Professional Documents

Culture Documents

1632 - Pbt-Pet Valox 815

Uploaded by

Vinoth SekarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1632 - Pbt-Pet Valox 815

Uploaded by

Vinoth SekarCopyright:

Available Formats

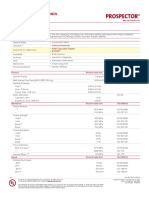

VALOX™ Resin 815 - Europe

Polybutylene Terephthalate www.ulprospector.com

SABIC

Technical Data

Product Description

15% GR PBT+ PET, excellent surface finish. Typical applications are hot air gun housing assemblies, industrial glue guns, appliance housings

and handles.

General

Material Status • Commercial: Active

UL Yellow Card 1 • E45329-236632

Search for UL Yellow Card

• SABIC

• VALOX™ Resin

Availability • Europe

• Appliances • Automotive Under the Hood • Lighting Applications

Uses • Electrical/Electronic

• Automotive Lighting Applications • Non-specific Food Applications

RoHS Compliance • RoHS Compliant

Also Available In • Asia Pacific • Latin America • North America

Physical Nominal Value Unit Test Method

ASTM D792

Density / Specific Gravity 1.43 g/cm³

ISO 1183

Specific Volume 0.700 cm³/g ASTM D792

Melt Mass-Flow Rate (MFR) ASTM D1238

250°C/5.0 kg 20 g/10 min

265°C/5.0 kg 60 g/10 min

Melt Volume-Flow Rate (MVR) ISO 1133

265°C/1.2 kg 12 cm³/10min

265°C/5.0 kg 50 cm³/10min

Molding Shrinkage Internal Method

Across Flow 3 0.60 to 1.0 %

Flow 3 0.40 to 0.80 %

Across Flow : 1.50 to 3.20 mm 0.50 to 0.80 %

Flow : 1.50 to 3.20 mm 0.40 to 0.60 %

Across Flow : 3.20 to 4.60 mm 0.80 to 1.1 %

Flow : 3.20 to 4.60 mm 0.60 to 0.90 %

Water Absorption

24 hr, 23°C 0.060 % ASTM D570

Saturation, 23°C 0.26 % ISO 62

Equilibrium, 23°C, 50% RH 0.060 % ISO 62

Mechanical Nominal Value Unit Test Method

Tensile Modulus

-- 4 6200 MPa ASTM D638

-- 6200 MPa ISO 527-2/1

Tensile Strength

Yield 5 100 MPa ASTM D638

Yield 100 MPa ISO 527-2/5

Break 5 100 MPa ASTM D638

Break 100 MPa ISO 527-2/5

Tensile Elongation

Yield 6 3.0 % ASTM D638

Yield 3.0 % ISO 527-2/5

Break 6 3.0 % ASTM D638

Break 3.0 % ISO 527-2/5

1 of 5 Form No. TDS-31806-en

UL and the UL logo are trademarks of UL LLC © 2020. All Rights Reserved. Document Created: Tuesday, November 10, 2020

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 10/29/2020

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

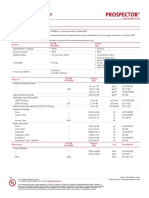

VALOX™ Resin 815 - Europe

Polybutylene Terephthalate

SABIC www.ulprospector.com

Mechanical Nominal Value Unit Test Method

Flexural Modulus

50.0 mm Span 7 5000 MPa ASTM D790

-- 8 5200 MPa ISO 178

Flexural Stress

-- 8, 9 150 MPa ISO 178

-- 8, 10 145 MPa ISO 178

Yield, 50.0 mm Span 7 155 MPa ASTM D790

Break, 50.0 mm Span 7 155 MPa ASTM D790

Flexural Strain - at Break 11 4.0 % ISO 178

Taber Abrasion Resistance Internal Method

1000 g, CS-17 Wheel 17.0 mg

Impact Nominal Value Unit Test Method

Charpy Notched Impact Strength

-30°C 12 4.0 kJ/m² ISO 179/1eA

-20°C 7.0 kJ/m² ISO 179/2C

23°C 12 5.0 kJ/m² ISO 179/1eA

23°C 7.0 kJ/m² ISO 179/2C

Charpy Unnotched Impact Strength 12 ISO 179/1eU

-30°C 30 kJ/m² ISO 179/2U

23°C 30 kJ/m²

Notched Izod Impact

-30°C 60 J/m ASTM D256

0°C 60 J/m ASTM D256

23°C 60 J/m ASTM D256

-30°C 13 6.0 kJ/m² ISO 180/1A

0°C 13 6.0 kJ/m² ISO 180/1A

23°C 13 6.0 kJ/m² ISO 180/1A

Unnotched Izod Impact

-30°C 390 J/m ASTM D4812

23°C 390 J/m ASTM D4812

-30°C 13 25 kJ/m² ISO 180/1U

23°C 13 30 kJ/m² ISO 180/1U

Hardness Nominal Value Unit Test Method

ASTM D785

Rockwell Hardness (R-Scale) 120

ISO 2039-2

Ball Indentation Hardness (H 358/30) 102 MPa ISO 2039-1

Thermal Nominal Value Unit Test Method

Deflection Temperature Under Load

0.45 MPa, Unannealed, 6.40 mm 210 °C ASTM D648

0.45 MPa, Unannealed, 4.00 mm, 100 mm Span 14 210 °C ISO 75-2/Be

0.45 MPa, Unannealed, 4.00 mm, 64.0 mm Span 13 210 °C ISO 75-2/Bf

1.8 MPa, Unannealed, 6.40 mm 160 °C ASTM D648

1.8 MPa, Unannealed, 4.00 mm, 100 mm Span 14 175 °C ISO 75-2/Ae

1.8 MPa, Unannealed, 4.00 mm, 64.0 mm Span 13 167 °C ISO 75-2/Af

Vicat Softening Temperature

ASTM D1525 15

-- 220 °C

ISO 306/A50 15

ASTM D1525 16

-- 204 °C

ISO 306/B50 16

-- 200 °C ISO 306/B120

Ball Pressure Test (123 to 127°C) Pass IEC 60695-10-2

2 of 5 Form No. TDS-31806-en

UL and the UL logo are trademarks of UL LLC © 2020. All Rights Reserved. Document Created: Tuesday, November 10, 2020

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 10/29/2020

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ Resin 815 - Europe

Polybutylene Terephthalate

SABIC www.ulprospector.com

Thermal Nominal Value Unit Test Method

CLTE

Flow : -40 to 40°C 4.5E-5 cm/cm/°C ASTM E831

Flow : 60 to 138°C 5.4E-5 cm/cm/°C ASTM E831

Flow : -40 to 40°C 3.2E-5 cm/cm/°C ISO 11359-2

Flow : 23 to 80°C 5.5E-5 cm/cm/°C ISO 11359-2

Flow : 23 to 150°C 2.4E-5 cm/cm/°C ISO 11359-2

Transverse : -40 to 40°C 9.3E-5 cm/cm/°C ASTM E831

Transverse : -40 to 40°C 7.2E-5 cm/cm/°C ISO 11359-2

Transverse : 23 to 80°C 8.5E-5 cm/cm/°C ISO 11359-2

Transverse : 23 to 150°C 1.8E-4 cm/cm/°C ISO 11359-2

Thermal Conductivity 0.19 W/m/K ISO 8302

RTI Elec 125 °C UL 746

RTI Imp 110 °C UL 746

RTI Str 125 °C UL 746

Electrical Nominal Value Unit Test Method

Surface Resistivity > 1.0E+15 ohms IEC 60093

Volume Resistivity

-- 5.6E+16 ohms·cm ASTM D257

-- > 1.0E+15 ohms·cm IEC 60093

Dielectric Strength

ASTM D149

1.60 mm, in Oil 24 kV/mm

IEC 60243-1

3.20 mm, in Air 22 kV/mm ASTM D149

0.800 mm, in Oil 30 kV/mm IEC 60243-1

1.00 mm 17 18 kV/mm IEC 60243-1

3.20 mm, in Oil 16 kV/mm IEC 60243-1

Dielectric Constant

ASTM D150

100 Hz 3.60

IEC 60250

1 MHz 3.50 ASTM D150

50 Hz 3.00 IEC 60250

60 Hz 3.00 IEC 60250

1 MHz 2.90 IEC 60250

Dissipation Factor

ASTM D150

100 Hz 2.0E-3

IEC 60250

50 Hz 1.0E-3 IEC 60250

60 Hz 1.0E-3 IEC 60250

1 MHz 0.020 IEC 60250

Arc Resistance 18 PLC 5 ASTM D495

Comparative Tracking Index (CTI) PLC 2 UL 746

Comparative Tracking Index IEC 60112

-- 325 V

Solution B 175 V

High Amp Arc Ignition (HAI) 19 PLC 2 UL 746

High Voltage Arc Tracking Rate (HVTR) PLC 1 UL 746

Hot-wire Ignition (HWI) PLC 2 UL 746

Flammability Nominal Value Unit Test Method

Flame Rating UL 94

1.5 mm HB

3.0 mm HB

Glow Wire Flammability Index (1.0 mm) 750 °C IEC 60695-2-12

3 of 5 Form No. TDS-31806-en

UL and the UL logo are trademarks of UL LLC © 2020. All Rights Reserved. Document Created: Tuesday, November 10, 2020

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 10/29/2020

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ Resin 815 - Europe

Polybutylene Terephthalate

SABIC www.ulprospector.com

Fill Analysis Nominal Value Unit Test Method

Melt Viscosity (260°C, 1500 sec^-1) 155 Pa·s ISO 11443

Injection Nominal Value Unit

Drying Temperature 110 to 120 °C

Drying Time 4.0 to 6.0 hr

Suggested Max Moisture 0.020 %

Hopper Temperature 40 to 60 °C

Rear Temperature 240 to 260 °C

Middle Temperature 255 to 280 °C

Front Temperature 260 to 280 °C

Nozzle Temperature 265 to 275 °C

Processing (Melt) Temp 260 to 285 °C

Mold Temperature 60 to 110 °C

Notes

1 A UL Yellow Card contains UL-verified flammability and electrical characteristics. UL Prospector continually works to link Yellow Cards to

individual plastic materials in Prospector, however this list may not include all of the appropriate links. It is important that you verify the association

between these Yellow Cards and the plastic material found in Prospector. For a complete listing of Yellow Cards, visit the UL Yellow Card Search.

2 Typical properties: these are not to be construed as specifications.

3 Tensile Bar

4 5.0 mm/min

5 Type I, 5.0 mm/min

6 Type I, 50 mm/min

7 1.3 mm/min

8 2.0 mm/min

9 at Yield

10 at Break

11 2 mm/min

12 80*10*4 sp=62mm

13 80*10*4 mm

14 120*10*4 mm

15 Rate A (50°C/h), Loading 1 (10 N)

16 Rate A (50°C/h), Loading 2 (50 N)

17 Shorttime

18 Tungsten Electrode

19 Surface

4 of 5 Form No. TDS-31806-en

UL and the UL logo are trademarks of UL LLC © 2020. All Rights Reserved. Document Created: Tuesday, November 10, 2020

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 10/29/2020

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

VALOX™ Resin 815 - Europe

Polybutylene Terephthalate

SABIC www.ulprospector.com

Where to Buy

Supplier

SABIC

,

Web: http://www.sabic.com/

Distributor

3Polymer (Guangzhou) Chemical Technology Co., Ltd.

Telephone: +86-20-3466-7988

Web: http://3polymer.com

Availability: China

AECTRA

Telephone: +33-4-72-54-36-42

Web: https://www.aectra.fr/

Availability: Bulgaria, Romania

AGI-Augusto Guimarães & Irmão

Telephone: +351-22753-7400

Web: https://www.agi.pt/en/

Availability: Portugal

GRÄSSLIN

Telephone: +49-7721-4040-261

Web: https://www.graesslin-kunststoffe.de

Availability: Germany

Guzmán Polymers

Telephone: +34-963-992-400

Web: https://www.guzmanglobal.com/en/productos/plastics/

Availability: Italy, Spain, Turkey

Lenorplastics

Telephone: +41-61-706-11-11

Web: https://www.lenorplastics.ch

Availability: Switzerland

Plastoplan

Telephone: +43-1-25040-0

Web: https://www.plastoplan.com/

Availability: Austria, Czech Republic, Hungary, Poland, Slovakia

POLYMIX

POLYMIX is a Pan European distribution company. Contact POLYMIX for availability of individual products by country.

Telephone: +33-3-8920-1380

Web: http://www.polymix.eu/

Availability: France

RESINEX Group

RESINEX is a Pan European distribution company. Contact RESINEX for availability of individual products by country.

Telephone: +32-14-672511

Web: http://www.resinex.com/

Availability: Europe

Ultrapolymers

Ultrapolymers is a Pan European distribution company. Contact Ultrapolymers for availability of individual products by country.

Telephone: +32-11-57-95-57

Web: http://www.ultrapolymers.com/

Availability: Belgium, Netherlands, South Africa

5 of 5 Form No. TDS-31806-en

UL and the UL logo are trademarks of UL LLC © 2020. All Rights Reserved. Document Created: Tuesday, November 10, 2020

UL Prospector | 800-788-4668 or 307-742-9227 | www.ulprospector.com. Added to Prospector: November 2000

Last Updated: 10/29/2020

The information presented here was acquired by UL from the producer of the product or material or original information provider. However, UL

assumes no responsibility or liability for the accuracy of the information contained on this website and strongly encourages that upon final product

or material selection information is validated with the manufacturer. This website provides links to other websites owned by third parties. The

content of such third party sites is not within our control, and we cannot and will not take responsibility for the information or content.

You might also like

- Obara BogbeDocument36 pagesObara BogbeOjubona Aremu Omotiayebi Ifamoriyo0% (1)

- LM2TB8 2018 (Online)Document252 pagesLM2TB8 2018 (Online)SandhirNo ratings yet

- Christena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Document293 pagesChristena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Emiliano CalabazaNo ratings yet

- Biblical Foundations For Baptist Churches A Contemporary Ecclesiology by John S. Hammett PDFDocument400 pagesBiblical Foundations For Baptist Churches A Contemporary Ecclesiology by John S. Hammett PDFSourav SircarNo ratings yet

- Ultradur® S 4090 G2Document4 pagesUltradur® S 4090 G2srinivasaNo ratings yet

- PC Lexan HP6NR Healthcare - ProspectorDocument5 pagesPC Lexan HP6NR Healthcare - ProspectorcountzeroaslNo ratings yet

- XENOY™ Resin 1760E - AmericasDocument4 pagesXENOY™ Resin 1760E - AmericasWellington C. de AraujoNo ratings yet

- LEXAN™ Copolymer 943X - AsiaDocument4 pagesLEXAN™ Copolymer 943X - AsiaaNo ratings yet

- Ultradur® B 4300 G6Document4 pagesUltradur® B 4300 G6srinivasaNo ratings yet

- PC Lexan 104Document4 pagesPC Lexan 104countzeroaslNo ratings yet

- Delrin® 127UV NC010Document3 pagesDelrin® 127UV NC010alejandrocharlescollNo ratings yet

- Hostalen H 2150Document3 pagesHostalen H 2150Silviu PadureanuNo ratings yet

- Wonderlite® PC-110Document3 pagesWonderlite® PC-110Rhekron PlasticsNo ratings yet

- SABIC® PC Resin PC0703R - AsiaDocument4 pagesSABIC® PC Resin PC0703R - AsiaLong Trịnh ĐìnhNo ratings yet

- ULTEM™ AUT230 Resin: SABIC Innovative PlasticsDocument4 pagesULTEM™ AUT230 Resin: SABIC Innovative PlasticsLeandro LacerdaNo ratings yet

- Tenac 4013ADocument3 pagesTenac 4013APhung LucNo ratings yet

- Product PDF 181Document2 pagesProduct PDF 181RicardoNo ratings yet

- PC Calibre Technical DataDocument4 pagesPC Calibre Technical DataMitja GorseNo ratings yet

- Ultraform W 2320 003 UNC Q600Document3 pagesUltraform W 2320 003 UNC Q600Patricio Bravo CastilloNo ratings yet

- Abs Ex58f - AsiaDocument4 pagesAbs Ex58f - AsiaGiang CaoNo ratings yet

- Kumho ABS 750SWDocument3 pagesKumho ABS 750SWVu TranNo ratings yet

- Starex SD 0150Document5 pagesStarex SD 0150claudiaNo ratings yet

- Kumho ABS 750Document2 pagesKumho ABS 750Murundu EstudioNo ratings yet

- PP GF30 - Hostacom PC072-3 Naturale-2Document2 pagesPP GF30 - Hostacom PC072-3 Naturale-2armando0% (1)

- Esab Welding RodDocument1 pageEsab Welding Rodv ictor manuel MunozNo ratings yet

- 202-Trinseo Calibre Megarad 2081-15 TDSDocument3 pages202-Trinseo Calibre Megarad 2081-15 TDSobeckoneNo ratings yet

- Akulon F136-C1: DSM Engineering Materials - Polyamide 6Document2 pagesAkulon F136-C1: DSM Engineering Materials - Polyamide 6bobNo ratings yet

- PBT Valox 865 30% GLDocument4 pagesPBT Valox 865 30% GLcountzeroaslNo ratings yet

- PP COPO GenericDocument4 pagesPP COPO GenericJames FaunceNo ratings yet

- CALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinDocument3 pagesCALIBRE™ MEGARAD™ 2081-15: Polycarbonate ResinmikeybhabaNo ratings yet

- Starex GR-4020: Lotte Advanced Materials Co., LTDDocument5 pagesStarex GR-4020: Lotte Advanced Materials Co., LTDsivalingabeastboy2002No ratings yet

- PC-Transparent 144RDocument5 pagesPC-Transparent 144Rsantosh.bhattNo ratings yet

- Pom Delrin 500alDocument5 pagesPom Delrin 500alcountzeroaslNo ratings yet

- ASA LI970: Description ApplicationDocument4 pagesASA LI970: Description ApplicationRonal Deiby Cadavid PinzonNo ratings yet

- Z-Ultrat SDSDocument4 pagesZ-Ultrat SDSmbelessisNo ratings yet

- Sabic® Pmma 20HRDocument2 pagesSabic® Pmma 20HRNguyễn Hồng NamNo ratings yet

- 4LAC® 10H10000 - Generic ABSDocument6 pages4LAC® 10H10000 - Generic ABSsrinivasaNo ratings yet

- POLYLAC® PA-765: Chi Mei CorporationDocument3 pagesPOLYLAC® PA-765: Chi Mei CorporationagungNo ratings yet

- Product PDF 102737Document5 pagesProduct PDF 102737vaibhav ShindeNo ratings yet

- iCLINOMTER CASING2017 1Document7 pagesiCLINOMTER CASING2017 1Lale ÖnerNo ratings yet

- PC Lexan 3412R 20% GL - IdesDocument5 pagesPC Lexan 3412R 20% GL - IdescountzeroaslNo ratings yet

- Document PDFDocument2 pagesDocument PDFAnthony KasenaNo ratings yet

- LEXAN™ FR Resin 916R - EuropeDocument3 pagesLEXAN™ FR Resin 916R - EuropesrinivasaNo ratings yet

- PC Makrolon 2405Document5 pagesPC Makrolon 2405countzeroaslNo ratings yet

- Abs - Terluran GP22.Document2 pagesAbs - Terluran GP22.armandoNo ratings yet

- ALTECH ABS C 2017/500 GF17: Technical Data SheetDocument1 pageALTECH ABS C 2017/500 GF17: Technical Data SheetarmandoNo ratings yet

- Atom Arc 7018-1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesDocument2 pagesAtom Arc 7018-1: Covered (Stick) Electrodes (Smaw) Low Hydrogen ElectrodesFranklin Aranda ChacónNo ratings yet

- Solvay - Ixef BXT2000Document5 pagesSolvay - Ixef BXT2000Renan GadioliNo ratings yet

- ATTANE™ 4404G: Ultra Low Density Polyethylene ResinDocument3 pagesATTANE™ 4404G: Ultra Low Density Polyethylene ResinRoberto De Mesa PNo ratings yet

- Abs - Terluran GP35.Document2 pagesAbs - Terluran GP35.armandoNo ratings yet

- Polylac® Pa-747Document3 pagesPolylac® Pa-747vicenteNo ratings yet

- Zytel® HTN 51G35HSLR BK420Document3 pagesZytel® HTN 51G35HSLR BK420Vignesh CmvrNo ratings yet

- Zytel® 70G30HSLR BK099Document4 pagesZytel® 70G30HSLR BK099srinivasaNo ratings yet

- ACRYREX® CM-211: Chi Mei CorporationDocument3 pagesACRYREX® CM-211: Chi Mei CorporationPhuoc Thinh TruongNo ratings yet

- LG Abs Af365bDocument2 pagesLG Abs Af365bPhung LucNo ratings yet

- ExxonMobil LLP846029 Rotational Molding ResinDocument2 pagesExxonMobil LLP846029 Rotational Molding ResinLuis Hernandez GarciaNo ratings yet

- Lustran® 433: INEOS StyrolutionDocument3 pagesLustran® 433: INEOS StyrolutionJames FaunceNo ratings yet

- Pa6 GF30 - Dupont Zytel® 73G30HSL BK416Document2 pagesPa6 GF30 - Dupont Zytel® 73G30HSL BK416armandoNo ratings yet

- Product PDF 14364Document2 pagesProduct PDF 14364Gerente IngenieriaNo ratings yet

- Hopelex Af 3100Document2 pagesHopelex Af 3100FarizNo ratings yet

- TDS - TS001 - Technyl A218Document3 pagesTDS - TS001 - Technyl A218oberta.andrzejNo ratings yet

- SABIC Innovative Plastics Cycoloy C6200 PCABSDocument3 pagesSABIC Innovative Plastics Cycoloy C6200 PCABSLex WangNo ratings yet

- Chem Resist ChartDocument13 pagesChem Resist ChartRC LandaNo ratings yet

- Neelima A Kulkarni ResumeDocument3 pagesNeelima A Kulkarni ResumeAcademics LecturenotesNo ratings yet

- Pest of Field Crops and Management PracticalDocument44 pagesPest of Field Crops and Management PracticalNirmala RameshNo ratings yet

- P. E. and Health ReportDocument20 pagesP. E. and Health ReportLESSLY ABRENCILLONo ratings yet

- Resume NetezaDocument5 pagesResume Netezahi4149No ratings yet

- Cad Data Exchange StandardsDocument16 pagesCad Data Exchange StandardskannanvikneshNo ratings yet

- Research On Export Trade in BangladeshDocument7 pagesResearch On Export Trade in BangladeshFarjana AnwarNo ratings yet

- Uneb U.C.E Mathematics Paper 1 2018Document4 pagesUneb U.C.E Mathematics Paper 1 2018shafickimera281No ratings yet

- International Patient Referral - Part 2 - Revised - 29-04-2010 - 2Document2 pagesInternational Patient Referral - Part 2 - Revised - 29-04-2010 - 2Fatah AssadNo ratings yet

- Bigbazaar PDFDocument14 pagesBigbazaar PDFazhagu sundaramNo ratings yet

- Onset Hobo Trade T Cdi 5200 5400 User ManualDocument3 pagesOnset Hobo Trade T Cdi 5200 5400 User Manualpaull20020% (1)

- Homework 1Document8 pagesHomework 1Yooncheul JeungNo ratings yet

- N50-200H-CC Operation and Maintenance Manual 961220 Bytes 01Document94 pagesN50-200H-CC Operation and Maintenance Manual 961220 Bytes 01ANDRESNo ratings yet

- Test Bank For Macroeconomics For Life Smart Choices For All2nd Edition Avi J Cohen DownloadDocument74 pagesTest Bank For Macroeconomics For Life Smart Choices For All2nd Edition Avi J Cohen Downloadmichaelmarshallmiwqxteyjb100% (28)

- Asuhan Keperawatan Pada Klien Dengan Proses Penyembuhan Luka. Pengkajian Diagnosa Perencanaan Implementasi EvaluasiDocument43 pagesAsuhan Keperawatan Pada Klien Dengan Proses Penyembuhan Luka. Pengkajian Diagnosa Perencanaan Implementasi EvaluasiCak FirmanNo ratings yet

- Historical Exchange Rates - OANDA AUD-MYRDocument1 pageHistorical Exchange Rates - OANDA AUD-MYRML MLNo ratings yet

- Lec. 2Document22 pagesLec. 2محمدNo ratings yet

- FAO-Assessment of Freshwater Fish Seed Resources For Sistainable AquacultureDocument669 pagesFAO-Assessment of Freshwater Fish Seed Resources For Sistainable AquacultureCIO-CIO100% (2)

- Mitsubishi FanDocument2 pagesMitsubishi FanKyaw ZawNo ratings yet

- Standard nfx15-211Document2 pagesStandard nfx15-211Luis Enrique Cóndor PorrasNo ratings yet

- Clash of Clans Hack Activation CodeDocument2 pagesClash of Clans Hack Activation Codegrumpysadness7626No ratings yet

- De DusterDocument6 pagesDe DusterArstNo ratings yet

- Lecture Notes 3A - Basic Concepts of Crystal Structure 2019Document19 pagesLecture Notes 3A - Basic Concepts of Crystal Structure 2019Lena BacaniNo ratings yet

- Laboratorio 1Document6 pagesLaboratorio 1Marlon DiazNo ratings yet

- Fmicb 10 02876Document11 pagesFmicb 10 02876Angeles SuarezNo ratings yet

- QuinnmcfeetersresumeDocument1 pageQuinnmcfeetersresumeapi-510833585No ratings yet