols, including

colours.

Chemical Safety: Mutetwa B 43

LABELLING AND MARKING –

CONT.

• UNRTG established five main pictograms for

easy visible recognition of dangerous goods and

significant hazard identification:

- Bomb – explosive

- Flame – flammable

- Skull and cross bone – toxic

- Trefoil – radioactive

- Liquid pouring out of two test-tubes on a hand and a

piece of metal –corrosive.

- Flame above a circle – oxidising substance.

- A gas bottle – non-flammable gases.

- 3 crescent signs imposed on a circle – infectious

substance.

Chemical Safety: Mutetwa B 44

TRANSFER OF CHEMICALS

• Employer should ensure that when

chemicals are transferred into other

containers or equipment, the contents are

indicated in a manner which will make

known to workers their identify, any

hazards associated with their use and any

safety precautions to be observed.

• Equipment or containers into which

chemicals are transferred should be

marked and labelled adequately.

Chemical Safety: Mutetwa B 45

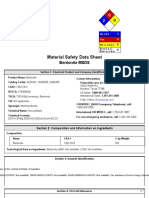

CHEMICAL SAFETY DATE SHEET

(CSDS)

• CSDS for hazardous chemicals should give

information about the identify of the chemical, its

supplier, classification, hazards, safety

precaution and relevant emergency procedures.

• Details of the type of information that should be

required are given below:

- Chemical product and company identification.

- Information on Ingredients

- Hazard Identification

- First aid measures

Chemical Safety: Mutetwa B 46

CHEMICAL SAFETY DATE SHEET

(CSDS) – CONT.

- Fire fighting measures

- Accident release measures

- Handling and storage.

- Exposure controls and personal protection.

- Physical and chemical properties.

- Stability and reactivity.

- Toxicological information

- Disposal consideration.

- Transport information

- Regulatory information

- Other information.

Chemical Safety: Mutetwa B 47

REFERENCES

• ILO. (1993). Safety in the Use of Chemicals at

Work International Labour Office, Geneva.

• ILO. (1990). Convention Concerning Safety in

the Use of Chemicals at Work.

• Stellman J M and Osinksy D (1998). Using,

Storing and Transporting Chemicals. In

Encyclopaedia of Occupational Health and

Safety, 4th Edition, Volume III. P 61.2

• WWW.ILO org

Chemical Safety: Mutetwa B 48

You might also like

- 95 Topic For Tool Box Talk PDFDocument102 pages95 Topic For Tool Box Talk PDFIra Maya Maukh100% (24)

- Rhodafac H66Document15 pagesRhodafac H66m daneshpourNo ratings yet

- Allegation: United Auburn Indian CommunityDocument16 pagesAllegation: United Auburn Indian CommunityABC10No ratings yet

- Chaper 7Document30 pagesChaper 7Yahya JuneydiNo ratings yet

- Lecture-1 WWT & ApcDocument34 pagesLecture-1 WWT & ApcSimon abebawNo ratings yet

- Chapter 4.2 Chemical Hazards PDFDocument34 pagesChapter 4.2 Chemical Hazards PDFhadrami muhdNo ratings yet

- Chemical Safety COSHHDocument9 pagesChemical Safety COSHHPRASAD6219100% (1)

- NGE AssignmentDocument8 pagesNGE AssignmentKHUSHAL KAKAR (kakaran.)No ratings yet

- DisasterDocument16 pagesDisasterJYOTI PRAKASH ROUTNo ratings yet

- Control Measures of Chemical Hazard.. Gondaleeya DevangDocument17 pagesControl Measures of Chemical Hazard.. Gondaleeya DevangDevang GondaliyaNo ratings yet

- SAFEWORK MONTH 2015 Hazardous Chemicals FMCDocument37 pagesSAFEWORK MONTH 2015 Hazardous Chemicals FMCpankajNo ratings yet

- Chapter 4.2 Chemical HazardsDocument32 pagesChapter 4.2 Chemical HazardsFarid Nasri100% (1)

- EHSEC Toolbox Talk ChemicalsDocument10 pagesEHSEC Toolbox Talk ChemicalsGeorge ScroubelosNo ratings yet

- Factsheet1 Clean ProductionDocument10 pagesFactsheet1 Clean ProductionCharith LiyanageNo ratings yet

- A European Campaign On Risk AssessmentDocument23 pagesA European Campaign On Risk AssessmentRisky Astia LianyNo ratings yet

- Nebosh Igc-2 Important Questions and Answers: Element 7Document7 pagesNebosh Igc-2 Important Questions and Answers: Element 7Wafula RobertNo ratings yet

- Construction Health and SAfetyDocument9 pagesConstruction Health and SAfetyDroffilc Nav Cm MulihamNo ratings yet

- 3.13 - Chemical Hazards-RECOGNITION, EVALUATION AND CONTROLP3Document7 pages3.13 - Chemical Hazards-RECOGNITION, EVALUATION AND CONTROLP3Chima ElokaNo ratings yet

- General Design ConsiderationsDocument37 pagesGeneral Design ConsiderationsArif AmancioNo ratings yet

- Responsible Care Guiding PrinciplesDocument177 pagesResponsible Care Guiding PrinciplesKhushi PatelNo ratings yet

- Cross ContaminationDocument47 pagesCross ContaminationAKKAD PHARMANo ratings yet

- Industrial HygieneDocument30 pagesIndustrial HygieneJes AsiNo ratings yet

- Hazard and Risk Management - Sarika MamDocument24 pagesHazard and Risk Management - Sarika MamSharon DsouzaNo ratings yet

- BOSHDocument31 pagesBOSHDANICA JORIELLE PALOGANNo ratings yet

- ETP Risk AssesmentDocument20 pagesETP Risk Assesmentvikkas verma0% (1)

- Ch2-General Design Considerations Week2Document61 pagesCh2-General Design Considerations Week2ميثة الغيثيةNo ratings yet

- Cross ContaminationDocument47 pagesCross ContaminationDorin BivolNo ratings yet

- BPE Aidana 2Document2 pagesBPE Aidana 2mohamed aliNo ratings yet

- Lecture #2 Chemical Engineering Plant Design: Prof - Dr.A.K SALARIYADocument49 pagesLecture #2 Chemical Engineering Plant Design: Prof - Dr.A.K SALARIYAAdil AslamNo ratings yet

- Chemical Hazards & Chemical Safety ManagementDocument45 pagesChemical Hazards & Chemical Safety ManagementAziful AimanNo ratings yet

- Drilling Fluids Manual HandbookDocument578 pagesDrilling Fluids Manual HandbookYuthia Aulia Riani100% (13)

- Guideline No. en - 015 Control of Substances Hazardous To Health and DangerDocument20 pagesGuideline No. en - 015 Control of Substances Hazardous To Health and Dangertp101267No ratings yet

- Environmental Health and Safety in Manufacturing IndustryDocument7 pagesEnvironmental Health and Safety in Manufacturing IndustryANUJANo ratings yet

- ESIA Chem Stewardship April 07Document4 pagesESIA Chem Stewardship April 07Paritosh JainNo ratings yet

- Element 7 Forms of Chemical AgentsDocument4 pagesElement 7 Forms of Chemical Agentsmohdakramk7No ratings yet

- HSE 2014 Unit I & IIDocument71 pagesHSE 2014 Unit I & IIBaby ChickooNo ratings yet

- LEV Course Part 1ppsxDocument42 pagesLEV Course Part 1ppsxHafizie ZainiNo ratings yet

- Chemical SafetyDocument27 pagesChemical SafetyVina May LaurioNo ratings yet

- KAP 3002 Chemical Safety Chater 1bDocument37 pagesKAP 3002 Chemical Safety Chater 1bSyahirah MisarihNo ratings yet

- AnswerDocument1 pageAnswersaeedaumar1954No ratings yet

- COSHH E-Learning CourseDocument29 pagesCOSHH E-Learning CourseCarolineNo ratings yet

- LearningsDocument15 pagesLearningssay.elleseNo ratings yet

- Chapter-10 Environment and Safety: 10-1 IntroductionDocument8 pagesChapter-10 Environment and Safety: 10-1 IntroductionPedro Paulo CordeiroNo ratings yet

- Ch6occupational Health and SafetyDocument33 pagesCh6occupational Health and Safetyusmail179No ratings yet

- Hsps04 Hazardous Substances Risk AssessmentDocument34 pagesHsps04 Hazardous Substances Risk AssessmentsaravanaayappanNo ratings yet

- ENVIRONMENTAL HEALTH AND SAFETY Module 1 To StudentsDocument87 pagesENVIRONMENTAL HEALTH AND SAFETY Module 1 To StudentsNEERAJ KISHORE PNo ratings yet

- DRRR Module 4Document16 pagesDRRR Module 4Joveliezel Jaducana Baroro Rodriguez100% (1)

- CHE135 - Ch2 Toxicity - MII - L2.1 - Sept 2017Document27 pagesCHE135 - Ch2 Toxicity - MII - L2.1 - Sept 2017SyafiyatulMunawarahNo ratings yet

- Occupational Health and HygieneDocument40 pagesOccupational Health and HygieneAISYAH NABILAH ROSLANNo ratings yet

- EHE PPT (OHS)Document29 pagesEHE PPT (OHS)Ramzi JamalNo ratings yet

- Unit 3 - ISEDocument60 pagesUnit 3 - ISEavenesh231No ratings yet

- Group7, BoshDocument26 pagesGroup7, Boshhernandez rayven p.No ratings yet

- 15 PUBLIC HEALTH SYSTEM and OUTREACH PROGRAMMES 225012301368Document3 pages15 PUBLIC HEALTH SYSTEM and OUTREACH PROGRAMMES 225012301368Nursing Superintendent (SH)No ratings yet

- Oh Notes (Control of Occupational Hazard)Document4 pagesOh Notes (Control of Occupational Hazard)AdebisiNo ratings yet

- WSH Guidelines MHCPDocument52 pagesWSH Guidelines MHCPngjsaNo ratings yet

- Untitled DocumentDocument57 pagesUntitled Documentgcad19323No ratings yet

- Chapter4a HealthhazardsDocument52 pagesChapter4a HealthhazardspyqxaaNo ratings yet

- Topic Six: Health Assessment & SurveillanceDocument29 pagesTopic Six: Health Assessment & Surveillancesrkam100% (1)

- Occupational HygieneDocument72 pagesOccupational HygieneVincent BerryNo ratings yet

- Introduction To Industrial Safety and Accident PreventionDocument42 pagesIntroduction To Industrial Safety and Accident PreventionAshwani DograNo ratings yet

- Safety and Human Factors EngineeringDocument57 pagesSafety and Human Factors EngineeringAkshayraj VrNo ratings yet

- Hazmat Msds Learning MaterialDocument70 pagesHazmat Msds Learning MaterialRifky Dwi Hendrawan100% (1)

- Effective microbiological sampling of food processing environments (1999)From EverandEffective microbiological sampling of food processing environments (1999)No ratings yet

- Barium CarbonateDocument114 pagesBarium CarbonateUmakant BallureNo ratings yet

- Active Pharmaceutical Ingredients - Development, Manufacturing, and Regulation, Second Edition (Drugs and The Pharmaceutical Sciences) - 9781439803363 - Medicine & Health Science Books @Document13 pagesActive Pharmaceutical Ingredients - Development, Manufacturing, and Regulation, Second Edition (Drugs and The Pharmaceutical Sciences) - 9781439803363 - Medicine & Health Science Books @Marwa Ahmed100% (1)

- Agricultural Control Chemicals (1950)Document277 pagesAgricultural Control Chemicals (1950)Sveti JeronimNo ratings yet

- Dimethylsulfoxyde MSDSDocument12 pagesDimethylsulfoxyde MSDSLarry MicksNo ratings yet

- Bentonite MSDS: Section 1: Chemical Product and Company IdentificationDocument5 pagesBentonite MSDS: Section 1: Chemical Product and Company IdentificationMuhammad FadliNo ratings yet

- SDS 217 Hydrofluorosilicic Acid NA Final 04302015 (Nutrien)Document12 pagesSDS 217 Hydrofluorosilicic Acid NA Final 04302015 (Nutrien)NourAldin AbuSalehNo ratings yet

- Glufosinate-Ammonium+SL+120C. 000000000030692706 SDS CPA US en 6-0Document14 pagesGlufosinate-Ammonium+SL+120C. 000000000030692706 SDS CPA US en 6-0Mv PatelNo ratings yet

- Toxicity of PesticidesDocument8 pagesToxicity of PesticidesmianNo ratings yet

- Safety Data Sheet: 1. Identification of The Substance/Preparation and CompanyDocument8 pagesSafety Data Sheet: 1. Identification of The Substance/Preparation and CompanyEdin Krdžalić EdoNo ratings yet

- LD 4 MSDSDocument19 pagesLD 4 MSDSKevin John P. PangilinanNo ratings yet

- Safety Data Sheet: Rando Ashless 8401Document11 pagesSafety Data Sheet: Rando Ashless 8401robinrajan1985No ratings yet

- Refresher Igien No GasDocument11 pagesRefresher Igien No GasClean UpNo ratings yet

- Msds Brake Fluids Federal-MogulDocument9 pagesMsds Brake Fluids Federal-MogulElías VillegasNo ratings yet

- MSDS Rheliant SystemDocument8 pagesMSDS Rheliant SystemJose AlejandroBlancoNo ratings yet

- Rarpolyol Ap 1606 XLDocument9 pagesRarpolyol Ap 1606 XLMahmoud FlefilNo ratings yet

- Septico Tank TreatmentDocument3 pagesSeptico Tank TreatmentfernandaNo ratings yet

- Medical Hazards of Cell Phones Wi-Fi Wireless Devices and Smart Meters 8.17.16 PDFDocument233 pagesMedical Hazards of Cell Phones Wi-Fi Wireless Devices and Smart Meters 8.17.16 PDFHannah LeeNo ratings yet

- Caustic Soda Data SheetDocument5 pagesCaustic Soda Data SheetKudakwashe Walter MakoniNo ratings yet

- NO CANCER RISK EPA 2012 Chemicals - EvaluatedDocument29 pagesNO CANCER RISK EPA 2012 Chemicals - EvaluateduncleadolphNo ratings yet

- MSDS Jotun Jotamastic 80 STD Comp BDocument11 pagesMSDS Jotun Jotamastic 80 STD Comp BBùi Văn HợpNo ratings yet

- MsdsDocument5 pagesMsdsCrissDhyonIINo ratings yet

- MSDS EliumDocument12 pagesMSDS EliumОлег ШибекоNo ratings yet

- Isopropyl Alcohol SDSDocument13 pagesIsopropyl Alcohol SDSNarayan SatyalNo ratings yet

- Safety Data Sheet: ItemDocument19 pagesSafety Data Sheet: Itemsiad houssamNo ratings yet

- FDS Zinc Bromide Brine 20.5 PPGDocument8 pagesFDS Zinc Bromide Brine 20.5 PPGnoe tellezNo ratings yet

- Solvent SDS Version 8 2021Document7 pagesSolvent SDS Version 8 2021johanbesarNo ratings yet

- Proxel XL2 - MSDSDocument13 pagesProxel XL2 - MSDSNayPa ChannelNo ratings yet