Professional Documents

Culture Documents

CO02 Earthmoving Check List

Uploaded by

Jansen Sunga0 ratings0% found this document useful (0 votes)

9 views4 pagesOriginal Title

CO02 Earthmoving check list

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views4 pagesCO02 Earthmoving Check List

Uploaded by

Jansen SungaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

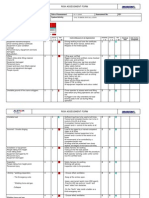

EARTHMOVING CHECK LIST

Date:

Area/section:

Work area:

Description of work:

Inspection number:

Inspection undertaken by: Inspection checked by:

Name and position Name and position

DESCRIPTION Yes No NA ACTION NEEDED

1 General conditions

Record with working instruction before undertaking

the activities, analysing, describing and approving the

1.1 preventive planning to be applied in the work, taking

into account the type of ground, protection means,

etc, among others.

Is there a study of the ground to determine its

properties and the subsequent definition of slopes

1.2 or, in default, the necessary shoring? Likewise, have

the affected conduits or utilities in the are of action

been identified?

Management and communication system, when

there is a modification to the design of equipment

1.3

and critical procedures, to avoid undertaking work

with rejected or obsolete procedures or material.

Choice of machinery:

- Work equipment certified or approved for the work

to be undertaken.

1.4 - Existence of instructions manual.

- Updated revisions sheet.

- Regulatory documentation as per country.

- Danger and warning signs.

Workers:

- Suitable and accredited training for the work to be

1.5 undertaken.

- Authorised to use the work equipment.

- Proven physical and mental capability.

2 Organisational actions

Is there a traffic and manoeuvring plan for vehicles

2.1

and earthmoving machinery?

2.2 The companies involved must be coordinated.

Code: CO02 Edition 00 Page 1 of 4

2.3 No plans for excavating in the same vertical plane.

Shifts and rest periods planned according to the type

2.4

of work to be undertaken.

3 Working environment

Is there a work permit for critical daily checking and

3.1

revision activities?

Does the work area have shoring, slopes, sheet piling

3.2 or any other method to suitably guarantee the risk of

persons being buried?

Delimiting of transited areas for workers on foot. Is

3.3 there safety delimiting for work with machinery,

setting a safe manoeuvring perimeter?

Suitable signposting for the exit to and entry from the

3.4

public road by vehicles and machinery.

Suitable lighting in the work area for the visual

3.5

requirements of the work to be undertaken.

Are there working procedures and/or preventive

3.6 measures that guarantee the elimination or reduction

of dust generation during the work?

Sufficient and suitable ventilation of the work area

3.7

for engine exhaust fumes.

Are workers on foot and machinery operators

3.8

protected from exposure to noise and vibration?

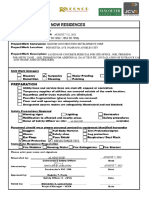

4 Machinery

Are the manufacturer’s instructions followed during

4.1 the use, conservation and maintenance of the

equipment?

Operators of the work equipment:

- Use clothing suitable for the weather that does not

4.2

impede the use of the controls.

- Use the retainer devices (safety belt).

Access to machinery:

- Access the machine facing it, using the steps and

grips provided for the purpose.

4.3

- Do not access the machine with objects in the

hands.

- Keep the steps and grips free of oil, mud, etc.

Cab:

- Is the cab free of objects that could hit the operator

in the event of overturning?

4.4 - No inflammable material (oil, greasy rags, etc) in the

cab.

- A suitable extinguisher must be available in or near

the machine.

Before starting the equipment, check:

4.5 - Controls in neutral to prevent unexpected

movement.

Code: CO02 Edition 00 Page 2 of 4

- Windows and mirrors clean.

- Proper functioning of lights and safety devices

(flashing light, reverse warning horn, etc).

No workers within reach of the machinery or

4.6 coordination measures set up with specific work

instruction.

Workers on foot must wear high visibility clothing

4.7 and maintain permanent visual contact with the

earthmoving equipment operator.

Is there a signalman for excavation and filling

4.8

manoeuvres when visibility is deficient?

Are there signs forbidding the use of cell phones

4.9 without a hands-free system and the use of

entertainment devices while driving?

For work with located affected utilities:

- Is there an action plan in case these utilities are

4.10 broken or affected?

- Are the affected utilities properly signposted?

- Are the marked safety distances respected?

Excavation machinery:

- Use the stabilisers on firm ground.

4.11

- Do not work on gradients steeper than those set by

the manufacturer.

Excavations:

4.12 - Must be suitably reinforced against overloading by

passing vehicles and machinery.

No workers must remain in the excavation during its

4.13 digging to prevent their being affected by collapsing

material.

Are there ladders or other means for the workers’

4.14

safe access to the excavation.

Do not overload the edge of the excavation with the

4.15

material removed or other materials.

Are there travel stops and signs preventing

4.16 machinery loading material from approaching the

edge of the excavation?

For demolition work, the cab must be fitted with a

4.17

structure to protect the driver from falling materials.

During the loading of material onto a truck:

- The scoop must not pass over the cab or persons on

foot.

4.18 - The scoop must be loaded stably to prevent

material from falling.

- Do not make sudden movements with the scoop

loaded.

For carrying and removing material from excavations:

- The material is positioned correctly without

4.19

destabilising the transport vehicle.

- No material falls from the vehicle during transport.

Code: CO02 Edition 00 Page 3 of 4

- Travel end stops are placed to prevent the tipper

truck from approaching the excavation.

For work with risk of overturning:

- The machinery is equipped with systems to protect

4.20 the driver in overturning (roll over protection for

cab).

- The operator uses the retainer system (safety belt).

The machines have reverse warning lights and horns

4.21

and flashing lights.

4.22 The site traffic signs are respected.

Passengers are not carried on areas not designed for

4.23

it.

All retractable parts of machinery must be kept

4.24 retracted to avoid hitting pedestrians or irregularities

in the ground.

Stopping the equipment:

- Equipment must be stopped on firm ground.

- Chocks must be placed to prevent movement on

gradients.

4.25

- All devices for starting must be disabled to prevent

starting by unauthorised persons.

- The machine’s implements (arm, shovel, etc) must

be resting on the ground.

VERIFICATION DATE:

Code: CO02 Edition 00 Page 4 of 4

You might also like

- Sop 001 Fibre CT Site Set UpDocument8 pagesSop 001 Fibre CT Site Set UpjoseltnNo ratings yet

- Nanyan SWP 1Document8 pagesNanyan SWP 1Sujan MiaNo ratings yet

- Method Statement Concrete Works 2019Document8 pagesMethod Statement Concrete Works 2019محمد فتحىNo ratings yet

- IOGP Recommended PracticeDocument18 pagesIOGP Recommended Practiceivan rocoNo ratings yet

- Piping Jacing and Erection of Placing BoomDocument3 pagesPiping Jacing and Erection of Placing BoomramsafeNo ratings yet

- Excavator Operator'S Training: ISO 14001:2015 CertifiedDocument60 pagesExcavator Operator'S Training: ISO 14001:2015 CertifiedJela ParadiseNo ratings yet

- Haul Truck Operation PDFDocument57 pagesHaul Truck Operation PDFRalph Castillo100% (2)

- TiremanDocument6 pagesTiremanKent Charles Monreal NotarioNo ratings yet

- Online LF Quizzes Answers GuideDocument18 pagesOnline LF Quizzes Answers GuideDaniel Galeano SerranoNo ratings yet

- Bored Pile Drilling Machine and Work InstructionDocument6 pagesBored Pile Drilling Machine and Work Instructionmiraç burak navruzNo ratings yet

- Method Statement Concrete Works 2019Document8 pagesMethod Statement Concrete Works 2019Derek obboNo ratings yet

- Workplan:: Heavy Equipment Hazards and ControlsDocument3 pagesWorkplan:: Heavy Equipment Hazards and ControlsRenauld WilsonNo ratings yet

- Method Statement and Risk Assessment For Electrical Cable Trench ExcavationDocument8 pagesMethod Statement and Risk Assessment For Electrical Cable Trench Excavationfehmi-fjr469650% (2)

- Revised Site Audit TemplateDocument4 pagesRevised Site Audit TemplateLucian100% (1)

- Dozer Operators Training: ISO 14001:2015 CertifiedDocument58 pagesDozer Operators Training: ISO 14001:2015 CertifiedJela ParadiseNo ratings yet

- 04 - Appendix Safety MeasuresDocument7 pages04 - Appendix Safety MeasuresKocic GradnjaNo ratings yet

- Lawn Scarifier PDFDocument1 pageLawn Scarifier PDFcityofdarwingisNo ratings yet

- AP 9 Safety During ConstructionDocument12 pagesAP 9 Safety During ConstructionlvnvprasadNo ratings yet

- Safe Operating Procedures 01 TRACTORDocument2 pagesSafe Operating Procedures 01 TRACTORJoel ChifunaNo ratings yet

- 11 - WMS - Turpentine - Plaster WorksDocument5 pages11 - WMS - Turpentine - Plaster WorksVikramaditya NayakNo ratings yet

- Bulldozer SOP FinalDocument10 pagesBulldozer SOP Finaljean claude BledouNo ratings yet

- Surveying and Setting OutDocument81 pagesSurveying and Setting OutJuneydiahmed100% (2)

- Generic Heavy Equipment Operator SOPDocument3 pagesGeneric Heavy Equipment Operator SOPImran KhanNo ratings yet

- Method Statement - Cleaning of Stairs, Landings, Balustrades EtcDocument4 pagesMethod Statement - Cleaning of Stairs, Landings, Balustrades EtcMark WilliamsNo ratings yet

- Topic Focus Igc 2 - Green World GroupDocument15 pagesTopic Focus Igc 2 - Green World GrouppmnasimNo ratings yet

- Bulldozer SOP FinalDocument10 pagesBulldozer SOP FinalsajiNo ratings yet

- JSW Dolvi RefDocument16 pagesJSW Dolvi Refpushpak26No ratings yet

- Mechanical Trades SOPDocument5 pagesMechanical Trades SOPadventmanurungNo ratings yet

- ATT400 Parts 241384Document767 pagesATT400 Parts 241384Nguyễn Hữu Dũng86% (7)

- Ilovepdf MergedDocument20 pagesIlovepdf MergedavisheklochunNo ratings yet

- XCMG XC948 Wheel Loader Operation and Maintenance ManualDocument296 pagesXCMG XC948 Wheel Loader Operation and Maintenance ManualSyeed Asif AliNo ratings yet

- Safety ProceduresDocument14 pagesSafety ProceduresJR BNo ratings yet

- Working at HeightDocument9 pagesWorking at Heightsixejo100% (6)

- Demolotion Work DirectionsDocument1 pageDemolotion Work Directionsmiraç burak navruzNo ratings yet

- ATT400 Operation Maint 241384Document805 pagesATT400 Operation Maint 241384Hữu Dũng Nguyễn100% (8)

- Risk Assessment For Sand Blasting PDFDocument8 pagesRisk Assessment For Sand Blasting PDFOvais FarooqNo ratings yet

- Standard Operating Procedures (Tractor Operation)Document2 pagesStandard Operating Procedures (Tractor Operation)Joel ChifunaNo ratings yet

- Method Statement SampleDocument3 pagesMethod Statement SampleAmrith RajNo ratings yet

- Heavy Equipment SOP FinalDocument9 pagesHeavy Equipment SOP FinalParmeshwor VetwalNo ratings yet

- R F (H W C) :: Operations & Screening CrushingDocument7 pagesR F (H W C) :: Operations & Screening Crushingkmohamedkeita906No ratings yet

- Service Truck Driver SOPDocument3 pagesService Truck Driver SOPVenkadesh PeriathambiNo ratings yet

- List of Contents: 8.0 HEALTH AND SAFETY HAZARDS . .7 9.0 EQUIPMENT AND TOOLS . .7Document4 pagesList of Contents: 8.0 HEALTH AND SAFETY HAZARDS . .7 9.0 EQUIPMENT AND TOOLS . .7Mahmoud Salih100% (1)

- Risk Asses 21-Gaz Turbine InstallationDocument6 pagesRisk Asses 21-Gaz Turbine InstallationRochdi Bahiri100% (1)

- Risk Assessment - RA - MC-17 - For TRG Ref - AKDocument5 pagesRisk Assessment - RA - MC-17 - For TRG Ref - AKnebumex100% (2)

- Code of Practice-OHSAS 18001Document18 pagesCode of Practice-OHSAS 18001Mudassar AdilNo ratings yet

- HSW Network FrameworkDocument5 pagesHSW Network FrameworkVedNo ratings yet

- Toolbox Talk Booklet A5 Version 1Document79 pagesToolbox Talk Booklet A5 Version 1NicholasKueh100% (4)

- Heavy Duty AssignmentDocument15 pagesHeavy Duty AssignmentSurafel MesfinNo ratings yet

- Lift PlanDocument26 pagesLift Planvinodhyper89% (9)

- TW Manuals Essential Standard 4 TelehandlersDocument4 pagesTW Manuals Essential Standard 4 TelehandlersdomagojNo ratings yet

- Bulldozer Operator SOPDocument3 pagesBulldozer Operator SOPJacksmith ThadiusNo ratings yet

- Risk Asses23 - Generator RotorDocument3 pagesRisk Asses23 - Generator RotorRochdi BahiriNo ratings yet

- Method Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksDocument3 pagesMethod Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksSagar SharmaNo ratings yet

- Cleaning Method Statement SiteDocument10 pagesCleaning Method Statement SiteKeemeNo ratings yet

- Contec Project FinaleDocument15 pagesContec Project FinaleephragekaroNo ratings yet

- Good Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsFrom EverandGood Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsNo ratings yet

- Excavator ChecklistDocument2 pagesExcavator ChecklistJansen SungaNo ratings yet

- Civil WorksDocument1 pageCivil WorksJansen SungaNo ratings yet

- Civil WorksDocument1 pageCivil WorksJansen SungaNo ratings yet

- Segnor IdDocument4 pagesSegnor IdJansen SungaNo ratings yet

- Segnor IdDocument4 pagesSegnor IdJansen SungaNo ratings yet

- HIRAC Risk AssessmentDocument39 pagesHIRAC Risk AssessmentDaveRaphaelDumanat100% (9)

- Scdc-Hirac WorksheetDocument8 pagesScdc-Hirac WorksheetJansen SungaNo ratings yet

- Civil WorksDocument1 pageCivil WorksJansen SungaNo ratings yet

- JHA - Excavation, Pile Hacking and Construction of Lean ConcreteDocument13 pagesJHA - Excavation, Pile Hacking and Construction of Lean ConcreteJansen SungaNo ratings yet

- Excavation Work PermitDocument1 pageExcavation Work PermitJansen SungaNo ratings yet

- Fire SafetyDocument16 pagesFire SafetyRyan Q. BlancoNo ratings yet

- Materals HandlingDocument24 pagesMaterals HandlingJansen SungaNo ratings yet

- TERMS CONDITIONS SURYA ROSHNI LTD DT 20th APR 22 STEELEZDocument8 pagesTERMS CONDITIONS SURYA ROSHNI LTD DT 20th APR 22 STEELEZEtrans 9No ratings yet

- Paper On Harmonization Eac - August 2011Document7 pagesPaper On Harmonization Eac - August 2011Jared MakoriNo ratings yet

- 3 4+Effect+of+Commercial+Traffic+Overloading+Enforcement+on+Pavement+Performance,+P +Ram+Mohan+RaDocument12 pages3 4+Effect+of+Commercial+Traffic+Overloading+Enforcement+on+Pavement+Performance,+P +Ram+Mohan+RaCity Aspire100% (1)

- Chapter 1 IntroductionDocument93 pagesChapter 1 IntroductionTewodros TadesseNo ratings yet

- Dot 27067 DS1Document89 pagesDot 27067 DS1ahmadNo ratings yet

- Clark SM 616 Service ManualDocument20 pagesClark SM 616 Service Manualenid100% (55)

- Cargo C3e100r 150rDocument4 pagesCargo C3e100r 150rJesus LarenasNo ratings yet

- CastersDocument34 pagesCasterselvisolmedo7482No ratings yet

- Liugong 012018-EngDocument12 pagesLiugong 012018-EngAkhmad SebehNo ratings yet

- Fibreglass Tank PDFDocument56 pagesFibreglass Tank PDFdadan yupi andika100% (1)

- List of Published Automotive Industry Standards (Updated On May 23, 2019)Document15 pagesList of Published Automotive Industry Standards (Updated On May 23, 2019)sagarNo ratings yet

- ITC.326.1 01 - Product Presentation-MITDocument29 pagesITC.326.1 01 - Product Presentation-MITNoel SumangaNo ratings yet

- Liebherr LTM 1150-6.1 Product AdvantagesDocument18 pagesLiebherr LTM 1150-6.1 Product AdvantagesMustafa Mahmoud Elsayed100% (1)

- PreviewDocument402 pagesPreviewOscarito VázquezNo ratings yet

- Aignerr KatalogDocument70 pagesAignerr Katalogванек долдаNo ratings yet

- TD-08 Sanchit Salvi SeminarDocument26 pagesTD-08 Sanchit Salvi Seminarshashank awasthiNo ratings yet

- SimbaDocument8 pagesSimbaedwardNo ratings yet

- Dd422i Specification Sheet EnglishDocument4 pagesDd422i Specification Sheet EnglishAbdalla Mohamed AbdallaNo ratings yet

- CX140E Spec SheetDocument6 pagesCX140E Spec SheetthomasNo ratings yet

- 50 Years of Hess Toy TrucksDocument11 pages50 Years of Hess Toy TrucksAnonymous arnc2g2NNo ratings yet

- 8 Sem Project Report1Document44 pages8 Sem Project Report1pulkit khandelwalNo ratings yet

- TSP 6500 7000 enDocument8 pagesTSP 6500 7000 enMahmoud ElerakyNo ratings yet

- FichaTecnica LinkBelt rt80130bDocument8 pagesFichaTecnica LinkBelt rt80130bromeo de la cruz hernandezNo ratings yet

- Gem Terms & ConditionsDocument2 pagesGem Terms & ConditionsJaydeepNo ratings yet

- EH750-3 & EH1100-3 & EH1700-3 EM8R6-1-4 Operator's ManualDocument410 pagesEH750-3 & EH1100-3 & EH1700-3 EM8R6-1-4 Operator's ManualJ O100% (1)

- Grove TMS800E PDFDocument36 pagesGrove TMS800E PDFGILMAR NIETONo ratings yet

- Escavadora 600C LC PDFDocument537 pagesEscavadora 600C LC PDFAnonymous KOtSfT6q100% (3)

- SAMPLE Forklift Safety ProgramDocument5 pagesSAMPLE Forklift Safety ProgramSudiatmoko SupangkatNo ratings yet

- Cat - Truck Mixers - ENGDocument7 pagesCat - Truck Mixers - ENGVasiliy PavliukNo ratings yet

- Moving Load Anlaysis As Per CSA-S6-10Document26 pagesMoving Load Anlaysis As Per CSA-S6-10rodwerNo ratings yet