Professional Documents

Culture Documents

Typical - Package ITP

Uploaded by

randyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Typical - Package ITP

Uploaded by

randyCopyright:

Available Formats

Managementsystem

FO-730-715-108

Form

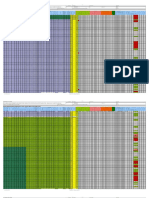

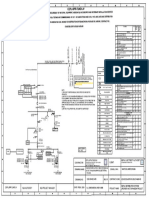

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

CONTENTS

BARE COMPRESSOR ..................................................................................................................................................................................................................................................... 3

MAIN MOTOR .................................................................................................................................................................................................................................................................. 3

PULSATION VESSELS ................................................................................................................................................................................................................................................... 3

LUBE OIL COOLER (RADIATOR TYPE) .................................................................................................................................................................................................................... 3

CLOSED WATER CONSOLE COOLER (AIR COOL HEAT EXCHANGER) ......................................................................................................................................................... 3

DELETED .......................................................................................................................................................................................................................................................................... 3

DELETED .......................................................................................................................................................................................................................................................................... 3

GAS PIPING ...................................................................................................................................................................................................................................................................... 3

PURGE SYSTEM AND VENT/DRAIN PIPING .......................................................................................................................................................................................................... 5

COOLING WATER SYSTEM ......................................................................................................................................................................................................................................... 6

LUBE OIL SYSTEM .......................................................................................................................................................................................................................................................13

DELETED ........................................................................................................................................................................................................................................................................18

DELETED ........................................................................................................................................................................................................................................................................18

MISCELLANEOUS ITEMS ...........................................................................................................................................................................................................................................18

Discharge check valve (if applicable) .............................................................................................................................................................................................................................19

Local panel ......................................................................................................................................................................................................................................................................19

Suction Process Strainer ..................................................................................................................................................................................................................................................19

All instrument Fittings & Tubes ......................................................................................................................................................................................................................................19

PSV on purge gas system................................................................................................................................................................................................................................................19

PSV on Oil system ...........................................................................................................................................................................................................................................................19

Pressure /Level/Temp./DPT Transmitter (as applicable) ...............................................................................................................................................................................................19

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01.12.2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 1 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Sight Glass (as applicable) ............................................................................................................................................................................................................................................... 20

Level Gauge (as applicable) ............................................................................................................................................................................................................................................20

Rota meter.........................................................................................................................................................................................................................................................................20

Cables................................................................................................................................................................................................................................................................................20

Cable Tray ........................................................................................................................................................................................................................................................................20

RTD’s................................................................................................................................................................................................................................................................................20

Cable Gland ......................................................................................................................................................................................................................................................................20

Spare parts ........................................................................................................................................................................................................................................................................20

All Instrumentation / Junction Boxes (Procured from Project approved vendors only) .............................................................................................................................................20

Main Skid + Motor slide rail ...........................................................................................................................................................................................................................................22

Flywheel guard .................................................................................................................................................................................................................................................................22

Piping Support, Instrument Rack& Support ...................................................................................................................................................................................................................22

Isolation Valves (Functional testing,...............................................................................................................................................................................................................................22

hydro test/pneumatic test ) ..............................................................................................................................................................................................................................................22

Restriction Orifice plates .................................................................................................................................................................................................................................................22

Cable Tray ........................................................................................................................................................................................................................................................................22

Lube Oil Heater ................................................................................................................................................................................................................................................................22

Cooling water Heater .......................................................................................................................................................................................................................................................22

COMPLETE MAIN SKID PACKAGE .........................................................................................................................................................................................................................23

QUALITY DOSSIER ......................................................................................................................................................................................................................................................23

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01.12.2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 2 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Separate ITP shall be submitted for Compressor for

1.0 BARE COMPRESSOR

Review

Separate ITP shall be submitted for Main Motor for

2.0 MAIN MOTOR

Review

PULSATION VESSELS Separate ITP shall be submitted for Pulsation vessel

3.0

(Suction & Discharge) for Review

LUBE OIL COOLER (RADIATOR Separate ITP shall be submitted for Lube oil cooler

4.0

TYPE) for Review

CLOSED WATER CONSOLE Separate ITP shall be submitted for closed water

COOLER (AIR COOL HEAT

5.0 EXCHANGER) console cooler for Review

6.0 DELETED

7.0 DELETED

8.0 CS GAS PIPING 0

Checking of received mat’s and API-618/ ASTM / ANSI B-

Per Documents /

8.1 components Dimensions, NEA 36.10 / ANSI B36.19 / NEA - RD RD RD 0

Type 3.1

completeness, quantity, flange face Piping Isometric Drawing/

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01.12.2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 3 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

roughness, mat’s certificates, job piping material spec.

material traceability (Refer Note) requirements for hydrogen

service

Compliance with iso.

Cutting, Weld preparation, Spool Isometric dwg. / ASME

8.2 NEA dwg. / As per - RD RD RD 0

assemblies Section IX /

specification

Welding - Weld information / Weld

8.3 NEA ASME Section IX Per Specification - RD RD RD 0

Procedure qualifications

8.4 Stud bolts and nuts NEA Pipe Material spec Per Specification - RD RD RD 0

8.5 Gaskets NEA Pipe Material spec Per Specification - RD RD RD 0

As per specifications,

Per Code / Per

8.6 Material Test Certificates NEA ASME Pressure Vessel - RD RD RD 0

Specs. /Type 3.1

Code Sect.-II

PWHT of weld joints & Radiography ASME 31.3 / ASME

8.8 NEA Per Code - RD* RD* RD 0

Test (100%) Section-VIII, Div-I

8.9 Hydrostatic Test and Drying NEA ASME Section-VIII, Div-I Per Code/ drawing - WP RN RD 0

Surface preparation & External Approved Unit Paint

8.10 NEA Per Approved Paint Plan - RD RD RD 0

painting Plan

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01.12.2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 4 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Approved Approved Documents

8.11 Inspection Data book & IRN NEA RD RD RD RD 0

Drawing & Documents & ITP

8.12 Packing & Shipping NEA Mfg. Std. Procedure Mfg. Std. Procedure - RD RD RD 0

PURGE SYSTEM AND

9.0 CS 0

VENT/DRAIN PIPING

Checking of received mat’s and

API-618/ ASTM / ANSI B-

components Dimensions,

36.10 / ANSI B36.19 / NEA Per Documents /Type

9.1 completeness, quantity, flange face NEA - RD RD RD 0

Piping Isometric Drawing. 3.1

roughness, mat’s certificates,

material traceability

Checking of received mat’s and

API-618/ ASTM / ANSI B-

components Dimensions,

36.10 / ANSI B36.19 / NEA Per Documents /Type

9.1 completeness, quantity, flange face NEA - RD RD RD 0

Piping Isometric Drawing. 3.1

roughness, mat’s certificates,

material traceability

Compliance with iso.

Cutting, Weld preparation, Spool Isometric dwg. / ASME

9.2 NEA dwg. / As per - RD RD RD 0

assemblies Section IX /

specification

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 5 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Welding - Weld information / Weld

9.3 NEA ASME Section IX Per Specification - RD RD RD 0

Procedure qualifications

9.4 Stud bolts and nuts NEA Pipe Material spec Per Specification - RD RD RD 0

9.5 Gaskets NEA Pipe Material spec Per Specification - RD RD RD 0

As per specifications, Per Code / Per

9.6 Material Test Certificates NEA ASME Pressure Vessel Specs. /Type 3.1 & - RD RD RD 0

Code Sect.-II 2.2

Dimensional control of completed Per isometric

9.7 NEA Isometric Dwg. - RD RD RD 0

pipe spools drawings

Per Code/ As per

9.8 RT- Spot per code (10%) NEA ASME Section-VIII, Div-I - RD* RD* RD 0

drawing

Per Code/ As per

9.9 Hydrostatic Test and Drying NEA ASME Section-VIII, Div-I - WP RN RD 0

drawing

Approved Unit Paint

9.10 External painting NEA Per Approved Paint Plan - WP RD RD 0

Plan

9.11 Packing & Shipping NEA Per Mfg. Standard Per Mfg. Standard - RD RD RD 0

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 6 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

C Suction Strainer RD 0

Make, Type, Material, Mesh, Hydro

10.5 ASTM Sec. II Part A ASTM Sec. II Part A RD RD RD RD 0

Test

10.6 Check for Process Connection RD RD RD RD 0

Mfg. Std. Drg Mfg. Std. Drg

D Valves 0

Make, Type, Material, Hydro test, Drg. Mfg. Std, NEA Drg. Mfg. Std, /

10.7 Approved Data Sheet for

WP WP RD RD 0

Set Point DS/QCP

Drg. Mfg. Std, NEA

Drg. Mfg. Std,

10.8 Check for Process Connection Approved Data Sheet for WP RD RD RD 0

DS/QCP

valves /QCP

E Instrument Manifolds 0

10.9 Make / Material / Hydro test Mfg. Std. Mfg. Std. RD RD RD RD 0

10.10 Check for Process Connection -- Mfg. Std. RD RD RD RD 0

F Sight Glass 0

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 7 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Make, Type, Size, Material, Hydro NEA As per approved As per approved

10.11 RD RD RD RD 0

test. drawing drawing

G Drive Motor 0

Make, Model, Mounting, Routing

test, Type test, Power supply,

Rating, RPM, Location of terminal NEA Approved Data Sheet Approved Data Sheet

10.12 box, No, of terminals, Degree of

WP WP RD RD 0

/ Mfg. Std./QCP / Mfg. Std.

Protection, Frame Size, Statutory

Certification (As applicable).

No. of Cable entries and size& NEA Approved Data Sheet Approved Data Sheet

10.13 RD RD RD RD 0

frame size / Mfg. Std./QCP / Mfg. Std.

H Instruments(PT,TT,PI,TI,TE,TD’s)

Make, Model / Material / Hydro test / Data Sheet / Approved / Data Sheet /

10.14 Calibration, statutory certificates (as Approved G.A. Drg./ Mfg. Approved G.A. Drg./ RD RD RD RD 0

applicable) Std. Mfg. Std.

Data Sheet Approved

10.15 Check for Process Connection -- RD RD RD RD 0

G.A. Drg./ Mfg. Std.

I JB & Push Button Station 0

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 8 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Dimensions / Model No. / Check for

Std. Product

Cable Entry Size & No. of Cable Std. Product Catalogue /

Catalogue / Mfg. Std.

10.16 Entries / No. of Terminals / Degree Mfg. Std. / NEA Approved RD RD RD RD 0

/ NEA Approved Drg.

of Protection, statutory certificates Drg.Std. / Approved Drg.

Std. / Approved Drg.

(as applicable)

J Pipes, Tubes and Plates 0

Surface Defects / Dimensional

10.17 ASME Sec II Part A,B ASME Sec II Part A,B RD RD RD RD 0

Check

Chemical Composition / Physical

10.18 ASME Sec II Part A,B ASME Sec II Part A,B RD RD RD RD 0

Properties

K Flanges / Fittings / Fasteners 0

BOM / ASME Sec. II

10.19 Material (Chemical & Mechanical) BOM / ASME Sec. II Part A RD RD RD RD 0

Part A/Type 3.1 & 2.2

ANSI B16.5 / B16.9 / ANSI B16.5 / B16.9 /

10.20 Visual Check and Dimensions RD RD RD RD 0

B16.11 B16.11

L Fabrication Control 0

10.21 Review of WPS / PQR / WPQ WPS/ PQR ASME Sec. IX RD RD RD RD 0

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 10 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Welding spec. / Approved. Welding spec. /

10.22 Weld Setup and Welding GA Drg. / P & ID, WPS- Approved. GA Drg. / RD RD RD RD 0

PQR P & ID, WPS-PQR

M Base Frame 0

Base Frame Fab.

Overall Dimensional / Foundation Base Frame Fab. Drg. /

10.23 Drg. / Approved GA RD RD RD RD 0

hole CTC Distance / Workmanship Approved GA Drg. & BOM

Drg. & BOM

O Piping 0

Liquid Penetrate Testing for ASME Sec. V / VIII

10.24 ASME Sec. V / VIII Div.1 RD RD RD RD 0

soundness of Weld Joints Div.1

Soundness of Butt Weld Joints by ASME Sec. V/VIII

10.25 ASME Sec. V/VIII Div. 1 RD RD RD RD 0

Radiographic Examination (10%) Div. 1

Hydro Test of Complete Approved GA Drg. / NO Approved GA Drg. /

10.26 RD WP WP RD 0

Interconnecting Piping leaks or Pr. drop NO leaks or Pr. drop

N Overall Final Inspection (Skid) 0

Terminal Point Dimensions and Approved GA Drg. P

10.27 NEA Approved GA Drg. P & I D RD RD RD RD 0

Tagging Verification &ID

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 11 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

PMI test for corrosion resistant alloy Per Specification / Per

10.28 Per Specification /

when used for Pressure retaining & NEA Code WP RD RD 0

Per Code

wetted parts per specs

Approved GA Drg. P

10.29 Visual Inspection for Completeness NEA Approved GA Drg. P & ID RD RD 0

& ID

Approved Painting

10.30 Surface Preparation & Painting NEA Approved Painting Plan RD RD RD RD 0

Plan

Approved Painting

10.31 Finishing DFT, Color Shade NEA Approved Painting Plan RD 0

Plan

10.32 Flushing Test of CWS Approved GA Drg. P & ID, Approved GA Drg. P WP WP

NEA & ID, Test Procedure RN 0

Test Procedure

Approved GA Drg. / P& ID / Approved GA Drg. /

10.33 Inspection Data book & IRN NEA

P& ID / 3.1 /MRB

RD WP RD 0

MRB Index

Pre - Dispatch Inspection, packing Approved G.A. Drg. P

10.34 NEA Approved G.A. Drg. P & ID RD RD RN RD 0

& shipping & ID

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 12 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

CS Skid

LUBE OIL SYSTEM.

11.0 & SS MS - - - 0

Piping

LO Pump

A 0

NEA Approved DS, Pump

Make, Type, Model, Material, Size Approved pump

11.1 Drg., API 676/ Cust. Spec./ RD RD RD RD 0

(Process Connection), Mounting. datasheet/QCP

Mfg. Std./QCP

Performance Test (RPM, Flow Rate,

Approved Data sheet, Pump

Suction & Dis. Pr., efficiency, Strip Approved pump

11.2 Drg., API 676/ Cust. Spec./ RD RD RD RD 0

Test, Sound level, Vibration – As datasheet

Mfg. Std. /QCP

applicable).

B Duplex Lube oil Filter 0

Data sheet/ Approved

Data sheet/ Approved GA

11.3 Make / Material GA drawing/ Mfg. RD RD RD RD 0

drawing/ Mfg. Drawing.

Drawing.

Data sheet/ Approved

Data sheet/ Approved GA

11.4 Dimensions GA drawing/ Mfg. RD RD RD RD 0

drawing/ Mfg. Drawing.

Drawing.

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 13 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

C Suction Strainer 0

Make, Type, Material, Mesh, Hydro

11.5 ASTM Sec. II Part A ASTM Sec. II Part A RD RD RD RD 0

Test

11.6 Check for Process Connection Mfg. Std. Drg Mfg. Std. Drg RD RD RD RD 0

D Valves (PCV, PSV, TCV) 0

Drg. Mfg. Std, Data Sheet Drg. Mfg. Std, Data

Make, Type, Material, Hydro test,

11.7 for PCV, TCV and PRV Sheet for PCV, TCV RD RD RD RD 0

Set Point

/QCP and PRV only. /QCP

Drg. Mfg. Std, Data Sheet Drg. Mfg. Std, Data

11.8 Check for Process Connection Sheet for PCV, TCV RD RD RD RD 0

for PCV, TCV and PRV

E Instrument Manifolds 0

11.9 Make / Material / Hydro test Mfg. Std. Mfg. Std. RD RD RD RD 0

11.10 Check for Process Connection -- Mfg. Std. RD RD RD RD 0

F Sight Glass (if applicable) 0

Make, Type, Size, Material, Hydro As per approved

11.11 As per approved drawing RD RD RD RD 0

test. drawing

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 14 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

G Drive Motor 0

Make, Model, Mounting, Routing

test, Type test, Power supply,

Rating, RPM, Location of terminal Approved Data Sheet / Mfg. Approved Data Sheet

11.12 RD WP RD RD 0

box, No, of terminals, Degree of Std. /QCP / Mfg. Std./QCP

Protection, Frame Size, Statutory

Certification (As applicable).

No. of Cable entries and size& frame IS 325, Approved Data IS 325, Approved Data

11.13 RD RD RD RD 0

size Sheet / Mfg. Std. Sheet / Mfg. Std.

Instruments

H 0

(PT,TT.DPI,PI,TI,TE,RTD’s)

Make, Model / Material / Hydro test / Data Sheet / Approved /

Data Sheet / Approved

11.14 Calibration, statutory certificates (as Approved G.A. Drg./ Mfg. RD RN RD RD 0

G.A. Drg./ Mfg. Std.

applicable) Std.

Data Sheet Approved

11.15 Check for Process Connection -- RD RN RD RD 0

G.A. Drg./ Mgf. Std.

I JB & Push Button Station 0

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 15 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Dimensions / Model No. / Check for

Std. Product

Cable Entry Size & No. of Cable Std. Product Catalogue /

Catalogue / Mfg. Std. /

11.16 Entries / No. of Terminals / Degree Mfg. Std. / Approved RD RD RD RD 0

Approved Drg.Std. /

of Protection, statutory certificates Drg.Std. / Approved Drg.

Approved Drg.

(as applicable)

J Pipes, Tubes and Plates 0

Surface Defects / Dimensional

11.17 ASME Sec II Part A,B ASME Sec II Part A,B RD RD RD RD 0

Check

Chemical Composition / Physical ASME Sec II Part A,B

11.18 ASME Sec II Part A,B RD WP RD RD 0

Properties /PMI /Type 3.1 & 2.2

K Flanges / Fittings / Fasteners 0

BOM / ASME Sec. II

11.19 Material (Chemical & Mechanical) BOM / ASME Sec. II Part A RD RD RD RD 0

Part A

ANSI B16.5 / B16.9 / ANSI B16.5 / B16.9 /

11.20 Visual Check and Dimensions RD RD RD RD 0

B16.11 B16.11

L Fabrication Control 0

11.21 Review of WPS / PQR / WPQ WPS/ PQR ASME Sec. IX RD RD RD RD 0

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 16 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Welding spec. / Approved. Welding spec. /

11.22 Weld Setup and Welding GA Drg. / P & ID, WPS- Approved. GA Drg. / P RD RD RD RD 0

PQR & ID, WPS-PQR

M Base Frame 0

Base Frame Fab. Drg.

Overall Dimensional / Foundation Base Frame Fab. Drg. /

11.23 / Approved GA Drg. & RD WP RD RD 0

hole CTC Distance / Workmanship Approved GA Drg. & BOM

BOM

N Piping 0

Liquid Penetrant Testing for ASME Sec. V / VIII

11.24 ASME Sec. V / VIII Div.1 RD RD RD RD 0

soundness of Weld Joints Div.1

Soundness of Butt Weld Joints by ASME Sec. V/VIII Div.

11.25 ASME Sec. V/VIII Div. 1 RD RD RD RD 0

Radiographic Examination 1

Hydro Test of Complete Approved GA Drg. / NO Approved GA Drg. /

11.26 WP WP RD 0

Interconnecting Piping leaks or Pr. drop NO leaks or Pr. drop

O Overall Final Inspection (Skid) MS /NEA 0

Terminal Point Dimensions and Approved GA Drg. P &

11.27 Approved GA Drg. P & I D RD WP RD 0

Tagging Verification ID

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 17 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Positive Material Identification (PMI) Per Specification / Per

11.28 Per Specification / Per Code WP RD RD 0

for all metallic alloy materials Code

As per approved test As per approved test

11.29 LOS Flushing Test H WP RN 0

procedure procedure

11.30 Visual Inspection for Completeness Approved GA Drg. P & ID Approved GA Drg. P & H WP RD 0

P Surface Preparation & Painting RD 0

11.31 Finishing DFT, Color Shade Approved Painting Plan Approved Painting RD RD RN RD 0

Approved GA Drg. / P& ID / Approved GA Drg. /

11.32 Inspection Data book & IRN P& ID / 3.1 /MRB RD H RD 0

MRB Index

Index

Pre - Dispatch Inspection, Packing & Approved G.A. Drg. P

11.33 Approved G.A. Drg. P & ID RD RD RN RD 0

Shipping & ID

12.0 DELETED

13.0 DELETED

14.0 MISCELLANEOUS ITEMS 0

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 18 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Discharge check valve (if

14.1 MS Per Document As per documents WP RD RD RD 0

applicable)

Approved drawings /NEA Approved drawings

14.2 Local panel MS Approved QCP /QCP WP WP RD RD 0

Functional & continuity Test / FAT of Per Document

14.3 MS Approved test procedure WP WP RN RD 0

Local Control Panel & PLC Panel. /Procedure

14.4 Suction Process Strainer MS Per Drawing Per Drawing WP RD RD RD 0

14.5 All instrument Fittings & Tubes MS Per Document As per documents WP RD RD RD 0

Per As per documents /

14.6 PSV on purge gas system MS WP WP RD RD 0

Document/Drawing/QCP drawing

As per documents /

14.7 PSV on Oil system MS Per Document/Drawing WP RD RD RD 0

drawing

Pressure /Level/Temp./DPT As per documents /

14.8 MS Per Document/Drawing WP RN RD RD 0

Transmitter (as applicable) drawing

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 19 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

As per documents /

14.9 Sight Glass (as applicable) MS Per Document/Drawing WP RD RD RD 0

drawing

As per documents /

14.10 Level Gauge (as applicable) MS Per Document/Drawing WP RD RD RD 0

drawing

Rota meter Per Document/Drawing As per documents /

14.11 MS WP RD RD RD 0

drawing

As per documents /

14.12 Cables MS Per Document/Drawing WP RN RD RD 0

drawing

14.13 Cable Tray MS Per Documents Per Document WP RD RD RD 0

14.14 RTD’s MS Per Documents Per Document WP RD RD RD 0

14.15 Cable Gland MS Per Document As per documents WP RD RD RD 0

Per approved spare

14.16 Spare parts NEA Per Document - WP RD RD 0

lsit documents

All Instrumentation / Junction Approved Instrument Per document

15.0 Various Boxes (Procured from Project MS 0

Data Sheets

approved vendors only)

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 20 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Per document

15.1 Bill of Material MS Approved instrument list RD RD RD RD 0

Per document

15.2 Gauges/ Transmitters/ Switches: MS Approved instrument list WP RN RD RD 0

Per document

15.3 Model No. MS Approved instrument list WP RD RD RD 0

Per document

15.4 Range MS Approved instrument list WP RD RD RD 0

15.5 Compliance Certificate MS Mfr. Standard Mfr. Standard WP RD RD RD 0

15.6 Instrument Tag MS Approved inst. List / P&ID Mfr. Standard WP WP RD RD 0

All Thermo wells Approved inst. List/ P&ID

15.7 MS Per document WP RN RD RD 0

Per document / type

15.8 Material Certificates MS Mfr. standard RD RD RD RD 0

3.1

Approved Junction Box

15.9 Local Junction Box MS wiring termination/Junction Per document WP RN RD RD 0

Box Specification

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 21 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

NEA Fabrication Per drawing / Per

16 Main Skid + Motor slide rail MS drawing/Dimensional NEA approved QCP / WP WP RD RD 0

Verification MTC 3.1

NEA Fabrication NEA Fabrication

Flywheel guard

17 MS drawing/Dimensional drawing/Dimensional WP WP RD RD 0

Verification Verification

18 Piping Support, Instrument MS NEA Fabrication drawing Per drawing WP WP RD RD 0

Rack& Support

Isolation Valves (Functional Manufacturer Manufacturer

19 testing, MS Standard/NEA approved Standard/NEA WP WP RD RD 0

hydro test/pneumatic test ) GA Drawing & QCP approved GA

As per NEA

20 Restriction Orifice plates MS As per NEA datasheet WP RD RD RD 0

datasheet

Per NEA approved

21 Cable Tray MS Mfg. Standard documents & test WP RN RD RD 0

reports

NEA Approved

22 Lube Oil Heater MS NEA Approved datasheet WP RD RD RD 0

datasheet

NEA Approved

23 Cooling water Heater MS NEA Approved datasheet WP RD RD RD 0

datasheet

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 22 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

24.0 COMPLETE MAIN SKID 0

PACKAGE

Verification of completed skid for

Dimensions / Alignment / Instrument GA, P&ID & Foundation Per document /

24.1 NEA WP WP WP 0

mountings / Battery Limit drawing. drawing.

connections.

24.2 Visual Inspection for Completeness NEA Approved GA Drg. P & ID Approved GA Drg. PID H WP RD 0

Approved Painting

24.3 Finishing DFT, Color Shade NEA Approved Painting Plan RD RD RN RD 0

Plan

Approved GA Drg. /

Approved GA Drg. / P& ID /

24.4 Inspection Data book & IRN NEA P& ID / Inspection RD H RD 0

documents

reports & Records

24.5 Packing & Shipping NEA Mfg. Standard Mfg. Standard RD RN RD 0

25 QUALITY DOSSIER NEA APPROVED QCP/ITP APPROVED QCP/ITP RD RD RD 0

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 23 / 24

Managementsystem

FO-730-715-108

Form

Quality Control / Inspection Test Plan for Skid Mounted Package Form Revision 1

Purchaser / Contractor – Ampol Refineries Ltd Project: 9K1C Replacement Project NEA CRM no.: 17277

Location: Australia

Type: -

R

Doc. Material Resp. Acceptance Purch 3rd

Sr.No Description of Activity Specification MS NEA e

No. (Qty.) Pers. Criteria aser party

v.

Note:

Material Test Certificate Type 3.1 replaces the 3.1B of previous edition of EN 10204

Material selection & Type 3.1 MTC for load carrying structural items, lifting lugs, Pressure retaining & wetted parts and Type 2.2 certificate for non-pressure parts &

non- process auxiliary parts.

Material Test Certificates for all items must be in compliance with project specs.

Cl2 content of hydro-test water quality shall be limited to max 50 ppm for Austenitic SS

Revision 0 *:Review of ‘x’/’r” Ray films-applicable

Date 01-12-2021 NB: Notified Body

Drawn SE H : Hold A : Approval

MS : Sub-Supplier WP : Witness RN : Random Witness FA : Final Approved

NEN : NEA Workshop Standard WP : Witness RD : Review Only Page: 24 / 24

You might also like

- ITP Format - Excel GEP 1120Document22 pagesITP Format - Excel GEP 1120raghuvarma100% (1)

- Environmental Aspects and Impacts Evaluation REV-003Document12 pagesEnvironmental Aspects and Impacts Evaluation REV-003sunthu100% (1)

- Larsen & Toubro Limited: ECC Division - EDRCDocument12 pagesLarsen & Toubro Limited: ECC Division - EDRCEngr. Nabid Rayhan KhalequeNo ratings yet

- Risk Assessment For Drainage uPVC PipesDocument1 pageRisk Assessment For Drainage uPVC PipesZameer Basha Navzath AliNo ratings yet

- QC Staff Rizqi FatullohDocument11 pagesQC Staff Rizqi FatullohRizqiNo ratings yet

- FMECA Worksheet: No. Functional Failures Failure Modes Causes EffectDocument15 pagesFMECA Worksheet: No. Functional Failures Failure Modes Causes EffectBarathNo ratings yet

- Past Defect History 2021Document10 pagesPast Defect History 2021RahulNo ratings yet

- SATR-W-2008 Rev 8 FD-1Document6 pagesSATR-W-2008 Rev 8 FD-1asiqna100% (1)

- Rfa-S-20 Method Statement For Repair of Cracks On Level 6 SlabDocument13 pagesRfa-S-20 Method Statement For Repair of Cracks On Level 6 SlabEngr Badz de DiosNo ratings yet

- 2539-00-ITP-012 - 0 - ITP For Plastic Piping PDFDocument17 pages2539-00-ITP-012 - 0 - ITP For Plastic Piping PDFdang2172014100% (1)

- Caterpillar Cat 330B L Excavator (Prefix 3YR) Service Repair Manual (3YR00001 and Up)Document26 pagesCaterpillar Cat 330B L Excavator (Prefix 3YR) Service Repair Manual (3YR00001 and Up)kfm8seuuduNo ratings yet

- Welding Activities ManagementDocument18 pagesWelding Activities ManagementStanley AlexNo ratings yet

- Potential Failure Mode and Effect Analysis: Doc - No.: FMEA/TL-01 A REV. NO.: 06 ORG. Date: 18.03.2021Document4 pagesPotential Failure Mode and Effect Analysis: Doc - No.: FMEA/TL-01 A REV. NO.: 06 ORG. Date: 18.03.2021Mukesh YadavNo ratings yet

- Small Boat Harbours Project: Inspection and Test Plan For Casting of Concrete Quay Wall BlocksDocument4 pagesSmall Boat Harbours Project: Inspection and Test Plan For Casting of Concrete Quay Wall BlockseleanorNo ratings yet

- Trio APS 4034F Impact Crusher ManualDocument53 pagesTrio APS 4034F Impact Crusher Manualclaudiu.gheorghe5710No ratings yet

- Chery Tiggo7 Electronics Guide VAJUSWUDocument84 pagesChery Tiggo7 Electronics Guide VAJUSWUamin mombiniNo ratings yet

- Q1 Mod 1 TVL Automotive Servicing Grade 12 StudentDocument17 pagesQ1 Mod 1 TVL Automotive Servicing Grade 12 StudentDarey Reyes100% (4)

- Manual de Partes PS 15SL Physiotrauma PDFDocument95 pagesManual de Partes PS 15SL Physiotrauma PDFMario AguirreNo ratings yet

- Raynera Vs HicetaDocument7 pagesRaynera Vs HicetaJoshua Erik MadriaNo ratings yet

- RAY-MK-L-LLS-0001-A Listado de Líneas PipingDocument5 pagesRAY-MK-L-LLS-0001-A Listado de Líneas PipingandradaingNo ratings yet

- Rotating Equipment List: A. ProcessDocument2 pagesRotating Equipment List: A. ProcesshungNo ratings yet

- H1006300MKD11 Sa00qw 02Document8 pagesH1006300MKD11 Sa00qw 02MarcoNo ratings yet

- Johnson Matthey CSF Line Expansion: Project Scope MatrixDocument5 pagesJohnson Matthey CSF Line Expansion: Project Scope MatrixchanjunkaiNo ratings yet

- 6420-6000-Et-5930-4 - Ra Part-1Document259 pages6420-6000-Et-5930-4 - Ra Part-1MayankNo ratings yet

- SPH Erection Piping System Rev 2-2-5Document4 pagesSPH Erection Piping System Rev 2-2-5dony ramdhani100% (2)

- AKT-ME-LIS-210-0001 Rev. A ReplaceDocument13 pagesAKT-ME-LIS-210-0001 Rev. A ReplaceBayu SaputraNo ratings yet

- In-Process FormatDocument5 pagesIn-Process Formatsantosh kumarNo ratings yet

- MKS-1904-HF-02 - Site Induction Attendance SheetDocument3 pagesMKS-1904-HF-02 - Site Induction Attendance SheetNindy FebrianiNo ratings yet

- Ph4 Si 1004 Var r2 Stress IsometricsDocument106 pagesPh4 Si 1004 Var r2 Stress IsometricsChirag ShahNo ratings yet

- Lampiran - IKA CM Rotating EquipmentDocument1 pageLampiran - IKA CM Rotating Equipmentahmadalfan662No ratings yet

- Me-2001b (3) - 231004-Basement 2 Layout Plan Sheet BDocument1 pageMe-2001b (3) - 231004-Basement 2 Layout Plan Sheet BhumcanopNo ratings yet

- Bench MarkDocument1 pageBench Markhow2beliveNo ratings yet

- G1996-20033-Re Measure 08 Jan 2024Document1 pageG1996-20033-Re Measure 08 Jan 2024Cam-ToolsNo ratings yet

- O&m Log SheetDocument41 pagesO&m Log SheetMohamed MousaNo ratings yet

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument5 pagesInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiNo ratings yet

- Plumbing, SanitaryDocument2 pagesPlumbing, Sanitarykumarakash122392No ratings yet

- DURI-GENF14GN000-MEC-LST-PHR-2003-00 Rev.0A Mechanical Equip List (List)Document3 pagesDURI-GENF14GN000-MEC-LST-PHR-2003-00 Rev.0A Mechanical Equip List (List)Budi KamilNo ratings yet

- Mcore Lab Private Limited: Test Report of Rock CoresDocument1 pageMcore Lab Private Limited: Test Report of Rock Coressivananda reddyNo ratings yet

- RA 14 - Concrete WorksDocument5 pagesRA 14 - Concrete WorksKlizman AmineNo ratings yet

- Hira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraDocument4 pagesHira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraZuberYousufNo ratings yet

- Me-2001a (3) - 231004-Basement 2 Layout Plan Sheet ADocument1 pageMe-2001a (3) - 231004-Basement 2 Layout Plan Sheet AhumcanopNo ratings yet

- HOT-RFA-NCI-016-Lamp Post - 2 LightsDocument2 pagesHOT-RFA-NCI-016-Lamp Post - 2 Lightskevin javateNo ratings yet

- 109018AE0026-27 - Rev - 0 Layout Panel de ControlDocument2 pages109018AE0026-27 - Rev - 0 Layout Panel de ControlAlonzo Rueda PeraltaNo ratings yet

- PTT Public Company Limited 7Th Gas Separation Plant ProjectDocument2 pagesPTT Public Company Limited 7Th Gas Separation Plant ProjectThane SkinnerNo ratings yet

- FORMATO. Component Supply Chain Chart (CSCC)Document1 pageFORMATO. Component Supply Chain Chart (CSCC)karimeNo ratings yet

- Anpqp - Component Supply Chain Chart (CSCC)Document1 pageAnpqp - Component Supply Chain Chart (CSCC)r.vargasNo ratings yet

- Index of Revisions Rev. Description And/ or Revised Sheets: Prge Ip-Rj/UpgnDocument3 pagesIndex of Revisions Rev. Description And/ or Revised Sheets: Prge Ip-Rj/UpgnAlireza GolpesarNo ratings yet

- Per-Qf-33 Plantilla of Step IncrementDocument1 pagePer-Qf-33 Plantilla of Step IncrementMichelle O. MatiasNo ratings yet

- (Project Name) : Inspection Checklist - External PlasteringDocument2 pages(Project Name) : Inspection Checklist - External PlasteringMohd TameziNo ratings yet

- SLD BudhebhaparDocument1 pageSLD BudhebhaparHarak DhamiNo ratings yet

- 78101-40700000-IC-MDL-10000 Copper Alarms Settings For DCS Configuration Rev0BDocument13 pages78101-40700000-IC-MDL-10000 Copper Alarms Settings For DCS Configuration Rev0BGemasgoodasdf DjdjdjNo ratings yet

- Circuit Diagram SAMSUNG GALAXY J200GUDocument7 pagesCircuit Diagram SAMSUNG GALAXY J200GUSathish RajanNo ratings yet

- R-216G-311 - 0 Manual Valve With Limit SwitchDocument3 pagesR-216G-311 - 0 Manual Valve With Limit SwitchFahmi HaidiNo ratings yet

- Dimmer System Control SchematicDocument2 pagesDimmer System Control SchematicCheah ChenNo ratings yet

- A-CAES Heat and Mass Balance Diagram 001Document3 pagesA-CAES Heat and Mass Balance Diagram 001IbraDinceNo ratings yet

- SPC Aaee M2Document5 pagesSPC Aaee M2Akshay khannaNo ratings yet

- 4200 459 D62 18139 Code 4 Rev 7Document4 pages4200 459 D62 18139 Code 4 Rev 7rcpuram01No ratings yet

- Diag, Schem Pp-Fire Protection 121T1290Document3 pagesDiag, Schem Pp-Fire Protection 121T1290Bounezra OussamaNo ratings yet

- Rwac TemplateDocument1 pageRwac TemplateJing MendozaNo ratings yet

- Plan of Land: Lot 10339-A-2, Psd-07-103358Document1 pagePlan of Land: Lot 10339-A-2, Psd-07-103358John Rey MontemorNo ratings yet

- Slab Design SheetDocument8 pagesSlab Design SheetMano CivilengineerNo ratings yet

- Sample TC 256Document2 pagesSample TC 256santanushee8No ratings yet

- Weld History SheetDocument2 pagesWeld History SheetAjin S100% (1)

- Electrical Work PermitDocument2 pagesElectrical Work PermitZain BashirNo ratings yet

- 141 CC 403 02008 - Q - CommentDocument25 pages141 CC 403 02008 - Q - CommentChandra KanthNo ratings yet

- Types of Pumps: Working Principle of PumpDocument12 pagesTypes of Pumps: Working Principle of PumpFe CaprichoNo ratings yet

- Linde Service Guide: ArrangementDocument2 pagesLinde Service Guide: ArrangementTrần Đức PhiNo ratings yet

- Strategic Quality and Systems ManagementDocument40 pagesStrategic Quality and Systems ManagementParadise 2026No ratings yet

- Frame and MountingDocument54 pagesFrame and MountingRepuesto GeneralNo ratings yet

- Diagram 1 A/C Heater ModuleDocument1 pageDiagram 1 A/C Heater ModuleEnrique Arevalo LeyvaNo ratings yet

- Controllers and Controller StationsDocument65 pagesControllers and Controller StationsLucian ChorusNo ratings yet

- Kubota Tecnical ReportDocument72 pagesKubota Tecnical ReporthumbertoNo ratings yet

- Mechanical Engineering Minor Project Report On Staircase Climber MAE IPUDocument26 pagesMechanical Engineering Minor Project Report On Staircase Climber MAE IPUAakash SachdevaNo ratings yet

- Design Calculation of Braking System (Landcruiser) : AbstractDocument4 pagesDesign Calculation of Braking System (Landcruiser) : AbstractDr. Aung Ko LattNo ratings yet

- Hyundai Motors: Presented By: Muhammed Suhail.VDocument16 pagesHyundai Motors: Presented By: Muhammed Suhail.VSuhail MohammedNo ratings yet

- PCX HybridDocument2 pagesPCX HybridHamizan ZafirahNo ratings yet

- ENG CS 889759 3 Timer Interconnection System 0712 PDFDocument260 pagesENG CS 889759 3 Timer Interconnection System 0712 PDFPetr -No ratings yet

- All Supplier: Order DeliveryDocument6 pagesAll Supplier: Order Deliverydasih mindasariNo ratings yet

- Utimec LF 090 D Stage V Tds 2021Document12 pagesUtimec LF 090 D Stage V Tds 2021Dmitry BezdnikovNo ratings yet

- IFC6000 ManualDocument8 pagesIFC6000 ManualJohn Alexander Bonilla AngelNo ratings yet

- Actuator TypeDocument18 pagesActuator TypelinhphamNo ratings yet

- 99SRDocument176 pages99SRjulimo4wNo ratings yet

- (AD - DIESEL) - (21-01-2020) : Parts ListDocument17 pages(AD - DIESEL) - (21-01-2020) : Parts ListVyacheslav ShatalovNo ratings yet

- Northeast - States-Review - of - Tire - Regulations - All StatesDocument26 pagesNortheast - States-Review - of - Tire - Regulations - All Statesgirish_patkiNo ratings yet

- Merceses BenzDocument9 pagesMerceses BenztoofastfhNo ratings yet

- EUGuide PressureEquipmentDocument93 pagesEUGuide PressureEquipmentK.S.MAYILVAGHANANNo ratings yet

- Placas ObservadasDocument219 pagesPlacas Observadasdessidiaz696No ratings yet

- Marketing Management Assignment 1Document2 pagesMarketing Management Assignment 1AleAhmedNo ratings yet