Professional Documents

Culture Documents

ZISE10 Eng

Uploaded by

Cox HuangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ZISE10 Eng

Uploaded by

Cox HuangCopyright:

Available Formats

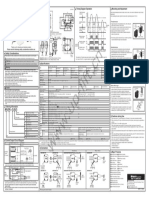

Digital Pressure Switch Connector Measurement mode The power is supplied

Names and Functions of Product Connecting/Disconnecting

The measurement mode is the condition

When mounting the connector, insert it straight into the socket, holding the Display to show the standard product

Names of individual parts where the pressure is detected and indicated,

Operation Manual Output (OUT1) display (Green)

button (SET)

Output (OUT2) display (Red)

lever and connector body, and fit the hook of the lever into the groove in the

housing to lock.

When removing the connector, press down the lever to release the hook

and the switch function is operating.

This is the basic mode, and other modes

1 s

Display to show the unit specification

Connector should be selected for setting change and 1 s

from the groove and pull the connector straight out.

ZSE10(F)/ISE10 LED display

button (UP)

Pin No. of the Connector

other function setting change. Display to show the product

Pin No. 1 s

button (DOWN) Housing DC(+) Brown 5

Display to show the pressure range

Socket OUT1 Black 4

Thank you for purchasing the SMC ZSE10(F)/ISE10 Series Digital Pressure Connector OUT2 White 3 1 s

(FUNC) Gray 2

Switch. Measurement mode

Concave DC(-) Blue 1

Please read this manual carefully before operating the digital pressure switch and Lever

make sure you understand the digital pressure switch, its capabilities and

limitations. Output (OUT1) display (Green): Lights ON when the switch output (OUT1) is

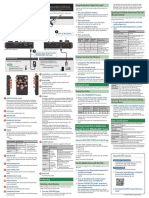

Function selection mode

Please keep this manual handy for future reference. turned ON. Pressure Setting In measurement mode, press

the button for 2 seconds or

Measurement mode

Press the button

Output (OUT2) display (Red): Lights ON when the switch output (OUT2) is turned for 2 s or longer.

To get information in detail for operating this product, refer to SMC website Set ON point and OFF point of the Pressure switch. longer to display [F 0]. Select to

ON. Function selection mode

(URL http://www.smcworld.com) or contact us. set value

display the function setting to

LED display: Displays the current status of pressure, setting mode and error code. Operation P_1 hysteresis be changed, [F ].

Pressure

button (UP): Selects the mode or increases the ON/OFF set value. When the pressure exceeds a set value, H_1

Press the button for

Press this button to change to the peak display mode. the Pressure switch will be turned on.

2 seconds or longer in function

Safety Instructions button (DOWN): Selects the mode or decreases the ON/OFF set value.

When the pressure falls below the set value

by the amount of hysteresis or more, the

[Pa] selection mode to return to

Press this button to change to the bottom display mode. measurement mode.

These safety instructions are intended to prevent hazardous situations and/or Pressure switch will be turned off. Switch ON

Setting functions

button (SET): Press this button to change to either mode and to set a value. The default setting of the output For normal output

equipment damage. Switch OFF ∗: Some functions are not available depending on part number. All functions are displayed with

These instructions indicate the level of potential hazard with the labels of set value is the central value Time [s] [F ] and followed with function description. If a function is not available for specified type, the

"Caution", " Warning" or "Danger". They are all important notes for safety and between the atmospheric pressure and the upper limit of the rated pressure range. function is displayed as [---].

must be followed in addition to International standards (ISO/IEC), Japan Industrial Mounting and Installation If the operation shown the right does not cause any problem, keep this operation setting.

Standards (JIS) and other safety regulations. <How to operate>

Installation [Hysteresis mode] Other Settings

Operator error could result in injury or equipment (1) Press the button once in measurement mode.

Caution: damage.

Mounting

∗: The tightening torque of piping port must be 1 Nm for Normal output Displays in turn

Peak/Bottom hold value indication

Zero clear

M5 (This is equivalent to approximate 1/6extra tighting (2) [P_1] or [n_1] and the set value are

Operator error could result in serious injury or loss of Key lock

Warning: life.

after manual tighting.) and 7 to 9 Nm for R1/8 and

NPT1/8.

displayed in turn. Reversed output

To set each function the above in detail, refer to SMC website

Mount with the set screws M3 size (2 pcs.) (3) Press the or button to change the set value. (URL http://www.smcworld.com) to get information in detail or contact us.

In extreme conditions, there is a possibility of serious

Danger: injury or loss of life.

for direct installation.

The tightening torque of the mounting screw M3

The button is for increase and the

Press the button once to

button is for decrease.

must be 0.5 to 0.7 Nm. increase by one figure, and Maintenance

Operator press it continuously to keep

How to reset the product for power cut or forcible de-energizing

Mounting with panel mount adapter increasing the set figure.

This operation manual is intended for those who have knowledge of • Panel mount adapter + Press the button once to The setting of the product will be retained as it was before a power cut or de-

Panel Front energizing.

machinery using pneumatic equipment, and have sufficient knowledge of Front protective cover decrease by one figure, and press it continuously to keep decreasing the

protective The output condition is also basically recovered to that before a power cut or de-

assembly, operation and maintenace of such equipment. Only those persons (Model: ZS-39-D) cover set figure.

are allowed to perform assembly, operation and maintenance. energizing, but may change depending on the operating environment. Therefore,

Read and understand this operation manual carefully before assembling, (4) Press the button to finish the setting. check the safety of the whole facility before operating the product.

operating or providing maintenance to the product. If 2 outputs specification is selected, [P_2] is displayed. Set OUT2 in the If the facility is using accurate control, wait until it has warmed up. (Approximately

Panel mount adapter

same way as OUT1. 10 minutes)

Safety Instructions Removal and mounting of DIN rail [ Window comparator mode ]

• It is necessary to prepare a DIN rail The Pressure switch turns on within a set pressure range (from P1L to P1H) Troubleshooting

Warning adapter for the mounting on the DIN rail. during window comparator mode. Set P1L (switch lower limit) and P1H (switch

Do not disassemble, modify (including changing the printed circuit board) or repair. (Model: ZS-39-R) upper limit) using the setting procedure above. Error indication function

An injury or failure can result. • Take care not to bend the claws of the DIN This function is to display error location and content when a problem or an error

rail adapter when mounting. Claw 1 Claw 2 Zero clear of indication occurs.

Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids. <Mounting of DIN rail adapter> Indication is reset to zero when and buttons are pressed simultaneously Error Name Error Display Error Type Troubleshooting Method

[2]

Fire, malfunction, or damage to the product can result.

Engage the pressure switch with claw 2 of for 1 second.

Verify the specifications before use.

the DIN rail adapter, then press down For the first operation, perform zero clear without pressure supply. Over current A load current of switch output is

Turn the power off and remove the

output factor for the over current.

Do not operate in an atmosphere containing flammable or explosive gases. Error 80 mA or more.

Fire or an explosion can result.

horizontally on to claw 1 until it clicks. Then turn the power on.

[3]

This product is not designed to be explosion proof. <Mounting on DIN rail>

Do not use the product in a place where static electricity is a problem.

Engage claw 1 of the adapter on to the DIN [1]

Claw 2 Setting of Function During zero clear operation, pressure

over ±7%F.S. ±3.5%F.S.for compound Perform zero clear operation again

Otherwise it can cause failure or malfunction of the system. rail as indicated [1], apply force in direction Claw 1 Zero-clear pressure) is applied. After 1 s, the mode after restoring the applied pressure

Error will reset to the measurement mode. to an atmospheric pressure

If using the product in an interlocking circuit:

[2] indicated, then press downward [1] Default setting ±1%F.S. of the zero clear range varies condition.

• Provide a double interlocking system, for example a mechanical system horizontally [3] until claw 2 clicks on to the At the time of shipment, the following settings are provided. with individual product differences.

• Check the product regularly for proper operation DIN rail. If the setting is acceptable, keep it for use. Pressure has exceeded the upper limit

Otherwise malfunction can result, causing an accident. Pressurizing of the set pressure range. Reset applied pressure to a level

<Removal of DIN rail> [2] To change setting, refer to SMC website (URL http://www.smcworld.com) to get Error Pressure has exceeded the lower limit within the set pressure range.

The following instructions must be followed during maintenance: Move in the direction [1], and remove claw information in detail or contact us. of the set pressure range.

• Turn off the power supply Claw 1

• Stop the air supply, exhaust the residual pressure and verify that the air is released before performing 1 as indicated with [2].

maintenance.

Claw 2 [F 0] Unit conversion function

Otherwise an injury can result. Piping Unit specification Pressure range Default setting

ISE10 MPa Turn the power off and turn it on

Connection using One-touch fitting Nil or M

Caution 1. Cut the tube perpendicularly.

ZSE10(F)

ISE10

kPa

System Error

Displayed in the case of an internal

again.

If resetting fails, an investigation by

Do not touch the terminals and connectors while the power is on. P PSI data error.

Otherwise electric shock, malfunction or damage to the product can result.

2. Hold the tube and insert it into the One- Tube ZSE10(F) SMC CORPORATION will be

touch fitting slowly until it bottoms out. required.

One-touch fitting [F 1] Setting of OUT1

After maintenance is complete, perform appropriate functional inspections and leak tests.

Stop operation if the equipment does not function properly or there is a leakage of fluid. Allow sufficient tube length to prevent twist, Item Explanation Default setting

When leakage occurs from parts other than the piping, the product might be faulty.

Disconnect the power supply and stop the fluid supply. tensile and moment load from being applied to the fitting and tube. Output mode Selects hysteresis mode or window comparator mode. Hysteresis mode

Do not apply fluid under leaking conditions. When using a tube manufactured by another company, check its outside Reversed output Selects reversed output. Normal output If the error can not be reset after the above measures are taken, then please

Safety cannot be assured in the case of unexpected malfunction. diameter accuracy satisfies the following conditions. ISE10: 0.500 MPa contact SMC.

Pressure setting Sets ON point or OFF point of the switch output ZSE10: -50.5 kPa

1) Nylon tube: ±0.1 mm maximum ZSE10F: 50.0 kPa

NOTE 2) Soft nylon tube: ±0.1 mm maximum

• The direct current power supply to be used should be UL approved as follows: 3) Polyurethane tube: +0.15 mm/-0.2 mm maximum

Hysteresis Chattering can be prevented by setting hysteresis. 5%

Specification

Circuit (of class 2) which is of maximum 30Vrms (42.4V peak) or less, with UL [F 2] Setting of OUT2

Wiring Same setting as [F 1] OUT1. Refer to the product catalogue or SMC website (URL http://www.smcworld.com) to

1310 class 2 power supply unit or UL 1585 class 2 transformer. get information about product specifications in detail.

• The Pressure switch is a approved product only if it has a mark on the Connection Other parameter setting

body. Make connection after turning the power off. Item Default setting

Use a separate route when connecting the wire of the Pressure switch.

Malfunction stemming from noise may occur if the wire is installed in the

[F 3] Setting of response time

[F 4] Setting of auto-preset

2.5 ms

Manual

Outline with Dimensions (in mm)

same route as that of power or high-voltage cable. [F 6] Setting of fine adjustment of display value 0% Refer to the product catalogue or SMC website (URL http://www.smcworld.com) to

Be sure to ground terminal FG when using a commercially available switch- [F11] Setting of display resolution 1000-split

get information about outline dimensions in detail.

mode power supply. When the switch-mode power supply is connected to [F80] Setting of power saving mode OFF

[F81] Setting of security code OFF

the Pressure switch, switching noise will be superimposed and product

[F90] Setting of all functions OFF URL http://www.smcworld.com

specification can no longer be met. This can be prevented by inserting a

[F97] Selection of copy function OFF Akihabara UDX 15F, 4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021, JAPAN

noise filter, such as a line noise filter and ferrite core, between the switch- [F98] Check of output Normal Phone: +81 3-5207-8249 Fax: +81 3-5298-5362

Ver.A

mode power supply and the Pressure switch, or by using a series power [F99] Reset to the default setting OFF Note: Specifications are subject to change without prior notice and any obligation on the part of the manufacturer.

supply instead of the switch-mode power supply. © 2009 SMC Corporation All Rights Reserved

You might also like

- 12 Presostato ZISE30A.engDocument1 page12 Presostato ZISE30A.engUlisesNo ratings yet

- SMC PFMB QuickguideDocument1 pageSMC PFMB QuickguideFRANNo ratings yet

- ISE40A Pressure Switch SetupDocument2 pagesISE40A Pressure Switch SetupFelipe rdzNo ratings yet

- Bowmar MX50 Electronic Calculator ManualDocument12 pagesBowmar MX50 Electronic Calculator ManualDjango RodNo ratings yet

- Trevi logic-sp-stp-tp user manual_enDocument2 pagesTrevi logic-sp-stp-tp user manual_enFrançois ClamourNo ratings yet

- Performance-Gear Guide en-USDocument2 pagesPerformance-Gear Guide en-USNermin BrkovicNo ratings yet

- C18 CatDocument2 pagesC18 Catjhonathan hernandez86% (7)

- Owner's Manual: Controls and FunctionsDocument2 pagesOwner's Manual: Controls and FunctionsmaiconNo ratings yet

- CRX7 ManualDocument1 pageCRX7 Manualjose thiagoNo ratings yet

- Yokogawa Ut350Document6 pagesYokogawa Ut350Jose Enrique Aleman RubiNo ratings yet

- Setup: Instruction ManualDocument2 pagesSetup: Instruction ManualnagatoNo ratings yet

- P 704Document2 pagesP 704presertec67% (3)

- Electricity 3 Lpt012Document3 pagesElectricity 3 Lpt012Nadah8No ratings yet

- Integrated Access Controller: User ManualDocument1 pageIntegrated Access Controller: User ManualLuis AldazNo ratings yet

- 908H serie LMD02385Document4 pages908H serie LMD02385electricista85No ratings yet

- I I I I: Operating Manual Double Relay Switch FGS-222-EN-A-v1.1Document2 pagesI I I I: Operating Manual Double Relay Switch FGS-222-EN-A-v1.1Ioan BogdanNo ratings yet

- G2 Chuck Rotary User GuideDocument1 pageG2 Chuck Rotary User GuideNémeth AmádéNo ratings yet

- Manual 700bar SPMK214L 2020.03Document1 pageManual 700bar SPMK214L 2020.03Aldrin Hernandez100% (1)

- DSE703 Installation InstructionsDocument2 pagesDSE703 Installation InstructionswisamNo ratings yet

- FBC9080 Fieldbus Converter Installation ManualDocument2 pagesFBC9080 Fieldbus Converter Installation ManualTHANGABALU RAJENDIRANNo ratings yet

- C50 1/16-Din Process Controller: Concise Product Manual - Im/C50Document2 pagesC50 1/16-Din Process Controller: Concise Product Manual - Im/C50AnthonyNo ratings yet

- User Manual: PWM Charge Controller Negative Grounded P2430N / P2440NDocument2 pagesUser Manual: PWM Charge Controller Negative Grounded P2430N / P2440NHafiz Sagheer HussainNo ratings yet

- Sipart PS2 ManualDocument2 pagesSipart PS2 ManualBio Metric100% (1)

- DG85 Ti06Document2 pagesDG85 Ti06Metalurgica VISILUNo ratings yet

- D8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pagesD8R Series II Track-Type Tractor Electrical System: Electrical Schematic Symbols and DefinitionsDarío Ache EmeNo ratings yet

- D8R II Plano Electrico PDFDocument2 pagesD8R II Plano Electrico PDFDarío Ache EmeNo ratings yet

- 777D and 773E Off-Highway Truck Electrical System CAT Detect Object DetectionDocument2 pages777D and 773E Off-Highway Truck Electrical System CAT Detect Object DetectionAndi BaraNo ratings yet

- User's Manual: InstallationDocument1 pageUser's Manual: InstallationneyebNo ratings yet

- Kick-NEKXA-Buds-Z10-User-Manual (1)Document1 pageKick-NEKXA-Buds-Z10-User-Manual (1)llaonunNo ratings yet

- Reaction Quimical MQDocument2 pagesReaction Quimical MQFranz SchindlerNo ratings yet

- Functional Description: Wiring DiagramDocument3 pagesFunctional Description: Wiring DiagramIshfaqAhmedMayoNo ratings yet

- The Comus International Group of Companies Consists Of:: DescriptionDocument2 pagesThe Comus International Group of Companies Consists Of:: DescriptionSteve WilsonNo ratings yet

- ACHIEVEMENT CHART ElectricalDocument2 pagesACHIEVEMENT CHART ElectricalCharis AbadNo ratings yet

- Control and Signalling UnitsDocument32 pagesControl and Signalling UnitsLaurentiu CatalinNo ratings yet

- Operation Manual: Caution: Warning: DangerDocument1 pageOperation Manual: Caution: Warning: Dangerisaias martinezNo ratings yet

- UENR2648 - Electrical SchematicDocument2 pagesUENR2648 - Electrical Schematickman548No ratings yet

- 704 Installation Instructions: NormalDocument2 pages704 Installation Instructions: NormalEzequielNo ratings yet

- Uen R 24200001Document4 pagesUen R 24200001Williams ArayaNo ratings yet

- k3p 07AS SheetDocument2 pagesk3p 07AS SheetsoniNo ratings yet

- Product Appearance Product Appearance Product Appearance Menu OthersetupDocument1 pageProduct Appearance Product Appearance Product Appearance Menu OthersetupM. ViertelNo ratings yet

- Dong Ho Ampe Kim Hioki 3288-20 - Manual 23012015054329Document2 pagesDong Ho Ampe Kim Hioki 3288-20 - Manual 23012015054329BRSantanaNo ratings yet

- AMPLIFICADORDocument2 pagesAMPLIFICADORJuanNo ratings yet

- Autonics BEN10M-TFR Details, Control Output Circuit Diagram, Specifications, Connection - Mounting and AdjustmentDocument1 pageAutonics BEN10M-TFR Details, Control Output Circuit Diagram, Specifications, Connection - Mounting and AdjustmentRebecca DangNo ratings yet

- Guia Rapida PF2M710S-N1-F-S pf2m7x - Quickguide - enDocument1 pageGuia Rapida PF2M710S-N1-F-S pf2m7x - Quickguide - enlauraalejandra1305.rodNo ratings yet

- Multi-turn CK actuators dimensions and specificationsDocument1 pageMulti-turn CK actuators dimensions and specificationsSuresh DNo ratings yet

- PG-SW023说明书 100G铜版纸双面印刷/单色印刷 尺寸:105x142mm: N-S BT GamepadDocument1 pagePG-SW023说明书 100G铜版纸双面印刷/单色印刷 尺寸:105x142mm: N-S BT Gamepadnarendrabagus123No ratings yet

- E3x Dac SDocument2 pagesE3x Dac StorrescrcjavierNo ratings yet

- AS_139626_MU-N_IM_96M17813_WW_GB_2014_1Document2 pagesAS_139626_MU-N_IM_96M17813_WW_GB_2014_1vripl.eprog.17No ratings yet

- CCT551003 HW 2016 38 en ZHDocument4 pagesCCT551003 HW 2016 38 en ZHSepuloh LabakhsiNo ratings yet

- Pocket-GT Eng02 WDocument1 pagePocket-GT Eng02 WAntônio NetoNo ratings yet

- FX3U 485ADP MB安裝manual - JY997D26301aDocument2 pagesFX3U 485ADP MB安裝manual - JY997D26301ahsuyiweiNo ratings yet

- KT-302H Series: Instruction ManualDocument1 pageKT-302H Series: Instruction ManualputrastevanofyNo ratings yet

- Plano Electrico 320BUDocument2 pagesPlano Electrico 320BUANA MARIANo ratings yet

- Panel component explanationDocument2 pagesPanel component explanationMarcio CruzNo ratings yet

- F200 Quick Start Guide: 1-Wire Sensor Connections Leak Detection Sensing CableDocument2 pagesF200 Quick Start Guide: 1-Wire Sensor Connections Leak Detection Sensing CableHector Ernesto Cordero AmaroNo ratings yet

- Component Locations: 345D and 349D Excavator Accugrade Electrical SystemDocument2 pagesComponent Locations: 345D and 349D Excavator Accugrade Electrical SystemRodrigo EvaristoNo ratings yet

- Guia Rapida C2 ENDocument1 pageGuia Rapida C2 ENaquaicejuanNo ratings yet

- Yamaha MG10XU ManualDocument2 pagesYamaha MG10XU ManualnewgytNo ratings yet

- Hacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesFrom EverandHacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesRating: 5 out of 5 stars5/5 (1)

- Owner's Guide: Clean Base Automatic Dirt DisposalDocument7 pagesOwner's Guide: Clean Base Automatic Dirt Disposalpedro parahybaNo ratings yet

- Immersion Suits Pressure Test Requirements1114Document4 pagesImmersion Suits Pressure Test Requirements1114rk singhNo ratings yet

- GR-900EX-4: Hydraulic Rough Terrain CraneDocument16 pagesGR-900EX-4: Hydraulic Rough Terrain CraneboooNo ratings yet

- Solar Systems: and Parts CatalogDocument8 pagesSolar Systems: and Parts Catalogmauro zarateNo ratings yet

- DeshumedecedorDocument35 pagesDeshumedecedorJack Duff50% (2)

- Eh tw480Document12 pagesEh tw480fefotroncitoNo ratings yet

- Dfs-tp-Ah-001-Us 012h10 Lgtechpaper Errorcodes Ls 091-121 HSVDocument2 pagesDfs-tp-Ah-001-Us 012h10 Lgtechpaper Errorcodes Ls 091-121 HSVbestxeroxshopNo ratings yet

- Section 3 Hydraulic SystemDocument3 pagesSection 3 Hydraulic SystemRafał DworakNo ratings yet

- 10A) Brochure Bevel GearsDocument4 pages10A) Brochure Bevel GearsAnonymous srN69mFENo ratings yet

- Himel Productos 70 9Document13 pagesHimel Productos 70 9eng.ahmed.radwanNo ratings yet

- Electrical Plan 1Document1 pageElectrical Plan 1Kherstine Muyano TantayNo ratings yet

- YcmDocument4 pagesYcmPrima YuwanaNo ratings yet

- ADM Approved Third Party Inspection Companies Updated 03Oct2021-ENDocument4 pagesADM Approved Third Party Inspection Companies Updated 03Oct2021-ENrajeshjoel26No ratings yet

- Pruftechnik-PULLALIGN Serie SheetDocument4 pagesPruftechnik-PULLALIGN Serie Sheetnguyenhaiphap50nlNo ratings yet

- 16 Drawer DresserDocument16 pages16 Drawer DresserTanga ManagementNo ratings yet

- VG MeDocument1 pageVG Memuhammad sandyNo ratings yet

- Tripod Inspection Form - FillableDocument1 pageTripod Inspection Form - FillablehienleeNo ratings yet

- Guia Motores Perkins IndustrialesDocument37 pagesGuia Motores Perkins IndustrialesMartin Flores67% (3)

- Telecrane Radio Remote Control F21 Series & F24 Series ManualDocument40 pagesTelecrane Radio Remote Control F21 Series & F24 Series Manualelin373No ratings yet

- A Universal Programming Cable For Radios: Schematic DiagramDocument60 pagesA Universal Programming Cable For Radios: Schematic Diagrambairt1972No ratings yet

- Fire Risk Assessment - 1Document4 pagesFire Risk Assessment - 1Zulfikar FitrahNo ratings yet

- LOCOMOTIVE FUEL SYSTEM MANUALDocument9 pagesLOCOMOTIVE FUEL SYSTEM MANUALyuri peña quispeNo ratings yet

- Iecex Ul 09.0010XDocument7 pagesIecex Ul 09.0010XFrancesco_CNo ratings yet

- Data Usulan R.S Ngawi 24Document26 pagesData Usulan R.S Ngawi 24medina madinahNo ratings yet

- Ken Pickerill - Today's Technician - Automotive Brake Systems, Shop Manual (2018, Cengage Learning) - Libgen - LiDocument567 pagesKen Pickerill - Today's Technician - Automotive Brake Systems, Shop Manual (2018, Cengage Learning) - Libgen - LiLovren “Lovren” LovrenNo ratings yet

- Komatsu Wa600 3 Wa600 3d TBG Spec Wheel Loader Service Repair ManualDocument20 pagesKomatsu Wa600 3 Wa600 3d TBG Spec Wheel Loader Service Repair Manualedna100% (36)

- MTPL-OM-PPM-CL-007 - PPM Checklist For TrackerDocument2 pagesMTPL-OM-PPM-CL-007 - PPM Checklist For TrackerVeerendra YduvanshiNo ratings yet

- Pce 28Document3 pagesPce 28Pop-Coman SimionNo ratings yet

- SECCIÓN 211-05 Interruptores de La Columna de La Dirección: Página ContenidoDocument7 pagesSECCIÓN 211-05 Interruptores de La Columna de La Dirección: Página ContenidoAdolfo BelloNo ratings yet

- S87389 ALUCAN Tetrad 202 CDL LOE X1 Tab Minster Press SparesDocument2 pagesS87389 ALUCAN Tetrad 202 CDL LOE X1 Tab Minster Press SparesRicardo Calmon0% (1)