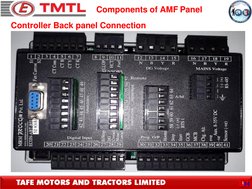

Components of AMF Panel

Controller Back panel Connection

114

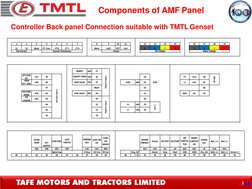

� Components of AMF Panel

Controller Back panel Connection suitable with TMTL Genset

214

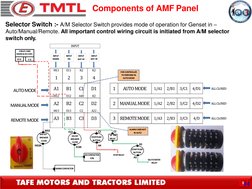

� Components of AMF Panel

Selector Switch :- A/M Selector Switch provides mode of operation for Genset in –

Auto/Manual/Remote. All important control wiring circuit is initiated from A/M selector

switch only.

INPUT

4 RELAY CARD

MAINS & DGCONT.

INPUT INPUT INPUT INPUT

M12 E12 MAINS DG BAT-VE BAT-VE

M11 E11 K2 K2 FOR CONTROLLER

TO PERFORM IN

1 2 3 4 AUTO MODE

AUTOMODE A1 B1 C1 D1 1 AUTO MODE 1/A1 2/B1 3/C1 4/D1 ALLCLOSED

M12 E12 A40 K2

MANUALMODE A2 B2 C2 D2 2 MANUALMODE 1/A2 2/B2 3/C2 4/D2 ALLCLOSED

M13 E13 C2 A22

REMOTE MODE A3 B3 C3 D3 3 REMOTEMODE 1/A3 2/B3 3/C3 4/D ALLCLOSED

ALARM CARDNOT

M13 E13 C2 C2 IN AUTO

SEB CKT 14 PIN

DG CKT STOPPUSH

BREAKER RELAY

BREAKER BUTTON

CLOSE

CLOSE

M13A A4 A5

E13A

STARTPUSH

BUTTON

DG CONTACTOR STOP RELAY

COIL A3

SELFSTARTER

RELAY

MAINSCONTACTOR

314

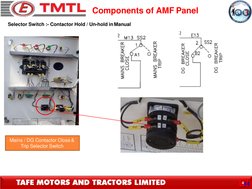

� Components of AMF Panel

Selector Switch :- Contactor Hold / Un-hold in Manual

Mains / DG Contactor Close &

Trip Selector Switch

414

� Components of AMF Panel

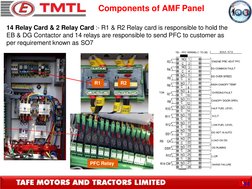

14 Relay Card & 2 Relay Card :- R1 & R2 Relay card is responsible to hold the

EB & DG Contactor and 14 relays are responsible to send PFC to customer as

per requirement known as SO7

R1 R2

PFC Relay

514

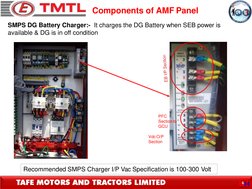

� Components of AMF Panel

SMPS DG Battery Charger:- It charges the DG Battery when SEB power is

available & DG is in off condition

PFC

Section to

GCU

Vdc O/P

Section

Recommended SMPS Charger I/P Vac Specification is 100-300 Volt

614

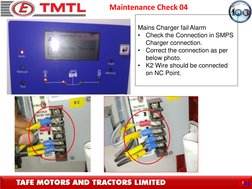

�Maintenance Check 04

Mains Charger fail Alarm

• Check the Connection in SMPS

Charger connection.

• Correct the connection as per

below photo.

• K2 Wire should be connected

on NC Point.

743

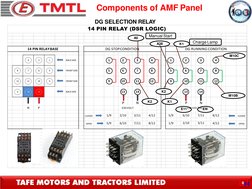

� Components of AMF Panel

DG SELECTION RELAY

14 PIN RELAY (DSR LOGIC)

A5

Manual Start

A38 K1 Charge Lamp

14 PIN RELAY BASE DG STOP CONDITION DG RUNNING CONDITION

M10C

3 2 1 BACK SIDE 1 2 3 4 1 2 3 4

8 7 6 5 FRONT SIDE 5 6 7 8 5 6 7 8

12 11 10 9 FRONT SIDE 9 10 11 12 9 10 11 12

4 14 13 BACK SIDE 13 14 K2 13 14

M10B

P N K2 K1 P N

N P 230 VOLT E11230 VOLT ACEN

CLOSED 1/9 2/10 3/11 4/12 5/9 6/10 7/11 8/12 CLOSED

OPEN 5/9 6/10 7/11 8/12 1/9 2/10 3/11 4/12 OPEN

814

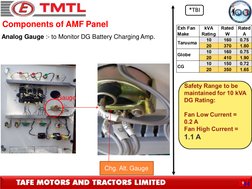

� *TBI

Components of AMF Panel

Analog Gauge :- to Monitor DG Battery Charging Amp.

Gauge

Chg. Alt. Gauge

914

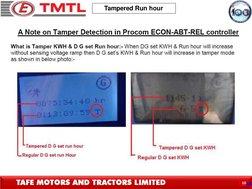

�Tampered Run hour

1014

�Tampered Run hour

Thanks

1114

�SO 7 Connection/UD Alarms

1214

� Controller Setting

Device Parameter

AMF CONTROLLER 0/P VDC,RESISTANCE SMPS MAKE Baud Stop

Slave/Device Id Parity

Rate Bits

GCU105C-1 4-5 VDC ELTEK 26 19200 NONE ONE

SEDMAC 120 OHMS GE/LINEAGE 26 19200 NONE ONE

PROCOM 800 TO 1200 OHMS DELTA 26 19200 NONE ONE

EXICOM 26 19200 NONE ONE

EMERSON 2 9600 NONE ONE

1343

� Controller Back panel :-

SEDEMAC R1

E11 Blank Blank EN M11 M31 M51 MN Blank Blank C5 C6 C3 C4 C1 C2 A42 A36 A39 K35 K30 K40 A37 K16 K99

C Hig. HFL LLOP HCT Emer. LFL

R Y B N R Y B N EL1 EL2 B1 B2 Y1 Y2 R1 R2 Remote D.Open

Temp. SW SW SW

Fire

stop SW

GENSET INPUT 110/230 V PH-N MAINS INPUT 110/230V PH-N CT INPUT 5A K J I F E D C B A

57 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33

DG VOLTAGE SENSING MAINS VOTAGE SENSING CT3 CT2 CT1 DG INPUT IN (-) VE

58 L

59 H 32 A A15

60

RESERVED SEDEMAC GC-2111 31 B A14

485

RS

61 30 GND GND

DG Out Put +ve (1A rating) ANALOG INPUT From BTS

RESERVED RESERVED

DG Battery Input DG Start Stop Alaram Out Put Contactor DG/EB DG Analog Sensor From DG/EB Con. Extra(-) DIG O DIG P

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 |26|27|28|29|

12/24V A B C D E F G D+ ANLG ANLG ANLG ANLG ANLG SENSO DG ANLG Input 60VDC

DG PR. Com. Over DG Mains Chag. LOP/ FL/ TEMP/ DGC/ MCB/ R AT./ MPU /DIG

(-) (+) Start Stop DIG J DIGK DIG L DIGM DIG N COMM. MNL (+) (-)

Heat Fault Speed Contac Contac Alt. P

K2A K3G A3 A4 A23 A21 A20 A24 A25 W/R/O K43 K26 Blank A41 A51 K2 A40 Blank Blank A30 A34

1443

�Controller Back panel :- SEDEMAC R2

1543

�Do’s and Don'ts

1643

�Maintenance Check - 01

Please check Air Vent Screw tightness

and Washer replacement During

commissioning and PM activity

1743

�Maintenance Check - 02

HET Switch and Sensor connection

• In Multicylinder HET Sensor (K32 )and Switch

(K40)Connection Need to check.

• HET Parameter on Procom should show ok in

running Condition.

• If shows open or Critical Get the Sensor validated.

1843

�Maintenance Check 03

DG and Mains Connections

• DG and Mains Earthing needs to checked.

It should not be connected or looped.

• Mains Supply in DG Power will lead

Reverse Power and Alternator Failure.

• Check the Mains Voltage and DG Voltage

During Commissioning and PM.

1943

�Maintenance Check 05

LLOP Switch and Sensor connection

• LLOP Sensor (K43 )and Switch (K30)

terminations Need to be checked.

• Check the LOP pressure in Procom, It

should be (between 2 to 5 kg/cm2) and

displays as OK.

• If it shows open or Critical please check

Sensor/Wiring or replace if required .

• Faulty Sensor or parameter can lead to

major failure of engines or leakage.

2043

�Maintenance Check 06

AMF Parameter

• Measure the load ampere with clamp

meter and check the same in Procom

parameter.

• Check the CT connection and CT ratio.

• Check Mains Contactor relay operation

in commissioning.

• Measure the BTS voltage in multi meter

and Confirm the same with GCU.

• Check the Fuel level % in Analog

Sensor and compare with Procom

Parameter.

• Check the Auto Manual and Selector

Switch Working Operation.

CT ratio Found

121/5

2143

�Maintenance Check 08

Check the Tightness of All Bolts and nuts

• Check for proper Dia., Long Bend,

clamping and Support for Exhaust Pipe.

• Check AVM Conditions, Bolt tightness.

• Loosened Bolts can lead to vibration

and abnormal sound in DG set or Major

failure as below.

2243

� Maintenance Check 09

Battery Voltage Check points

• Check the battery voltage in Clamp

meter and Match with Procom

Parameter.

• Check the battery Charging amp In

analog gauge .

• Check the battery Electrolytes and

Specific Gravity.

2343

� Maintenance Check 10

Mains Not Available in this Site

MC/GC Relay polarity

• During EB availability Contactor

holds for 5 seconds then

unholds.

• Please check MC Relay

Polarity in System parameter.

• MCB Polarity Should be

Normally open.

D Input 8 Canopy Temp

D Input Polarity 8 Normal Open

MCB Polarity Normally Open

Fan High Current (10/20 kVA) 1.1/2.5

2443

� Field Issues

S no. Type of Failures Need to check at Site

GCU fault History required

Lube oil Level and Condition required

1 Engine Seizure

Phtograph of Failed Component

load as per Site technician on DG and SMPS setting

GCU fault History required

Failed component Photo

Photograph of AMF panel/ PIU and Contactors

2 Alternator Burnt

Alternator Bearing Condition

Alternator Fan Condition (Melted/ Correct)

EB meter Photograph

Sr. No of GCU and Make (Procom, Sedmec, Utopia)

Physical condition of Procom (Burnt/ damaged)

AMF Panel Photograph along with Contactor

3 GCU failures

CT ratio as per CT coil

Photograph of Backside of GCU

Photograph of RS485 During Checking in case of Everest

Mains Voltage as per clamp meter and Fault history

Photograph of Low Mains Voltage Setting

4 Mains Contactor Failure Photograph of high Mains Voltage Setting

Photograph of Mains Contactor relay

Contactor Coil or Contactor required for replacement

2543

� Field Issues

S no. Type of Failures Need to check at Site

CT Ratio Setting and CT ratio Physical.

No. of Battery module and Capacity.

5 DG Overloading SMPS charging Current.

DG Voltage and RPM

DG fault History

Snap Required for Clamp Meter Reading and Procom

Parameter.

CT Ratio Setting and CT ratio Physical.

KWH not GCU Dg setting for Single/ three phase (in System Parameter)

6

increasing

Load cable Routing in CT coil

Photograph of CT coil Common Connection in Sedmec and

Procom.

2643

�Thanks

2743