Professional Documents

Culture Documents

Ball Check Valves Flanged

Uploaded by

eliiiiiiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ball Check Valves Flanged

Uploaded by

eliiiiiiCopyright:

Available Formats

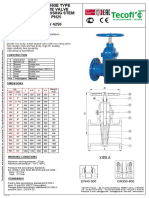

Ref. : CBL 3240.

pas FLANGED BALL

Rev. : R CHECK VALVE

Date : 23/05/2014

Page : 1/1 CBL 3240

APPLICATION

General uses: waste water, stickly fluids, raising water

(purification, water treatment, pumping...)

GENERAL CHARACTERISTICS

Design in accordance with standard NF EN 12334.

Range: From DN 40 to DN 600.

Tight and working in horizontal or vertical position.

Low head loss.

Full bore thanks to the moving of the ball.

The photographies and technical art works are not contractual. The specifications of the presented products are open to modifications without previous advice.

Self-cleaning ball.

Lifting hook in the cover for easy handling.

Easy and quick disassembling cover.

Cap allowing the takeoff of the ball.

Body: oven baked epoxy 150 μm, RAL 5019.

CONSTRUCTION V ie w B

6 1 Degassing plug Stainless steel Only for DN 40-400

5 1 Gasket Nitril

4 2/4 Nut Stainless steel

Nitril coated steel

3 1 Ball

DIN: GGG 40

Ductile iron

2 1 Bonnet ASTM: A536 65-45-12

EN-GJS-400-15

BS: 1563 EN-JS1030

DIN: GGG 40

Ductile iron

1 1 Body ASTM: A536 65-45-12

EN-GJS-400-15

BS: 1563 EN-JS1030

Rep. Nb. Description Material

DIMENSIONS

DN Minimum

O Ring Weight

L H ØD Ø K nxØ M opening

mm inch Ø int. x Ø torus (kg)

pressure (mbar)

40 1"1/2 180 113 150 110 4 x Ø19 Ø59,7 x Ø5,3 6,9 6,00

50 2" 200 145 165 125 4 x Ø18,5 Ø68,4 x Ø5,3 12,6 9,45

65 2"1/2 240 169 185 145 4 x Ø18,5 Ø105,4 x Ø5,3 20,5 14.0

80 3" 260 169 200 160 8 x Ø18,5 Ø105,4 x Ø5,3 12,0 15.1

100 4" 300 211 220 180 8 x Ø18 Ø133,6 x Ø5,7 16,0 22.7

125 5" 350 275 250 210 8 x Ø18 Ø188,6 x Ø5,7 41,6 38.1 nx M

150 6" 400 294 285 240 8 x Ø22 Ø188,6 x Ø5,7 25,7 47.8

200 8" 500 395 340 295 8 x Ø22 Ø257,8 x Ø8,6 26,7 91

250 10" 600 482 400 350 12 x Ø22 Ø317,8 x Ø8,6 32,5 144

300 12" 700 573 455 400 12 x Ø22 Ø382,8 x Ø8,6 35,7 222

350 14" 800 654 505 460 16 x Ø23 Ø455 x Ø10 54,2 367 K

400 16" 900 781 565 515 16 x Ø26 Ø530 x Ø10 64,0 499

500 20" 1100 880 670 620 20 x Ø27 - - 580

600 24” 1300 1030 780 725 20 x Ø30 - - 1080 Following vie w B

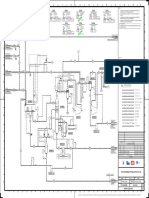

WORKING CONDITIONS

ΔP(mCE)

DN125

DN300

DN150

Maximum working pressure: 10 bar.

DN100

DN250

DN200

DN350

DN500

DN600

DN400

DN40

DN65

DN50

DN80

Maximum temperature: -10°C / +80°C. 10

Warning: On request for low load.

Pressure test according to standards

EN 12266-1, DIN 3230, BS 6755 and ISO 5208 :

Body : 15 bar. 1

Seat : 11 bar.

STANDARDS

Manufacture according to the requirements of the European 0.1

directive 97/23/CE «Equipment under pressure» 10.00 100.00 1000.00 10000.00

Modulate H. (DN 40-400) mCE - mètre colonne d'eau / meter water column Débit / Flow (m3/h)

Face to face according to standards NF EN 558-1 serie 48,

DIN 3202/1 serie F6. Standard mounting flanges according to

EN 1092-2 ISO PN 10, PN 16 and ASA 150 lbs on request.

TECOFI France - 83, Rue Marcel Mérieux 69960 Corbas - FRANCE

Tél. +33 (0) 4 72 79 05 79 - Fax +33 (0) 4 78 90 19 19 / +33 (0) 4 72 79 05 70

Adresses e-mail : sales@tecofi.fr / Site web : www.tecofi.fr

Indic e 00

You might also like

- Borax Vpn3449 00 - enDocument1 pageBorax Vpn3449 00 - enManu Galdeano RuizNo ratings yet

- Gate Valve Resilient Seat: Rev.: D Ref.: VOC4241C-00.pasDocument1 pageGate Valve Resilient Seat: Rev.: D Ref.: VOC4241C-00.pasedmar jay conchadaNo ratings yet

- Check Valve Pn16 Flanged Type Swing: Ref.: CB 3240PN16.pasDocument1 pageCheck Valve Pn16 Flanged Type Swing: Ref.: CB 3240PN16.pasedmar jay conchadaNo ratings yet

- Valvula FolatadoraDocument1 pageValvula FolatadoraJC ParedesNo ratings yet

- Globe Valve W BellowDocument1 pageGlobe Valve W BellowIvan TijerinaNo ratings yet

- With External Clamping Ring: PropertiesDocument1 pageWith External Clamping Ring: Propertiesmiguel.cruzNo ratings yet

- Pole FoundationDocument1 pagePole FoundationM Rashid Latif GhouriNo ratings yet

- KS-304 Kiosk Substation Plinth Details Enclosure Type 4-15Document1 pageKS-304 Kiosk Substation Plinth Details Enclosure Type 4-15RickNo ratings yet

- QL Design 120 Series Overview Tab 1984Document2 pagesQL Design 120 Series Overview Tab 1984Alan MastersNo ratings yet

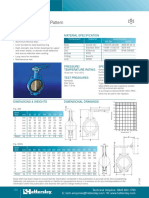

- Butterfly ValvesDocument6 pagesButterfly ValvestezgidenNo ratings yet

- Fig 950 950GDocument1 pageFig 950 950GAsmaaNo ratings yet

- V-700 - Volume BottleDocument1 pageV-700 - Volume BottleRizki FadhlurrohmanNo ratings yet

- CW542ME5UNW1 Spec SheetDocument1 pageCW542ME5UNW1 Spec Sheetnishant81No ratings yet

- LK 003 TRI - ... - enDocument2 pagesLK 003 TRI - ... - enJalil ChoueiryNo ratings yet

- (For Single Column) (For Single Column) (For Double Column) (For Single Column)Document1 page(For Single Column) (For Single Column) (For Double Column) (For Single Column)Tôn Huỳnh ĐoànNo ratings yet

- Apollo LD14102BE10A Data SheetDocument2 pagesApollo LD14102BE10A Data SheetJacobs San RomanNo ratings yet

- Apollo LD14102BE10A Data SheetDocument2 pagesApollo LD14102BE10A Data SheetJacobs San RomanNo ratings yet

- Q285 CatalogueDocument65 pagesQ285 Cataloguecahyo hutomoNo ratings yet

- Butterfly Valve Q 011Document4 pagesButterfly Valve Q 011JOHNNo ratings yet

- Specification: App. Leng Mark Size Service Rat Ing Remark Design Data For VesselDocument1 pageSpecification: App. Leng Mark Size Service Rat Ing Remark Design Data For VesselcayovinNo ratings yet

- Fig. 822 & 922 Fig. 810 & 910 Y-Type Strainers: DN50-DN300 DN350-DN600Document1 pageFig. 822 & 922 Fig. 810 & 910 Y-Type Strainers: DN50-DN300 DN350-DN600Manuel CampoyNo ratings yet

- Valvula Check CraneDocument1 pageValvula Check CraneMIGUEL ANGELNo ratings yet

- T1 - (Ø12 - 4 NOS.) : 4 Nos Holes Ø22 Thru. On 360 P.C.D. EquispacedDocument1 pageT1 - (Ø12 - 4 NOS.) : 4 Nos Holes Ø22 Thru. On 360 P.C.D. EquispacedDhilipkumar GNo ratings yet

- Rubber Expansion Joint With Swivel FlangesDocument1 pageRubber Expansion Joint With Swivel FlangesHai PhanNo ratings yet

- I T5 A LVN: Street Light Fittings With Lower CoverDocument1 pageI T5 A LVN: Street Light Fittings With Lower Coverionelg834549No ratings yet

- Res Techb Slabedge InsulationDocument3 pagesRes Techb Slabedge InsulationPaola RCNo ratings yet

- 9 DS 224 3Document4 pages9 DS 224 3genas7265No ratings yet

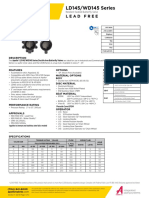

- LD145/WD145 Series: Lead FreeDocument3 pagesLD145/WD145 Series: Lead FreeDaniel SanNo ratings yet

- Shut-Off Valves: Types SVA-DL and SVA-DH 250-300Document8 pagesShut-Off Valves: Types SVA-DL and SVA-DH 250-300miguel callataNo ratings yet

- MTC - MoC 3934 - PA334 - DW001Document1 pageMTC - MoC 3934 - PA334 - DW001Tuan Anh LuuNo ratings yet

- Rev Kantor Asuransi Ruko Yanglim LT 3-ModelDocument1 pageRev Kantor Asuransi Ruko Yanglim LT 3-ModelHengky SarjalieNo ratings yet

- (For Double Column) (For Single Column) (For Single Column) (For Single Column)Document1 page(For Double Column) (For Single Column) (For Single Column) (For Single Column)Tôn Huỳnh ĐoànNo ratings yet

- DS W9Document3 pagesDS W9Dar FallNo ratings yet

- Non-Contacting, Outward Pumping Dual Gas Seal: Performance Capabilities Product DescriptionDocument8 pagesNon-Contacting, Outward Pumping Dual Gas Seal: Performance Capabilities Product DescriptionimtiyazNo ratings yet

- HYD691 Datasheet: Introducing The Hyd691... Standard Materials of ConstructionDocument4 pagesHYD691 Datasheet: Introducing The Hyd691... Standard Materials of ConstructionIdehen KelvinNo ratings yet

- HYD691 Datasheet: Introducing The Hyd691... Standard Materials of ConstructionDocument4 pagesHYD691 Datasheet: Introducing The Hyd691... Standard Materials of ConstructionjujuroyaleNo ratings yet

- PN16 Joints Dismantling: Ref.: JT4243 .Pas Rev.: Initial Date: 30/05/2016 Page: 1/1Document1 pagePN16 Joints Dismantling: Ref.: JT4243 .Pas Rev.: Initial Date: 30/05/2016 Page: 1/1edmar jay conchadaNo ratings yet

- Prospekt Strahlrohr enDocument8 pagesProspekt Strahlrohr enForum PompieriiNo ratings yet

- NSK R Serisi Ovalanmis Bilyali Vida BrosurDocument30 pagesNSK R Serisi Ovalanmis Bilyali Vida Brosurfreddy noel romeroNo ratings yet

- Product Sheet 2112 DN40-DN300Document2 pagesProduct Sheet 2112 DN40-DN300Justin ReyesNo ratings yet

- SBF, SBN Powerflood Floodlight: ApplicationsDocument2 pagesSBF, SBN Powerflood Floodlight: ApplicationsKarlos Antonio Salinas MoralesNo ratings yet

- Stop Valves SVA-DL & SVA-DH 250-300: Technical BrochureDocument8 pagesStop Valves SVA-DL & SVA-DH 250-300: Technical BrochureFernando David RamirezNo ratings yet

- 1.concentric Butterfly Valve in Various ApplicationDocument10 pages1.concentric Butterfly Valve in Various ApplicationMaciekNo ratings yet

- (For Double Column) (For Double Column) (For Single Column) (For Double Column Inside)Document1 page(For Double Column) (For Double Column) (For Single Column) (For Double Column Inside)Tôn Huỳnh ĐoànNo ratings yet

- 1.5.1 Lay Out 497791-101Document1 page1.5.1 Lay Out 497791-101Nikhil chaundkarNo ratings yet

- Bearing NTNballDocument26 pagesBearing NTNballZakNo ratings yet

- For Common Fluids, Simple Industrial Installation... : Rev.: Initial Ref.: V 4250.pasDocument1 pageFor Common Fluids, Simple Industrial Installation... : Rev.: Initial Ref.: V 4250.pasJun Bryan Ramirez AbangNo ratings yet

- SR Series: J Flow ControlsDocument5 pagesSR Series: J Flow ControlsJimmy RojasNo ratings yet

- Anchor Pocket and Hawse Pipe - Reinforcement - : Emerg. ExitDocument3 pagesAnchor Pocket and Hawse Pipe - Reinforcement - : Emerg. ExitSteven SahaniNo ratings yet

- K2000-Serie ENDocument1 pageK2000-Serie ENbala subramaniyam TSNo ratings yet

- 756-100-671 - Avk002ax - Eni - 432306 DOUBLE ECCENTRIC FLANGE BUTERFLY VALVE (AVK)Document3 pages756-100-671 - Avk002ax - Eni - 432306 DOUBLE ECCENTRIC FLANGE BUTERFLY VALVE (AVK)arixbonengNo ratings yet

- DG 090 12233 0001 - 00 - 001Document1 pageDG 090 12233 0001 - 00 - 001yohanes153No ratings yet

- Brosur Valve Hatersley 2Document1 pageBrosur Valve Hatersley 2Muhamad SuryaNo ratings yet

- HOLY FAMILY OKHALA-Layout1Document1 pageHOLY FAMILY OKHALA-Layout1sy9866956No ratings yet

- Flow Side Control: A B C Weight (KG) DNDocument1 pageFlow Side Control: A B C Weight (KG) DNHai PhanNo ratings yet

- FP 700 EngineeringDocument8 pagesFP 700 EngineeringCarlos Alberto VargasNo ratings yet

- Design Proposal For North Public & Suite Areas Decorative Lighting, Solaire Quezon CityDocument42 pagesDesign Proposal For North Public & Suite Areas Decorative Lighting, Solaire Quezon CityRichard Libunao BelduaNo ratings yet

- FCS Brochure PCV ENG 200316Document2 pagesFCS Brochure PCV ENG 200316Bùi Cảnh TrungNo ratings yet

- Pipe Finished Painting: Site Inspection & Test ReportDocument2 pagesPipe Finished Painting: Site Inspection & Test ReporteliiiiiiNo ratings yet

- Please Note That This Spreadsheet Contains Inspection Forms For Many LocationsDocument11 pagesPlease Note That This Spreadsheet Contains Inspection Forms For Many LocationseliiiiiiNo ratings yet

- Pipe Sandblasting &: Priming Inspection Report Qa/Qc FormDocument4 pagesPipe Sandblasting &: Priming Inspection Report Qa/Qc FormeliiiiiiNo ratings yet

- 2005 OES Analysis of MetalsDocument2 pages2005 OES Analysis of MetalseliiiiiiNo ratings yet

- Pasargard Qeshm Utility Production Plant Construction Project Organization ChartDocument1 pagePasargard Qeshm Utility Production Plant Construction Project Organization CharteliiiiiiNo ratings yet

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- Quality Control Plan: ClientDocument7 pagesQuality Control Plan: ClienteliiiiiiNo ratings yet

- Rehabilitation of Automobile Crankshafts by Submerged-Arc WeldingDocument18 pagesRehabilitation of Automobile Crankshafts by Submerged-Arc WeldingeliiiiiiNo ratings yet

- Scm822M 13crmo44 16crmo44 Fxlc130 Astralloy V 21crmov511Document2 pagesScm822M 13crmo44 16crmo44 Fxlc130 Astralloy V 21crmov511eliiiiiiNo ratings yet

- 007 SAE InternationalDocument2 pages007 SAE InternationaleliiiiiiNo ratings yet

- Corrosiveness To Copper From Petroleum Products by Copper Strip TestDocument10 pagesCorrosiveness To Copper From Petroleum Products by Copper Strip TesteliiiiiiNo ratings yet

- Procedure Qualification Record SheetDocument2 pagesProcedure Qualification Record SheeteliiiiiiNo ratings yet

- Dimension & Visual Check ReportDocument1 pageDimension & Visual Check Reporteliiiiii50% (2)

- IC Project Tracking Template 8640 V1Document3 pagesIC Project Tracking Template 8640 V1eliiiiiiNo ratings yet

- Decoration ProposalDocument4 pagesDecoration ProposaleliiiiiiNo ratings yet

- Welding Coordination Activities and Responsibilities To ISO 14731 Task Allocation ListDocument7 pagesWelding Coordination Activities and Responsibilities To ISO 14731 Task Allocation ListeliiiiiiNo ratings yet

- Dynamics Meriam ADocument8 pagesDynamics Meriam AeliiiiiiNo ratings yet

- IC Project Tracking Template 8640 V1Document3 pagesIC Project Tracking Template 8640 V1eliiiiiiNo ratings yet

- (BOSCH2002) BOSCH Automotive HandbookDocument1,391 pages(BOSCH2002) BOSCH Automotive HandbookBalaji RamanNo ratings yet

- IC Simple Gantt Chart Template 8640 V1Document17 pagesIC Simple Gantt Chart Template 8640 V1eliiiiiiNo ratings yet

- Marketing Strategy of Higher Education Institutions: Mediterranean Journal of Social SciencesDocument5 pagesMarketing Strategy of Higher Education Institutions: Mediterranean Journal of Social ScienceseliiiiiiNo ratings yet

- Public Speaking-From Preparation To Presentation: How To Become Confident, Relaxed and MeaningfulDocument4 pagesPublic Speaking-From Preparation To Presentation: How To Become Confident, Relaxed and MeaningfulNadya KhairunaNo ratings yet

- Interdisciplinary Research Process and Theory 3rd Edition Repko Test BankDocument3 pagesInterdisciplinary Research Process and Theory 3rd Edition Repko Test BankMichaelFloresjidbc100% (16)

- Individual Defending SessionDocument6 pagesIndividual Defending SessionAnonymous FN27MzNo ratings yet

- Ass Fucked by A GiantDocument5 pagesAss Fucked by A GiantSwetaNo ratings yet

- Alumni Association Action Plan 2017: Republic of The PhilippinesDocument2 pagesAlumni Association Action Plan 2017: Republic of The PhilippinesLea Cardinez100% (1)

- "The World On The Turtle's Back" by The IroquoisDocument9 pages"The World On The Turtle's Back" by The IroquoisCaleb Morales100% (1)

- AFFIRMATIONS of LOUISE HAYDocument18 pagesAFFIRMATIONS of LOUISE HAYVRnlp91% (32)

- People Vs AbellaDocument12 pagesPeople Vs AbellaRaymond SanchezNo ratings yet

- Gynecology Part 1Document12 pagesGynecology Part 1Subramaniam Sundaram100% (3)

- About Bacon and His EssaysDocument5 pagesAbout Bacon and His EssaysNexus FallingNo ratings yet

- Quiz Sensation 103Document11 pagesQuiz Sensation 103amandeep251702No ratings yet

- History of Make UpDocument15 pagesHistory of Make Upaprilann baldo100% (1)

- Singapore Visa Specimen FormDocument7 pagesSingapore Visa Specimen Formaniket_ghanvatkarNo ratings yet

- A3002RU Datasheet V1.5Document3 pagesA3002RU Datasheet V1.5adadaNo ratings yet

- Kingdeli Adhesive Catalogue 2020Document21 pagesKingdeli Adhesive Catalogue 2020Md Farid AhmedNo ratings yet

- Web First Floor 1 PDFDocument1 pageWeb First Floor 1 PDFDeendayal KumawatNo ratings yet

- 9 Budgets - Budgetary ControlDocument10 pages9 Budgets - Budgetary ControlLakshay SharmaNo ratings yet

- Bible Study MethodsDocument60 pagesBible Study MethodsMonique HendersonNo ratings yet

- Als Assessment Form 1 Individual Learning Agreement: Department of EducationDocument9 pagesAls Assessment Form 1 Individual Learning Agreement: Department of EducationRitchie ModestoNo ratings yet

- Haramaya University: R.NO Fname Lname IDDocument13 pagesHaramaya University: R.NO Fname Lname IDRamin HamzaNo ratings yet

- Transit Short Cuts-Bepin Bihari PDFDocument4 pagesTransit Short Cuts-Bepin Bihari PDFinterestedguy100% (1)

- Aircraft OrdnanceDocument78 pagesAircraft OrdnancemariA ANNA100% (1)

- 8-31 AhlamDocument14 pages8-31 AhlamJeff BowmanNo ratings yet

- 13 - Chapter 3Document22 pages13 - Chapter 3manoj varmaNo ratings yet

- Glycemic Index MontignacDocument4 pagesGlycemic Index MontignacCristina HanuschiNo ratings yet

- M. L. Dahanukar College of Commerce B. Com. (Accounting & Finance) Fees Details For The Year 2017-2018Document1 pageM. L. Dahanukar College of Commerce B. Com. (Accounting & Finance) Fees Details For The Year 2017-2018MLastTryNo ratings yet

- Chapter7 The Cyanotype ProcessDocument48 pagesChapter7 The Cyanotype ProcessIni CobaNo ratings yet

- West Wendover Proposed OrdinanceDocument16 pagesWest Wendover Proposed OrdinanceA Safer Nevada DirectorNo ratings yet

- Army Aviation Digest - Nov 1972Document52 pagesArmy Aviation Digest - Nov 1972Aviation/Space History LibraryNo ratings yet

- Approaches To The Study of Environment: Carl RitterDocument12 pagesApproaches To The Study of Environment: Carl RitterArshdeep SinghNo ratings yet