Professional Documents

Culture Documents

Method Statement Site Development - Excavation and Fill

Uploaded by

Shubham PatelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement Site Development - Excavation and Fill

Uploaded by

Shubham PatelCopyright:

Available Formats

METHOD STATEMENT FOR SITE

CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

DOC No.: SW-FEL-TL-MS-AR-001 REV. 00

Page 1 of 12

DATE: 18.04.2022

METHOD STATEMENT FOR SITE CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

Shubham Patel Amit Mitra Soloman S S

PREPARED BY: APPROVED BY:

REVIEWED BY

`

METHOD STATEMENT FOR SITE

CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

DOC No.: SW-FEL-TL-MS-AR-001 REV. 00

Page 2 of 12

DATE: 18.04.2022

CONTENTS

SL NO. DESCRIPTION PAGE NO.

1 PURPOSE 3

2 SCOPE 3

3 EXCLUSION 3

4 APPLICABILITY 3

5 EQUIPMENTS 3

6 CONSTRUCTION SEQUENCE 3

7 ACCEPTANCE CRITERIA 7

8 SAFETY MEASURES / PRECAUTIONS 7

9 Do’s and Don’ts 10

10 COMPACTION CRITERIA 11

Shubham Patel Amit Mitra Soloman S S

PREPARED BY: APPROVED BY:

REVIEWED BY

`

METHOD STATEMENT FOR SITE

CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

DOC No.: SW-FEL-TL-MS-AR-001 REV. 00

Page 3 of 12

DATE: 18.04.2022

1) PURPOSE:

This document describes the step wise work procedure to carry out the Site Clearance, Land

development, Excavation and Filling , Compaction for Plot in planned and controlled manner

with reference to the drawings, technical specification and standards.

2) SCOPE :

It includes Site Clearance, Land development, Excavation and Filling , Compaction for Plot in all

types of soil. The work shall be carried out in accordance with the specification and

corresponding approved drawings.

3) EXCLUSION :

In case of very specific & mandatory customer’s need their processes & formats can be followed

as a part or in full. However in case of any conflict most stringent norms must be followed.

4) APPLICABILITY :

This procedure is primarily developed for Substation works.

5) EQUIPMENTS :

Total Station

Measurement Tape

Water Level Gauge

Compactor

Tamper Plate

Hydraulic Excavator

Water Pumps

6) CONSTRUCTION SEQUENCE :

Shubham Patel Amit Mitra Soloman S S

PREPARED BY: APPROVED BY:

REVIEWED BY

`

METHOD STATEMENT FOR SITE

CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

DOC No.: SW-FEL-TL-MS-AR-001 REV. 00

Page 4 of 12

DATE: 18.04.2022

a) SITE PREPARATION CLEARING AND GRUBBING:

The permitted area of working shall be verified. Care shall be taken to ensure no damage

occurs to land or property outside this area. If additional space is required then permission

from the landowners shall be obtained prior to commencing the activity.

The work site shall be cleared of all materials and obstruction that may impede the site

activities. This requires the clearing of tree stumps and bushes and any other materials to

keep the area suitable for safe and proper placement of construction material and provide a

safe area for performing the foundation activities.

Clearing includes the removal of all trees and other vegetation, rubbish, stumps, pipes,

fences, stone walls, surface boulders, or other material that is not required.

Certain trees may be designated for saving, and these shall be carefully preserved. The

landscaper land architects approval must be obtained prior to removal of any trees.

Clearing shall include all the area affected by excavation and filling together with sufficient

additional area on which to stockpile stripped topsoil, and may also include further areas as

shown on the plans within the area of the development or subdivision.

Cleared material may be burnt on site unless otherwise directed, and provided such burning

is allowed by the relevant Authorities and carried out in compliance with their

requirements. The Contractor is responsible for obtaining a fire permit, and for any costs

relating to such. All ash and residual material from burning shall be removed from the site.

The Contractor is responsible for establishing a tipping point for all other rubbish, and for

any fees relating to such.

The area on which the fill is to be placed and the area from which the cut is to be removed

should be stripped of all vegetation and of such soils as are deemed by the Consultant

Engineer to be unsuitable to support the proposed loadings or for incorporation in fills.

Topsoil will need to be stripped to spoil as unsuitable material or stockpiled in positions as

required for subsequent re-vegetation. Any material which the Consultant Engineer

considered will inhibit or prevent the satisfactory placement of subsequent fill layers will not

be allowed to remain in the foundations of fills or will be treated as directed as directed by

the Consultant Engineer.

All trees up to a girth (perimeter) of 30 cm measured at one meter above the ground level

shall also be cut and useful portion of the trees so cut shall be stacked at a suitable place as

directed by the Engineer-in-Charge and shall be considered incidental to clearing and

grubbing operations.

Shubham Patel Amit Mitra Soloman S S

PREPARED BY: APPROVED BY:

REVIEWED BY

`

METHOD STATEMENT FOR SITE

CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

DOC No.: SW-FEL-TL-MS-AR-001 REV. 00

Page 5 of 12

DATE: 18.04.2022

The roots of trees shall be dug up to 60 cm below the ground level or 15 cm below

formation level whichever is deeper and after removal of all vegetable and organic matter

from the holes so formed by removal of the roots, holes and hollows shall be filled with

good earth in layer of 20 cm, well rammed, consolidated and levelled.

Stockpile locations will be subjected to the approval of the Consultant Engineer, and

regardless of this approval will be chosen so that they are unlikely to initiate instability of

either the stockpile or the natural ground. Stockpile sites will also be chosen so that the

stockpile does not inhibit natural drainage of the area.

b) EXCAVATION

Excavation shall be carried out in a phased manner to suit the construction schedule.

Excavation shall be by means of scrapers, bulldozers, hydraulic excavators, loaders, and

trucks or other self-propelled bulk earth-moving machinery.

Excavation shall be executed manually or hydraulic excavator shall be used to excavate the

earth and to off load onto the sides of Pits maintaining angle of repose distance. While

excavating, the earth is cut vertically / tapered / in steps as per the soil conditions at site to

avoid any kind of mishap caused by collapsing of the pit sides during the course of

excavation and foundation work.

The excavated earth is to be kept at a sufficient distance so that it does not create any

burden on the sides of excavated earth pits.

Cutting shall be done from top to bottom & also in tapper formation.

During excavation in sandy soil or water bearing strata, and particularly in black cotton soil

where there is every likelihood of collapsing of the sides of the pits, shoring and shuttering

made of wooden planks of sufficient thickness or steel frames of adequate strength to meet

the requirement are to be provided.

No undercutting of side of excavation shall be allowed.

Excavation in soft rock is done with the help of chisels (in case of manual excavation). Some

types of soft rock soils need to be soaked in water before excavation can be carried out. It is

not recommended to use blasting for excavation in soft rock.

Considering the quantum of excavation involved sufficient number of ramps with enough

road width for the movement of Hydraulic excavators / dumpers / tractor considered. Also

the slope of excavation shall be established.

Shubham Patel Amit Mitra Soloman S S

PREPARED BY: APPROVED BY:

REVIEWED BY

`

METHOD STATEMENT FOR SITE

CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

DOC No.: SW-FEL-TL-MS-AR-001 REV. 00

Page 6 of 12

DATE: 18.04.2022

The movement of equipment, trucks and storage of excavated materials, shall be such that

it shall not obstruct any construction activities of adjacent structures.

Material suitable for Fill shall be stored near the site at designated area.

Ensure that a suitable drainage arrangements to prevent surface water from any source

entering the foundation pits.

Ensure the arrangements lighting, fencing and others suitable measures for protection

against risk or accidents due to open excavation.

c) BENCHING

Shall be carried out where fill is to be placed on sloping ground (generally steeper than 6

horizontal to 1 vertical) These benches shall be cut nearly horizontally with fall towards the

fill area and shall be free draining. The width and height of the bench will depend on the

original ground slope. The rear batter of the bench shall have a slope of about 1 horizontal

to 2 vertical, unless otherwise approve by the Consultant Engineer.

d) LIMITS OF EXCAVATION

Care shall be taken that ground beyond the limits of the work shown on the plans is not

disturbed by excavation procedures.

Excavation shall be carried out to the lines, levels, dimensions and slopes shown in the

Drawings. The excavated faces shall be neatly trimmed and the top edges of the cuttings

neatly rounded. Under cutting of slopes will not be permitted under any circumstances.

Excavation shall be carried out in such a manner as to prevent erosion or slips, working faces

shall be limited to safe heights and slopes, and surfaces shall be drained to avoid ponding

and erosion.

Overhanging, loose or unstable material likely to slip should be cut back removed or

stabilized.

Rock cuttings and exposed rock surfaces shall be excavated so as to obtain smooth,

uniformly trimmed surfaces. Batters in cuttings shall be carried around curves in an even

and regular manner. Finished batters shall not have a slope steeper than that specified.

e) TOPSOIL

Topsoil shall be removed over the area which will be occupied by the complete works plus a

clearance of 2 metres. Topsoil shall be placed in a stockpile clear of the work to enable its

re-use in landscaping and re-vegetation.

Shubham Patel Amit Mitra Soloman S S

PREPARED BY: APPROVED BY:

REVIEWED BY

`

METHOD STATEMENT FOR SITE

CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

DOC No.: SW-FEL-TL-MS-AR-001 REV. 00

Page 7 of 12

DATE: 18.04.2022

Unsuitable material includes topsoil, peat and other highly organic soils, logs, stumps,

perishable material, rubbish, material susceptible to spontaneous combustion, free draining

susceptible to scouring, very fine sand, silt and organic clay and material with a CBR<1. Such

material shall be excavated and disposed off-site except for top soil required for vegetation.

Dispersive soils can be used only in accordance with guidelines provided by a Geotechnical

Engineer. Where unsuitable material exists in excessive depths the advice of a Geotechnical

Engineer is required. The Contractor shall lightly scarify the surface of the areas to receive

topsoil to a depth of 50 mm. This shall be achieved by use of a rigid fine harrow making at

least 3 passes or an approved alternative method.

Topsoil shall be spread over the prepared surface in sufficient quantity to result in a

compacted thickness 100 mm or thicker to make use of all topsoil stripped from the site.

The placed topsoil shall be lightly harrowed to give a uniform appearance and compacted by

flat rolling.

f) PROCEDURE FOR FILLING

Filling will be carried out in a phased manner.

Fill materials will be free from clod, salts and sulphates, organic or other foreign material

and all decomposable or perishable material shall be removed from the excavations.

Organic matter, silt and oversize rocks shall not be employed to fill. (Usable soil removed

during the Earthwork from area and stacked shall be used).

To the extent available, selected surplus soil from excavated material shall be used as fill.

Surface to receive Fill will be removed of any vegetarian, debris, unsatisfactory soil

materials, Water logging (Water Quantity which may cause localized slush or bumping while

compacting), any other obstructions or harmful materials.

Fill material shall be placed in near horizontal layers of uniform thickness deposited

systematically across the fill area. The thickness of each layer should be appropriate for the

equipment used, but not exceeding 200 mm 1oose thickness. At cut to fill junctions, and at

the edges of fills, the foundation shall be excavated or "boxed" so that the minimum

thickness of fill to be placed is 100 mm.

Where fill is to be placed directly onto rock the exposed surface shall be tined or scarified to

a depth of 150 mm minimum and re-compacted with a pad foot roller.

Shubham Patel Amit Mitra Soloman S S

PREPARED BY: APPROVED BY:

REVIEWED BY

`

METHOD STATEMENT FOR SITE

CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

DOC No.: SW-FEL-TL-MS-AR-001 REV. 00

Page 8 of 12

DATE: 18.04.2022

Before any loose layer of fill is compacted, the material and its moisture condition should be

as uniform as practicable throughout its depth.

The maximum particle size of any rocks or other lumps within the layer after compaction

should not exceed 100 mm.

Each layer being leveled, wetted and tamped properly before the succeeding layer is laid.

Each layer of earth shall be consolidated by ramming with approved mechanical compaction

machines.

Compaction of the back fill shall be conducted evenly throughout the excavation area.

Compaction from one corner or one side of an excavation hole shall not be allowed.

The Fill shall be compacted to the maximum while filling the layers one over other.

Manual compaction by tampers shall be allowed in some cases.

Mechanized rollers / plate compactors shall be used for compaction to achieve the required

compaction. At site moisture content shall be checked with the help of rapid moisture

meter or by drying in oven in lab (as required by client).

If there is a delay in the placement of subsequent layers, previously accepted layers which

have wetted up or dried out, shall be tined, moisture conditioned and again compacted to

the requirements of this Specification.

Where fill is to be placed over wet or boggy areas, a heavy grade non-woven geotextile such

as Bidim A34 or equivalent shall be placed directly onto the prepared Pit.

*IT SHALL BE ENSURED THAT MATERIALS FILLING PROCEDURES COMPACTION METHODS

SHALL COMPLY TO PROVISION OF ENGINEERING/STRUCTURAL/LOAD BEARING FILL.

g) FILL MOISTURE CONTROL

Material to be used as fill shall be moisture conditioned as required to permit it to be

compacted to the criteria specified. Fill shall not be compacted at moisture content outside

the limit of 5% of the Standard Optimum Moisture Content (NZS 4402) without approval

from the Consultant Engineer.

If the moisture content of the fill falls below the specified minimum, water should be added

either on the fill or in the cut/borrow areas before it is transported to the fill area. Water

applied to the fill should be finely sprayed and uniformly blended throughout the full depth

of uncompacted material. If the moisture content of the uncompacted fill is non-uniform,

the material should be mixed to provide a consistent moisture distribution. Care is needed

to ensure that mixing or blending does not produce segregation of the fill material.

If the moisture content of material is above the specified maximum, drying of the material

may be accelerated by aeration or by blending with dry materials.If rain is threatening or the

Shubham Patel Amit Mitra Soloman S S

PREPARED BY: APPROVED BY:

REVIEWED BY

`

METHOD STATEMENT FOR SITE

CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

DOC No.: SW-FEL-TL-MS-AR-001 REV. 00

Page 9 of 12

DATE: 18.04.2022

site is to be left unattended, the surface of the fill shall be sealed with rubber-tire or

smooth-wheeled plant and graded to prevent ponding.

7) ACCEPTANCE CRITERIA

Conformity to Plot Marking.

Conformity to depth of excavation.

Conformity for Compaction of Filled soil.

Conformity to Drawing and Technical Specification

8) SAFETY MEASURES / PRECAUTIONS:

Before starting the work ensure that no under live electrical cable or chemical / water pipe

line is passing through the area of excavation.

An excavation work permit should be issued before starting excavation work.

Before starting of the excavation the required material for barricading to be arranged.

Safe working distance/height to be maintained while working under overhead energized line

or substation structures.

Excavation shall be protected from all sides by erecting barricades with caution signs and

shall have warning tape.

Ensure proper lighting arrangement for work at night.

Stairs, ladders or ramps must be provided where workers are required to enter excavated

area.

Ensure proper shoring to be done in case of loose soil or rocks.

Ensure person works only after proper fixing of wooden/steel sheets along the sides of pit

wall.

Excavated materials / other construction material shall not be kept at the edge of the

excavation pit. The excavated earth need to be dumped at least 1-2 m away from the edge

of the excavation.

Dewatering from excavated pit ‐ Moving parts of Dewatering pump shall be guarded. Power

supply for the pump shall be through ELCB and the pump shall be earthed. PPE’s, like safety

helmets, hand gloves, gumboots / safety shoes etc. shall be used.

Shubham Patel Amit Mitra Soloman S S

PREPARED BY: APPROVED BY:

REVIEWED BY

`

METHOD STATEMENT FOR SITE

CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

DOC No.: SW-FEL-TL-MS-AR-001 REV. 00

Page 10 of 12

DATE: 18.04.2022

The fitness of the equipment (JCB which is going to be used) and driver to be checked by the

concerned engineer/ supervisor and safety supervisor. In any case if the safety supervisor

could not reach the spot on the same day, the work can be started after the concerned site

supervisor is satisfied after checking the equipment. It must be ensured that the operator is

having the valid license to operate the equipment.

Before starting filling ensure that area is clear from construction utility material.

Before starting the filling ground condition and stability shall be checked.

Don’t stand near to the earth moving equipment in operation.

Use stoppers for not letting filler machine to go near the edge of the pit.

No one other than operator shall be allowed to sit in operator’s cabin.

Filling shall be done layer by layer after confirming proper compaction in each layer.

Proper access to the area to be Filled shall be ensured.

Ramps should not have more than 15‐degree angle.

Ramps should be free from obstruction.

9) Do’s and Don’ts

Shubham Patel Amit Mitra Soloman S S

PREPARED BY: APPROVED BY:

REVIEWED BY

`

METHOD STATEMENT FOR SITE

CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

DOC No.: SW-FEL-TL-MS-AR-001 REV. 00

Page 11 of 12

DATE: 18.04.2022

Shubham Patel Amit Mitra Soloman S S

PREPARED BY: APPROVED BY:

REVIEWED BY

`

METHOD STATEMENT FOR SITE

CLEARANCE, LAND DEVELOPMENT,

EXCAVATION AND FILLING

DOC No.: SW-FEL-TL-MS-AR-001 REV. 00

Page 12 of 12

DATE: 18.04.2022

10) COMPACTION CRITERIA

Fill shall be compacted to a minimum dry density ratio of 98% Standard Proctor (NZS4402)

unless otherwise specified, or shown on the Drawings. Testing shall be undertaken by the

Contractor as required by the Engineer, in accordance with the guidelines presented in

NZS4402, to confirm that the fill has been compacted to these specified minimum criteria.

The achieved compaction may also be checked using a dynamic cone penetrometer

(NZS4402), but this will only be undertaken after a correlation between dry density ratio and

penetration resistance has been established for the particular site and for each of the typical

materials encountered. Where a dispute exists as to the achieved compaction, the results of

direct measurements of dry density ration (NZS4402) shall be deemed to apply.

The upper layer of filling immediately below road sub-grade level shall be compacted to a

minimum dry density ratio of 98% Standard Proctor. This may be carried out at the time of

pavement construction. The Contractor must allow in the lump sum tender price for

compaction tests as required by the Engineer.

All fill layers have to be compacted, tested and approved by the Engineer prior to filling

upper subsequent layers. Contractor to allow compaction testing at a rate of 1 test per

100m2 (10x10m grid).

Shubham Patel Amit Mitra Soloman S S

PREPARED BY: APPROVED BY:

REVIEWED BY

`

You might also like

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Portable Accommodation Modules Guide May14Document46 pagesPortable Accommodation Modules Guide May14Mike MidgettNo ratings yet

- Department of Construction Sessional Examination (Spring Semester)Document9 pagesDepartment of Construction Sessional Examination (Spring Semester)Harry LaiNo ratings yet

- DOE ESCP ChecklistDocument6 pagesDOE ESCP ChecklistChong Chee YenNo ratings yet

- 2010 10 OnlineDocument72 pages2010 10 OnlineSanja RadovicNo ratings yet

- Hoisting & RiggingDocument5 pagesHoisting & RiggingRam SinghNo ratings yet

- Chapter 26 - Scaffolding GuidelineDocument32 pagesChapter 26 - Scaffolding GuidelineCharlyn Burce MadridNo ratings yet

- Petroleum Development Oman Signs Catalogue SpecificationDocument97 pagesPetroleum Development Oman Signs Catalogue SpecificationSiva ShankarNo ratings yet

- Speed Deck 508: Metal Roof & Wall Cladding SystemDocument6 pagesSpeed Deck 508: Metal Roof & Wall Cladding SystemMuraleedharanNo ratings yet

- Working ScheduleDocument96 pagesWorking ScheduleAli MasyhurNo ratings yet

- ScaffoldingDocument21 pagesScaffoldingKrm ChariNo ratings yet

- Contractors Guide To Work Method StatementsDocument6 pagesContractors Guide To Work Method StatementsMuhammed AliNo ratings yet

- SFPSG-Reducing Unintended Movement of PlantDocument60 pagesSFPSG-Reducing Unintended Movement of PlantLyle KorytarNo ratings yet

- Temporary Jetty Development for Hinkley Point C ProjectDocument28 pagesTemporary Jetty Development for Hinkley Point C Projectsofyan_shahNo ratings yet

- Lifting Operations Management SystemDocument44 pagesLifting Operations Management SystemHUỲNH HOÀNG TÚNo ratings yet

- 7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingDocument9 pages7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingMoustafa FaresNo ratings yet

- TI 801-02 Volume 2 - Statement of WorkDocument81 pagesTI 801-02 Volume 2 - Statement of WorkMohamed FathiNo ratings yet

- Standard Lift Plan TemplateDocument2 pagesStandard Lift Plan TemplateInbarajNo ratings yet

- RingLock Brocure 110812Document17 pagesRingLock Brocure 110812Mohammed AdnanNo ratings yet

- Kavin Engineering - ProjectDocument2 pagesKavin Engineering - Projectagarwal.rmNo ratings yet

- Weighbrige GuideDocument80 pagesWeighbrige Guidebarun patraNo ratings yet

- 012 Piling WorkDocument17 pages012 Piling WorkSarah HaiderNo ratings yet

- Cpc07e-Ms-str-0010 Method of Statement For Installation of BridgeDocument13 pagesCpc07e-Ms-str-0010 Method of Statement For Installation of BridgeMariam MousaNo ratings yet

- Earthworks SpecificationDocument18 pagesEarthworks SpecificationMohd Syaril Mohd Ali100% (1)

- TB-18UDV1-C-TOA-2001 - Working Plan-Temporary Sheet Pile - Shoring Works-Limestone Storage ShedDocument33 pagesTB-18UDV1-C-TOA-2001 - Working Plan-Temporary Sheet Pile - Shoring Works-Limestone Storage Shedanh leNo ratings yet

- MS - MasterTop 135PGDocument4 pagesMS - MasterTop 135PGAzhar Shaikh100% (1)

- SingaporeDocument162 pagesSingaporeabdirahmanNo ratings yet

- Basics of post-installed rebar connectionsDocument33 pagesBasics of post-installed rebar connectionsHaitham KayyaliNo ratings yet

- Method Statement For Workshop Activities RevDocument4 pagesMethod Statement For Workshop Activities RevEmadHassanNo ratings yet

- Scaffolding For LifeDocument27 pagesScaffolding For LifeSameer Kulkarni100% (1)

- Silica Gel Blue MSDSDocument5 pagesSilica Gel Blue MSDSRajesh GalgalikarNo ratings yet

- Checklist Site and Security Fencing SchoolsDocument2 pagesChecklist Site and Security Fencing Schoolsakshay aryaNo ratings yet

- A) SS 536: 2008, Code of Practice For The Safe Use of Mobile CranesDocument18 pagesA) SS 536: 2008, Code of Practice For The Safe Use of Mobile CranesMainrajNo ratings yet

- Guide To Safe Lifting & ProppingDocument34 pagesGuide To Safe Lifting & ProppingAlly KhooNo ratings yet

- Overhead Protection SystemsDocument8 pagesOverhead Protection SystemsmangatamritNo ratings yet

- Pile Driving ChecklistDocument2 pagesPile Driving ChecklistHeng KimsanNo ratings yet

- K017-T12-0003 - 0 Method Statement For Extension Work of Temporary JettyDocument16 pagesK017-T12-0003 - 0 Method Statement For Extension Work of Temporary JettyBayu PutraNo ratings yet

- China Harbour Engineering Company Safety PlanDocument126 pagesChina Harbour Engineering Company Safety Plandi2p2th22s2nNo ratings yet

- Distribution Conductor Equipment for the 21st CenturyDocument21 pagesDistribution Conductor Equipment for the 21st Centurymadhava_srinivasan174No ratings yet

- CNC Oxyacetylene Flame Cutting MachineDocument12 pagesCNC Oxyacetylene Flame Cutting MachineNaman JoharNo ratings yet

- Working Platform For Installing and Dismantling Aluminum Formwork PDFDocument9 pagesWorking Platform For Installing and Dismantling Aluminum Formwork PDFmohd zulhafizNo ratings yet

- Method Statement for Table Formwork ErectionDocument18 pagesMethod Statement for Table Formwork ErectionMade GileeNo ratings yet

- 6-Impact of Adhesive Thickness On The Capacity of The Surface Mounting Steel Plates Strengthening TechniqueDocument9 pages6-Impact of Adhesive Thickness On The Capacity of The Surface Mounting Steel Plates Strengthening TechniqueMr A. M. OlajumokeNo ratings yet

- A Guide To Commissioning Scaffold Design: 1 of 6 June 2020Document6 pagesA Guide To Commissioning Scaffold Design: 1 of 6 June 2020Matthew PowellNo ratings yet

- ZCC850H: 85 Ton CapacityDocument8 pagesZCC850H: 85 Ton CapacityYulianto JoeNo ratings yet

- Scaffolding Erection &dismanlting JSADocument7 pagesScaffolding Erection &dismanlting JSAShahid Bhatti100% (1)

- Procedure For Trenching ExcavationDocument7 pagesProcedure For Trenching ExcavationMecon HyderabadNo ratings yet

- Dbi Sala Catalog PDFDocument60 pagesDbi Sala Catalog PDFvikrant911No ratings yet

- Temporary Works (CBE44707S) SyllabusDocument7 pagesTemporary Works (CBE44707S) Syllabusskywalker_handsomeNo ratings yet

- Portacabin Foundation Design ReportDocument43 pagesPortacabin Foundation Design ReportAaron DikiboNo ratings yet

- MOS UnloadingDocument3 pagesMOS UnloadingSyerifaizal Hj. MustaphaNo ratings yet

- Erection MethodologyDocument30 pagesErection MethodologyravindraNo ratings yet

- Is3696 1-1987Document33 pagesIs3696 1-1987sbkcivilNo ratings yet

- Health, Safety, & Environment Manual: General Safety Requirement For Sub Structure Works (Foundation)Document4 pagesHealth, Safety, & Environment Manual: General Safety Requirement For Sub Structure Works (Foundation)rizal azizanNo ratings yet

- What Is Bearing Pressure - Independent Design House LTDDocument6 pagesWhat Is Bearing Pressure - Independent Design House LTDCE Passaj100% (1)

- Method Statement For General LiftingDocument13 pagesMethod Statement For General LiftingtusharDJNo ratings yet

- Construction Procedure Earth WorkDocument28 pagesConstruction Procedure Earth WorkDimas DzununNo ratings yet

- Managing Temporary Works: Andrea Robbins HM Inspector of Health and SafetyDocument47 pagesManaging Temporary Works: Andrea Robbins HM Inspector of Health and Safetyمحمد ابراهيم100% (1)

- Excavation Breaking of Concrete and Re Instatement WorkDocument5 pagesExcavation Breaking of Concrete and Re Instatement WorksujanNo ratings yet

- SOP ExcavationDocument5 pagesSOP ExcavationCharantej TejaNo ratings yet

- Ground Improvement Techniques For Railway Embankments Malaysia (Published Version)Document12 pagesGround Improvement Techniques For Railway Embankments Malaysia (Published Version)Eric ChanNo ratings yet

- E Book Dark Side of Fashion - Melanie de VriesDocument23 pagesE Book Dark Side of Fashion - Melanie de VriesTatiana MolinaNo ratings yet

- Estimation of Soil Erosion and Sediment Yield ConcDocument15 pagesEstimation of Soil Erosion and Sediment Yield ConcALFRED CHEAM JIA JING -No ratings yet

- Removal of Heavy Metals From Wastewater: A ReviewDocument4 pagesRemoval of Heavy Metals From Wastewater: A ReviewInternational Journal of Application or Innovation in Engineering & Management100% (1)

- Estimation of Soil Erosion and Sediment Yield UsinDocument17 pagesEstimation of Soil Erosion and Sediment Yield UsinFelipe Ribeiro BorgesNo ratings yet

- Forests and Forest Policy in Germany: An OverviewDocument40 pagesForests and Forest Policy in Germany: An OverviewJoao Paulo SilveiraNo ratings yet

- Project ppt-2Document17 pagesProject ppt-2brijeshNo ratings yet

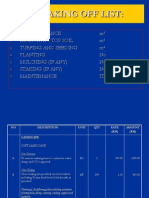

- Estimation 1: Lesson 4 - ExcavationDocument47 pagesEstimation 1: Lesson 4 - ExcavationmexiricaNo ratings yet

- Soft Landscape BQsDocument8 pagesSoft Landscape BQsIqram MeonNo ratings yet

- Unit 6A: Interdependence and AdaptationDocument15 pagesUnit 6A: Interdependence and AdaptationpriyaspvNo ratings yet

- Class 8 Science Chapter 7 Conservation QuestionsDocument7 pagesClass 8 Science Chapter 7 Conservation Questionstechy techyNo ratings yet

- Combined Ground-Penetrating Radar (GPR) and ElectricalDocument9 pagesCombined Ground-Penetrating Radar (GPR) and ElectricalTauseefNo ratings yet

- Comparison of CVA, DRIS, MDRIS and CND Norms in Rhizomes ofDocument4 pagesComparison of CVA, DRIS, MDRIS and CND Norms in Rhizomes ofShailendra RajanNo ratings yet

- Slope Stability and Landslide PreventionDocument25 pagesSlope Stability and Landslide PreventionAce SantosNo ratings yet

- Part 1 Final The Effects of Organic and Inorganic Fertilizer GR 12Document52 pagesPart 1 Final The Effects of Organic and Inorganic Fertilizer GR 12Rhandell BornasalNo ratings yet

- Calculation of Field Dry Density & Moisture ContentDocument2 pagesCalculation of Field Dry Density & Moisture Contentkeshab npnNo ratings yet

- Weathering and Soil Formation: The Breakdown of RocksDocument46 pagesWeathering and Soil Formation: The Breakdown of Rocksfaizankhan23100% (1)

- Science SQP 1Document9 pagesScience SQP 1f20210921No ratings yet

- Environmental Science Toward A Sustainable Future 12th Edition Wright Solutions Manual Full Chapter PDFDocument34 pagesEnvironmental Science Toward A Sustainable Future 12th Edition Wright Solutions Manual Full Chapter PDFRoseWilliamsqnpt100% (9)

- Gao2018 Article LandscapeHeterogeneityAndHydroDocument20 pagesGao2018 Article LandscapeHeterogeneityAndHydroMagdalena QuirogaNo ratings yet

- ARU - Practical Approaches To Wetland MonitoringDocument44 pagesARU - Practical Approaches To Wetland MonitoringFrancisco Vargas-BianchiNo ratings yet

- Stabilization of Laterite Soil With Eggshell Powder and Sodium Silicate Used As Fill Material in Road ConstructionDocument12 pagesStabilization of Laterite Soil With Eggshell Powder and Sodium Silicate Used As Fill Material in Road ConstructionAZOJETE UNIMAIDNo ratings yet

- LPSDP-Mine Rehabilitation HandbookDocument77 pagesLPSDP-Mine Rehabilitation HandbookNgô Đức Tâm100% (1)

- Comprehensive Land Use Plan - TarlacDocument72 pagesComprehensive Land Use Plan - TarlacDino Siopongco86% (21)

- SOIL SCIENCE FUNDAMENTALSDocument13 pagesSOIL SCIENCE FUNDAMENTALSXDXDXDNo ratings yet

- Avances en Horticultura-ReviewDocument15 pagesAvances en Horticultura-Reviewsrikanthbitra1412No ratings yet

- Tabel Data (Direct Shear)Document34 pagesTabel Data (Direct Shear)RIZALNo ratings yet

- Soil Security: David G. RossiterDocument1 pageSoil Security: David G. RossiterMoezselmi.12 SelmiNo ratings yet

- Bio-Fertilizers: Profile No.: 06 NIC Code: 24129Document14 pagesBio-Fertilizers: Profile No.: 06 NIC Code: 24129arpit85No ratings yet

- NAT Class 2 OPP NewDocument46 pagesNAT Class 2 OPP NewankitabindalNo ratings yet