Professional Documents

Culture Documents

TPE-WI-INT-003 Valve Air Pressure Test

Uploaded by

Basuki BaskiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TPE-WI-INT-003 Valve Air Pressure Test

Uploaded by

Basuki BaskiCopyright:

Available Formats

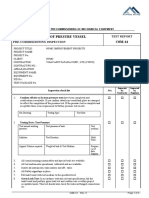

WORKING INSTRUCTION Doc No TPE-WI-INT-003

Rev No 00

VALVE AIR PRESSURE TEST Date 15 December 2013

Page 1 of 4

Revision Date Changes Prepared Approved

00 15 December 2013 Initial Release Mahendra Joko S

PT. TPE INDONESIA

Printed version is uncontrolled, unless stamped “CONTROLLED COPY” in red by QUALITY Department.

WORKING INSTRUCTION Doc No TPE-WI-INT-003

Rev No 00

VALVE AIR PRESSURE TEST Date 15 December 2013

Page 2 of 4

PROCESS DETAILS

PREPARATION

Prepare the following stuff:

1. Test Worksheet Forms.

2. Test Valve Tool Kit.

3. Nitrogen.

1 2 4. Flange and hoses.

5. Valves to be tested.

6. Correct Tools

Reminder:

All personnel working on Hydro Test

must uses appropriate Personal Protective

4 Equipment (PPE); safety shoes, goggles,

3

glove, earplug and helmet.

5 6

PT. TPE INDONESIA

Printed version is uncontrolled, unless stamped “CONTROLLED COPY” in red by QUALITY Department.

WORKING INSTRUCTION Doc No TPE-WI-INT-003

Rev No 00

VALVE AIR PRESSURE TEST Date 15 December 2013

Page 3 of 4

SET UP

1. Open up the Test Valve Tool Kit.

2. Install appropriate pressure gauge,

ensure that the maximum range of

pressure gauge is at least 2 times

of pressure to be tested/reached.

3. Check and ensure “air regulator,

hydro release, nitrogen block and

hydro block” are at close position,

otherwise close it.

4. Install valve being test at the

appropriate flange, ensure all

connection are tight and secure.

5. Connect flange hose to the

“outlet” of the Test Valve Tool

Kit.

6. Connect nitrogen hose to the

“nitrogen inlet” of Test Valve

Tool Kit.

AIR PRESSURE / NITROGEN TEST 1. Check set pressure requirement of

valve being test.

2. Check and ensure “air regulator,

hydro release, nitrogen block and

hydro block” are at close position,

otherwise close it.

3. By adjusting its regulator, set

Regulator nitrogen output pressure, same as

pressure gauge upper range.

4. Slowly open “nitrogen block”.

5. Closely monitor the “pressure

gauge” reading.

6. Once the valve is lifting / open,

observed value displayed at the

pressure gauge and record into

worksheet as lift value.

7. Immediately close the “nitrogen

PT. TPE INDONESIA

Printed version is uncontrolled, unless stamped “CONTROLLED COPY” in red by QUALITY Department.

WORKING INSTRUCTION Doc No TPE-WI-INT-003

Rev No 00

VALVE AIR PRESSURE TEST Date 15 December 2013

Page 4 of 4

block”, wait until the pressure is

stable and record the value into

worksheet as close value.

8. If pressure being injected is

reaching 110% value of set

pressure, but valve still does not

lift, lower down the pressure and

valve is considered as “FAILED

(STUCK)” record into worksheet.

9. If the lifting value is tally with set

pressure and the close value is 3%

-5% lower than set pressure, valve

is determined as GOOD,

otherwise FAILED and need to be

repaired.

10. Decrease the pressure to 90 % of

set pressure and check for any

leakage. You may use bubbles to

check any leaks.

11. If no leaks found valve is

determined as GOOD, otherwise

FAILED and need to be repaired.

12. After repair is done, repeat step 1

to 11 until get the GOOD result.

13. After testing completed, return all

tools and stuff to its designed

place and perform 5R activity.

PT. TPE INDONESIA

Printed version is uncontrolled, unless stamped “CONTROLLED COPY” in red by QUALITY Department.

You might also like

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Jsa For Piping Hydro Test, Pneumatic TestDocument8 pagesJsa For Piping Hydro Test, Pneumatic Testsanath adhikaryNo ratings yet

- Leak Test Procedure PDFDocument6 pagesLeak Test Procedure PDFanon_456282505100% (3)

- BLP 530 Gas Porosimeter127 20 - InstructionsDocument11 pagesBLP 530 Gas Porosimeter127 20 - InstructionsDonig FermanianNo ratings yet

- C: P: D: Factory Acceptance Test Procedure For Control Valve C - D N .: - Ptcs D N .: FCS-SOP-001. R 01 S: 1 10Document13 pagesC: P: D: Factory Acceptance Test Procedure For Control Valve C - D N .: - Ptcs D N .: FCS-SOP-001. R 01 S: 1 10Hicham BelmaatiNo ratings yet

- Jsa - Hydro Pressure Testing (2296)Document6 pagesJsa - Hydro Pressure Testing (2296)asaf ali100% (1)

- STS QAC SOP 015 PSV ServicingDocument11 pagesSTS QAC SOP 015 PSV Servicingmohd as shahiddin jafri100% (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Hydrostatic Pressure Test-SpoolDocument8 pagesHydrostatic Pressure Test-SpoolJoby JacobNo ratings yet

- Hydrotesting of VALVE AND REFURBISHMENT PROCEDUREDocument16 pagesHydrotesting of VALVE AND REFURBISHMENT PROCEDUREISAACNo ratings yet

- Guidelines For Hydrostatic Leak TeatingDocument4 pagesGuidelines For Hydrostatic Leak TeatingClyde CoopperNo ratings yet

- Vapor Recovery Test Procedure: Adopted: February 1, 2001 Amended: July 3, 2002 Amended: October 8, 2003Document10 pagesVapor Recovery Test Procedure: Adopted: February 1, 2001 Amended: July 3, 2002 Amended: October 8, 2003ObaidUrRehmanNo ratings yet

- Hydrotesting Procedure Rev 4Document6 pagesHydrotesting Procedure Rev 4Rajesh K PillaiNo ratings yet

- Valtek MK1 IOMDocument12 pagesValtek MK1 IOMJuan HernandezNo ratings yet

- P-T4061-016 Rev. 02 - Hydrotest ProcedureDocument4 pagesP-T4061-016 Rev. 02 - Hydrotest ProcedureBudhi SuharnantoNo ratings yet

- Skid Mounted Test UnitDocument30 pagesSkid Mounted Test UnitSALIM ALI AFIFFNo ratings yet

- JSA - Hydro-Testing of Pipe & EquipmentDocument1 pageJSA - Hydro-Testing of Pipe & EquipmentRajuNo ratings yet

- Ak TrainingDocument2 pagesAk TrainingX'mix ĐreamerNo ratings yet

- Piping Fundamentals Part 3 (Testing) RevisedDocument86 pagesPiping Fundamentals Part 3 (Testing) RevisedJazille LardizabalNo ratings yet

- IDC SOP #2 Pressure Test of The StandpipeDocument5 pagesIDC SOP #2 Pressure Test of The StandpipekareemNo ratings yet

- Hydrostatic Pressure Testing of ValvesDocument40 pagesHydrostatic Pressure Testing of Valvesa.solvevNo ratings yet

- Calibration Instruction: VP300-1-200 1.preparation Works Product VP300 NoDocument6 pagesCalibration Instruction: VP300-1-200 1.preparation Works Product VP300 NoIgnacio NicolasNo ratings yet

- Technical Maintenance Manual: Legend First StageDocument18 pagesTechnical Maintenance Manual: Legend First StageValdrickNo ratings yet

- IBHCVDocument71 pagesIBHCVdvmahiidaNo ratings yet

- SRP 003x PRESSURE TEST PROCEDUREDocument10 pagesSRP 003x PRESSURE TEST PROCEDURECavid MAMMADOVNo ratings yet

- E1003-13 Standard Practice For Hydrostatic Leak Testing PDFDocument3 pagesE1003-13 Standard Practice For Hydrostatic Leak Testing PDFudomNo ratings yet

- Hydrotest Procedure For Pressure VesselDocument6 pagesHydrotest Procedure For Pressure VesselAbdul Kharis100% (1)

- Dokumen Pak RudiDocument7 pagesDokumen Pak RudiAlfarizki wuka nugrahaNo ratings yet

- Safety ValvesDocument11 pagesSafety Valvesravindra_jivaniNo ratings yet

- Drager Julian PEEP Valve Installation InstructionsDocument3 pagesDrager Julian PEEP Valve Installation Instructionssamlu71No ratings yet

- 08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Document12 pages08-KU-TWK-50-QA-PRO-2163-Hydrotest and Flushing procedure-REV 0Avak NishanNo ratings yet

- Technical Maintenance Manual: Atx 200 First StageDocument18 pagesTechnical Maintenance Manual: Atx 200 First StageFernando Cadena DuqueNo ratings yet

- Testing Procedure For Ball Valve MAPDocument16 pagesTesting Procedure For Ball Valve MAPbasuki100% (3)

- Hydrostatic Test ProcedureDocument6 pagesHydrostatic Test ProcedureLuhur PrandikaNo ratings yet

- Hydrotest ProcedureDocument6 pagesHydrotest Procedurebagusu_6No ratings yet

- Emrsn HTP 001 A1Document7 pagesEmrsn HTP 001 A1Karthik BanariNo ratings yet

- Mnaual de Instrucciones Instalacion y Operacion 12661RWGVOperManRevDocument12 pagesMnaual de Instrucciones Instalacion y Operacion 12661RWGVOperManRevБехар ТиагоNo ratings yet

- Checklist For Pressure Testing Safely 2Document2 pagesChecklist For Pressure Testing Safely 2Jonathan CambaNo ratings yet

- JXN ITR-A Piping PDFDocument21 pagesJXN ITR-A Piping PDFAmyNo ratings yet

- Hydro Test ProcedureDocument8 pagesHydro Test Procedurevinoth100% (3)

- Apeks Atx 200 1st StageDocument16 pagesApeks Atx 200 1st StagetxabitaNo ratings yet

- C0M-14 Hydrostatic Test of Pressure VesselDocument3 pagesC0M-14 Hydrostatic Test of Pressure VesselHong Trung DuongNo ratings yet

- Job Safety Analysis Sheet: FacilityDocument1 pageJob Safety Analysis Sheet: FacilityjoshuaNo ratings yet

- For Approval: Nghi Son 2 Bot Thermal Power Plant ProjectDocument19 pagesFor Approval: Nghi Son 2 Bot Thermal Power Plant ProjectĐể MaiNo ratings yet

- Contoh Soal Psikotes Kerja Dan Kunci JawabanDocument8 pagesContoh Soal Psikotes Kerja Dan Kunci JawabanArie BfmvNo ratings yet

- Hydrotest ProcedureDocument3 pagesHydrotest Proceduresas13No ratings yet

- Hydrotest Rev.1Document4 pagesHydrotest Rev.1arsil5840No ratings yet

- Hydrostatic Testing of Fabricated Piping: 1. ScopeDocument2 pagesHydrostatic Testing of Fabricated Piping: 1. ScopeNicolae StanescuNo ratings yet

- 2.0 Pressure TestingDocument11 pages2.0 Pressure TestingHATEMNo ratings yet

- MS (Pneumatic Test - Heat Exchanger)Document4 pagesMS (Pneumatic Test - Heat Exchanger)Zubair Ahmed KhaskheliNo ratings yet

- Construction Leak Test ProcedureDocument6 pagesConstruction Leak Test Procedurezack zeeartNo ratings yet

- ASTM D2713.uyel3577Document3 pagesASTM D2713.uyel3577Philippe AlexandreNo ratings yet

- Delval Series - 50/52, 5A/5B Butterfly Valves: Delval Flow Controls Private LimitedDocument9 pagesDelval Series - 50/52, 5A/5B Butterfly Valves: Delval Flow Controls Private LimitedProcess Controls & ServicesNo ratings yet

- Leak Test Procedure For SubDocument5 pagesLeak Test Procedure For Subpallav chatterjeeNo ratings yet

- Pneumatic Testing Procedure For Mechanical EquipmentDocument39 pagesPneumatic Testing Procedure For Mechanical EquipmentCepi Sindang KamulanNo ratings yet

- Method Statement For Hydro-Testing of Pipes: 0 Issued For Approval Rev Date Description Prepared Checked ApprovedDocument7 pagesMethod Statement For Hydro-Testing of Pipes: 0 Issued For Approval Rev Date Description Prepared Checked ApprovedAnish KumarNo ratings yet

- Job Safety Analysis Sheet: Pre - WorkDocument2 pagesJob Safety Analysis Sheet: Pre - Workmalimsaidi_160040895100% (1)

- STD 132Document31 pagesSTD 132Valesh MonisNo ratings yet

- Piping Hydrostatic Test Procedure Rev0Document8 pagesPiping Hydrostatic Test Procedure Rev0smsunil12345No ratings yet