Professional Documents

Culture Documents

Pom Delrin 500al

Uploaded by

countzeroaslOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pom Delrin 500al

Uploaded by

countzeroaslCopyright:

Available Formats

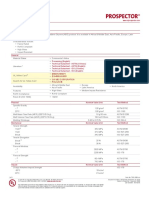

Delrin® 500AL NC010

ACETAL RESIN

DuPont Performance Polymers ides.com/prospector

Technical Data

Product Description

Delrin® 500AL is a medium viscosity acetal homopolymer, with an advanced system of lubrication for applications requiring low wear and/or

coefficient of friction against steel, itself or other plastics.

General

Material Status • Preliminary Data 1

• Typical Processing for DuPont Engineering Polymers (English)

Literature 2 • Processing - Injection Molding (English)

• Technical Datasheet

UL Yellow Card 3 • E41938-257636

Search for UL Yellow Card

• DuPont Performance Polymers

• Delrin®

• Africa & Middle East • Europe

Availability • Asia Pacific • Latin America • South America

• Central America • North America

Additive • Lubricant

• Good Creep Resistance • Low Friction

Features • Good Wear Resistance • Lubricated • Ultrasonic Weldable

• Homopolymer • Medium Viscosity

Uses • Conveyors • Engineering Parts • Gears

RoHS Compliance • Contact Manufacturer

Appearance • Natural Color

Forms • Pellets

Processing Method • Injection Molding

Part Marking Code (ISO 11469) • >POM-S<

Resin ID (ISO 1043) • POM-S

Physical Nominal Value (English) Nominal Value (SI) Test Method

Specific Gravity

-- 1.39 1.39 g/cm³ ASTM D792

-- 1.39 g/cm³ 1.39 g/cm³ ISO 1183

Melt Mass-Flow Rate (MFR)

190°C/1.05 kg 6.0 g/10 min 6.0 g/10 min ASTM D1238

190°C/2.16 kg 14 g/10 min 14 g/10 min ISO 1133

Melt Volume-Flow Rate (MVR) (190°C/2.16 kg) 0.732 in³/10min 12.0 cm³/10min ISO 1133

Molding Shrinkage

Flow: 24 hr, 0.126 in (3.20 mm) 0.017 to 0.020 in/in 1.7 to 2.0 % ASTM D955

Across Flow: 24 hr, 0.126 in (3.20 mm) 0.017 to 0.020 in/in 1.7 to 2.0 % ASTM D955

Across Flow: 0.0787 in (2.00 mm) 1.7 % 1.7 % ISO 294-4

Flow: 0.0787 in (2.00 mm) 1.8 % 1.8 % ISO 294-4

Across Flow: 0.157 in (4.00 mm) 1.9 % 1.9 % ISO 294-4

Flow: 0.157 in (4.00 mm) 1.9 % 1.9 % ISO 294-4

Mechanical Nominal Value (English) Nominal Value (SI) Test Method

Tensile Modulus

73°F (23°C) 5 460000 psi 3170 MPa ASTM D638

73°F (23°C) 435000 psi 3000 MPa ISO 527-2

Tensile Strength

Yield, 73°F (23°C) 5 9570 psi 66.0 MPa ASTM D638

Yield, 73°F (23°C) 9430 psi 65.0 MPa ISO 527-2

73°F (23°C) 5 9570 psi 66.0 MPa ASTM D638

1 of 4 Form No. TDS-51609-en

UL and the UL logo are trademarks of UL LLC © 2013. All Rights Reserved. Document Created: Tuesday, May 28, 2013

UL IDES | 800-788-4668 or 307-742-9227 | www.ides.com. Added to Prospector: April, 2001

Last Updated: 5/16/2013

The information presented on this datasheet was acquired by UL IDES from the producer of the material. UL IDES makes substantial efforts to assure the

accuracy of this data. However, UL IDES assumes no responsibility for the data values and strongly encourages that upon final material selection, data points are

validated with the material supplier.

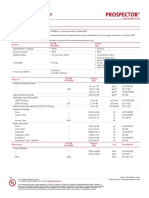

Delrin® 500AL NC010

ACETAL RESIN

DuPont Performance Polymers ides.com/prospector

Mechanical Nominal Value (English) Nominal Value (SI) Test Method

Tensile Elongation

Yield, 73°F (23°C) 5 10 % 10 % ASTM D638

Yield, 73°F (23°C) 11 % 11 % ISO 527-2

Break, 73°F (23°C) 5 30 % 30 % ASTM D638

Break, 73°F (23°C) 35 % 35 % ISO 527-2/50

Nominal Tensile Strain at Break ISO 527-2

73°F (23°C) 23 % 23 %

Tensile Creep Modulus ISO 899-1

1 hr 348000 psi 2400 MPa

1000 hr 232000 psi 1600 MPa

Flexural Modulus

73°F (23°C) 431000 psi 2970 MPa ASTM D790

73°F (23°C) 406000 psi 2800 MPa ISO 178

Flexural Strength ASTM D790

5.0% Strain, 73°F (23°C) 12800 psi 88.0 MPa

Impact Nominal Value (English) Nominal Value (SI) Test Method

Charpy Notched Impact Strength ISO 179/1eA

-22°F (-30°C) 2.9 ft·lb/in² 6.0 kJ/m²

73°F (23°C) 3.3 ft·lb/in² 7.0 kJ/m²

Charpy Unnotched Impact Strength ISO 179/1eU

-22°F (-30°C) 62 ft·lb/in² 130 kJ/m²

73°F (23°C) 76 ft·lb/in² 160 kJ/m²

Notched Izod Impact

73°F (23°C) 1.1 ft·lb/in 58 J/m ASTM D256

-40°F (-40°C) 2.4 ft·lb/in² 5.0 kJ/m² ISO 180/1A

73°F (23°C) 2.9 ft·lb/in² 6.0 kJ/m² ISO 180/1A

Thermal Nominal Value (English) Nominal Value (SI) Test Method

Deflection Temperature Under Load

66 psi (0.45 MPa), Unannealed 336 °F 169 °C ASTM D648

66 psi (0.45 MPa), Unannealed 327 °F 164 °C ISO 75-2/B

264 psi (1.8 MPa), Unannealed 226 °F 108 °C ASTM D648

264 psi (1.8 MPa), Unannealed 207 °F 97.0 °C ISO 75-2/A

ISO 11357-3

Melting Temperature 6 352 °F 178 °C

ASTM D3418

CLTE

Flow: 73 to 131°F (23 to 55°C) 0.000066 in/in/°F 0.00012 cm/cm/°C ASTM E831

Flow: -40 to 73°F (-40 to 23°C) 0.000056 in/in/°F 0.00010 cm/cm/°C ISO 11359-2

Flow: 73 to 131°F (23 to 55°C) 0.000067 in/in/°F 0.00012 cm/cm/°C ISO 11359-2

Flow: 131 to 212°F (55 to 100°C) 0.000083 in/in/°F 0.00015 cm/cm/°C ISO 11359-2

Transverse: 73 to 131°F (23 to 55°C) 0.000064 in/in/°F 0.00012 cm/cm/°C ASTM E831

Transverse: -40 to 73°F (-40 to 23°C) 0.000056 in/in/°F 0.00010 cm/cm/°C ISO 11359-2

Transverse: 73 to 131°F (23 to 55°C) 0.000067 in/in/°F 0.00012 cm/cm/°C ISO 11359-2

Transverse: 131 to 212°F (55 to 100°C) 0.000094 in/in/°F 0.00017 cm/cm/°C ISO 11359-2

RTI Elec UL 746

0.0295 in (0.750 mm) 122 °F 50.0 °C

0.0591 in (1.50 mm) 230 °F 110 °C

0.118 in (3.00 mm) 230 °F 110 °C

RTI Imp UL 746

0.0295 in (0.750 mm) 122 °F 50.0 °C

0.0591 in (1.50 mm) 185 °F 85.0 °C

0.118 in (3.00 mm) 194 °F 90.0 °C

2 of 4 Form No. TDS-51609-en

UL and the UL logo are trademarks of UL LLC © 2013. All Rights Reserved. Document Created: Tuesday, May 28, 2013

UL IDES | 800-788-4668 or 307-742-9227 | www.ides.com. Added to Prospector: April, 2001

Last Updated: 5/16/2013

The information presented on this datasheet was acquired by UL IDES from the producer of the material. UL IDES makes substantial efforts to assure the

accuracy of this data. However, UL IDES assumes no responsibility for the data values and strongly encourages that upon final material selection, data points are

validated with the material supplier.

Delrin® 500AL NC010

ACETAL RESIN

DuPont Performance Polymers ides.com/prospector

Thermal Nominal Value (English) Nominal Value (SI) Test Method

RTI Str UL 746

0.0295 in (0.750 mm) 122 °F 50.0 °C

0.0591 in (1.50 mm) 194 °F 90.0 °C

0.118 in (3.00 mm) 203 °F 95.0 °C

Electrical Nominal Value (English) Nominal Value (SI) Test Method

Surface Resistivity 4.0E+15 ohm 4.0E+15 ohm ASTM D257

Volume Resistivity (73°F (23°C)) 7.0E+14 ohm·cm 7.0E+14 ohm·cm ASTM D257

Dielectric Strength 7 ASTM D149

73°F (23°C), 0.126 in (3.20 mm) 450 V/mil 18 kV/mm

Dielectric Constant (73°F (23°C), 1 MHz) 3.60 3.60 ASTM D150

Dissipation Factor (73°F (23°C), 1 MHz) 0.0060 0.0060 ASTM D150

Comparative Tracking Index (CTI) UL 746

0.118 in (3.00 mm) 600 V 600 V

Flammability Nominal Value (English) Nominal Value (SI) Test Method

Flame Rating UL 94

0.0295 in (0.750 mm) HB HB IEC 60695-11-10,

-20

0.0591 in (1.50 mm) HB HB

0.118 in (3.00 mm) HB HB

Injection Nominal Value (English) Nominal Value (SI)

Drying Temperature 176 °F 80.0 °C

Drying Time - Desiccant Dryer 2.0 to 4.0 hr 2.0 to 4.0 hr

Suggested Max Moisture < 0.10 % < 0.10 %

Processing (Melt) Temp 410 to 428 °F 210 to 220 °C

Melt Temperature, Optimum - Injection Molding 419 °F 215 °C

Mold Temperature 176 to 212 °F 80.0 to 100 °C

Mold Temperature, Optimum - Injection Molding 194 °F 90 °C

Not normally Not normally

required unless required unless

moisture content of moisture content of

Drying Recommended

resin exceeds resin exceeds

recommended recommended

level level

Notes

1

The above data are preliminary and are subject to change as additional data are developed on subsequent lots.

2

These links provide you with access to supplier literature. We work hard to keep them up to date; however you may find the most current

literature from the supplier.

3

A UL Yellow Card contains UL-verified flammability and electrical characteristics. UL IDES continually works to link Yellow Cards to individual

plastic materials in Prospector, however this list may not include all of the appropriate links. It is important that you verify the association between

these Yellow Cards and the plastic material found in Prospector. For a complete listing of Yellow Cards, visit the UL Yellow Card Search.

4

Typical properties: these are not to be construed as specifications.

5

0.20 in/min (5.0 mm/min)

6

10°C/min

7

Method A (Short-Time)

3 of 4 Form No. TDS-51609-en

UL and the UL logo are trademarks of UL LLC © 2013. All Rights Reserved. Document Created: Tuesday, May 28, 2013

UL IDES | 800-788-4668 or 307-742-9227 | www.ides.com. Added to Prospector: April, 2001

Last Updated: 5/16/2013

The information presented on this datasheet was acquired by UL IDES from the producer of the material. UL IDES makes substantial efforts to assure the

accuracy of this data. However, UL IDES assumes no responsibility for the data values and strongly encourages that upon final material selection, data points are

validated with the material supplier.

Delrin® 500AL NC010

ACETAL RESIN

DuPont Performance Polymers ides.com/prospector

Where to Buy

Supplier

DuPont Performance Polymers

Wilmington, DE USA

Telephone: 302-999-4592

Web: http://plastics.dupont.com/

Distributor

Biesterfeld Plastic GmbH

Biesterfeld Plastic GmbH is a Pan European distribution company. Contact Biesterfeld Plastic GmbH for availability of individual

products by country.

Telephone: +49-40-32008-0

Web: http://www.biesterfeld-plastic.com/

Availability: Algeria, Austria, Belgium, Bosnia and Herzegovina, Bulgaria, Croatia, Cyprus, Czech Republic, Egypt, France, Germany,

Greece, Hungary, Italy, Libyan Arab Jamahiriya, Luxembourg, Mauritania, Morocco, Netherlands, Poland, Portugal, Romania, Serbia,

Slovakia, Slovenia, Spain, Switzerland, Tunisia, Turkey

PolyOne Distribution

PolyOne Distribution is a global distribution company. Contact PolyOne Distribution for availability of individual products by country.

Telephone: 800-894-4266

Web: http://polyonedistribution.com/

Availability: Global

4 of 4 Form No. TDS-51609-en

UL and the UL logo are trademarks of UL LLC © 2013. All Rights Reserved. Document Created: Tuesday, May 28, 2013

UL IDES | 800-788-4668 or 307-742-9227 | www.ides.com. Added to Prospector: April, 2001

Last Updated: 5/16/2013

The information presented on this datasheet was acquired by UL IDES from the producer of the material. UL IDES makes substantial efforts to assure the

accuracy of this data. However, UL IDES assumes no responsibility for the data values and strongly encourages that upon final material selection, data points are

validated with the material supplier.

Founded in 1986 and based in Laramie, Wyoming, IDES is now part of the UL family of companies. UL is a premier

global independent safety science company with more than a century of proven history. Employing nearly 10,000

professionals in over 100 countries, UL has five distinct business units -- Product Safety, Environment, Life & Health,

Knowledge Services and Verification Services -- to meet the expanding needs of our customers and to deliver on our

public safety mission.

Prospector Plastics Database - www.ides.com/prospector

Prospector is a searchable online database that includes 85,000 data sheets from 875 manufacturers and 44,000 UL yellow

cards. Each data sheet includes property, processing and supplier contact information. Prospector is relied on by nearly

400,000 design engineers and plastics processors. Using Prospector, they save time with plastic material selection by

quickly and easily referencing technical information critical to the success of their products.

“Prospector is absolutely the best and most well-known search engine for plastic raw materials in the world. We use

Prospector every day – it’s a real time saver!”

– Birgit Elvardt Bader, Production Manager, Micotron

Power Searches

Property Search – select plastics by 500 key properties and design parameters.

Alternative Resins Search – find replacement plastics within minutes.

Automotive Plastics Search – easily locate automotive approved plastics.

Curve Data – view, overlay and export curve data.

Material Data Management – www.ides.com/datasheets

With our data management services, plastic suppliers and distributors can have custom search interfaces available on their

website for their customers, website visitors, sales and customer service teams. These provide intuitive ways to find and

view technical data sheets for their products.

“With UL IDES data services, our website now displays the most current information on the products we distribute and links

to our backend RFQ and sales order system, adding both value and service for our customers.”

– Kevin Chase, Owner & President, Chase Plastics

Advertising – www.ides.com/advertise

Reach 365,000 pre-qualified plastics professionals and generate leads with proven techniques. Electronic newsletter

insertions, sponsored webinars and powerful online ads are available to make the most of your lead-generation program.

For more information, call: 800.788.4668 or 307.742.9227 ext. 220

UL and the UL logo are trademarks of UL LLC © 2013.

You might also like

- Ultradur® B 4300 G6Document4 pagesUltradur® B 4300 G6srinivasaNo ratings yet

- POM Delrin 100Document5 pagesPOM Delrin 100countzeroaslNo ratings yet

- Duracon® CP15XDocument3 pagesDuracon® CP15XRhekron PlasticsNo ratings yet

- Sasol Polymers PP HNR100Document3 pagesSasol Polymers PP HNR100Albert FortunatoNo ratings yet

- Wonderlite® PC-110Document3 pagesWonderlite® PC-110Rhekron PlasticsNo ratings yet

- TPE-TPV Sarlink 4155 ProspectorDocument4 pagesTPE-TPV Sarlink 4155 ProspectorcountzeroaslNo ratings yet

- Elvax® 460 PDFDocument2 pagesElvax® 460 PDFXuân Giang NguyễnNo ratings yet

- Product PDF 181Document2 pagesProduct PDF 181RicardoNo ratings yet

- Santoprene™ 101-64: Thermoplastic VulcanizateDocument4 pagesSantoprene™ 101-64: Thermoplastic VulcanizateMohitNo ratings yet

- PC Makrolon 2405Document5 pagesPC Makrolon 2405countzeroaslNo ratings yet

- Ultradur® S 4090 G2Document4 pagesUltradur® S 4090 G2srinivasaNo ratings yet

- Para - Solvay Ixef 1022Document8 pagesPara - Solvay Ixef 1022armandoNo ratings yet

- Zytel® Lc6601 Bk551: Dupont Transportation & IndustrialDocument2 pagesZytel® Lc6601 Bk551: Dupont Transportation & IndustrialbobNo ratings yet

- Delrin® 127UV NC010Document3 pagesDelrin® 127UV NC010alejandrocharlescollNo ratings yet

- Santoprene 101-73Document4 pagesSantoprene 101-73Ewerthon Brand'sNo ratings yet

- TDS BorSafe ME3444 (E115026)Document2 pagesTDS BorSafe ME3444 (E115026)charlesNo ratings yet

- Basell 2427KDocument2 pagesBasell 2427KPhuoc TranNo ratings yet

- Technical Data Sheet MarlexDocument2 pagesTechnical Data Sheet MarlexWilly NursalimNo ratings yet

- Polylac® Pa-747Document3 pagesPolylac® Pa-747vicenteNo ratings yet

- Tenac 4013ADocument3 pagesTenac 4013APhung LucNo ratings yet

- Titanvene™ HD5502GA: Lotte Chemical Titan (M) Sdn. BHDDocument3 pagesTitanvene™ HD5502GA: Lotte Chemical Titan (M) Sdn. BHDVu TranNo ratings yet

- Panlite® L-1225YDocument3 pagesPanlite® L-1225YLiew FongNo ratings yet

- Product PDF 244478Document3 pagesProduct PDF 244478lorejaz84071127No ratings yet

- Solvay - Ixef BXT2000Document5 pagesSolvay - Ixef BXT2000Renan GadioliNo ratings yet

- Pulse GX50Document3 pagesPulse GX50Daniel Lack PendásNo ratings yet

- ABS CHIMEI Pa-757Document3 pagesABS CHIMEI Pa-757Muslim N FNo ratings yet

- 2186 - Pc-Abs Pulse gx70Document3 pages2186 - Pc-Abs Pulse gx70mikeburnsthrowaccNo ratings yet

- TDS SantopreneT 8211-55B100Document3 pagesTDS SantopreneT 8211-55B100Adi HermawanNo ratings yet

- Santoprene 201 87Document4 pagesSantoprene 201 87AdileneNo ratings yet

- TPE-TPV Sarlink 4155 Teknor Apex_2013Document3 pagesTPE-TPV Sarlink 4155 Teknor Apex_2013countzeroaslNo ratings yet

- Dynaflex G7660-1 (Natural)Document3 pagesDynaflex G7660-1 (Natural)gobinath VPNo ratings yet

- Zytel® 101F Nc010: Dupont Performance PolymersDocument4 pagesZytel® 101F Nc010: Dupont Performance PolymersagungNo ratings yet

- 300.056 Magnum 3416 SCDocument3 pages300.056 Magnum 3416 SCEnrique ChavezNo ratings yet

- Technical Datasheet - Vistamaxx™ 6102Document2 pagesTechnical Datasheet - Vistamaxx™ 6102BegenkzNo ratings yet

- Santoprene™ 201-87: Thermoplastic VulcanizateDocument4 pagesSantoprene™ 201-87: Thermoplastic VulcanizateallenNo ratings yet

- Resina Nueva Validacion SkytronDocument2 pagesResina Nueva Validacion SkytronAlbert FortunatoNo ratings yet

- POLYLAC® PA-765: Chi Mei CorporationDocument3 pagesPOLYLAC® PA-765: Chi Mei CorporationagungNo ratings yet

- LEXAN™ Copolymer 943X - AsiaDocument4 pagesLEXAN™ Copolymer 943X - AsiaaNo ratings yet

- TDS - TS001 - Technyl A218Document3 pagesTDS - TS001 - Technyl A218oberta.andrzejNo ratings yet

- Product PDF 301308Document2 pagesProduct PDF 301308Andrew JacksonNo ratings yet

- Ultraform W 2320 003 UNC Q600Document3 pagesUltraform W 2320 003 UNC Q600Patricio Bravo CastilloNo ratings yet

- Para - Solvay Ixef 1032Document7 pagesPara - Solvay Ixef 1032armandoNo ratings yet

- Tristar® PC-05GFRDocument3 pagesTristar® PC-05GFRRhekron PlasticsNo ratings yet

- Kumho ABS 750Document2 pagesKumho ABS 750Murundu EstudioNo ratings yet

- MAGNUM™ 3416 SC: ABS ResinDocument3 pagesMAGNUM™ 3416 SC: ABS ResinEduardo MazariegosNo ratings yet

- 4LAC® 10H10000 - Generic ABSDocument6 pages4LAC® 10H10000 - Generic ABSsrinivasaNo ratings yet

- Kumho ABS 750SWDocument3 pagesKumho ABS 750SWVu TranNo ratings yet

- Titanvene™ HD6070EADocument2 pagesTitanvene™ HD6070EAputriNo ratings yet

- Surlyn Pc-2000: Dupont Packaging & Industrial Polymers - Ethylene Methacrylic AcidDocument1 pageSurlyn Pc-2000: Dupont Packaging & Industrial Polymers - Ethylene Methacrylic AcidArtemio RsNo ratings yet

- Pebax® 5533 SP 01: Arkema Technical PolymersDocument3 pagesPebax® 5533 SP 01: Arkema Technical PolymersPhuoc Thinh TruongNo ratings yet

- 3d Systems Figure 4 RUBBER 65a BLK Datasheet Us A4 2020 06 30 WebDocument8 pages3d Systems Figure 4 RUBBER 65a BLK Datasheet Us A4 2020 06 30 WebMallikarjuna KorrapatiNo ratings yet

- Akulon F136-C1: DSM Engineering Materials - Polyamide 6Document2 pagesAkulon F136-C1: DSM Engineering Materials - Polyamide 6bobNo ratings yet

- Hostalen H 2150Document3 pagesHostalen H 2150Silviu PadureanuNo ratings yet

- Repol® C015Eg: Reliance Industries LimitedDocument2 pagesRepol® C015Eg: Reliance Industries LimitedCamilo ObandoNo ratings yet

- PC-ABS Bayblend FR110Document3 pagesPC-ABS Bayblend FR110countzeroaslNo ratings yet

- 214 - Pei Ultem 1000Document4 pages214 - Pei Ultem 1000Chandrasekar KrishnamurthyNo ratings yet

- Hostacom M2 N01 PDFDocument1 pageHostacom M2 N01 PDFbetoNo ratings yet

- 1632 - Pbt-Pet Valox 815Document5 pages1632 - Pbt-Pet Valox 815Vinoth SekarNo ratings yet

- PA BASF Ultramid 7523-2AM MSDSDocument5 pagesPA BASF Ultramid 7523-2AM MSDScountzeroaslNo ratings yet

- TPE-TPV Sarlink 4155 ProspectorDocument4 pagesTPE-TPV Sarlink 4155 ProspectorcountzeroaslNo ratings yet

- TPU Estane 2102-80ADocument1 pageTPU Estane 2102-80AcountzeroaslNo ratings yet

- TPU Estane 2102-80ADocument1 pageTPU Estane 2102-80AcountzeroaslNo ratings yet

- PA BASF Ultramid B3ZG6 MSDSDocument5 pagesPA BASF Ultramid B3ZG6 MSDScountzeroaslNo ratings yet

- PA BASF Ultramid 8333GHI BK102 MSDSDocument5 pagesPA BASF Ultramid 8333GHI BK102 MSDScountzeroaslNo ratings yet

- PA 66 Zytel 101Document2 pagesPA 66 Zytel 101countzeroaslNo ratings yet

- PBT-PC Valox 357Document5 pagesPBT-PC Valox 357countzeroaslNo ratings yet

- RTPU LTL TPU11015 BK700 RoHS 3 2015-863-EUDocument1 pageRTPU LTL TPU11015 BK700 RoHS 3 2015-863-EUcountzeroaslNo ratings yet

- PC Lexan 500 10%GLDocument3 pagesPC Lexan 500 10%GLcountzeroaslNo ratings yet

- Abs Irpc Polimaxx SP100Document2 pagesAbs Irpc Polimaxx SP100countzeroaslNo ratings yet

- PC Lexan HP6NR Healthcare - ProspectorDocument5 pagesPC Lexan HP6NR Healthcare - ProspectorcountzeroaslNo ratings yet

- Cypher System Open License 2022 07 25Document2 pagesCypher System Open License 2022 07 25countzeroaslNo ratings yet

- ABS RTP PermaStat 600 - RoHS 02-20-15Document1 pageABS RTP PermaStat 600 - RoHS 02-20-15countzeroaslNo ratings yet

- Kenton HawthorneDocument3 pagesKenton HawthornecountzeroaslNo ratings yet

- SPI Customs Practices MoldmakingDocument21 pagesSPI Customs Practices MoldmakingcountzeroaslNo ratings yet

- Magic Attacks in Mass WarfareDocument6 pagesMagic Attacks in Mass WarfarecountzeroaslNo ratings yet

- Design-In Ergonomics GuidelinesDocument66 pagesDesign-In Ergonomics GuidelinesAsmaa DalashNo ratings yet

- Siemens SW The Executives Guide To Digital Manufacturing E Book Tcm27 100102Document20 pagesSiemens SW The Executives Guide To Digital Manufacturing E Book Tcm27 100102countzeroaslNo ratings yet

- 3d Graph PaperDocument1 page3d Graph PapercountzeroaslNo ratings yet

- SPI GuidelinesDocument6 pagesSPI GuidelinesGerardo ArroyoNo ratings yet

- Failure Mode and Effects Analysis PDFDocument50 pagesFailure Mode and Effects Analysis PDFcountzeroaslNo ratings yet

- Viscosity Comparison ChartDocument1 pageViscosity Comparison ChartcountzeroaslNo ratings yet

- DD 5e FormFillable Calculating Charsheet1.7 PDFDocument2 pagesDD 5e FormFillable Calculating Charsheet1.7 PDFSvan HlačaNo ratings yet

- LNP Wear Resistant PlasticsDocument26 pagesLNP Wear Resistant PlasticscountzeroaslNo ratings yet

- Paint Mate 200ia Series - 27Document4 pagesPaint Mate 200ia Series - 27countzeroaslNo ratings yet

- Yellowing and Pinking of White PE & PPDocument6 pagesYellowing and Pinking of White PE & PPcountzeroaslNo ratings yet

- 001 How To Use The 5-Whys For Root Cause AnalysisDocument9 pages001 How To Use The 5-Whys For Root Cause AnalysisAbd ZouhierNo ratings yet

- Overmold Design GuideDocument18 pagesOvermold Design GuideCuco MartinezNo ratings yet

- Materials SpectrumDocument7 pagesMaterials SpectrumJoshua MathewNo ratings yet

- Smart Color-Changing Textile With High Contrast Based On Single-Sided Conductive FabricDocument7 pagesSmart Color-Changing Textile With High Contrast Based On Single-Sided Conductive FabricAlex FariaNo ratings yet

- Long Fiber CompoundsDocument14 pagesLong Fiber CompoundsspoorthiprasannaNo ratings yet

- Simpolo Sanitaryware Products PDFDocument32 pagesSimpolo Sanitaryware Products PDFABHINAV KUMARNo ratings yet

- Ces 3Document5 pagesCes 3LegendaryNNo ratings yet

- Weldrite BrochureDocument59 pagesWeldrite Brochuremetalphoto indiaNo ratings yet

- Noise Pollution Control A ReviewDocument3 pagesNoise Pollution Control A ReviewEditor IJTSRDNo ratings yet

- Rebar Bending Formula & Hook Design - ACI-318Document1 pageRebar Bending Formula & Hook Design - ACI-318ויליאם סן מרמיגיוס100% (4)

- Special Cables Catalogue PDFDocument116 pagesSpecial Cables Catalogue PDFMoataz Abd El rahmanNo ratings yet

- ES8067-TS0231-V575-FKM75 Bisphenol Cured - ApprovedDocument2 pagesES8067-TS0231-V575-FKM75 Bisphenol Cured - ApprovedBogdan CăpățînăNo ratings yet

- Basic Rate of Materials: S.No. Description Unit Rate RemarksDocument29 pagesBasic Rate of Materials: S.No. Description Unit Rate RemarksNishan GajurelNo ratings yet

- Ba 9 Ca 637 F 0 A 9Document144 pagesBa 9 Ca 637 F 0 A 9ARUN RAWATNo ratings yet

- Technology of Paints & Coatings With FormulationsDocument15 pagesTechnology of Paints & Coatings With Formulationseiribooks46% (37)

- Vasant Vihar Office Renovation Project Cost EstimateDocument2 pagesVasant Vihar Office Renovation Project Cost EstimateAmarinder DhillonNo ratings yet

- Curriculum Vitae-Dr. Srinivasa C.V.Document19 pagesCurriculum Vitae-Dr. Srinivasa C.V.srinivasa c vNo ratings yet

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDocument8 pagesHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesradziNo ratings yet

- Feasibility of Copper Slag-Fly Ash Mix As A Road Construction MaterialDocument2 pagesFeasibility of Copper Slag-Fly Ash Mix As A Road Construction MaterialB VAMSI KRISHNANo ratings yet

- Steel-Ladles - EN - RHIDocument28 pagesSteel-Ladles - EN - RHIarseniyNo ratings yet

- Brayco Micronic 864 Ht/200: S S G S S SDocument4 pagesBrayco Micronic 864 Ht/200: S S G S S SDavid ArauzNo ratings yet

- Lab Report - Exp-7 - UploadDocument6 pagesLab Report - Exp-7 - Uploadliton dharNo ratings yet

- ATEST ALU LIM 2mmDocument1 pageATEST ALU LIM 2mmNedžad MehmedbegovićNo ratings yet

- Tensile TestingDocument17 pagesTensile TestingNanak BatraNo ratings yet

- Zinc-Coated Steel Strand For Messenger Support of Figure 8 CableDocument3 pagesZinc-Coated Steel Strand For Messenger Support of Figure 8 CableDarwin DarmawanNo ratings yet

- Imcc 2Document4 pagesImcc 2Valipireddy NagarjunNo ratings yet

- AldenHighVoltageCataloglr 25OCT2017Document28 pagesAldenHighVoltageCataloglr 25OCT2017priyanka choudhryNo ratings yet

- Building Papers - Products, Standards and Installation (PDFDrive)Document61 pagesBuilding Papers - Products, Standards and Installation (PDFDrive)fatimahNo ratings yet

- Aggregates & Binders in ConcreteDocument53 pagesAggregates & Binders in Concretehoda melhemNo ratings yet

- No. 38: Index Numbers of Wholesale Prices in India - by Groups and Sub-Groups 2011 April-MarchDocument12 pagesNo. 38: Index Numbers of Wholesale Prices in India - by Groups and Sub-Groups 2011 April-MarchNarendra SaiNo ratings yet

- Specialitypolymerspptonsiliconesbydeepakrawal 180316163004 PDFDocument36 pagesSpecialitypolymerspptonsiliconesbydeepakrawal 180316163004 PDFJudy Ahmed IbrahimNo ratings yet

- Bond Durability of Basalt-Fiber-Reinforced-Polymer (BFRP) Bars Embedded in Concrete in Aggressive EnvironmentsDocument11 pagesBond Durability of Basalt-Fiber-Reinforced-Polymer (BFRP) Bars Embedded in Concrete in Aggressive EnvironmentsMabel LoNo ratings yet

- Nalfleet Nalcool 2000Document2 pagesNalfleet Nalcool 2000ferdy110276No ratings yet