Professional Documents

Culture Documents

The Design and Construction of The World S Tallest Building The Burj Khalifa Dubai

Uploaded by

Mohammed FdmmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Design and Construction of The World S Tallest Building The Burj Khalifa Dubai

Uploaded by

Mohammed FdmmCopyright:

Available Formats

Structural Engineering International

ISSN: 1016-8664 (Print) 1683-0350 (Online) Journal homepage: https://www.tandfonline.com/loi/tsei20

The Design and Construction of the World’s Tallest

Building: The Burj Khalifa, Dubai

Bill Baker (Partner) & James Pawlikowski (Associate Director)

To cite this article: Bill Baker (Partner) & James Pawlikowski (Associate Director) (2015) The

Design and Construction of the World’s Tallest Building: The Burj Khalifa, Dubai, Structural

Engineering International, 25:4, 389-394, DOI: 10.2749/101686615X14355644770857

To link to this article: https://doi.org/10.2749/101686615X14355644770857

Published online: 23 Mar 2018.

Submit your article to this journal

Article views: 1322

View related articles

View Crossmark data

Citing articles: 8 View citing articles

Full Terms & Conditions of access and use can be found at

https://www.tandfonline.com/action/journalInformation?journalCode=tsei20

The Design and Construction of the World’s Tallest

Building: The Burj Khalifa, Dubai

Bill Baker, Partner; James Pawlikowski, Associate Director; SOM LLP, Chicago, USA.

Contact: James.Pawlikowski@som.com

DOI: 10.2749/101686615X14355644770857

Abstract

The design of the Burj Khalifa rep-

resents a truly collaborative effort

between all members of the design

team. A tower of such height required

interaction and input from all par-

ties to create a system and form that

responds efficiently to wind and gravity

loads, while also facilitating construc-

tion and enhancing building function.

This paper will focus on the challenges

faced by the design team, as well as the

lessons learned during the design and

construction phases, and how they can

be applied to the next generation of

supertall buildings.

Keywords: wind engineering; but-

tressed core; high-performance con-

crete; tall buildings.

Introduction

International Shanghai Taipei 101 One world Makkah Royal Burj khalifa

The challenge of the Burj Khalifa was Commerce World Trade Clock Tower

Centre Financial Center Hotel

not only to create the world’s tallest Center

building, but it was to do so utilizing Hong Kong Shanghai Taipei New York Mecca Dubai

conventional systems, materials, and 2010 2008 2004 2014 2012 2010

construction methods, albeit modified 484 M 492 M 508 M 541 M 601 M 828 M

and utilized in new capacities. A tower

of this height had never before been Fig. 1: World’s tallest buildings

seen, which required much innovation,

both in terms of new ideas, and in devel- Makkah Royal Clock Tower Hotel Tower Form

oping new ways to use and advance is currently the second tallest in all

current technologies. To achieve this, three categories at 601, 601 and 559 m, A primary concern in the engineering

the design required intensive and con- respectively (ctbuh.org). of tall buildings is the effect of wind

stant collaboration between architects, on the buildings’ structure. The form

The 163 story Tower is the center-

engineers, and specialty consultants to of the Burj Khalifa is the result of

piece of a USD20+ billion develop-

develop a building form that addressed collaboration between the architects

ment located just outside of downtown

structural efficiency, constructabil- and engineers to vary the shape of

Dubai. It is a mixed-use building, con-

ity, building aesthetics, and function the building along its height, thereby

sisting primarily of residential and

simultaneously. minimizing wind forces on the build-

office usage, as well as an Armani hotel

At the height of 828 m, Burj Khalifa and retail outlets. The project included ing, while also keeping the structure

eclipsed the previous record holder by the Tower, an adjacent podium struc- simple and fostering constructability

over 300 m (Taipei 101 at 508 m) (Fig. ture, and low-rise office and pool (Fig. 2). The floor plan of the Tower

1). From the outset of the project, the annex buildings. The total area for the consists of a tri-axial, Y-shaped plan,

owner—Emaar Properties PJSC of project is 465 000 m2, with the Tower formed by having three separate

Dubai—intended that the Tower be portion being 280 000 m2. Construction wings connected to a central core. As

the world’s tallest building. It currently for the preliminary works and foun- the Tower rises in height, one wing at

holds the record for height in all three dations began in January 2004. After each tier “sets back” in a spiraling pat-

categories as defined by the Council a hiatus in work on the site, the con- tern, further emphasizing its height.

on Tall Buildings and Urban Habitat struction of the superstructure started The result is 24 different primary floor

(CTBUH): height to architectural top in April 2005 and was completed in plates (plus some less major varia-

(828 m); height to tip (830 m); and January 2009. The Tower was opened tions), creating a stepping geometry

highest occupied floor (585 m). The in January 2010. that presents multiple building widths

Structural Engineering International 4/2015 Technical Report 389

the building spreads out as the grav- tional load then helps stabilize the

ity and wind forces accumulate. As a structure by utilizing the weight of the

result, even though the global forces building to resist the wind. The result

are large, the forces in the individual is a very efficient tower, which is also

members are not. extremely stiff laterally and torsion-

ally. In fact, because of the shape of

the building and the harmonics of the

Tower Superstructure—The structure, the forces and motions were

Buttressed Core greatly reduced, and the motion and

acceleration criteria could be satis-

The structural system for the Tower

fied without the use of supplemental

has been termed a “buttressed core”

damping devices.

system. The buttressed core represents

a new type of system, a conceptual The majority of the Tower is a rein-

change in structural design whose evo- forced concrete structure, with the but-

lutionary development began with an tressed core system extending through

earlier design for Tower Palace III in occupied space to Level 156. Above

Seoul. The system allows for a dramatic Level 156, a structural steel braced

increase in height, using conventional frame supports an approximately 230

materials and construction techniques. m tall spire. Concrete strengths for

Its essence is a three-winged structure the Tower’s columns and walls range

in which a strong hexagonal central from C80 to C60, and utilize Portland

core anchors three building wings. It cement, fly ash, and admixtures. The

is an inherently stable system in that C80 concrete was specified as high-

each wing is buttressed by the other modulus concrete in order to provide

two (Fig. 3). increased stiffness to the system, with

a minimum specified Young’s Elastic

Within the wings, corridor walls

Modulus of 43 800 N/mm2 at 90 days.

extend from the central core to near

The contractor, however, often deliv-

the end of the wing, terminating in

ered concrete that could be classified

thickened cross walls referred to as

as C100 with a Young’s elastic modu-

hammerhead walls. The central core

lus of 48 000 N/mm2. Wall and column

provides the torsional resistance for

sizes were proportioned according to

the building, while the wings provide

their desired contributions to the lat-

the shear resistance and increased

eral load resisting system, providing

moment of inertia. Perimeter columns

efficiency by placing material where it

and flat plate floor construction com-

was the most effective. The effects of

plete the system. At the mechanical

creep and shrinkage on the concrete

floors, outrigger walls are provided to

structure were also a major consider-

Fig. 2: Tower photo (Units: [–]) tie all the walls and columns together

ation when sizing the wall and column

allowing the perimeter columns to

elements. Perimeter columns were

participate in the lateral load resist-

sized to provide equal gravity stress to

over the height of the building, provid- ing system. In this manner, the Burj

that seen in the interior walls, so as to

ing an environment that “confuses the Khalifa acts as one giant concrete

minimize the differential movement

wind”—the wind vortices never get beam cantilevering out of the ground

between these two elements because

organized, because at each new tier with the system working together as

of creep. Additionally, the outriggers

the wind encounters a different build- a single unit. Every piece of vertical

that tie the columns to the core wall

ing shape. The Y-shaped plan is ideal concrete (and thereby every gravita-

system are not only critical in estab-

for residential and hotel usage, in that tional force) is part of this giant beam,

lishing the lateral load resisting system,

it allows maximum views outward, used to resist the wind. The gravita-

but they also provide an opportunity

without overlooking a neighboring

for the gravity load to distribute over

unit. The wings contain the residential

the entire structure, providing for uni-

units and hotel guest rooms, with the

form gravity stress throughout the

central core housing all of the elevator

system. Further, similar volume-to-sur-

and mechanical closets. Additionally,

face ratios were established for the col-

the Tower is serviced by five separate

umns and walls by providing matching

mechanical zones, located approxi-

thicknesses for these elements, which

mately 30 floors apart over the height

allowed the columns and walls to gen-

of the building. Above the occupied

erally shorten at the same rate because

portion of the Tower is a largely open

of shrinkage.

spire, which houses mechanical func-

tions and future communications

usages at its base. The overall shape Wind Engineering

is an extremely efficient solution to

the potentially conflicting structural The wind tunnel was an essential

requirements of a supertall residential partner in the design process from

tower. Starting from a slender top, Fig. 3: Typical floor plan the beginning of the project, as it was

390 Technical Report Structural Engineering International 4/2015

immediately apparent that for a build-

ing of this height and slenderness, wind

forces and the resulting motions in the

upper levels would become dominant

factors in the structural design. An

extensive program of wind tunnel tests

and other studies was conducted utiliz-

ing boundary layer wind tunnels. The

wind tunnel program included rigid-

model force balance tests, full multi-

degree of freedom aeroelastic model

studies, measurements of localized

pressures, pedestrian wind environ-

ment studies, and wind climatic stud-

ies (Fig. 4). Using the wind tunnel to

understand and optimize wind perfor-

mance was key to the Tower’s design.

Several rounds of force balance tests

were undertaken as the geometry of the

Tower evolved and was refined. After

each round of tests, the data was ana-

lyzed and the building was reshaped to

further minimize the wind effects. As

a result of this effort, several revisions Fig. 4: Aeroelastic wind tunnel model at RWDI

to the building were made. Some were

related to the geometry of the Tower: A

the size and shape of the wings were

modified, and the number and spacing

of the setbacks changed throughout

the process, as were their locations:

the original massing had the setbacks Higher impact

occurring in a spiraling counter- wind direction

clockwise pattern, which was revised (tail)

to be in a clockwise direction. Taken

together, these measures had a signifi-

cant impact in encouraging disorga-

nized vortex shedding over the height

of the Tower. Another revision was

related to the orientation of the build-

ing. The Tower has six important wind

directions, all parallel to the major axes

of the wings—three directions where C B

wind is blowing into the “nose” of each Lower impact

wing, and three directions where wind wind direction

(nose)

is blowing into the “tail” of each wing

at the center of the building (Fig. 5). Fig. 5: Wind directions in plan

The orientation of the Tower was then

selected to better accommodate the

most frequent strong wind directions in height by 60% from the begin- A pile load testing program was con-

for Dubai: northwest, south, and east. ning of the wind tunnel testing to the ducted prior to production piling,

final building, the wind forces for the whereby the 1.5 m piles were tested

The wind tunnel test results were also

final building were 30% less than that to more than twice the rated capacity

used to “tune” the Tower’s dynamic

for the original, significantly shorter (over 6000 t) (Fig. 7). The piles utilized

properties, so as to further minimize

Tower (Fig. 6). C60 self-consolidating concrete (SCC)

wind effects. This was accomplished

and were placed by the tremie method

by first using the tests to determine

using polymer slurry.

the harmonic frequency of wind gusts Tower Foundations

and eddies under various wind condi- The mat utilized 12 500 m3 of C50

tions, and then using this information The Tower is founded on a 3.7 m thick SCC concrete. Such a volume of con-

to set targets for the building’s natural solid reinforced concrete raft, sup- crete required the mat to be poured in

frequencies and mode shapes. The ported by 194 bored cast-in-place piles. four separate pours—first at each of

result of these efforts, coupled with the The piles are 1.5 m in diameter and ~43 the three wings, and then at the central

shaping and orientation refinements, m long, with a capacity of 3000 t. The core. Each of the raft pours occurred

had a dramatic impact by reducing diameter and length of the piles rep- over at least a 24 h period. Because of

wind forces and motions on the Tower. resented the largest and longest piles the thickness of the raft, limiting the

In fact, even though the Tower grew conventionally available in the region. peak differential temperatures result-

Structural Engineering International 4/2015 Technical Report 391

to this enhancement, pile rebar cages

were placed so as to orient the rebar

cage such that the raft bottom rebar

could be threaded through the numer-

ous pile rebar cages without interrup-

tion, which greatly simplified the raft

construction.

Construction Methods

and Concrete Technology

The latest advancements in construc-

tion techniques and material technol-

ogy were used by the prime contractor

to construct the Burj Khalifa. Three

primary tower cranes were located

Initial scheme Intermediate scheme Final scheme Tallest tested scheme adjacent to the central core, with

each continuing to various heights as

Base moment required. One of the keys to speed

0

100%

65%

100%

76%

100%

72%

100%

and to facilitate construction was to

minimize the time these cranes were

Acceleration needed: automatic self-climbing form-

0

100%

65%

100%

66%

100%

45%

100%

work was employed to form the walls

and perimeter blade columns: wall

Fig. 6: Tower’s improved wind behavior reinforcement was prefabricated on

the ground in 8 m segments to facili-

tate rapid placement; and high-speed,

high-capacity construction hoists were

used to transport workers and mate-

rials. The nose columns were formed

with circular steel forms, and the floor

slabs were placed on panel formwork.

A specialized GPS monitoring system

was developed to ensure the verticality

of the structure.

The construction sequence for the

structure had the central core and

slabs cast first, in three sections, fol-

lowed by the wing walls and their

slabs, and then the wing nose columns

and slabs (Fig. 9). With the exception

of the wing noses, the contractor used

Fig. 7: Pile load test

ing from the heat of hydration was an Special attention was given to rein-

important consideration in determin- forcement detailing for the founda-

ing the raft concrete mix design and tion elements to assist in facilitating

placement methods. The C50 raft mix in their construction. “Pour enhance-

incorporated 40% fly ash, to slow the ment strips” were created throughout

process, and a water-to-cement ratio of the raft, providing for ease of access to

0.34. Additionally, some water was sub- the bottom of the raft and allowing for

stituted with ice to limit the heat gain. simplified concrete placement. These

A testing program was instigated prior strips were created by omitting every

to the first pour whereby large-scale, tenth reinforcing bar in each direction,

3.7 m test cubes of the concrete mix which established a grid of 600 mm ×

were poured to verify the concrete’s 600 mm access points throughout the

temperature performance, as well as raft (raft reinforcement was typically

the concrete placement procedures. spaced at 300 mm) (Fig. 8). In addition Fig. 8: Raft reinforcement

392 Technical Report Structural Engineering International 4/2015

a very rapid “up-up” system where pumped as needed. This trial consisted More specifically, perimeter columns

the vertical concrete proceeded sev- of a long length of pipe with several require outriggers that tie them to the

eral stories above the slab concrete. 180° bends to simulate the pressure central core structure, which are typi-

Concrete was distributed to each wing loss in pumping to heights over 600 m. cally heavily reinforced members that

utilizing concrete booms, which were Putzmeister concrete pumps, including require a significant amount of time

attached to the formwork system. One two of the world’s largest, were used in to construct. A system that eliminates

of the most challenging construction the final pumping system. these columns and, more importantly,

issues was to provide a system and mix the outriggers can greatly simplify

design that could support pumping The Next Generation of and accelerate construction. A review

the high-performance, high-modulus of the Burj Khalifa construction data

concrete over 600 m in a single stage.

Supertall Buildings—Lessons

has shown that a typical floor cycle

Four separate basic mix designs were Learned from Burj Khalifa required as little as 2.5 days; however,

created to enable reduced pumping the outrigger zone took much longer

The final design of the Burj Khalifa is

pressure as the building grew in height. to construct. As such, the key to accel-

an appropriate response to its many

Additionally, a horizontal pumping erating construction speed is to make

influences. However, an analysis of

trial prior to the start of the super- every floor a typical floor, whereby

the design and construction of the

structure construction was conducted the construction does not need to slow

Burj Khalifa gives an opportunity to

to ensure that the concrete could be down or stop in order to construct

investigate the further refinement of

supertall building design and the but- atypical elements.

tressed core on subsequent project The architect developed a further

proposals. This analysis assists in the refined scheme as described above

development of the next generation for the Kingdom Tower competition

of structural systems, which can allow in 2009 (Fig. 10). Termed the “stayed

for even taller heights with greater buttressed core,” it represents the next

efficiency and construction speed. One generation of the Burj Khalifa, and

such refinement is to consider elimi- realizes the full potential of the but-

nating the stepping setbacks character- tressed core concept. The Tower has a

istic to (the) Burj, and instead provide tripod plan, and tapers to over 1000 m

a tapered tower. This establishes an in height. No perimeter columns are

environment in which the wind vor- required; instead, the floor plates can-

tices never get organized due to the tilever off the core wall system via

continuously changing building width. reinforced concrete cantilever framing.

Additionally, the gravity load flow This new structural system eliminates

down the building is one smooth load the need for outriggers, and is eas-

path in that it is not interrupted with ily constructed within a standardized

the addition of new structure that is

formwork system. The result is a taller

seen at each setback location.

building than Burj Khalifa, using virtu-

Another refinement is to consider ally the same concrete quantities per

the impact of the perimeter columns. square meter.

Fig. 9: Tower construction

(a) (b)

Fig. 10: Kingdom Tower proposal—rendering (a); typical plan (b)

Structural Engineering International 4/2015 Technical Report 393

Conclusion Baker W, Korista S, Novak L, Pawlikowski J,

Young B. The structural design of the world’s SEI Data Block

The structural system and form of the tallest structure: the Burj Dubai Tower.

Proceedings of the 2008 IABSE Conference, 2008. Owner:

Burj Khalifa are the result of close col-

Emaar Properties PJSC

laboration among all members of the Baker W, Pawlikowski J, Young B. The challenges

design team. The Tower is a model of in designing the world’s tallest structure: the Architect, Structural Engineer, MEP

structural efficiency, wind behavior, Burj Dubai Tower. Proceedings of the Structures Engineer:

2009 ASCE SEI Conference, 2009. Skidmore, Owings & Merrill LLP

and construction. Its development,

innovations, and success have changed Baker W, Mazeika A, Pawlikowski J. Integrated Architect and Engineer of Record:

how tall buildings are designed and design: everything matters – the development Hyder Consulting

of Burj Dubai and the new Beijing Poly Plaza.

constructed, and will pave the way

Proceedings of the Structures 2009 ASCE SEI Contractor:

for the next generation of supertall Conference, 2009. Samsung, BeSix, and Arabtec

buildings.

Baker W, Pawlikowski J. Higher and higher: the Estimated cost (EUR million):

evolution of the buttressed core. Civil Eng. 2012;

References 82(10): 58–65. Service Date: January 2010

Parts of this paper have been published previ- Council on Tall Buildings and Urban Habitat.

ously in the following proceedings and articles: Tall Building Database. ctbuh.org.

IABSE Conference Guangzhou 2016

Bridges and Structures Sustainability -

Seeking Intelligent Solutions

May 8 -11, 2016, Guangzhou, China

Conference Topics

Structural Sustainability

Intelligent Solutions

High-Performance Materials

Challenges in Major Projects

Organised by

The Chinese Group of IABSE

and Guangzhou University

Tongji University

Hong Kong Zhuahai-Macau Bridge Authority

www.iabse.org/Guangzhou2016

394 Technical Report Structural Engineering International 4/2015

You might also like

- Design of Burj Al KhalifaDocument6 pagesDesign of Burj Al Khalifamilon7566No ratings yet

- Seminar ReportDocument29 pagesSeminar ReportAnjuNo ratings yet

- The Buttressed Core Structural SystemDocument30 pagesThe Buttressed Core Structural Systemdouaa50% (2)

- 4262 Tall Buildings of The Future As Seen From The PresentDocument9 pages4262 Tall Buildings of The Future As Seen From The Presentsuazu1234No ratings yet

- Constructing the Buttressed Core StructureDocument19 pagesConstructing the Buttressed Core StructureHussain shaikhNo ratings yet

- Report (Print Whole)Document22 pagesReport (Print Whole)rounit prashantNo ratings yet

- Burj Khalifa 22 PDFDocument1 pageBurj Khalifa 22 PDFDenilson Cuya RiveraNo ratings yet

- 1326 Engineering The Worlds Tallest Burj BubaiDocument11 pages1326 Engineering The Worlds Tallest Burj BubaiYogesh BangNo ratings yet

- Buttressed CoreDocument28 pagesButtressed CoreAnjuNo ratings yet

- Engineering the World's Tallest Skyscraper - Burj DubaiDocument10 pagesEngineering the World's Tallest Skyscraper - Burj DubaiSyeda Sana Naqi100% (2)

- Case Study Shanghai Tower 2Document13 pagesCase Study Shanghai Tower 2Arjun Middha100% (2)

- Top 10 Sky ScraperDocument11 pagesTop 10 Sky ScraperBoxtrolls Mushroom100% (1)

- Burj Khalifa - HP ConcreteDocument8 pagesBurj Khalifa - HP ConcreteMazhar ZamanNo ratings yet

- The Buttressed Core: Chase Smethurst (Cas233@pitt - Edu), Billy Green (Weg22@pitt - Edu)Document6 pagesThe Buttressed Core: Chase Smethurst (Cas233@pitt - Edu), Billy Green (Weg22@pitt - Edu)Rohan ChauguleNo ratings yet

- The Harmony Between Architectural Forms and Structural Case Study: Burj Khalifa DubaiDocument12 pagesThe Harmony Between Architectural Forms and Structural Case Study: Burj Khalifa DubaiHisham AbdehNo ratings yet

- Burj Khalifa - World's Tallest BuildingDocument15 pagesBurj Khalifa - World's Tallest BuildingVinay VishwakarmaNo ratings yet

- Burj Khalifa: A Seminar Report OnDocument25 pagesBurj Khalifa: A Seminar Report Onkenneth youngNo ratings yet

- 01-A New Urban Giant-The Bow TowerDocument3 pages01-A New Urban Giant-The Bow TowerTari SeptariantiNo ratings yet

- Poulos - Tall Building Foundation. Design Methods & ApplicationsDocument51 pagesPoulos - Tall Building Foundation. Design Methods & ApplicationsWaiyee SooNo ratings yet

- DD Draft1 Abhsihek-CompressedDocument34 pagesDD Draft1 Abhsihek-CompressedRUTWIK JOSHINo ratings yet

- 2384 Case Study Kingdom Tower JeddahDocument9 pages2384 Case Study Kingdom Tower JeddahAlaa W TonsyNo ratings yet

- Burj Khalifa CoreDocument6 pagesBurj Khalifa CoreBNo ratings yet

- Geotechnical Foundation Design For Some of The WorDocument14 pagesGeotechnical Foundation Design For Some of The WorShankar PeriasamyNo ratings yet

- Shanghai World Financial CenterDocument6 pagesShanghai World Financial CenterIshan AroraNo ratings yet

- Design and Construction of Burj-Dubai 104Document11 pagesDesign and Construction of Burj-Dubai 104Selvam KaliamoorthyNo ratings yet

- DD Draft1 AbhsihekDocument30 pagesDD Draft1 AbhsihekRUTWIK JOSHINo ratings yet

- Geotechnical Foundation Design For Some of The Wor PDFDocument14 pagesGeotechnical Foundation Design For Some of The Wor PDFJEFFERSON LAZON ZAMORANo ratings yet

- Burj KhalifaDocument9 pagesBurj KhalifaOdín Wotan KronosNo ratings yet

- Burjkhalifa Tecno PDFDocument8 pagesBurjkhalifa Tecno PDFDenilson Cuya RiveraNo ratings yet

- Chhatrapati Shivaji International Airport Integrated Terminal BuildingDocument6 pagesChhatrapati Shivaji International Airport Integrated Terminal BuildingRiddhi PatelNo ratings yet

- Fa21 BCT 003Document11 pagesFa21 BCT 003Ali nawazNo ratings yet

- HIGH-RISE CONSTRUCTION CORE DESIGNDocument2 pagesHIGH-RISE CONSTRUCTION CORE DESIGNNasserZakiNo ratings yet

- CVE 601 Struct 1Document8 pagesCVE 601 Struct 1Peter UkwuejiNo ratings yet

- Free PPT Templates: Insert The Sub Title of Your PresentationDocument60 pagesFree PPT Templates: Insert The Sub Title of Your PresentationBimo KusNo ratings yet

- Burj Khalifa - A New High For High-Performance Concrete: Proceedings of IceDocument8 pagesBurj Khalifa - A New High For High-Performance Concrete: Proceedings of IceJonathan MendozaNo ratings yet

- HSE aspects in construction of Burj KhalifaDocument22 pagesHSE aspects in construction of Burj KhalifasansamDudeNo ratings yet

- Burj Khalifa MBMCW Jan 2010Document5 pagesBurj Khalifa MBMCW Jan 2010drnsmani100% (1)

- The Price of Height: S W F T ' SDocument8 pagesThe Price of Height: S W F T ' SNadya PriciliaNo ratings yet

- 14 Case Study Shanghai World Financial CenterDocument6 pages14 Case Study Shanghai World Financial CenterElvin Michaels100% (1)

- CTBUH Technical Paper Subject Building CDocument8 pagesCTBUH Technical Paper Subject Building CChai Weng KuakNo ratings yet

- Innovative Foundation Design for Dubai's Iconic Creek TowerDocument9 pagesInnovative Foundation Design for Dubai's Iconic Creek TowerJEFFERSON LAZON ZAMORANo ratings yet

- Burj Khalifa Park FinalDocument6 pagesBurj Khalifa Park FinalNirmal ManandharNo ratings yet

- Exploring Structure Systems of High-RisebuildingsDocument25 pagesExploring Structure Systems of High-Risebuildingszuhaferoz2No ratings yet

- The Evolution of the Buttressed Core Structural SystemDocument26 pagesThe Evolution of the Buttressed Core Structural SystemAnju100% (1)

- Burj Khalifa: The World's Tallest BuildingDocument27 pagesBurj Khalifa: The World's Tallest BuildingVishal KumarNo ratings yet

- Design and Construction Planning of The Burj Khalifa, Dubai, UAEDocument13 pagesDesign and Construction Planning of The Burj Khalifa, Dubai, UAEPatanNo ratings yet

- Civil Burj KhalifaDocument15 pagesCivil Burj KhalifaRITU KUMARINo ratings yet

- IAG Sept 2017 PDFDocument2 pagesIAG Sept 2017 PDFAnonymous xmWrLGFzrNo ratings yet

- Kingdom Tower: The World's Tallest BuildingDocument15 pagesKingdom Tower: The World's Tallest BuildingDivyaa Saxena100% (1)

- Integrated Design and Construction of Tall Buildings (Moon 2010)Document8 pagesIntegrated Design and Construction of Tall Buildings (Moon 2010)Jose Antoni LasdNo ratings yet

- Dancing Dragon TowerDocument5 pagesDancing Dragon TowerCokde AgraNo ratings yet

- MB Concrete Tall Buildings Feb18 PDFDocument20 pagesMB Concrete Tall Buildings Feb18 PDFAlparslan GureNo ratings yet

- National Convention CentreDocument1 pageNational Convention CentreMahmood RashwanNo ratings yet

- 13 Case Study CCTV Building Headquarters Cultural CenterDocument13 pages13 Case Study CCTV Building Headquarters Cultural CenterIbrahem HakamNo ratings yet

- Comparing Structural Systems in Contemporary High-Rise BuildingsDocument19 pagesComparing Structural Systems in Contemporary High-Rise BuildingsBagoes Rama Al AriefqiNo ratings yet

- Burj KhalifaDocument7 pagesBurj Khalifaionutvld0% (1)

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresFrom EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNo ratings yet

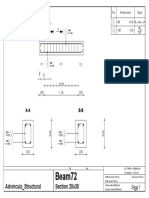

- Beam72: Advincula - Structural Section 20x30Document1 pageBeam72: Advincula - Structural Section 20x30Jeremy BuelbaNo ratings yet

- Primary and Secondary Treatment (Part1)Document29 pagesPrimary and Secondary Treatment (Part1)Mohammed FdmmNo ratings yet

- Foundation Lectures 3Document11 pagesFoundation Lectures 3Mohammed FdmmNo ratings yet

- Ch11.softeninig (Part 1)Document13 pagesCh11.softeninig (Part 1)Mohammed FdmmNo ratings yet

- Untitled: Image © 2023 Maxar TechnologiesDocument1 pageUntitled: Image © 2023 Maxar TechnologiesMohammed FdmmNo ratings yet

- Aerodynamic Drag Reduction For A Simple Bluff Body Using Base BleedDocument7 pagesAerodynamic Drag Reduction For A Simple Bluff Body Using Base BleedJuantxoGarcia100% (1)

- Determination of Blockage Correction in Open-Jet Wind TunnelDocument6 pagesDetermination of Blockage Correction in Open-Jet Wind Tunnelmoro1381100% (1)

- Modeling FlightDocument202 pagesModeling Flightaeroprince100% (3)

- AE2251 – AERODYNAMICS – I Question BankDocument10 pagesAE2251 – AERODYNAMICS – I Question BankKalpit KauraseNo ratings yet

- Kirchner, PaulDocument1 pageKirchner, PaulRaphael BazanNo ratings yet

- Identi"cation of #Utter Derivatives of Bridge Decks: Ming Gu, Ruoxue Zhang, Haifan XiangDocument12 pagesIdenti"cation of #Utter Derivatives of Bridge Decks: Ming Gu, Ruoxue Zhang, Haifan XiangBuay BuayNo ratings yet

- Wind Load Simulation in Autodesk Robot Structural Analysis Professional PDFDocument8 pagesWind Load Simulation in Autodesk Robot Structural Analysis Professional PDFrobinhovrNo ratings yet

- Savonious Blade Design-ComparisonDocument16 pagesSavonious Blade Design-ComparisonNikhil ChordiyaNo ratings yet

- Wind Tunnel Experiments 10 11Document4 pagesWind Tunnel Experiments 10 11Kaashyap SarmaNo ratings yet

- Porous Dust Fences in SotckyardsDocument7 pagesPorous Dust Fences in SotckyardsDiego DiazNo ratings yet

- Design and Testing of an Autorotative Payload Delivery SystemDocument11 pagesDesign and Testing of an Autorotative Payload Delivery SystemvictorNo ratings yet

- NORSOK Helideck StandardsDocument16 pagesNORSOK Helideck StandardsdakidofdaboomNo ratings yet

- 10.1108@aeat 12 2019 0247Document10 pages10.1108@aeat 12 2019 0247İhsan Alp OzdemirNo ratings yet

- Designing and Optimizing Side-View Mirrors: Martin OlssonDocument97 pagesDesigning and Optimizing Side-View Mirrors: Martin OlssonAndrei StoicescuNo ratings yet

- Fundamentals of Wind Tunnel Design PDFDocument11 pagesFundamentals of Wind Tunnel Design PDFOroitz Elgezabal Gómez100% (1)

- Momentum Absorption by Vegetation: Quart. 97Document16 pagesMomentum Absorption by Vegetation: Quart. 97Ivan RodrigoNo ratings yet

- Validations and Applications of A CFD Tool Dedicated To Wind Assessment in Urban AreasDocument6 pagesValidations and Applications of A CFD Tool Dedicated To Wind Assessment in Urban AreasMeteodyn_UrbawindNo ratings yet

- Experimental Aerodynamics Course DescriptionDocument7 pagesExperimental Aerodynamics Course DescriptionBalaji HimakarNo ratings yet

- Performance - Analysis - of - A - Small - Scale - Master Airscrew PropellerDocument10 pagesPerformance - Analysis - of - A - Small - Scale - Master Airscrew Propellerfelip987No ratings yet

- Aerodynamics ExaminationDocument4 pagesAerodynamics ExaminationBeverly Montaño MediodiaNo ratings yet

- 33-Impact of CFD On Aircraft Design PDFDocument42 pages33-Impact of CFD On Aircraft Design PDFJohn MaclinsNo ratings yet

- Design, Development and Testing of Low-Cost Force Balance For Wind TunnelDocument12 pagesDesign, Development and Testing of Low-Cost Force Balance For Wind TunnelSatya SuryaNo ratings yet

- A CFD Study To Analyze The Aerodynamic Torque, Lift, and Drag Forces For A Butterfly Valve in The Mid-Stroke PositionDocument9 pagesA CFD Study To Analyze The Aerodynamic Torque, Lift, and Drag Forces For A Butterfly Valve in The Mid-Stroke PositionAhmed NahrawyNo ratings yet

- NASA Labs FacilitiesDocument50 pagesNASA Labs FacilitiesjjdjdjNo ratings yet

- Reddy J.N. - Solution Manual For Introduction To Finite Element Analysis-MGH (2005)Document13 pagesReddy J.N. - Solution Manual For Introduction To Finite Element Analysis-MGH (2005)Debabrata PodderNo ratings yet

- How How How How: The Air Force Thunderbirds Perform The "Delta Pass and Revue" ManeuverDocument16 pagesHow How How How: The Air Force Thunderbirds Perform The "Delta Pass and Revue" Maneuverkit fisotNo ratings yet

- Aeronautical Engineer - MicroTau - LinkedInDocument5 pagesAeronautical Engineer - MicroTau - LinkedInMuhammad ShehzadNo ratings yet

- Dodge Viper ACR AerodynamicsDocument6 pagesDodge Viper ACR AerodynamicsznamNo ratings yet

- Aeolus Aero Tech PVT LTD PDFDocument14 pagesAeolus Aero Tech PVT LTD PDFThamarai ElanthirayanNo ratings yet

- BUILDING CLIMATOLOGY Module 3Document95 pagesBUILDING CLIMATOLOGY Module 3aqsam aliNo ratings yet