Professional Documents

Culture Documents

148 114 - Falk Gear Drive Coupling Guards - Installation Manual

Uploaded by

nugroho.wildhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

148 114 - Falk Gear Drive Coupling Guards - Installation Manual

Uploaded by

nugroho.wildhanCopyright:

Available Formats

Falk™ Gear Drive Coupling Guards • Installation

All Types (Page 1 of 2)

INTRODUCTION WARNING: Lock out power source and remove all external

loads from unit before servicing unit or accessories.

The following assembly instructions apply to Falk™ OSHA type

guards illustrated in Figures 1 and 2. Guard heights may be Consult applicable local and national safety codes for proper

increased with shims and pedestals as illustrated in Figures 1 guarding of rotating members.

thru 4. Sleeve lengths are manufactured to suit the application. Where heat is generated by the slipping action of fluids or

Fasteners for securing the guard to the foundation are to be friction linings in couplings, clutches, etc., use guards with

furnished by the installer. Guard shapes, sizes, and components louvered sides to permit air circulation and heat dissipation.

vary with specific requirements. The general instructions on Page NOTE: The portion of the fluid coupling guard in line with the

2 apply to most guard types. Refer to the drawing furnished with

fusible plugs must be of solid construction.

the order for the guard locating dimensions.

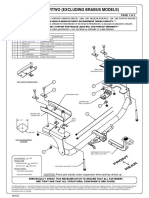

TYPICAL GUARD ASSEMBLIES

FLAT TOP GUARDS

SLANT TOP FLAT TOP (OR SLANT TOP)

Figure 1 Figure 2 Figure 3 Figure 4

GUARD WITH GUARD WITH GUARD WITH GUARD

OR W/O SHIMS OR W/O SHIMS BOTTOM PLATE & SHIMS WITH PEDESTAL

FLAT AND SLANT TOP GUARD PARTS

3 5 5

INTER- 6

INTER-

CHANGEABLE CHANGEABLE

Figure 7 BOTTOM PLATE

4

1 4

2 8

6 9

6

Figure 5 FLAT TOP GUARD Figure 6 SLANT TOP GUARD

PART NUMBERS

1. Guard Half (Flat Top) 6. Shims (1” maximum)

2. Guard (Slant Top) 7. Bottom Plate Figure 8 PEDESTALS

3. Cover 8. Pedestal (Design #1)

4. Sleeve 9. Pedestal (Design #2)

5. Enclosure Plate

Rexnord Industries, LLC, Gear Group 148-114

3001 W. Canal St., Milwaukee, WI 53208-4200 USA Telephone: 414-342-3131 March 1985

Fax: 414-937-4359 e-mail: info@rexnord.com web: www.rexnord.com Supersedes 9-78

Installation • Falk™ Gear Drive Coupling Guards

(Page 2 of 2) All Types

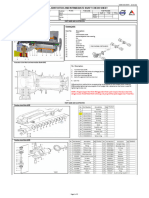

PRELIMINARY STEPS

HALF

SLEEVE

STRAIGHT

EDGE

GUARD SUPPORT ADD SLEEVES AFTER

GUARD IS IN POSITION

Figure 9 Figure 10 Figure 11

Bolt guard support to Sizes 1000 thru 1300FZ motor brackets Bolt half sleeves (or enclosure plate) to Flat top half guard

when using 364 and larger motor frames. Use 5/16-18 UNC x (Figure 10) before installation and after installation to Slant

5

/8 fasteners. Top guard (Figure 11). Bolt other half sleeves to guards after

final alignment.

GUARD INSTALLATION

(Flat Top Guard Illustrated

ONE HALF ENGAGE

FLAT TOP GUARD ALIGNMENT

CLIPS

Figure 12 Figure 13 Figure 14 Figure 15

Flat Top Guard Installation Position one-half of guard (and Slant Top Guard Installation Position the guard (and

components) as illustrated in Figures 12, 13, or 14. Position components) as illustrated in Figures 12, 13, or 14 for flat top

the other half of guard (without half sleeves) as illustrated in guard and then bolt the half sleeves shown in Figure 11 (or

Figure 15. Engage alignment clips. closure plate) into position.

GUARD ALIGNMENT

Flat and Slant Top Guard Alignment

1. Position guard within the limits shown in Figures 16, 17,

and 18 for all applications.

2. Scribe foot mounting holes from the guard or pedestal on

the mounting surface and drill (or drill and tap) bolt holes .38 MAX CLEARANCE

into the mounting surface. When shim blocks are furnished B B

END CLEARANCES ARE

over .25” thick, scribe the outline of the shim blocks on the NOT ALWAYS EQUAL

A A

mounting surface. Then remove all parts except the shims .38 MAX. CLEARANCE

and use them as a guide for scribing the mounting holes.

If the guard mounting holes overlap slots or hand holes in

the mounting surface, relocate the mounting holes if

possible, or bolt an oversize bottom plate over the holes

and then mount the guard to the plate. .12 MIN CLEARANCE AT POINTS A THRU G

SLEEVE

3. Bolt the guard and pedestal to their mounting surfaces. B

E

A C D F

4. Recheck clearances. Reposition guard if necessary. CPLG. O.D. G

GUARD SHAFT

5. Assemble remaining sleeve halves or enclosure plates per

Figures 5 and 6 on Page 1.

POSITION GUARD FOR EQUAL POSITION GUARD FOR EQUAL

6. Bolt cover to pre-drilled flat top guard half per Figure 5 CLEARANCE BETWEEN COUPLING

O.D. & GUARD AT POINTS A & C

CLEARANCE BETWEEN SHAFT

O.D. & SLEEVE I.D.

using 1/4-20 UNC x 7/16”screws.

VIEW A-A VIEW B-B

Figure 16 Figure 17

148-114 Rexnord Industries, LLC, Gear Group

March 1985 3001 W. Canal St., Milwaukee, WI 53208-4200 USA Telephone: 414-342-3131

Supersedes 9-78 Fax: 414-937-4359 e-mail: info@rexnord.com web: www.rexnord.com

You might also like

- Installation Instructions Power Cat 6A Data Gate Shielded Patch PanelDocument6 pagesInstallation Instructions Power Cat 6A Data Gate Shielded Patch PanelflyingcowintheskyNo ratings yet

- BMW 335i & 335xi (EXCLUDING DIESEL) 11756: Do Not Exceed Vehicle Manufacturer'S Recommended Towing Capacity.Document2 pagesBMW 335i & 335xi (EXCLUDING DIESEL) 11756: Do Not Exceed Vehicle Manufacturer'S Recommended Towing Capacity.joker63000No ratings yet

- Eaton: Hydraulic MotorDocument4 pagesEaton: Hydraulic MotorRidha AbbassiNo ratings yet

- Model 6116022-42: Assembly InstructionsDocument2 pagesModel 6116022-42: Assembly InstructionsMiguel AngelNo ratings yet

- Instruction Manual For DODGE Para-Flex High Speed and Flywheel CouplingsDocument2 pagesInstruction Manual For DODGE Para-Flex High Speed and Flywheel CouplingsJonNo ratings yet

- Double Door Wall Locker (DDWL) Install Instructions: Sheet OFDocument14 pagesDouble Door Wall Locker (DDWL) Install Instructions: Sheet OFEdson MárioNo ratings yet

- Chum Saf-Xt ManualDocument8 pagesChum Saf-Xt Manualingrojas_No ratings yet

- Holland Hitch AdjustmentDocument4 pagesHolland Hitch AdjustmentMarlin StraubNo ratings yet

- ZeissDocument3 pagesZeissfajriNo ratings yet

- F550 User Manual v1.9 en PDFDocument7 pagesF550 User Manual v1.9 en PDFAnonymous MGQjG1No ratings yet

- Smart Car ManualDocument2 pagesSmart Car ManualvmarinelliNo ratings yet

- F-4U Corsair Oz12840 PDFDocument3 pagesF-4U Corsair Oz12840 PDFEden RaphNo ratings yet

- TCB Barrel CatalogueDocument17 pagesTCB Barrel CataloguekaranNo ratings yet

- Bearing Catalog PDFDocument10 pagesBearing Catalog PDFLucho ChaustreNo ratings yet

- Series TY-FRL - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard Coverage General DescriptionDocument6 pagesSeries TY-FRL - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard Coverage General DescriptionnicolasNo ratings yet

- Anexo 03 Instructivo Instalación Herraje de Suspensión OPGW - ADSSDocument4 pagesAnexo 03 Instructivo Instalación Herraje de Suspensión OPGW - ADSSDidier solanoNo ratings yet

- DF65 v6 Rigging Instructions v1.0Document16 pagesDF65 v6 Rigging Instructions v1.0-No ratings yet

- DODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualDocument4 pagesDODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualALFONSO FERNANDEZ MULETNo ratings yet

- Chapter 9 - Towing: BHT-206A/B-SERIES-MM-2Document4 pagesChapter 9 - Towing: BHT-206A/B-SERIES-MM-2Wisuit SookthaweeNo ratings yet

- Wombot Exilis Kit Assembly ManualDocument67 pagesWombot Exilis Kit Assembly ManualwindharmenNo ratings yet

- EZ-Set Torsion Spring System InstallationDocument12 pagesEZ-Set Torsion Spring System InstallationbrookbabcockNo ratings yet

- BPI Zap TLok Headed Bar InstructionsDocument3 pagesBPI Zap TLok Headed Bar InstructionshectoriturbeNo ratings yet

- Warning!: 1999-2007 Gsx1300R Z-Fi Installation Instructions P/N 400613, 127012Document2 pagesWarning!: 1999-2007 Gsx1300R Z-Fi Installation Instructions P/N 400613, 127012solidsnake11No ratings yet

- Installation Instructions: Parts List Honda Dealer: Please Give A Copy of These Instructions To Your CustomerDocument4 pagesInstallation Instructions: Parts List Honda Dealer: Please Give A Copy of These Instructions To Your CustomerMinghao HongNo ratings yet

- Manual Instalacion de Transmisiones Evinrude E Tec 2010Document6 pagesManual Instalacion de Transmisiones Evinrude E Tec 2010URIEL CABALLERONo ratings yet

- OPGW Bolted Dead End InstructionsDocument2 pagesOPGW Bolted Dead End InstructionsAndika HandyNo ratings yet

- Hitch A35EDocument5 pagesHitch A35EImam MuhhudaNo ratings yet

- Tiron Cuello de Ganso - Gnrk1115 InstallatioDocument6 pagesTiron Cuello de Ganso - Gnrk1115 InstallatioRoy NavarreteNo ratings yet

- IMF51Document4 pagesIMF51juwon aprilagaNo ratings yet

- Convertir A Prueba de LluviaDocument2 pagesConvertir A Prueba de LluviaRuben PachoNo ratings yet

- TJ Full Cage Kit Install: Parts ListDocument7 pagesTJ Full Cage Kit Install: Parts ListMark BarberaNo ratings yet

- Opticom Rack Mount Fiber Enclosures: Assembly ViewDocument8 pagesOpticom Rack Mount Fiber Enclosures: Assembly ViewMehdi SHNo ratings yet

- Clutch Hino 2.5Document4 pagesClutch Hino 2.5Yeam_90No ratings yet

- Top-of-Pole Mount For 8 Modules (TPM8) For Module Types D, E, F, G, & HDocument16 pagesTop-of-Pole Mount For 8 Modules (TPM8) For Module Types D, E, F, G, & HtongaiNo ratings yet

- 7821 - 316 - 2 DECK BM&M Manual PDFDocument35 pages7821 - 316 - 2 DECK BM&M Manual PDFPRASHANTHNo ratings yet

- BTS75V - EF 75V BF - EF 80 - EF Package E INS 0221Document10 pagesBTS75V - EF 75V BF - EF 80 - EF Package E INS 0221Alex SmNo ratings yet

- Yakima Q Tower ManualDocument30 pagesYakima Q Tower ManualjohnNo ratings yet

- Stream DocumentDocument4 pagesStream DocumentalphonseduculotNo ratings yet

- Stereo Turntable: Operating InstructionsDocument10 pagesStereo Turntable: Operating InstructionsBarbaraNo ratings yet

- Arrow-Pak Retrievingtool: Specification GuideDocument5 pagesArrow-Pak Retrievingtool: Specification GuideTech AlfaNo ratings yet

- Floorport Series Activation Covers & Barrier Kits: Important: Please Read All Instructions Before BeginningDocument8 pagesFloorport Series Activation Covers & Barrier Kits: Important: Please Read All Instructions Before BeginningCarlos MoralesNo ratings yet

- SnugTop BedCap Commercial CombineDocument41 pagesSnugTop BedCap Commercial Combinevalsimon88No ratings yet

- SA Separator Installation SheetDocument1 pageSA Separator Installation SheetvenkNo ratings yet

- Mech-Tech CCU Interchangeable Stock Instructions: Pg.1 of 5Document5 pagesMech-Tech CCU Interchangeable Stock Instructions: Pg.1 of 5shunkadu2No ratings yet

- Rekluse Motor SportsDocument13 pagesRekluse Motor SportsJoshuaFulkersonNo ratings yet

- Procédure Installation Des Porte-FusiblesDocument2 pagesProcédure Installation Des Porte-Fusiblesouamor djelouadjiNo ratings yet

- T2 Speed-Grip Spacers Installation InstructionsDocument2 pagesT2 Speed-Grip Spacers Installation InstructionsLamthong LvkNo ratings yet

- Aeolus RSL Integrated Road Handlebar/stem Installation ManualDocument1 pageAeolus RSL Integrated Road Handlebar/stem Installation ManualRudy AriyantoNo ratings yet

- 2007 HD TouringDocument68 pages2007 HD TouringRod SturgeonNo ratings yet

- Sect 09 Multi-Stage FracturingDocument8 pagesSect 09 Multi-Stage FracturingpaimanNo ratings yet

- Instructions: Headlamp Visor KitDocument2 pagesInstructions: Headlamp Visor KitPaco JonesNo ratings yet

- Suzuki GSX-S1000 Heater Grip Installation GuideDocument108 pagesSuzuki GSX-S1000 Heater Grip Installation GuideseowshengNo ratings yet

- Top-of-Pole Mount For 9 Modules (TPM9) For Module Types C, D, E, F, G, & HDocument12 pagesTop-of-Pole Mount For 9 Modules (TPM9) For Module Types C, D, E, F, G, & HtongaiNo ratings yet

- BR3 002 ManualDocument10 pagesBR3 002 ManualEric LempkeNo ratings yet

- Elf Assembly Version 1-5 PDFDocument15 pagesElf Assembly Version 1-5 PDFDaiben SulitNo ratings yet

- Air Conditioner Installation Manual FriedrichDocument42 pagesAir Conditioner Installation Manual FriedrichDavid GarciaNo ratings yet

- Turbo Levo SL Alloy Schematics 1Document11 pagesTurbo Levo SL Alloy Schematics 1Simon ChoeNo ratings yet

- Cooling Tower Fan 301 Sr. DS Installation Manual 2006.12Document8 pagesCooling Tower Fan 301 Sr. DS Installation Manual 2006.12Krishna BadheNo ratings yet