Professional Documents

Culture Documents

Exxon™ Bromobutyl 2211: Rubber

Uploaded by

Maram YasserOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exxon™ Bromobutyl 2211: Rubber

Uploaded by

Maram YasserCopyright:

Available Formats

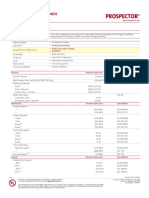

Product Datasheet

Exxon™ Bromobutyl 2211

Rubber

Product Description Key Features

Exxon™ bromobutyl 2211 rubber is a brominated copolymer of Due to the low amount of bromine present, bromobutyl is faster curing

isobutylene and isoprene. Exxon™ bromobutyl is a trademark than standard butyl, is more heat stable and is more compatible with

designating a series of polymers made by brominating isobutylene/ highly unsaturated rubbers. The Exxon™ bromobutyl 2211 rubber is

isoprene copolymers (butyl). designed as a fast cure product. The most important end uses are in

tubeless tire innerliners, tire sidewalls, pharmaceutical stoppers and

mechanical goods.

General

Availability 1 • Africa & Middle East • Europe • North America

• Asia Pacific • Latin America

Appearance • Uniform, white to light amber in color; free of contamination

Form(s) • Bale

Revision Date • 02/06/2023

Resin Properties Typical Value (English) Typical Value (SI) Test Based On

Density 0.93 g/cm³ 0.93 g/cm³ ASTM D297

Mooney Viscosity 2 (ML 1+8, 257°F (125°C)) 32 MU 32 MU ASTM D1646

(mod)

Antioxidant (non-staining) 0.02 wt% min 0.02 wt% min ExxonMobil

Method

Bromine 2.0 wt% 2.0 wt% ExxonMobil

Method

Calcium 0.13 wt% 0.13 wt% ExxonMobil

Method

Stabilizer 1.3 wt% 1.3 wt% ExxonMobil

Method

Water 0.3 wt% max 0.3 wt% max ExxonMobil

Method

Volatiles < 0.6 wt% < 0.6 wt% ASTM D5668

(mod)

Ash < 0.4 wt% < 0.4 wt% ASTM D5667

(mod)

Cure Characteristics (Rheometer) Typical Value (English) Typical Value (SI) Test Based On

ts2 3 3.7 min 3.7 min ASTM D5289

t'50 3 3.9 min 3.9 min ASTM D5289

t'90 3 5.9 min 5.9 min ASTM D5289

Minimum Torque 3 2.2 dN·m 2.2 dN·m ASTM D5289

Maximum Torque 3 6.5 dN·m 6.5 dN·m ASTM D5289

Additional Information

Storage: All inventory must be stored in dry conditions in an enclosed warehouse, protected from contaminants, and outdoor light exposure

(including during shipment and transfers). Shipping Policy: 2 years from date of production. Packaging: 34 +/-0.68kg bales in dispersible EVA film

or release film, in metal crates of 36 bales (1224 kgs) or 30 bales (1020kgs). For material with dispersible film wrap, Vicat softening point less than

or equal to 85°C (ASTM 1525-87).

Legal Statement

For detailed product compliance information, please contact customer Service.

This product is not intended for use in food contact applications.

This product, including the product name, shall not be used or tested in any medical application without prior written acknowledgement of

ExxonMobil Chemical as to the intended use.

Effective Date: 02/06/2023 ExxonMobil Page: 1 of 2

Product Datasheet

Exxon™ Bromobutyl 2211

Rubber

Notes

Typical properties: these are not to be construed as specifications.

1Product may not be available in one or more countries in the identified Availability regions. Please contact your Sales Representative for complete

Country Availability.

2 MV 2000 or equivalent

3Rotor less curemeter (cure conditions - 160°C, 30 min; preheat - none; oscillation - 1.7 Hz, Arc ±0.5°), Standard compound : ASTM D3958 (Test

Formulation - Exxon™ bromobutyl 2211 (100 phr), Carbon black IRB 8 (40 phr), Zinc Oxide IRM 91 (5 phr), Stearic Acid IRM 021 (1 phr), mill mixed

compound)

For additional technical, sales and order assistance: www.exxonmobilchemical.com/ContactUs

©2023 ExxonMobil. ExxonMobil, the ExxonMobil logo, the interlocking “X” device and other product or service names used herein are trademarks of

ExxonMobil, unless indicated otherwise. This document may not be distributed, displayed, copied or altered without ExxonMobil's prior written

authorization. To the extent ExxonMobil authorizes distributing, displaying and/or copying of this document, the user may do so only if the document

is unaltered and complete, including all of its headers, footers, disclaimers and other information. You may not copy this document to or reproduce it

in whole or in part on a website. ExxonMobil does not guarantee the typical (or other) values. Any data included herein is based upon analysis of

representative samples and not the actual product shipped. The information in this document relates only to the named product or materials when

not in combination with any other product or materials. We based the information on data believed to be reliable on the date compiled, but we do not

represent, warrant, or otherwise guarantee, expressly or impliedly, the merchantability, fitness for a particular purpose, freedom from patent

infringement, suitability, accuracy, reliability, or completeness of this information or the products, materials or processes described. The user is solely

responsible for all determinations regarding any use of material or product and any process in its territories of interest. We expressly disclaim liability

for any loss, damage or injury directly or indirectly suffered or incurred as a result of or related to anyone using or relying on any of the information in

this document. This document is not an endorsement of any non-ExxonMobil product or process, and we expressly disclaim any contrary implication.

The terms “we,” “our,” "ExxonMobil Product Solutions" and "ExxonMobil" are each used for convenience, and may include any one or more of

ExxonMobil Product Solutions Company, Exxon Mobil Corporation, or any affiliate either directly or indirectly stewarded.

exxonmobilchemical.com

Effective Date: 02/06/2023 ExxonMobil Page: 2 of 2

You might also like

- Exxon™ Bromobutyl 2222: RubberDocument2 pagesExxon™ Bromobutyl 2222: RubberMaram YasserNo ratings yet

- Exxon™ Bromobutyl 2255: RubberDocument2 pagesExxon™ Bromobutyl 2255: RubberMaram YasserNo ratings yet

- Exxon™ Bromobutyl 2235: RubberDocument2 pagesExxon™ Bromobutyl 2235: RubberMaram YasserNo ratings yet

- Exxon™ Chlorobutyl 5066: RubberDocument2 pagesExxon™ Chlorobutyl 5066: RubberMaram YasserNo ratings yet

- Exxpro™ 3433: Specialty ElastomerDocument2 pagesExxpro™ 3433: Specialty ElastomerMaram YasserNo ratings yet

- Exxon™ Butyl 268S: RubberDocument2 pagesExxon™ Butyl 268S: RubberMaram YasserNo ratings yet

- Exxon™ Butyl 365S: RubberDocument2 pagesExxon™ Butyl 365S: RubberMaram YasserNo ratings yet

- Exxon™ Butyl 268: RubberDocument2 pagesExxon™ Butyl 268: RubberMaram YasserNo ratings yet

- Exxon™ Butyl 065S: RubberDocument2 pagesExxon™ Butyl 065S: RubberMaram YasserNo ratings yet

- Exxon™ Butyl 068S: RubberDocument2 pagesExxon™ Butyl 068S: RubberMaram YasserNo ratings yet

- TDS Vistamaxx 6102FLDocument2 pagesTDS Vistamaxx 6102FLsaied shabanaNo ratings yet

- Vista MaxxDocument2 pagesVista MaxxNoe floresNo ratings yet

- Vistamaxx™ Performance Polymer 6202: Propylene ElastomerDocument2 pagesVistamaxx™ Performance Polymer 6202: Propylene Elastomermd-ariful.islamNo ratings yet

- Product PDF 243943Document2 pagesProduct PDF 243943Mauricio Alejandro Castillo SorianoNo ratings yet

- Technical Datasheet - Vistamaxx™ 6102Document2 pagesTechnical Datasheet - Vistamaxx™ 6102BegenkzNo ratings yet

- Escorene Ultra LD728.61Document2 pagesEscorene Ultra LD728.61José Roberto LazoNo ratings yet

- FT Calcipur 2 OGDocument1 pageFT Calcipur 2 OGZorenny TovarNo ratings yet

- Exxo ld723.28Document2 pagesExxo ld723.28Osmar ContrerasNo ratings yet

- Exceed 0019imDocument2 pagesExceed 0019imzhen liuNo ratings yet

- Technical Data Sheet Rigid 4000Document2 pagesTechnical Data Sheet Rigid 4000dikimanNo ratings yet

- More Production: in Less TimeDocument2 pagesMore Production: in Less TimeDaniel GarciaNo ratings yet

- aluminium trihydrateDocument1 pagealuminium trihydrateprchnandagawaliNo ratings yet

- Eastman Turbo Oil 2197 TDS PDFDocument2 pagesEastman Turbo Oil 2197 TDS PDFstas2moskalenkoNo ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- Exceed™ XP 8656MK: Performance PolymerDocument2 pagesExceed™ XP 8656MK: Performance PolymerCristian RodriguezNo ratings yet

- Enable 3505MCDocument2 pagesEnable 3505MCNicho Francisco WiryonoNo ratings yet

- Aegis5-14 Film Validation Guide: Five-Layer, 14 Mil Cast Fi LMDocument15 pagesAegis5-14 Film Validation Guide: Five-Layer, 14 Mil Cast Fi LMCampaign MediaNo ratings yet

- Tough 1500 TDS ENDocument2 pagesTough 1500 TDS ENMert SunNo ratings yet

- Castes Resin by FormlabDocument2 pagesCastes Resin by FormlabAhmed IbrahimNo ratings yet

- Vistamaxx™ 8880: Performance PolymerDocument2 pagesVistamaxx™ 8880: Performance Polymerwenseslao hernandezNo ratings yet

- enDocument2 pagesenabdelmoumene djafer beyNo ratings yet

- 1632 - Pbt-Pet Valox 815Document5 pages1632 - Pbt-Pet Valox 815Vinoth SekarNo ratings yet

- Data Sheet Exxol D60Document2 pagesData Sheet Exxol D60Jorge TorresNo ratings yet

- LEXAN™ Copolymer 943X - AsiaDocument4 pagesLEXAN™ Copolymer 943X - AsiaaNo ratings yet

- Enable™ 4009MC Blown: Performance PolymerDocument2 pagesEnable™ 4009MC Blown: Performance PolymerCristian RodriguezNo ratings yet

- 84968_sourceDocument1 page84968_sourceQuy NguyenNo ratings yet

- Vistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore ADocument2 pagesVistalon 3666 / 8600 EPDM Rubber Dense Weatherseal - 40 Shore AShalom JohnNo ratings yet

- Exact™ 3040 Cast: Ethylene-Based Plastomer ResinDocument2 pagesExact™ 3040 Cast: Ethylene-Based Plastomer ResinManuel HerreraNo ratings yet

- Certene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneDocument1 pageCertene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneRoberto De Mesa PNo ratings yet

- Exxsol D60 TDSDocument1 pageExxsol D60 TDSmain.chfNo ratings yet

- Achieve™ Advanced PP8285E1: Polypropylene Impact CopolymerDocument2 pagesAchieve™ Advanced PP8285E1: Polypropylene Impact CopolymermosesNo ratings yet

- Exceed™ XP 8656ML: Performance PolymerDocument2 pagesExceed™ XP 8656ML: Performance PolymerCristian RodriguezNo ratings yet

- Solvay - Ixef BXT2000Document5 pagesSolvay - Ixef BXT2000Renan GadioliNo ratings yet

- Vistamaxx™ 6202: Performance PolymerDocument2 pagesVistamaxx™ 6202: Performance PolymerJose Luis Arana AguilarNo ratings yet

- Federal Specification for Methanol GradesDocument6 pagesFederal Specification for Methanol GradesMoh. Yudhistira Firmansyah Teknik KimiaNo ratings yet

- Exceed™ 2718CB: Metallocene Polyethylene ResinDocument2 pagesExceed™ 2718CB: Metallocene Polyethylene ResinRoberto De Mesa PNo ratings yet

- PC Lexan HP6NR Healthcare - ProspectorDocument5 pagesPC Lexan HP6NR Healthcare - ProspectorcountzeroaslNo ratings yet

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsDocument4 pagesULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaNo ratings yet

- TDS - TS001 - Technyl A218Document3 pagesTDS - TS001 - Technyl A218oberta.andrzejNo ratings yet

- Exceed™ XP 6056ML: Performance PolymerDocument2 pagesExceed™ XP 6056ML: Performance PolymerkjmontilNo ratings yet

- IP2028 DowpolDocument1 pageIP2028 DowpolRhea TalibNo ratings yet

- Datasheet Turbo Oil 2197Document2 pagesDatasheet Turbo Oil 2197loopkkNo ratings yet

- Exxon LD 100 BWDocument2 pagesExxon LD 100 BWAli KüçükNo ratings yet

- Document PDFDocument2 pagesDocument PDFAnthony KasenaNo ratings yet

- Exxonmobil™ Pp7815E1: Polypropylene Impact CopolymerDocument2 pagesExxonmobil™ Pp7815E1: Polypropylene Impact CopolymermosesNo ratings yet

- Achieve™ Advanced PP1605: Polypropylene HomopolymerDocument2 pagesAchieve™ Advanced PP1605: Polypropylene HomopolymerSwapnil KumarNo ratings yet

- Exceed™ XP 8318MJ: Performance PolymerDocument2 pagesExceed™ XP 8318MJ: Performance PolymerMaram YasserNo ratings yet

- Bapolene 200fDocument2 pagesBapolene 200fDiana SarmientoNo ratings yet

- Spectrasyn Elite™ 300: Metallocene Polyalphaolefin (Mpao) FluidDocument2 pagesSpectrasyn Elite™ 300: Metallocene Polyalphaolefin (Mpao) FluidMaram YasserNo ratings yet

- Spectrasyn Plus™ 3.6: Advanced Polyalphaolefin (Pao) FluidDocument2 pagesSpectrasyn Plus™ 3.6: Advanced Polyalphaolefin (Pao) FluidMaram YasserNo ratings yet

- Spectrasyn Plus™ 3.6: Advanced Polyalphaolefin (Pao) FluidDocument2 pagesSpectrasyn Plus™ 3.6: Advanced Polyalphaolefin (Pao) FluidMaram YasserNo ratings yet

- Exceed™ S 9333 Series: Performance PolymerDocument2 pagesExceed™ S 9333 Series: Performance PolymerMaram YasserNo ratings yet

- Vistalon™ 8800: Ethylene Propylene Diene Terpolymer RubberDocument1 pageVistalon™ 8800: Ethylene Propylene Diene Terpolymer RubberMaram YasserNo ratings yet

- Exceed XP 7052MLDocument2 pagesExceed XP 7052MLsaied shabanaNo ratings yet

- Vistalon™ 805: Ethylene Propylene Copolymer RubberDocument1 pageVistalon™ 805: Ethylene Propylene Copolymer RubberMaram YasserNo ratings yet

- Spectrasyn Elite™ 300: Metallocene Polyalphaolefin (Mpao) FluidDocument2 pagesSpectrasyn Elite™ 300: Metallocene Polyalphaolefin (Mpao) FluidMaram YasserNo ratings yet

- Exceed™ XP 8346CB: Performance PolymerDocument2 pagesExceed™ XP 8346CB: Performance PolymerMaram YasserNo ratings yet

- Vistalon™ 8731: Ethylene Propylene Diene Terpolymer RubberDocument1 pageVistalon™ 8731: Ethylene Propylene Diene Terpolymer RubberMaram YasserNo ratings yet

- Exceed™ XP 8656MK: Performance PolymerDocument2 pagesExceed™ XP 8656MK: Performance PolymerCristian RodriguezNo ratings yet

- Exceed™ XP 8656ML: Performance PolymerDocument2 pagesExceed™ XP 8656ML: Performance PolymerCristian RodriguezNo ratings yet

- Exceed™ XP 8346CB: Performance PolymerDocument2 pagesExceed™ XP 8346CB: Performance PolymerMaram YasserNo ratings yet

- Exceed XP 7052MLDocument2 pagesExceed XP 7052MLsaied shabanaNo ratings yet

- Vistalon™ 8731: Ethylene Propylene Diene Terpolymer RubberDocument1 pageVistalon™ 8731: Ethylene Propylene Diene Terpolymer RubberMaram YasserNo ratings yet

- Excedd XP 8784 Series PDS PDFDocument2 pagesExcedd XP 8784 Series PDS PDFchinchotarngNo ratings yet

- Exxon™ Butyl 065S: RubberDocument2 pagesExxon™ Butyl 065S: RubberMaram YasserNo ratings yet

- Exxon™ Bromobutyl 7211: RubberDocument2 pagesExxon™ Bromobutyl 7211: RubberMaram YasserNo ratings yet

- Exxon™ Butyl 365S: RubberDocument2 pagesExxon™ Butyl 365S: RubberMaram YasserNo ratings yet

- Exxon™ Butyl 065S: RubberDocument2 pagesExxon™ Butyl 065S: RubberMaram YasserNo ratings yet

- Exxon™ Butyl 268S: RubberDocument2 pagesExxon™ Butyl 268S: RubberMaram YasserNo ratings yet

- Exxon™ Butyl 365S: RubberDocument2 pagesExxon™ Butyl 365S: RubberMaram YasserNo ratings yet

- AP XX Mobil Delvac MX 20W 50Document3 pagesAP XX Mobil Delvac MX 20W 50Maram YasserNo ratings yet

- Maintenance Heavy EquipmentDocument442 pagesMaintenance Heavy EquipmentMaram YasserNo ratings yet

- Three States of MatterDocument36 pagesThree States of MatterFozia ShaikhNo ratings yet

- Experiment 1Document7 pagesExperiment 1Luxemberg Ng100% (4)

- Functions of GeosyntheticsDocument24 pagesFunctions of GeosyntheticsAzaz AhmedNo ratings yet

- Technical Sheet EUROSTAR Lightning Protection SystemsDocument2 pagesTechnical Sheet EUROSTAR Lightning Protection SystemsnabaroonNo ratings yet

- Chapter 1 DesignDocument17 pagesChapter 1 DesignAbera Mamo100% (2)

- Physics XII CH 7 Physics Assertion Reasoning Alternating CurrentDocument9 pagesPhysics XII CH 7 Physics Assertion Reasoning Alternating CurrentAshwinNo ratings yet

- Study of The Kitaev Models: Arnab Barman RayDocument20 pagesStudy of The Kitaev Models: Arnab Barman RayArnab Barman RayNo ratings yet

- Applications of Schrodinger Wave Equation: V (X), A X 0Document4 pagesApplications of Schrodinger Wave Equation: V (X), A X 0jasonNo ratings yet

- 4 - Rotary DryerDocument24 pages4 - Rotary DryerkhawarNo ratings yet

- Rites LTD Stainless Steel Sheet / Plate: Inspection & Test PlanDocument3 pagesRites LTD Stainless Steel Sheet / Plate: Inspection & Test Plansrisabarinath sugumarNo ratings yet

- Synthesis and Optical Properties of Uantum-Size Metal Sulfide Particles in Aqueous SolutionDocument4 pagesSynthesis and Optical Properties of Uantum-Size Metal Sulfide Particles in Aqueous SolutionANGIE PAOLA RODELO PANZANo ratings yet

- June 2013 QP - Unit 2 Edexcel PhysicsDocument26 pagesJune 2013 QP - Unit 2 Edexcel PhysicsnaamashirNo ratings yet

- Final HallDocument29 pagesFinal HallUnknownNo ratings yet

- According To DIN 50150: Hardness Comparison TableDocument1 pageAccording To DIN 50150: Hardness Comparison Tablerbagri100% (1)

- MagnetismDocument20 pagesMagnetismmadhumitharajNo ratings yet

- Properties of CompoundsDocument2 pagesProperties of CompoundsAngel OghayonNo ratings yet

- SANDVIK FRP TOOL SUMMARY c-2920-30Document63 pagesSANDVIK FRP TOOL SUMMARY c-2920-30yanuar_adhiNo ratings yet

- Phase Equilibria Andsolidification Sequences Ofwhite Cast Irons Containing Vanadium and ChromiumDocument9 pagesPhase Equilibria Andsolidification Sequences Ofwhite Cast Irons Containing Vanadium and ChromiumLeví Damasceno CruzNo ratings yet

- Work Done by An Expanding GasDocument11 pagesWork Done by An Expanding Gasstreetrat133No ratings yet

- 3 - The Role of Oxygen-Permeable Ionomer For Polymer Electrolyte Fuel CellsDocument9 pages3 - The Role of Oxygen-Permeable Ionomer For Polymer Electrolyte Fuel CellsFaseeh KKNo ratings yet

- Tutorial 3. Prestressed ConcreteDocument4 pagesTutorial 3. Prestressed ConcreteNisarg SutharNo ratings yet

- INTRO REFRIGERATIONDocument60 pagesINTRO REFRIGERATIONadityanarang147100% (1)

- (Biomedical Engineering) : BM: Biosciences and BioengineeringDocument22 pages(Biomedical Engineering) : BM: Biosciences and BioengineeringDevasyaNo ratings yet

- Virtual Test AbaqusDocument13 pagesVirtual Test AbaqusMohit ShuklaNo ratings yet

- Chapter3 - Ideal GasDocument19 pagesChapter3 - Ideal GasShafiq HafizullahNo ratings yet

- Klueberbio ALO 32-4000 009019 PI GB enDocument2 pagesKlueberbio ALO 32-4000 009019 PI GB enMuhammad SaputraNo ratings yet

- Tutorial MultiphaseInterFoamDocument21 pagesTutorial MultiphaseInterFoamAnonymous 9pln4v92SNo ratings yet

- Processing Strategies in BionanocompositesDocument47 pagesProcessing Strategies in BionanocompositesEDILENE DE CÁSSIA DUTRA NUNESNo ratings yet

- Fluid Phase Equilibria: Azam Shadloo, Kiana PeyvandiDocument17 pagesFluid Phase Equilibria: Azam Shadloo, Kiana PeyvandizibaNo ratings yet

- Lecture 5Document22 pagesLecture 5Icy45No ratings yet