Professional Documents

Culture Documents

Profile-LF303W-EM#75-303W REV.B IV - Lead Free Wire Sn99.3Cu0.7

Uploaded by

Phung Cam VanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Profile-LF303W-EM#75-303W REV.B IV - Lead Free Wire Sn99.3Cu0.7

Uploaded by

Phung Cam VanCopyright:

Available Formats

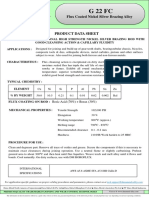

PRODUCT PROFILE

ELECTROLOY NO CLEAN

LEAD FREE WIRE

Product Name Product Code

#75 FLUX CORED SOLDER EM#75-303W

-LEAD FREE ALLOY-Sn99.3/Cu0.7

The information and statements herein are believed to be reliable but are not to be construed as a warranty or representation for which we assure legal

responsibility. Users should undertake sufficient verification and testing to determine the suitability for their own particular purpose of any information or

products referred to herein. No warranty of fitness for a particular purpose is made. Properties are typical and not to be used as specifications.

DOC CATEGORY: 3 PF – EM#75-303W – 15042019 – REV.B – Page 1 of 4

Singapore . Malaysia . China . Vietnam . India

PRODUCT DESCRIPTION

EM#75-303W is a halogen free† no-clean cored flux lead free wire with alloy composition 99.3%Tin,

and 0.7%Copper. This type of cored flux wire provides good wetting and leaves clear residue. This is

a RoHS compliance lead free solder wire.

† Halogen free as per specification of the standard IPC 4101B, IEC 61249-2-21 and JPCA-ES01

CHEMICAL COMPOSITION OF ALLOY

Quality of Electroloy’s EM#75-303W lead free solder wire in terms of composition of alloy is controlled

strictly under Electroloy’s Lead Free Specification LF-303.

Elements Specification

(%wt/wt)

Tin Sn Remainder

Lead Pb Max 0.050

Aluminium Al Max 0.005

Antimony Sb Max 0.050

Arsenic As Max 0.030

Bismuth Bi Max 0.050

Copper Cu 0.6 – 0.8

Iron Fe Max 0.010

Zinc Zn Max 0.003

Cadmium Cd Max 0.002

Silver Ag Max 0.050

Nickel Ni Max 0.010

Indium In Max 0.050

Gold Au Max 0.050

The information and statements herein are believed to be reliable but are not to be construed as a warranty or representation for which we assure legal

responsibility. Users should undertake sufficient verification and testing to determine the suitability for their own particular purpose of any information or

products referred to herein. No warranty of fitness for a particular purpose is made. Properties are typical and not to be used as specifications.

DOC CATEGORY: 3 PF – EM#75-303W – 15042019 – REV.B – Page 2 of 4

Singapore . Malaysia . China . Vietnam . India

CHEMICAL COMPOSITION OF FLUX

The standard flux content for this type of solder wire is 2.5 +/- 0.2%. However, other percentages of

flux are available upon request. The range for the flux percentage is 2.0% – 3.5%.

FEATURES OF CORED FLUX

Flux

Cored Features Cleaning Method

Type

Halogen free† with clear flux residue suited for no-clean

No-Clean

hand soldering assemblies. Exhibit good wetting

Halogen

characteristics. Widely and most popular choice for No-clean

Free†

assemblies requiring no-clean, clear residue

EM#75

characteristics.

CHARACTERISTICS OF CORED FLUX EM#75

Physical Properties

and Specification Test Method Result (Typical)

Reliability Data

Halogen Free†

Flux Type - -

No Clean

Class Type Refer to J-STD-004 - ROL1

Color/Appearance - - Milky Yellow

Odor - - Mild

Halide Content (%) JIS Z 3197,

Max 0.08 % 0.00 %

(Chloride and Bromide) Method 8.1.4.2.1

J-STD-004,

Corrosion Test Pass IPC-TM-650, Pass

Method 2.6.15

SIR,IPC(Typical) J-STD-004,

85°C / 85% RH Min 1×10 8 IPC-TM-650, ≥1.0×109

After 168 hours Method 2.6.3.3

Min 65%

JIS Z 3197, Method

Spreading (%) Lead Free Solder ≥80%

8.3.1.1

(JIS 3283:2006)

The information and statements herein are believed to be reliable but are not to be construed as a warranty or representation for which we assure legal

responsibility. Users should undertake sufficient verification and testing to determine the suitability for their own particular purpose of any information or

products referred to herein. No warranty of fitness for a particular purpose is made. Properties are typical and not to be used as specifications.

DOC CATEGORY: 3 PF – EM#75-303W – 15042019 – REV.B – Page 3 of 4

Singapore . Malaysia . China . Vietnam . India

PHYSICAL APPEARANCE

Electroloy’s solder wire exhibits a shinning appearance and in grey uniform color. A wide range of

diameter for the wire is available, 0.2– 2.4mm (+/-0.05mm) , 2.5mm – 3.5mm (+/-0.1mm) ,3.6mm –

4.5mm (+/-0.2mm) and ≥4.6mm(+/-0.3mm).

CLEANING

The flux residue is not conductive and is not corrosive to metal parts. Therefore, cleaning is not

required in most application.

APPLICATION

Solder iron tip temperature should be between 350 – 430oC. Hold the solder iron tip at a 45o to 60o

angle with work surface. The solder iron should contact both the component lead and PCB pad

surface.

PACKAGING

Each spool of solder wire is approximately 0.5kg or 1.0kg and shall be secured by paper and rolling

tape. The solder wire shall be packed in carton boxes of about 10kg per box. Other special size and

packaging requirement can be requested. The traceable information will be shown on the box such as

vendor’s name, alloy composition, net weight and lot number.

DELIVERY

Each shipment shall be accompanied with Certificate of Analysis for each lot, which indicate the

amount of constituents and impurities.

STORAGE AND SHELF LIFE

Electroloy’s EM#75-303W lead free solder wire has limited shelf life which is 18 months from the date

of manufactured when handled properly. Dry and non-corrosive storage environment is needed to

minimize the wires from further oxidation. Ensure that the packaging is not damaged and the wires

are not exposed to dust and other foreign materials.

HEALTH AND SAFETY

Refer to the SDS for guidance on safety and health issues.

The information and statements herein are believed to be reliable but are not to be construed as a warranty or representation for which we assure legal

responsibility. Users should undertake sufficient verification and testing to determine the suitability for their own particular purpose of any information or

products referred to herein. No warranty of fitness for a particular purpose is made. Properties are typical and not to be used as specifications.

DOC CATEGORY: 3 PF – EM#75-303W – 15042019 – REV.B – Page 4 of 4

Singapore . Malaysia . China . Vietnam . India

You might also like

- PF-EM#75-315W REV.B Solder Wire Halogen FreeDocument4 pagesPF-EM#75-315W REV.B Solder Wire Halogen FreePhung Cam VanNo ratings yet

- (LF303W) Pf-Em#53hd-303w Rev.a IvDocument4 pages(LF303W) Pf-Em#53hd-303w Rev.a IvPhung Cam VanNo ratings yet

- Pf-Emco#218-63p Rev.bDocument6 pagesPf-Emco#218-63p Rev.bPhung Cam VanNo ratings yet

- Böhler Er Ti 2-Ig: Classifications EN ISO 24034 AWS A5.16Document1 pageBöhler Er Ti 2-Ig: Classifications EN ISO 24034 AWS A5.16Thanh TamNo ratings yet

- Sa105sa350de Data SheetDocument1 pageSa105sa350de Data SheetMr PokeRexNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisNo ratings yet

- G 22 FC Product Data Sheet (With Specs)Document1 pageG 22 FC Product Data Sheet (With Specs)candraNo ratings yet

- 105 AWB ModelDocument1 page105 AWB ModelBajak HatiNo ratings yet

- B 654 - B 654M - 03 - Qjy1nc9cnju0ts1sruqDocument7 pagesB 654 - B 654M - 03 - Qjy1nc9cnju0ts1sruqZahid AnwerNo ratings yet

- Charoong Thai Wire & Cable Public Company Limited: CTW - Aluminum RodDocument1 pageCharoong Thai Wire & Cable Public Company Limited: CTW - Aluminum RodAchint KumarNo ratings yet

- Datasheet Zincalume G550Document2 pagesDatasheet Zincalume G550adihindNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355novkovic1984No ratings yet

- Zincalume G550 Steel: Metallic Coated - MC Structural - SDocument1 pageZincalume G550 Steel: Metallic Coated - MC Structural - SEwo50 New0% (1)

- 36CrB4 Rod - Wire Rev4 PDFDocument6 pages36CrB4 Rod - Wire Rev4 PDFKarthi KeyanNo ratings yet

- BNi-7 TDSDocument2 pagesBNi-7 TDSQuang Thuận NguyễnNo ratings yet

- Al 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSADocument2 pagesAl 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSAAlex GăuruşNo ratings yet

- NiAll-HX-M290-400W Material Data Sheet 10-15 enDocument5 pagesNiAll-HX-M290-400W Material Data Sheet 10-15 enAmit PowarNo ratings yet

- GHCL Labs08 - LsaDocument1 pageGHCL Labs08 - LsaUmar HayatNo ratings yet

- RD 360 1post File 2019 12 10 161048Document1 pageRD 360 1post File 2019 12 10 161048Adityo Bambang WNo ratings yet

- Catálogo 1-0900766b8157c0d9Document6 pagesCatálogo 1-0900766b8157c0d9Rafael Román García-sec DNo ratings yet

- Metalcor 2.4375 Alloy K500Document1 pageMetalcor 2.4375 Alloy K500Gourav SharmaNo ratings yet

- Bleeder Resistor CatalogueDocument2 pagesBleeder Resistor CatalogueradikahendryNo ratings yet

- Electrode Booklet F Web 110Document1 pageElectrode Booklet F Web 110satnamNo ratings yet

- Zincalume® G550 Technical Datasheet MalaysiaDocument2 pagesZincalume® G550 Technical Datasheet MalaysiaJeffrey RonquilloNo ratings yet

- NALCO Aluminium INGOT - Specification PDFDocument3 pagesNALCO Aluminium INGOT - Specification PDFThambik DuraiNo ratings yet

- Metalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520Document1 pageMetalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520NitinNo ratings yet

- Catalogue NewDocument28 pagesCatalogue NewDebabrata SahaNo ratings yet

- Alpha Om-353 Solder Paste en 08nov19 TBDocument7 pagesAlpha Om-353 Solder Paste en 08nov19 TBShamsur RahmanNo ratings yet

- TDS Nycolube NL127B-1E1 PDFDocument1 pageTDS Nycolube NL127B-1E1 PDFRoman GrantNo ratings yet

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- Bronze Alloys MsdsDocument11 pagesBronze Alloys MsdssalcabesNo ratings yet

- MRA05-E03Document1 pageMRA05-E03magikalea90No ratings yet

- Ind0116 - FDocument4 pagesInd0116 - Frajit kumarNo ratings yet

- COVERED ELECTRODES FOR MILD STEEL WELDINGDocument1 pageCOVERED ELECTRODES FOR MILD STEEL WELDINGKannan MurugesanNo ratings yet

- Product Overview: 1N5400: Standard Recovery Rectifier, 50 V, 3.0 ADocument1 pageProduct Overview: 1N5400: Standard Recovery Rectifier, 50 V, 3.0 AZando KhanNo ratings yet

- Dense Soda Ash SpecificationDocument1 pageDense Soda Ash SpecificationUmar HayatNo ratings yet

- Key Facts Typical Wire Analysis: - Bossweld 71T-1Document1 pageKey Facts Typical Wire Analysis: - Bossweld 71T-1cj elec techNo ratings yet

- TDS Ru5black 000 EngDocument3 pagesTDS Ru5black 000 Engphistore19No ratings yet

- SA/AS 1548 - PT460NR (L0, L20) XLERPLATE Steel: Plate - PL Pressure Vessel - PVDocument3 pagesSA/AS 1548 - PT460NR (L0, L20) XLERPLATE Steel: Plate - PL Pressure Vessel - PVJang CoiNo ratings yet

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraNo ratings yet

- Anodos MartyDocument2 pagesAnodos MartyEmilsa EsturbanNo ratings yet

- BM Full CatalogueDocument109 pagesBM Full CatalogueMiguelNo ratings yet

- As1548 Pt46onrlo l20 August2010bDocument3 pagesAs1548 Pt46onrlo l20 August2010bchoopoNo ratings yet

- 2 HBI in EAF Fact Sheet Rev3 PDFDocument2 pages2 HBI in EAF Fact Sheet Rev3 PDFAaquil RaziNo ratings yet

- 1993 - Recycled LeadDocument9 pages1993 - Recycled LeadgutobegaNo ratings yet

- S-717XM-12K_engDocument12 pagesS-717XM-12K_engamir bizhehNo ratings yet

- AS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsDocument2 pagesAS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsAdamNo ratings yet

- Shielding Gases for Welding & CuttingDocument12 pagesShielding Gases for Welding & CuttingJuan Carlos100% (3)

- Aerospace Material Specification: Nickel, Sheet and Strip Low (0.02 Max) Carbon AnnealedDocument5 pagesAerospace Material Specification: Nickel, Sheet and Strip Low (0.02 Max) Carbon AnnealedMehdi MokhtariNo ratings yet

- MSDS - BeCu AlloyDocument6 pagesMSDS - BeCu AlloyTaherNo ratings yet

- OK 67.70 ESAB 309moDocument1 pageOK 67.70 ESAB 309moSadashiva sahooNo ratings yet

- Nickel ChlorideDocument1 pageNickel ChlorideVinod KumarNo ratings yet

- TDC_SAE 8620_Rev-04Document2 pagesTDC_SAE 8620_Rev-04ramanjotgill.ramanNo ratings yet

- PDS Poweroil Hone 7SDocument1 pagePDS Poweroil Hone 7SthenuamuNo ratings yet

- 4 Lead and Its AlloysDocument36 pages4 Lead and Its AlloysmohansaiNo ratings yet

- Aero Metal Alliance - Aluminium Alloy QQ A 25011 T6 Sheet - 200Document2 pagesAero Metal Alliance - Aluminium Alloy QQ A 25011 T6 Sheet - 200erikaNo ratings yet

- Zincalume G550 G550S PDFDocument2 pagesZincalume G550 G550S PDFkartikkeyyanNo ratings yet

- item22-LNT 502Document1 pageitem22-LNT 502VVan TanNo ratings yet

- Techalloy 99: Conformances Key FeaturesDocument2 pagesTechalloy 99: Conformances Key FeaturesDaniel Lvqve GarciaNo ratings yet

- Ross MetalsDocument368 pagesRoss MetalsPradeepNo ratings yet

- Octavia DashDocument12 pagesOctavia DashBerniSomex Somexemos100% (1)

- JST Vol. 22 (1) Jan. 2014 (View Full Journal)Document360 pagesJST Vol. 22 (1) Jan. 2014 (View Full Journal)Asma FarahNo ratings yet

- Gold Tin - The Unique Eutectic Solder AlloyDocument2 pagesGold Tin - The Unique Eutectic Solder AlloyJackFlash31No ratings yet

- Panasonic Th-P42ut30 Chassis Gpf14d-ADocument116 pagesPanasonic Th-P42ut30 Chassis Gpf14d-AYoly Rio RamosNo ratings yet

- Powders and Industrial Applications of Silver and Other MetalsDocument1 pagePowders and Industrial Applications of Silver and Other MetalsGabi OcheaNo ratings yet

- Yamaha Rx-A1060 rx-v1081Document204 pagesYamaha Rx-A1060 rx-v1081Raimundo de LimaNo ratings yet

- Water Level Indicator With AlarmDocument26 pagesWater Level Indicator With AlarmJitendra SinghNo ratings yet

- Sony Dsc-w35 Level3 Ver1.0 SMDocument22 pagesSony Dsc-w35 Level3 Ver1.0 SMJorge Alberto Castaño OrtegaNo ratings yet

- Pioneer MVH-8200-BT Service ManualDocument110 pagesPioneer MVH-8200-BT Service ManualJavier AlvarezNo ratings yet

- Panasonic TC l32c12 PDFDocument57 pagesPanasonic TC l32c12 PDFluis6508No ratings yet

- Pioneer Ddj-Wego-K Rrv4381 Service ManualDocument58 pagesPioneer Ddj-Wego-K Rrv4381 Service Manualyiyus1100% (1)

- Class Viii Week 6 Lesson 3Document12 pagesClass Viii Week 6 Lesson 3Mahrukh JawedNo ratings yet

- Panasonic KX TG1100FXDocument81 pagesPanasonic KX TG1100FXSrđan KneževićNo ratings yet

- Philips MCI 298 Service ManualDocument68 pagesPhilips MCI 298 Service Manualfalla naNo ratings yet

- G7 8 CSS Explo Module 5Document16 pagesG7 8 CSS Explo Module 5Heart NicoleNo ratings yet

- B907 162021 2 04 Standard Specification For Zinc, Tin and CadmiumDocument6 pagesB907 162021 2 04 Standard Specification For Zinc, Tin and CadmiumShodji MabungaNo ratings yet

- SHARP LED TV Lc32le260m SERVICE MANUALDocument36 pagesSHARP LED TV Lc32le260m SERVICE MANUALJustin Ng71% (7)

- 42PFL4007G-78 Service+fonte PDFDocument74 pages42PFL4007G-78 Service+fonte PDFPedro AfonsoNo ratings yet

- Yamaha R-s500 SMDocument84 pagesYamaha R-s500 SMguacher100% (1)

- SWN 39005 - 01 Material Restrictions: Rohs Requirements Definitions Delivery StandardDocument2 pagesSWN 39005 - 01 Material Restrictions: Rohs Requirements Definitions Delivery StandardSara SánNo ratings yet

- Lead AlloysDocument4 pagesLead AlloysMuhammad AsifNo ratings yet

- SolderDocument11 pagesSolderahmedNo ratings yet

- Inclusion Voiding in Gull Wing Solder JointsDocument12 pagesInclusion Voiding in Gull Wing Solder Jointsruzicda3No ratings yet

- Ansys Ballard CVMDocument1 pageAnsys Ballard CVMhaithamNo ratings yet

- Long-Term Storage of Components, Subassemblies and Devices: Guidelines For TheDocument32 pagesLong-Term Storage of Components, Subassemblies and Devices: Guidelines For TheJoão Pedro AlmeidaNo ratings yet

- CLP-920/CLP-930 Service Manual GuideDocument88 pagesCLP-920/CLP-930 Service Manual GuideChellakumar ValentineNo ratings yet

- L04a Ad 3122785158810Document96 pagesL04a Ad 3122785158810Вячеслав ЖигалкинNo ratings yet

- LG 26lc51 26lc51a - 26lc7r - 26lc7r-Za-Chassis Lp78a ServicemanualDocument38 pagesLG 26lc51 26lc51a - 26lc7r - 26lc7r-Za-Chassis Lp78a ServicemanualC.Rama MurthhyNo ratings yet