88% found this document useful (8 votes)

29K views4 pagesPCB Diagram

This document provides a summary of the layout and components of several PCB diagrams:

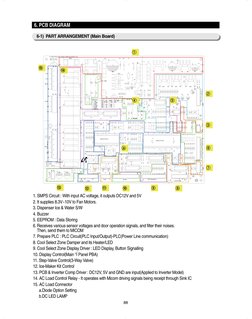

1. The main board diagram lists components like an SMPS circuit, fan motor control, dispenser components, sensors, PLC circuit, display drivers, relays, and connectors.

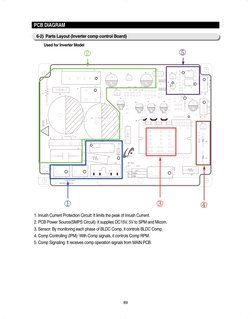

2. The inverter control board diagram describes an inrush protection circuit, power supply, sensor monitoring of the BLDC compressor, compressor control circuitry, and signaling components.

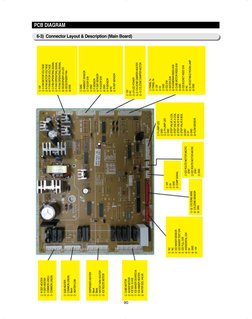

3. The main board connector layout details interfaces for heating, sensors, the ice maker system, step valves, reed switches and more.

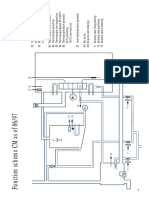

4. The inverter board connector layout is specific to inverter models.

Uploaded by

Fernando MadeiraCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

88% found this document useful (8 votes)

29K views4 pagesPCB Diagram

This document provides a summary of the layout and components of several PCB diagrams:

1. The main board diagram lists components like an SMPS circuit, fan motor control, dispenser components, sensors, PLC circuit, display drivers, relays, and connectors.

2. The inverter control board diagram describes an inrush protection circuit, power supply, sensor monitoring of the BLDC compressor, compressor control circuitry, and signaling components.

3. The main board connector layout details interfaces for heating, sensors, the ice maker system, step valves, reed switches and more.

4. The inverter board connector layout is specific to inverter models.

Uploaded by

Fernando MadeiraCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- PCB Diagram - Part Arrangement: Details the part arrangement on the main board showing inputs, outputs, and circuit functions.

- PCB Diagram - Parts Layout: Illustrates the layout for inverter comp control board, focusing on current protection and power supply.

- Connector Layout & Description (Main Board): Displays and describes the main board connectors and the purpose of each component labeled.

- Connector Layout & Description (Inverter Comp Control Board): Provides visual layout and description of the connectors specific to the inverter control board.