Professional Documents

Culture Documents

Fuel Filter bw212

Fuel Filter bw212

Uploaded by

Gabriel Paredes E.0 ratings0% found this document useful (0 votes)

21 views4 pagesOriginal Title

fuel filter bw212

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views4 pagesFuel Filter bw212

Fuel Filter bw212

Uploaded by

Gabriel Paredes E.Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

Fuel filter 11.22

11.22Fuel filter

Deut_31

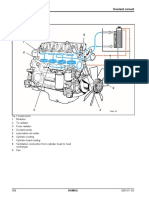

Fig. Fuel prewiter

Hand pump

Bleeding valve

Filter element

Water and ditt collecting bow!

Drain valve

Water separator sensor connection (B124)

Fuel pre-heating connection (R79) 200 Watt (op-

tion)

008 911 63 BOMAG 339

11.22

Fuel filter

General

The quality of the fuel fiter and the compliance with

the specified service intervals are decisive for the life-

time of the fuel injection system. The heart of the fuel

filter is made of hydrophobic special paper, which is,

spirally wound in form of a bag in order to offer the

largest possible filtering area under the prevailing spa-

tial conditions and thus to achieve a high lifetime in

combination with a high dirt retaining capacity

‘The fuel pre-fiter / water separator mainly consists of:

* the dirt / water collecting bow!

* and the filter element

Function

‘The fuel lift pump draws the fuel through this fiter.

‘Any water contained in the fuel deposits on the dirt

side of the filter paper and separates from the fuel in

form of large drops on the clean side of the filter (coa-

lescence effect).

Water is heavier than diesel fuel, it settles as a differ-

ent colour fluid on the bottom,

‘Once the water level reaches the height of the warn-

ing connections (sensor 8124), the warming lamp

(H70) in the monitoring board (A15) will come on,

Fuel pre-heating (option)

In diesel engines the pre-heating of the fuel prevents

malfunctions caused by the formation of jelly (paraffin

separation) inthe fuel under low temperatures.

‘The integrated heating is a starting aid for cold weath-

er applications. The heating is delivered with an auto-

matic thermostat to start the heating when the fuel

temperature drops below 7*C. The generated heat

works directly under the filter element and melts the

wax crystals that have formed, so that the fuel can

flow through the fiter element without restriction. The

heating automatically shuts down at a fuel tempera-

ture of 24°C. The 200W heating is supplied with 12V

D.C-current. The heater is activated when operating

the ignition switch; this should take place at least 5

minutes before starting the engine.

‘A normal On/Off switch may be installed to operate

the relay. This can be used to e.g. interrupt the current,

flow to the relay in the summer season,

Draining off water or fuel

‘Should the fiter element be clogged prematurely (no-

ticeable e.g. by a drop in power), operation of the ma-

chine can be continued with the following procedure:

* Open the bleeding screw (this applies atmospheric

pressure to the filter element and loosens larger dirt

particles from the underside of the filter, which will

then drop down),

* Open the drain valve and drain off approx. 0.5 | of

fuel. The fuel above the filter element presses

through the filter element and frees the underside

from dirt

* Close the drain valve again.

Perform

‘A power drop or poor starting of the engine is mainly

caused by leaks in the fuel system. If you suspect a fil-

ter problem, you should check whether bleeding

screw and drain valve are tightly closed and the filter

element is flush with the sight glass. Check the filter

connections for leaks and the lines for clogging or po-

rous points.

Main fuel filter

Fig. 2 Main fel titer

[A Caution

‘The main fuel filter is subjected to the approx. 10,

bar fuel pre-pressure from the fuel lift pump. This

pressure value is considerably higher than on oth-

er engines. You should therefore only use original,

filter elements (Fig. 2) at this point. Similar looking

filters with identical dimensions are not necessar-

ily pressure proof!

A filter, with insufficient pressure resistance, will

be destroyed and disintegrate by this high pres-

sure This will cause severe damage in the injec

tion system!

340

BOMAG

008 911 63

Check, clean the water separator

11.23

11.23Check, clean the water sepa-

rator

Danger of injury!

‘Support the engine hood for all maintenance and

repair work.

1 Note

The service intervals for the water separator depend

on the water content in the fuel and can therefore not

be determined precisely. After taking the engine into

operation you should therefore check the water sepa-

rator every day for signs of water.

Ifa to high quantity is drained off, the filter must be re-

filled with fuel. See chapter "maintenance as re-

quired’, bleeding the fuel system.

[Z= Environment

Catch running out fuel and dispose of environ-

mentally.

Figs

* Slacken the drain plug (Fig. 3) for a few turns and

‘catch running out fuel / water.

* Tighten the drain plug again and check for leaks, if

necessary replace the seal ring,

11.24Change the fuel pre-filter car-

tridge

Fire hazard!

When working on the fuel system do not use open

fre da not ike and do not spi any fac

een Tanning ont navTaOTNae in aeep ene

ground.

to act ahale any al uaa,

“d hele

Fig4

‘+ Unscrew the fuel filter cartridge (Fig. 4) using an ap-

propriate filter wrench.

* Clean the sealing face on the filter carrier from any

dir.

i

Fig.

+ Unscrew the water separator from the filter car-

tridge (Fig. 5).

008 911 63

BOMAG, 341

Change the fuel filter cartridge

a] an Sa}

we)

"ep ata

oo

Feo

* Apply a thin coat of ol to the rubber seal of the water

separator 1 (Fig. 6).

* Screw the water separator on by hand (2), until the

seal contacts

* Tighten the water separator for another half turn (3).

* Fill the filter cartridge with clean diesel fuel (4).

* Apply some oil to the rubber seal of the filter ele-

‘ment (5) and screw it on by hand, until the seal con-

tacts.

* Tighten the fiter element for another half turn (6).

* Check the filter cartridge for leaks after a short test

run

[Note

Air in the fuel system causes irregular running of the

engine, a drop in engine power, stalls the engine and

makes starting impossible.

Therefore bleed the fuel system after changing the

fuel prefilter.

SA

* Slacken the bleeding screw (Fig. 7) on the fuel pre-

filter for 2 to 3 turns.

* Operate the hand pump manually, until fuel flows

out of the slackened bleeding screw (Fig. 7) without

air bubbles.

* Then tighten the bleeding screw while pumping

11.25Change the fuel filter cartridge

Fire hazard!

When working on the fuel system do not use open

fire, do not smoke and do not spill any fuel.

Catch running out fuel, do not let it seep into the

ground,

Do not inhale any fuel fumes.

Fig.

* Loosen and unscrew the fuel filter cartridge (Fig. 8)

using an appropriate filter wrench

‘* Clean the sealing face on the fiter carrier from any

dirt

Fig.

** Slightly oil the rubber seal (Fig. 9) on the new filter

cartridge.

Fill the filter cartridge with clean diesel fuel.

* Turn the new filter cartridge on by hand, until the

seal contacts.

* Tighten the filter element for another half turn.

Check the filter cartridge for leaks after a short test

run,

342

BOMAG

(008 911 63

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PC209 PA55-PA56 Operations 5-98Document14 pagesPC209 PA55-PA56 Operations 5-98Gabriel Paredes E.100% (1)

- Service Manual Winch Models Pa55 & Pa56: SENR5358-04Document62 pagesService Manual Winch Models Pa55 & Pa56: SENR5358-04Gabriel Paredes E.No ratings yet

- Electric Throttle Control Bomag bw212Document2 pagesElectric Throttle Control Bomag bw212Gabriel Paredes E.No ratings yet

- Coolant Circuit bw212Document2 pagesCoolant Circuit bw212Gabriel Paredes E.No ratings yet

- Water Separator bw212Document1 pageWater Separator bw212Gabriel Paredes E.No ratings yet

- Where Is Bear? Where Is Bear?: A Terrific Tale For 2-Year-Olds A Terrific Tale For 2-Year-OldsDocument11 pagesWhere Is Bear? Where Is Bear?: A Terrific Tale For 2-Year-Olds A Terrific Tale For 2-Year-OldsGabriel Paredes E.No ratings yet

- Technical Specs D6 and D6 XE DozersDocument18 pagesTechnical Specs D6 and D6 XE DozersGabriel Paredes E.No ratings yet

- Shell Spirax S4 TXM: Performance, Features & BenefitsDocument2 pagesShell Spirax S4 TXM: Performance, Features & BenefitsGabriel Paredes E.No ratings yet

- Electric Starting System - Test: Shutdown SIS Previous ScreenDocument5 pagesElectric Starting System - Test: Shutdown SIS Previous ScreenGabriel Paredes E.0% (1)

- Get Uk 2019Document32 pagesGet Uk 2019Gabriel Paredes E.100% (1)

- NuevoDocumento 2019-06-07 13.08Document1 pageNuevoDocumento 2019-06-07 13.08Gabriel Paredes E.No ratings yet

- Volvo SD100D SERIES LUBINFODocument2 pagesVolvo SD100D SERIES LUBINFOGabriel Paredes E.50% (2)