Professional Documents

Culture Documents

PQ 701

PQ 701

Uploaded by

Paramendra Singh ShekhawatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PQ 701

PQ 701

Uploaded by

Paramendra Singh ShekhawatCopyright:

Available Formats

AXA Performance Department Maint.

Parenterals Ltd. Qualification

Village Kishanpur Jamalpur, Effective date 1/11/2006

Roorkee.Uttaranchal For

BOILER Page 1 of 9

Revision 00

PERFORMANCE

QUALIFICATION

PROTOCOL

OF

BOILER

Prepared by Checked by Approved by Authorised by

Document No:

APL/MAINT//PQ

701

Sudhir Awatade J.P.Sharma Dinesh Tanwar R.A.More

Shift Incharge Asst.Mgr. Maint. Dy. Mgr. QA AGM-Works

AXA Performance Department Maint.

Parenterals Ltd. Qualification

Village Kishanpur Jamalpur, Effective date 1/11/2006

Roorkee.Uttaranchal For

BOILER Page 2 of 9

Revision 00

TABLE OF CONTENTS

1.0 Performance qualification Protocol Approval

2.0 Objective

3.0 Pre requisites

4.0 Scope

5.0 Responsibilities

6.0 References

7.0 Equipment / System Description

8.0 Qualification Tests

9.0 Summary And Conclusion

10.0 Performance Qualification Approval

1.0 PERFORMANCE QUALIFICATION PROTOCOL APPROVAL:

Prepared by Checked by Approved by Authorised by

Document No:

APL/MAINT//PQ

701

Sudhir Awatade J.P.Sharma Dinesh Tanwar R.A.More

Shift Incharge Asst.Mgr. Maint. Dy. Mgr. QA AGM-Works

AXA Performance Department Maint.

Parenterals Ltd. Qualification

Village Kishanpur Jamalpur, Effective date 1/11/2006

Roorkee.Uttaranchal For

BOILER Page 3 of 9

Revision 00

Prepared by

Mr. Sudhir R. Awatade

Originator Date :26/10/2006

Checked by

Mr. J.P. Sharma

Project/Engineering Manager Date:27/10/2006

Mr. H.P. Reddy

Production Manager Date:27/10/2006

Mr. Dinesh Tanwar

Quality assurance manager Date:27/10/2006

Approved by

Mr. J.P. Sharma

Maintenance Head Date:27/10/2006

Mr. R.A. More

A.G.M. Works Date:28/10/2006

2.0 OBJECTIVE:

Prepared by Checked by Approved by Authorised by

Document No:

APL/MAINT//PQ

701

Sudhir Awatade J.P.Sharma Dinesh Tanwar R.A.More

Shift Incharge Asst.Mgr. Maint. Dy. Mgr. QA AGM-Works

AXA Performance Department Maint.

Parenterals Ltd. Qualification

Village Kishanpur Jamalpur, Effective date 1/11/2006

Roorkee.Uttaranchal For

BOILER Page 4 of 9

Revision 00

The objective of this protocol is to establish documented evidence that the BOILER under commission

will produce the results consistently, within the specified acceptance limits, when operated as per the

standard operating procedures.

3.0 PRE – REQUISITES:

i) User requirement specification for BOILER – APL/MAINT/URS/701.

ii) Design qualification for BOILER- APL/MAINT/DQ/701

iii) Installation qualification for BOILER – APL/MAINT/IQ/701

iv) Operation qualification for BOILER.- APL/MAINT/OQ/701

4.0 SCOPE:

The scope of this particular protocol is applicable for BOILER installed at AXA Parenterals

Limited, Boiler steam is used in various machineries like Chiller, Distillation, Sterilizer & Bottle filling

machine. The capacity of Boiler (Steam) is 5000kgs/hr.

.

5.0 RESPONSIBILITIES:

Sr. No. Responsibilities Name of Department

1. Development of Documents Production / Maintenance

2. Provision of qualified personnel to assist in the protocol Production / Maintenance

preparation and execution.

3. Approval of the protocol and final report. Q.A.

4. Final determination of the system acceptability A.G.M. (Works)

5. Provision of the qualified personnel to assist the execution. A.G.M. (Works)

6. Review and assembling of data into a final report. Q.A.

Name of personnel for performing to the Performance Qualification: -

Name Title Responsibility Signature

Prepared by Checked by Approved by Authorised by

Document No:

APL/MAINT//PQ

701

Sudhir Awatade J.P.Sharma Dinesh Tanwar R.A.More

Shift Incharge Asst.Mgr. Maint. Dy. Mgr. QA AGM-Works

AXA Performance Department Maint.

Parenterals Ltd. Qualification

Village Kishanpur Jamalpur, Effective date 1/11/2006

Roorkee.Uttaranchal For

BOILER Page 5 of 9

Revision 00

Sudhir R. Awatade Shift Incharge Development of documents

J.P. Sharma Asst.Manager Provision of guidance for operation

Maintenance

Dinesh Tanwar Q.A. Manager Review and approval of the protocol and

report

R.A. More A.G.M. Works Final determination of system

6.0 REFERENCES:

The list of reference documents, which were referred for preparation and review of this document, is as

follows: -

6.1 Standard Operating Procedures as per APL / MAINT/SOP/701

6.2 Manual supplied by INDCON BOILERS LIMITED.

7.0 EQUIPMENT / SYSTEM DESCRIPTION:

INDCON BOILERS plant is a Horizontal construction smoke tube design steam Boiler consisting of shell,

smoke tubes & Water wall confirming to latest Indian Boiler Regulation (IBR), fully welded class - I

construction using Boiler Quality steel plates, 100% weld, radio graphed & hydraulically pressure testing.

This chapter describes the working cycle of the BOILER & the functions of its various components. The

Operation of various parts of the BOILER is described here,

Furnace:

It made up of fire bricks, refractory, fire cement, castable refractory to maintain heat.

Variable Speed feeder: Electronic control variable speed screw feeders to maintain air to fuel ratio for higher

efficiency.

Fluidizations System:

Consisting of plannum chamber complete with high velocity air to nozzles for proper fluidization & sand

discharge system.

Air Pre –Heater:

An air pre heater which will utilize heat of outgoing flue gases for the purpose of heating of combustion air.

Multicyclone Dust collector:

A high efficiency design- Indexa multicyclone dust arrestor is provided with number of centrifuge –dust

arrestor tube to clean the pollutant gases & ash is collecting at bottom of the arrestor.

Prepared by Checked by Approved by Authorised by

Document No:

APL/MAINT//PQ

701

Sudhir Awatade J.P.Sharma Dinesh Tanwar R.A.More

Shift Incharge Asst.Mgr. Maint. Dy. Mgr. QA AGM-Works

AXA Performance Department Maint.

Parenterals Ltd. Qualification

Village Kishanpur Jamalpur, Effective date 1/11/2006

Roorkee.Uttaranchal For

BOILER Page 6 of 9

Revision 00

Water feed Pump:

High pressure pump driven by motor for feed of soft water to Boiler.

Forced Draught fan:

Heavy duty fan complete with suitable motor air control damper made out of heavy duty gauge MS body

with dynamically balanced impeller, heavy grade cast iron bearing brackets complete with MS hub.

Spherical roller bearings complete with pulleys & motor base frame suitable to handle air at ambient

temperature.

Moberly control:

Complete with requisite valves provision for high & low water level control in the boiler.

Induced Draughts Fan: Induced draft fan with suction damper, expansion joint to handle flue gases at high

temperature.

8.0 QUALIFICATION TESTS:

The BOILER will be qualified for performance after carrying out the performance test of STEAM produced

as per instructions given in the manual by the manufacturer for operation of BOILER.

The performance qualification of the BOILER begins when the equipment has been verified as installed and

operating correctly. (I.e. after Installation Qualification & Operation Qualification), during this phase the

STEAM will be produced with Horizontal construction smoke tube design technology.

8.1. Verification of BOILER CAPACITY.

This study is carried out to ensure that the BOILER is capable of producing the STEAM at a higher speed as

mentioned by the manufacturer in the manual without affecting the quality of the STEAM. From the studies

it was found that the maximum STEAM generation capacity of the BOILER is 5 ton/hour ±15%

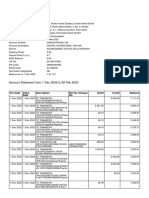

PERFORMANCE REPORT OF BOILER

Date: 23/10/2006

Sr. Description Unit Specification Actual

No.

Prepared by Checked by Approved by Authorised by

Document No:

APL/MAINT//PQ

701

Sudhir Awatade J.P.Sharma Dinesh Tanwar R.A.More

Shift Incharge Asst.Mgr. Maint. Dy. Mgr. QA AGM-Works

AXA Performance Department Maint.

Parenterals Ltd. Qualification

Village Kishanpur Jamalpur, Effective date 1/11/2006

Roorkee.Uttaranchal For

BOILER Page 7 of 9

Revision 00

1 Boiler feed water pump flow – 1 ltr/ hour 5000 More More More

&2 than than than

5000ltr 5000ltr 5000ltr

hour hour hour

2 F.D. FAN MMWC 300 310 320 310

3 Fuel Bed Temperature (Furnace) ºC 400 to 700 580 680 460

4 Fuel gas Temperature (Furnace) ºC 500 to 850 670 690 710

5 Boiler steam pressure Kg/ cm² 4.5 to 10.5 9.5 9.0 9.5

Date: 24/10/2006

Sr. Description Unit Specification Actual

No.

1 Boiler feed water pump flow – 1 ltr/ hour 5000 More More More

&2 than than than

5000ltr 5000ltr 5000ltr

hour hour hour

2 F.D. FAN MMWC 300 315 320 315

3 Fuel Bed Temperature (Furnace) ºC 400 to 700 585 685 590

4 Fuel gas Temperature (Furnace) ºC 500 to 850 690 690 690

5 Boiler steam pressure Kg/ cm² 4.5 to 10.5 9.5 9.0 9.5

Date: 25/10/2006

Sr. Description Unit Specification Actual

No.

1 Boiler feed water pump flow – 1 ltr/ hour 5000 More More More

&2 than than than

5000ltr 5000ltr 5000ltr

hour hour hour

2 F.D. FAN MMWC 300 310 320 310

3 Fuel Bed Temperature (Furnace) ºC 400 to 700 610 680 650

4 Fuel gas Temperature (Furnace) ºC 500 to 850 670 690 720

5 Boiler steam pressure Kg/ cm² 4.5 to 10.5 9.5 9.0 9.5

Acceptance criteria:

As indicative from all the test result, we can conclude that all the variable parameters are well with in the

acceptance limit also during the checking period no parameters were changed or altered, which are directly

related.

9.0 SUMMARIES AND CONCLUSION:

Prepared by Checked by Approved by Authorised by

Document No:

APL/MAINT//PQ

701

Sudhir Awatade J.P.Sharma Dinesh Tanwar R.A.More

Shift Incharge Asst.Mgr. Maint. Dy. Mgr. QA AGM-Works

AXA Performance Department Maint.

Parenterals Ltd. Qualification

Village Kishanpur Jamalpur, Effective date 1/11/2006

Roorkee.Uttaranchal For

BOILER Page 8 of 9

Revision 00

From the studies performed during the execution of this protocol and from the results obtained as attached in

this sheet, it may be concluded that the BOILER, when operated under a given set of conditions is capable of

producing STEAM consistently and hence the said equipment is qualified for performance and thus can be

used for regular operation.

10.0 PERFORMANCE QUALIFICATION APPROVAL:

Prepared by Checked by Approved by Authorised by

Document No:

APL/MAINT//PQ

701

Sudhir Awatade J.P.Sharma Dinesh Tanwar R.A.More

Shift Incharge Asst.Mgr. Maint. Dy. Mgr. QA AGM-Works

AXA Performance Department Maint.

Parenterals Ltd. Qualification

Village Kishanpur Jamalpur, Effective date 1/11/2006

Roorkee.Uttaranchal For

BOILER Page 9 of 9

Revision 00

The personnel involved in preparation, review and approval of this protocol shell authorize the completion

and approval of this document for performance qualification.

Name Signature Date

Prepared by

Sudhir Awatade

(Shift Incharge)

Checked by

J.P. Sharma

(Asst. Manager Maint.)

Approved by

Dinesh Tanwar

(Q.A.)

Authorized by

R.A. More

(A.G.M.Works)

Prepared by Checked by Approved by Authorised by

Document No:

APL/MAINT//PQ

701

Sudhir Awatade J.P.Sharma Dinesh Tanwar R.A.More

Shift Incharge Asst.Mgr. Maint. Dy. Mgr. QA AGM-Works

You might also like

- VMware vSAN Network Design PDFDocument169 pagesVMware vSAN Network Design PDFFederico MiliaccaNo ratings yet

- 4.101 M.com Research Methodology in Commerce Sem III & IVDocument8 pages4.101 M.com Research Methodology in Commerce Sem III & IVBrijrajSharmaNo ratings yet

- EIA JawahardweepDocument398 pagesEIA JawahardweeparchsubhankarNo ratings yet

- Sunny Island Operating ManualDocument164 pagesSunny Island Operating Manualbedilu77No ratings yet

- Operations Readiness PlanDocument40 pagesOperations Readiness PlanJakechris Sicad80% (5)

- Performance Re-Qualification RMGDocument13 pagesPerformance Re-Qualification RMGJaswant SinghNo ratings yet

- 10 KG Weighing Balance (XL-WH-WB-001) ... IOQDocument64 pages10 KG Weighing Balance (XL-WH-WB-001) ... IOQAshok LenkaNo ratings yet

- SMS Procedures and Trouble ShootingDocument59 pagesSMS Procedures and Trouble ShootingRandyNo ratings yet

- NCT SCN 000 E10 00001 - A01 - Quality Requirements For Subcontractors (High Criticality)Document21 pagesNCT SCN 000 E10 00001 - A01 - Quality Requirements For Subcontractors (High Criticality)Charles KingNo ratings yet

- SAS FDC PDFDocument105 pagesSAS FDC PDFDevas Shukla100% (1)

- Int-UpperInt Placement Test PDFDocument3 pagesInt-UpperInt Placement Test PDFh1238709mNo ratings yet

- PMR - CPP Solar Turbines Taurus - 70 Driven Compressor Set PackagesDocument15 pagesPMR - CPP Solar Turbines Taurus - 70 Driven Compressor Set PackagesAceh NyakponNo ratings yet

- Vignesh Well Test Operator-DaqDocument4 pagesVignesh Well Test Operator-Daqjohn MNo ratings yet

- Ball LevitationDocument7 pagesBall LevitationsumlusemloNo ratings yet

- Quality Record ProcedureDocument5 pagesQuality Record ProcedurepojokbioNo ratings yet

- Fault Identification and ReportingDocument2 pagesFault Identification and ReportingNoel BlancaNo ratings yet

- 10 KG Weighing Balance (XL-WH-WB-01) ... URSDocument7 pages10 KG Weighing Balance (XL-WH-WB-01) ... URSAshok Lenka100% (4)

- 370-1 An PremiumDocument178 pages370-1 An PremiumDejan Pušac100% (3)

- PQ of AutoclaveDocument23 pagesPQ of Autoclavedinesh000786100% (7)

- Sop ZetasizerDocument3 pagesSop ZetasizerP SWETHANo ratings yet

- TPCIL - 16-R1 - Inspection Calls, IR & RNsDocument7 pagesTPCIL - 16-R1 - Inspection Calls, IR & RNsGopal RamalingamNo ratings yet

- Hse Plan - Rev-1Document81 pagesHse Plan - Rev-1srirambaskyNo ratings yet

- Audit Report ASA3 PTPN V TandunDocument89 pagesAudit Report ASA3 PTPN V TandunAdri Ayah BaimNo ratings yet

- Operation Qualification Protocol Cum OF Weighing Balance: Document No. MG/OQ/BAL-00 Page 1 of 11 Effective DateDocument11 pagesOperation Qualification Protocol Cum OF Weighing Balance: Document No. MG/OQ/BAL-00 Page 1 of 11 Effective DateMAXTAR BIO-GENICSNo ratings yet

- 021 Finalsmp - PheDocument6 pages021 Finalsmp - PhePankaj PandeyNo ratings yet

- F 392 0 r01 Supplier Quality AssessmentDocument12 pagesF 392 0 r01 Supplier Quality AssessmentSiddheshwarr JabagoudarNo ratings yet

- Annexure VI QAP For 30KW PMA and ControllerDocument27 pagesAnnexure VI QAP For 30KW PMA and Controllerrakesh bardepurNo ratings yet

- 020512-Revised Manufacturing Quality Plan For JPL Project - CAT-IDocument17 pages020512-Revised Manufacturing Quality Plan For JPL Project - CAT-ISunny SharmaNo ratings yet

- Ipp Tag FormatDocument1 pageIpp Tag FormatSKAI AUTO100% (1)

- Approval Note FormatDocument5 pagesApproval Note FormatqualityNo ratings yet

- 05 SMP of Sodium Analyzer Ver-03-Rev-01-2021Document4 pages05 SMP of Sodium Analyzer Ver-03-Rev-01-2021Sandeep PatialNo ratings yet

- Document Title: Standard Specification: Duplex Induction Bends COPI Doc No.: ID-G-BU-KK0-STS-GN-00-0008Document15 pagesDocument Title: Standard Specification: Duplex Induction Bends COPI Doc No.: ID-G-BU-KK0-STS-GN-00-0008Solikhul HarisNo ratings yet

- BASKARDocument5 pagesBASKARGodwin GodwinNo ratings yet

- RWTP GB Mne Msa 000147 SignedDocument26 pagesRWTP GB Mne Msa 000147 Signedslayerzzz22No ratings yet

- Performance Qualification Protocol Cum OF Weighing Balance: Document No. MG/PQ/BAL-00 Page 1 of 12 Effective DateDocument12 pagesPerformance Qualification Protocol Cum OF Weighing Balance: Document No. MG/PQ/BAL-00 Page 1 of 12 Effective DateMAXTAR BIO-GENICSNo ratings yet

- Testing & Process: Employment History: Date Position Location CommentsDocument3 pagesTesting & Process: Employment History: Date Position Location Commentsjohn MNo ratings yet

- 17a BOBRN Rake Placement in Track HopperDocument7 pages17a BOBRN Rake Placement in Track HoppersachnpandeyNo ratings yet

- KGF - OQ - P - EQ-MB-012 - 01 - Compressed Air SamplerDocument2 pagesKGF - OQ - P - EQ-MB-012 - 01 - Compressed Air SamplerAbuNo ratings yet

- Welding Procedure DocumentDocument7 pagesWelding Procedure DocumentikponmwonsaNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- RWTP GB Mne Msa 000095 Spring Isolator SignedDocument26 pagesRWTP GB Mne Msa 000095 Spring Isolator Signedslayerzzz22No ratings yet

- Filosofia Standard Operacion Caldera ThermaxDocument37 pagesFilosofia Standard Operacion Caldera ThermaxAndújar Báez CésarNo ratings yet

- Nuclear Power Corporation of India Limited: Quality Assurance PlanDocument2 pagesNuclear Power Corporation of India Limited: Quality Assurance PlanRavindra TiwariNo ratings yet

- Urs Incinerator 200 KGDocument7 pagesUrs Incinerator 200 KGSugiarto SudarsonoNo ratings yet

- Welding Procedure DocumentDocument7 pagesWelding Procedure DocumentikponmwonsaNo ratings yet

- PROSEDUR Perawatan Submarine HoseDocument5 pagesPROSEDUR Perawatan Submarine HoseTaufik ismailNo ratings yet

- 193201DVDAS5873 EXDE01 01 Bottom Plate Development For Off Spec Condensate Storage TankDocument1 page193201DVDAS5873 EXDE01 01 Bottom Plate Development For Off Spec Condensate Storage TankKareem AbdelazizNo ratings yet

- CV of Muhammad Ashfaq HussainDocument5 pagesCV of Muhammad Ashfaq HussainIshfaq UrrehmanNo ratings yet

- RWTP GB Mne Msa 000144 SignedDocument19 pagesRWTP GB Mne Msa 000144 Signedslayerzzz22No ratings yet

- Design Qualification: Cip Skid & Distribution Piping (Veg Blender Flavours Powder)Document12 pagesDesign Qualification: Cip Skid & Distribution Piping (Veg Blender Flavours Powder)Chay Nag100% (1)

- OQ-K7-QA-VC-003 Sterilizing Tunnel - Rev00Document16 pagesOQ-K7-QA-VC-003 Sterilizing Tunnel - Rev00jpmaurya77No ratings yet

- NAAFCO Pharma Ltd. Bhaluka, Mymensingh Title: Performance Qualification Report For Hoonga-Blister MachineDocument17 pagesNAAFCO Pharma Ltd. Bhaluka, Mymensingh Title: Performance Qualification Report For Hoonga-Blister Machinebejoy karimNo ratings yet

- Annual Report2022 23Document308 pagesAnnual Report2022 23prateek goyalNo ratings yet

- Napino Auto & Electronics LTD.: Initial Production Part TagDocument2 pagesNapino Auto & Electronics LTD.: Initial Production Part TagSACHIN KUMARNo ratings yet

- Resume - 02.09.2016 - R4Document4 pagesResume - 02.09.2016 - R4BabbooNo ratings yet

- Annexure VI Environmental Monitoring Oriental StructuresDocument16 pagesAnnexure VI Environmental Monitoring Oriental Structuressabul1276No ratings yet

- Resume: Post For Applied: Production / Commissioning/Field OperatorDocument5 pagesResume: Post For Applied: Production / Commissioning/Field OperatorRebel Add100% (1)

- SUPPORT (Scaph, Ducting) QAP R02 080822Document2 pagesSUPPORT (Scaph, Ducting) QAP R02 080822Pavul RajNo ratings yet

- Nayeem Ahmed Resume 22 Jan 20Document4 pagesNayeem Ahmed Resume 22 Jan 20yunus_mohammed1641No ratings yet

- Raut Enterprises ProfileDocument13 pagesRaut Enterprises Profileapi-477814325No ratings yet

- RWTP GB Mne Msa 000049Document44 pagesRWTP GB Mne Msa 000049slayerzzz22No ratings yet

- 09:36:30 PDFDocument4 pages09:36:30 PDFRANAJIT KUMAR MOHANTYNo ratings yet

- HAV-EXT-HS-PRO-0144: Hot Work Safety ProcedureDocument14 pagesHAV-EXT-HS-PRO-0144: Hot Work Safety Procedureum erNo ratings yet

- 04 SMP of Silica Analyser Ver-03-Rev-01-2021Document3 pages04 SMP of Silica Analyser Ver-03-Rev-01-2021Sandeep PatialNo ratings yet

- Part': February 1975Document100 pagesPart': February 1975Jesus BRANDULAS MUIÑONo ratings yet

- DevopsbootcampcloerDocument115 pagesDevopsbootcampcloersongacoNo ratings yet

- Assignment 2 - SolutionsDocument14 pagesAssignment 2 - Solutionshassaniqbal84No ratings yet

- Project Assignment: Power System Simulation For Engineers (PSS/E Version 34)Document12 pagesProject Assignment: Power System Simulation For Engineers (PSS/E Version 34)Suterm SeccionNo ratings yet

- Potterton Performa System HE User GuideDocument12 pagesPotterton Performa System HE User GuideReUp2009No ratings yet

- Human Resource Information SystemDocument26 pagesHuman Resource Information SystemharpreetlkoNo ratings yet

- Module D ZS4200 R4.0 Operator V1.01Document31 pagesModule D ZS4200 R4.0 Operator V1.01stefan63byNo ratings yet

- Introduction To Healthcare System of IndiaDocument22 pagesIntroduction To Healthcare System of Indiakratika GaurNo ratings yet

- Adi GodrejDocument12 pagesAdi GodrejMurtuza17No ratings yet

- Prep 2 Booklet 2nd Term 2016Document45 pagesPrep 2 Booklet 2nd Term 2016mina samirNo ratings yet

- JJM-10!02!20-452 - Full - Full Handbook - Jaguar X-Type Owner's Handbook - MY 2004Document216 pagesJJM-10!02!20-452 - Full - Full Handbook - Jaguar X-Type Owner's Handbook - MY 2004kukkatiesNo ratings yet

- My ResumeDocument8 pagesMy ResumeShaikh Mohd ShahbazNo ratings yet

- English Newspaper ThingyDocument13 pagesEnglish Newspaper Thingytimothy.imannuelNo ratings yet

- HarmonesDocument6 pagesHarmonesbaskarNo ratings yet

- Catálogo Alisson Transmission - GMK 6300Document2 pagesCatálogo Alisson Transmission - GMK 6300EdilsonNo ratings yet

- ATTANE™ 4404G: Ultra Low Density Polyethylene ResinDocument3 pagesATTANE™ 4404G: Ultra Low Density Polyethylene ResinRoberto De Mesa PNo ratings yet

- Sli Ia 01Document3 pagesSli Ia 01Rose JessicaNo ratings yet

- Citadels of Chaos by Cornelius Carl Veith 45Document214 pagesCitadels of Chaos by Cornelius Carl Veith 45joeycrackNo ratings yet

- Report Sultanpur LodhiDocument39 pagesReport Sultanpur Lodhiunderthearch.studioNo ratings yet

- Fundamental Research in Electrical Engineering: ArticleDocument16 pagesFundamental Research in Electrical Engineering: ArticlepriyanNo ratings yet

- NBIMS-US V3 4.9 WSieDocument350 pagesNBIMS-US V3 4.9 WSiemahmoud mokhtarNo ratings yet

- City of Manila v. Coca-Cola BottlersDocument17 pagesCity of Manila v. Coca-Cola BottlersRo CheNo ratings yet