Professional Documents

Culture Documents

Caustic Recovery NF

Uploaded by

RamkiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caustic Recovery NF

Uploaded by

RamkiCopyright:

Available Formats

0

Hydranautics Process Membrane

Presentation

to

Manikandan Henry Daniel Raj

Sr. Field Regional Account Executive

Service Engineer Process Separations

©2020 Nitto Denko Corporation. All Rights Reserved.

Mercerization in Textiles

Mercerization is a chemical treatment process in

which textiles (typically cotton) are treated with a

caustic (NaOH) solution.

• Improve Luster

• Increase ability to absorb dye

• Improve reaction with a variety of chemicals

• Improve stability of form

• Improve strength/elongation

• Improve smoothness

The caustic actually rearranges the cellulose molecules

in the fiber to produce these changes. Higher-end

fabrics may be double or triple mercerized for added

benefits.

©2020 Nitto Denko Corporation. All Rights Reserved.

What all can be Mercerized

1. Cotton Fibers & Fabrics

2. Yarn for Denim

3. Linen

4. Wool

Mercerization of denim is usually carried out after the denim is

woven, and so it is different from the more common method of

mercerizing cotton yarn.

Mercerization of denim may be used for achieving ring dyeing,

thus keeping the dye on the surface of the yarns or fabrics

and to prevent dyes from fully penetrating the fibers.

©2020 Nitto Denko Corporation. All Rights Reserved.

Mercerization Process 5

The treatment consists of immersing the yarn or fiber in a

solution of sodium hydroxide (caustic soda) for short periods

of time, usually less than four minutes.

The material is then treated with water or acid to neutralize

the sodium hydroxide. If the material is held under tension

during this stage, it is kept from shrinking appreciably; if no

tension is applied, the material may shrink by as much as

one-fourth.

©2020 Nitto Denko Corporation. All Rights Reserved.

Factors of Mercerizing 6

Effective Mercerization requires attention to following variables

Twaddle (Concentration of NaOH):

If the concentration of NaOH is increased, improvement in luster will be attained but if it is decreased, the

quality of luster will begin to be adversely affected.

Temperature:

High degree of luster is attained at temperature 18-20Deg C. As the temperature is increased the quality of

luster is adversely affected but on lowering the temperature no improvement in the luster is obtained.

Tension:

For acquiring better luster the material must be stretch to its original dimension (both in warp and weft

direction during mercerization). If the material is allowed to shrink during mercerizing then quality of luster

will be impaired.

Time:

The optimum time for mercerizing is 30-60 seconds to maximum 5 minutes

©2020 Nitto Denko Corporation. All Rights Reserved.

8

Feed Parameters

Sno. Location Typical Feed Parameters

Typical 225 to 325gpl at room temp. (23 to 33% Conc). 4litres of

1 Feed to Caustic Bath

water per Kg of fabric.

2 Drain from Caustic Bath / Feed to CRP Caustic at 30 to 50gpl at 80 DegC

3 Expected outlet quality from CRP Caustic at 280gpl

1 2 3

©2020 Nitto Denko Corporation. All Rights Reserved.

9

Typical Caustic Recovery Process (CRP)

Weak

Caustic

Lye

Strong

Caustic Lye

post CRP

©2020 Nitto Denko Corporation. All Rights Reserved.

Caustic Recovery Process with NF 10

Weak

Caustic

Lye

Strong

Caustic

Lye post

CRP

with NF

©2020 Nitto Denko Corporation. All Rights Reserved.

• Chemically tolerant NF

membranes

HYDRACoRe • Works at 80 DegC

• Low and high pH

Nanofiltration tolerance

Solutions for

Caustic Recovery

©2020 Nitto Denko Corporation. All Rights Reserved.

12

©2020 Nitto Denko Corporation. All Rights Reserved.

13

©2020 Nitto Denko Corporation. All Rights Reserved.

Benefits of NF based pretreatment 14

• Decolorization of weak caustic lye which helps in reusing it for Light shades also

• Removal of color helps in reducing the scale formation in MEE, there by better system performance

• More reuse of weak caustic lye, there by reducing the load to ETP and subsequent OPEX reduction

©2020 Nitto Denko Corporation. All Rights Reserved.

16

THANK YOU

©2020 Nitto Denko Corporation. All Rights Reserved.

You might also like

- Project ProposalDocument2 pagesProject ProposalSaidur Rahman Sajib100% (3)

- Clariantmildsurfactants PDFDocument39 pagesClariantmildsurfactants PDFcontentdrive4 drive4No ratings yet

- The World Quality Leader in Cashew Liquid Technology: Coating Products PortfolioDocument8 pagesThe World Quality Leader in Cashew Liquid Technology: Coating Products Portfolioمحمد عزتNo ratings yet

- Magnasoft 986ntDocument4 pagesMagnasoft 986ntbobbymayaaNo ratings yet

- CarbolineDocument18 pagesCarbolineimaduddinshaNo ratings yet

- LavaSperseBase 01Document2 pagesLavaSperseBase 01UtpalNo ratings yet

- Revacryl Ae 4620 JaDocument1 pageRevacryl Ae 4620 Jazaryab khanNo ratings yet

- Abe Construction Chemicals Ds Epidermix365Document3 pagesAbe Construction Chemicals Ds Epidermix365Brendon BNo ratings yet

- Clariant Flyer Plantasens Olive LDDocument2 pagesClariant Flyer Plantasens Olive LDNadia GrafNo ratings yet

- MK - Adhesive Used in - Corugate IndustryDocument2 pagesMK - Adhesive Used in - Corugate Industryamila209No ratings yet

- Ion Exchange Resins: Products ManualDocument13 pagesIon Exchange Resins: Products Manualnermeen ahmedNo ratings yet

- Keratech Eco FlowDocument1 pageKeratech Eco Flowzaid8182No ratings yet

- Fluent Comprehensive BrochureDocument6 pagesFluent Comprehensive Brochurepallavan.kNo ratings yet

- Selection & Specification Data Substrates & Surface PreparationDocument2 pagesSelection & Specification Data Substrates & Surface PreparationJuanNo ratings yet

- Interspeed 6200/6200NA: Controlled Depletion Polymer AntifoulingDocument2 pagesInterspeed 6200/6200NA: Controlled Depletion Polymer AntifoulingHaidar KurniaNo ratings yet

- Bauder LiquiFINISH Product Data SheetDocument2 pagesBauder LiquiFINISH Product Data Sheetshivarajs12340987No ratings yet

- Reducing The Environmental Impact of Paint Removal of Marine VesselsDocument19 pagesReducing The Environmental Impact of Paint Removal of Marine VesselsIoannis MetsiosNo ratings yet

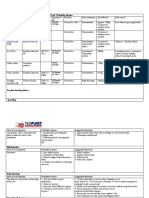

- Viscosity of Different Printing PasteDocument29 pagesViscosity of Different Printing Pastefathi mustafaNo ratings yet

- Chempart SC 400 TDSDocument1 pageChempart SC 400 TDSmarco_ravelo_10No ratings yet

- Introduction To Suspension Concentrate (SAI June 2021)Document19 pagesIntroduction To Suspension Concentrate (SAI June 2021)Richard HartonoNo ratings yet

- Visen Industries Ltd. : Visicryl 76Document3 pagesVisen Industries Ltd. : Visicryl 76Kamal RaoNo ratings yet

- PAVISINT SEALER 45 - enDocument2 pagesPAVISINT SEALER 45 - enrjmscNo ratings yet

- Whitechem PPG 2000 TdsDocument1 pageWhitechem PPG 2000 TdsGİZEM DEMİRNo ratings yet

- Ciba Invatex MD: Cracking AgentDocument12 pagesCiba Invatex MD: Cracking Agentomer reis100% (1)

- Zincanode 620 Voc v1 Jan 2018Document2 pagesZincanode 620 Voc v1 Jan 2018Moin AltafNo ratings yet

- LAB Histopathologic-Technique EmbeddingInfiltration Finals 002Document3 pagesLAB Histopathologic-Technique EmbeddingInfiltration Finals 002Jashmine May TadinaNo ratings yet

- Technical Presentation: Improve Water Resistance With Rheology AdditivesDocument30 pagesTechnical Presentation: Improve Water Resistance With Rheology AdditivesAPEX SON100% (1)

- Hydranautics - Nitto Membrane Applications, Case Studies, Lessons LearntDocument37 pagesHydranautics - Nitto Membrane Applications, Case Studies, Lessons Learntkalyan patilNo ratings yet

- SACI® 6400 - Daubert Chemical Company, Inc.Document2 pagesSACI® 6400 - Daubert Chemical Company, Inc.Long An ĐỗNo ratings yet

- Crude Oil DesulphurizationDocument11 pagesCrude Oil DesulphurizationmartinNo ratings yet

- Epilux 58 M.I.O.: Product DescriptionDocument2 pagesEpilux 58 M.I.O.: Product DescriptionMoin AltafNo ratings yet

- Denim Garments Processing 1Document14 pagesDenim Garments Processing 1Mudassar AliNo ratings yet

- Anti Fouling Paints ComparedDocument6 pagesAnti Fouling Paints ComparedDean Foote100% (1)

- Enduro MG Product Data SheetDocument1 pageEnduro MG Product Data SheetAbu Bilal AbdillahNo ratings yet

- Paints and CoatingsDocument28 pagesPaints and CoatingsMaximiliano MackeviciusNo ratings yet

- VITEC 55™ Antiscalant/Dispersant - Liquid Product DatasheetDocument1 pageVITEC 55™ Antiscalant/Dispersant - Liquid Product DatasheetaftabNo ratings yet

- International Intertuf 262Document4 pagesInternational Intertuf 262shunanlatheefNo ratings yet

- Lamination Non ConformancesDocument3 pagesLamination Non ConformancesMATTHEW MUNGAINo ratings yet

- Garment Dyeing With PigmentsDocument30 pagesGarment Dyeing With Pigmentsyadi haryadiNo ratings yet

- Datasheet Z-PrimercoatDocument1 pageDatasheet Z-PrimercoatСтанислав ПодольскийNo ratings yet

- Epvc 367NKDocument1 pageEpvc 367NKDevashish AgnihotriNo ratings yet

- Crystic 625PA: Isophthalic Resin For Large StructuresDocument2 pagesCrystic 625PA: Isophthalic Resin For Large StructuresEldiyar AzamatovNo ratings yet

- Epilux 800Document2 pagesEpilux 800anandNo ratings yet

- Pds Zincanode 620 VocDocument2 pagesPds Zincanode 620 VocmuthukumarNo ratings yet

- Redicote E-7000: Versatile Emulsifier: Provides Both AniDocument1 pageRedicote E-7000: Versatile Emulsifier: Provides Both AniRabin Bera0% (1)

- Pds Zincanode 690 VocDocument2 pagesPds Zincanode 690 VocmuthukumarNo ratings yet

- Clariant - Hydroperm RPU New Liq C - FTDocument4 pagesClariant - Hydroperm RPU New Liq C - FTAna AntunesNo ratings yet

- Tech Tip 3 - Viscosity and TIDocument2 pagesTech Tip 3 - Viscosity and TIflavioferiNo ratings yet

- Agc-40 CS AwDocument2 pagesAgc-40 CS AwlartarorNo ratings yet

- Investing in Ethiopia's Industrial Minerals - DiatomiteDocument4 pagesInvesting in Ethiopia's Industrial Minerals - Diatomiteamsalu_fkNo ratings yet

- LavaCellPower 01Document2 pagesLavaCellPower 01UtpalNo ratings yet

- AISIN Fully Synthetic AFW Dex III Product DatasheetDocument2 pagesAISIN Fully Synthetic AFW Dex III Product DatasheetMurphy Salbino TaquioNo ratings yet

- Cashewnut Shell LiquidDocument4 pagesCashewnut Shell LiquidakashNo ratings yet

- Epilux 155Document2 pagesEpilux 155Allana100% (1)

- Epimastic 7200: Product DescriptionDocument2 pagesEpimastic 7200: Product DescriptionSu KaNo ratings yet

- Liquid Nitrogen GasDocument9 pagesLiquid Nitrogen GasFuture EngineersNo ratings yet

- General Properties Rheological Properties: PVC Paste Resin (Homopolymer)Document2 pagesGeneral Properties Rheological Properties: PVC Paste Resin (Homopolymer)AminulIslamNo ratings yet

- AFM - Solbar Case StudyDocument1 pageAFM - Solbar Case StudyBlanca VelezNo ratings yet

- Lec-8 EtchingDocument20 pagesLec-8 Etchingmohammad.eee.200105229No ratings yet

- Chempart SC 100 2016 PDFDocument1 pageChempart SC 100 2016 PDFDeepak WalhekarNo ratings yet

- Filmtec Fortilife Cr-100I: Is Your Site Getting Ready To Replace Reverse Osmosis Elements?Document1 pageFilmtec Fortilife Cr-100I: Is Your Site Getting Ready To Replace Reverse Osmosis Elements?Yang SunmanNo ratings yet

- Caustic Recovery Using NFDocument14 pagesCaustic Recovery Using NFRamkiNo ratings yet

- P&id - GDCL - Etp 70 KLD MBR - R3 - 19.09.20Document1 pageP&id - GDCL - Etp 70 KLD MBR - R3 - 19.09.20RamkiNo ratings yet

- PIBE Inclined Plate ClarifiersDocument6 pagesPIBE Inclined Plate ClarifiersRamkiNo ratings yet

- Rajapalayam Textile Mill Visit Report For CRP - SGPDocument2 pagesRajapalayam Textile Mill Visit Report For CRP - SGPRamkiNo ratings yet

- Rim-Flo ClarifiersDocument8 pagesRim-Flo ClarifiersRamkiNo ratings yet

- Nanofiltration Membranes Synthesis, Characterization, and Applications by Ismail, Ahmad Fauzi Jye, Lau WoeiDocument184 pagesNanofiltration Membranes Synthesis, Characterization, and Applications by Ismail, Ahmad Fauzi Jye, Lau WoeiRamkiNo ratings yet

- UAE Cooling Tower Blow DownDocument3 pagesUAE Cooling Tower Blow DownRamkiNo ratings yet

- Package Treatment Plant Drawing P09-ESC A&bDocument2 pagesPackage Treatment Plant Drawing P09-ESC A&bRamkiNo ratings yet

- PRESENTATION CcwsDocument61 pagesPRESENTATION CcwsRamkiNo ratings yet

- Making The Grade On Safe Drinking Water For The City of Boca RatonDocument4 pagesMaking The Grade On Safe Drinking Water For The City of Boca RatonRamkiNo ratings yet

- Chemical Coagulants Used in Water Treatment: Chemistry Industry SectorsDocument3 pagesChemical Coagulants Used in Water Treatment: Chemistry Industry SectorsRamkiNo ratings yet

- Activated Sludge ProcessDocument162 pagesActivated Sludge ProcessRamkiNo ratings yet

- Membrane Fouling PredectionDocument31 pagesMembrane Fouling PredectionRamkiNo ratings yet

- Filter Press Size CalculationDocument3 pagesFilter Press Size CalculationRamki0% (1)

- Flux Decline:: Concentration Polarization Is A Term Used in The Scientific FieldsDocument15 pagesFlux Decline:: Concentration Polarization Is A Term Used in The Scientific FieldsRamkiNo ratings yet

- Feed SpacerDocument239 pagesFeed SpacerRamkiNo ratings yet

- Webinar On " How To Re-Start Your ETP & STP After Lockdown ? by - Ashutosh Vadanagekar - Amalgam BiotechDocument45 pagesWebinar On " How To Re-Start Your ETP & STP After Lockdown ? by - Ashutosh Vadanagekar - Amalgam BiotechRamkiNo ratings yet

- Water CalculationDocument6 pagesWater CalculationRamkiNo ratings yet

- Design Calculations: Flash Mixing TankDocument4 pagesDesign Calculations: Flash Mixing TankRamkiNo ratings yet

- Membrane FoulingDocument17 pagesMembrane FoulingRamkiNo ratings yet

- Water TechnologyDocument15 pagesWater TechnologyRamkiNo ratings yet

- Unit 22Document4 pagesUnit 22thienthanboyNo ratings yet

- Denim Jeans Stitching Unit (Rs. 19.04, Dec-2015)Document21 pagesDenim Jeans Stitching Unit (Rs. 19.04, Dec-2015)Hammad TauqeerNo ratings yet

- Denim Jeans Project (1) (1) NewDocument10 pagesDenim Jeans Project (1) (1) Newsherrinmaryaliyas23No ratings yet

- Industrial Visit Report On Amber DenimDocument3 pagesIndustrial Visit Report On Amber DenimMaisha MalihaNo ratings yet

- Defects of GarmentsDocument10 pagesDefects of GarmentsSîronamHin MonirNo ratings yet

- Weaving Commission CalculationsDocument1 pageWeaving Commission Calculationsraj_85No ratings yet

- Life Cycle Assessment of Reuse and Recycle of Denim Fabric in The Textile IndustryDocument70 pagesLife Cycle Assessment of Reuse and Recycle of Denim Fabric in The Textile IndustryVersha AmyNo ratings yet

- Diesel Denim SS 2011Document21 pagesDiesel Denim SS 2011thomasso1981No ratings yet

- Indigo Dyeing Machinery The Concept Dyes Chemicals Express TextileDocument6 pagesIndigo Dyeing Machinery The Concept Dyes Chemicals Express TextilechtamoorNo ratings yet

- Assignment: Name: Farhan Eshraq Jesun ID:1720446 SEC:3Document5 pagesAssignment: Name: Farhan Eshraq Jesun ID:1720446 SEC:3Farhan Eshraq JeshanNo ratings yet

- Denim Brochures 2Document7 pagesDenim Brochures 2Talha NafeesNo ratings yet

- Factory Profile of Smart Jeans LTD (11!04!12)Document8 pagesFactory Profile of Smart Jeans LTD (11!04!12)tareqsmartjeans100% (2)

- 01 EXPRESS Apparel Performance Standards Guidance Manual - REV 2-6jan 201 PDFDocument56 pages01 EXPRESS Apparel Performance Standards Guidance Manual - REV 2-6jan 201 PDFNguyễn Thanh QuỳnhNo ratings yet

- Wrinkle Finish On Denim by Resin Treatment PDFDocument6 pagesWrinkle Finish On Denim by Resin Treatment PDFAzizNo ratings yet

- Bb178919 - Irfan Khan NDocument75 pagesBb178919 - Irfan Khan NNagaveniNo ratings yet

- Sourcing of DenimDocument11 pagesSourcing of DenimSeveshNo ratings yet

- F0118-i1STF (1HL) (17.05.23) (R-613)Document1 pageF0118-i1STF (1HL) (17.05.23) (R-613)Beximco Denim LabNo ratings yet

- Textail Asia 2012 Event Catalog PDFDocument153 pagesTextail Asia 2012 Event Catalog PDFMuhammad Farooq Kokab100% (1)

- Activity Sheet in TNCT: Members: 12-Humsst - Ignatius Mrs - Maria Elena DascoDocument17 pagesActivity Sheet in TNCT: Members: 12-Humsst - Ignatius Mrs - Maria Elena DascoVera Eunice ButaNo ratings yet

- B.tech English NotesDocument32 pagesB.tech English Notessharik2022bele022No ratings yet

- Untouched World Untouched World: West of Windwhistle, Winter 2006Document37 pagesUntouched World Untouched World: West of Windwhistle, Winter 2006kiwigirl74No ratings yet

- A Short History of DenimDocument7 pagesA Short History of Denimapi-3838281100% (1)

- Fabric and Garment FinishingDocument33 pagesFabric and Garment FinishingSurya Bakshi100% (4)

- SKU Size Colour Kurti FabricDocument4 pagesSKU Size Colour Kurti FabricAnurag KanaujiaNo ratings yet

- Mens FashionDocument45 pagesMens FashionGopi KrishnaNo ratings yet

- Arvind Textiles Internship ReportDocument107 pagesArvind Textiles Internship ReportKim hyun Jin16No ratings yet

- Tintin PDFDocument2 pagesTintin PDFSaidur Rahman SajibNo ratings yet

- Garment ProcessingDocument35 pagesGarment ProcessingKeshav Dhawan0% (1)

- Denim Jeans: Part Number Part Name Description Supplier Country of OriginDocument1 pageDenim Jeans: Part Number Part Name Description Supplier Country of OriginRafiul HasanNo ratings yet