Professional Documents

Culture Documents

Differential Pressure Gauge Model D201: Max. Static Pressure 400 Bar

Uploaded by

Yuri SeifaneOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Differential Pressure Gauge Model D201: Max. Static Pressure 400 Bar

Uploaded by

Yuri SeifaneCopyright:

Available Formats

Differential pressure gauge

Model D201

Max. Static pressure 400 bar

Nominal size 63 (2.5”) 100 (4”) and 150 mm (6”)

ASME B40.100 / EN 837 / IS-3624

Accuracy: 2 % Ascending

Features

Stainless steel case and several wetted parts

Static pressure up to 400 bar (6000 psi)

Protection IP65

Smooth pointer motion

Dry or liquid filled

Magnetic coupling, solid front not required

Ranges

0 ... 5 psi up to 0 ... 150 psi

0 ... 0.25 bar up to 0 ... 10 bar & kg/cm2

0 … 25 kPa up to 0 … 1000 kPa

Applications

Chemical and petrochemical industry

Machine and apparatus construction

Filters, Hydraulic systems

Water treatment

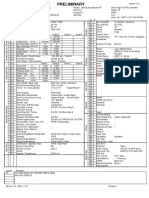

Technical specification D201

Dial size in mm 63 (2.5”) 100 (4”) 150 (6”)

Construction Cylindrical case

Measuring principle Magnetic coupling, solid front not required

Actuator Piston

Process fluid migration Minimal

Range

kg/cm2 (or bar) 0.25 0.5 1 1.6 2 2.5 4 6 10

psi 5 10 15 20 25 30 40 50 60 80 100 150

Max. static pressure

bar 200, optional 400

psi 3000, optional 6000

Overpressure limit Maximum static pressure is also maximum pressure allowed on one side

Pressure type Differential

Process connection 1/4” BSP / NPT,

others on request

Connection location Lower, back, in-line

Material

Wetted parts Body material, spring, screw, magnet

Body, piston Aluminum, brass or stainless steel 316

Magnet Ceramic

O-Ring Buna-N, optional Viton

Case SS304

Window Acrylic glass

Dial Aluminum, black markings on white background

Pointer Aluminum, black, optional red set hand or maximum pointer

Accuracy, ascending only 2 %, 5% for liquid filled

Permissible

Ambient temperature 0 ... 80 °C (32 … 176 °F)

Medium temperature Max. 80 °C (Max 176 °F)

Storage temperature 0 ... 60 °C (32 … 140 °F)

Effect Max. 0,3 % / 10 K

Protection according IP65

Filling liquids Glycerin, Silicon on request

Mounting Direct, optional panel or 2" pipe mounting (only for inline connections), others on request

Accessories, options 3 or 5 way remote mounted manifolds, valves

All specifications are subject to change without notice.

IN.D201 Rev. F 09/10/2019

General dimensions in mm [inch]

Order information

Size Type Body Execution Process Connection Range Engineer- Filling / Case Options

connection orientation ing units

(63) D201 (F) Aluminum (L) IP65 (02T)1/4” NPT (F) (S) In-line 0/ 0,25 kg/cm2 (=) Standard (NH) Tagging wired

63 mm standard 0/ 0,5 (or bar) no filling

(A) Brass case (13T)1/4” BSP (F) (L) Lower 0/ 1 (CS) Dual scale

(100) 0/ 1,6 (GR) Glycerin

100 mm (S) 316 (02)1/4” NPT (M) (B) Back 0/ 2 (DA) Dial marking

0/ 2,5 (GV) Silicon

(150) (13)1/4” BSP (M) 0/ 4 (FX) Front Panel

150 mm 0/ 6

0/ 10 (VD) Viton O-Rings

0/ 5 PSI (PN400) Static 400 bar

0/ 10

0/ 15 (TM) 2" pipe mounting

0/ 20 bracket 1)

0/ 25

0/ 30 (V5) 1 SPDT with DIN

0/ 40 plug

0/ 50

0/ 60 Equivalent (EP) Maximum pointer

0/ 80 ranges in kPa,

MPa and

Others on request 0/ 100 others on

0/ 150 request

1) For inline connection orientation only

Order example

Size Type Body Execution Process Connection Range Engineering Filling/case/ Options

connection orientation unit contacts

100 D201 S L 02T S 0/1 KG/CM2 = NH

Precision Mass Products Pvt. Ltd.

Plot No.: 2306, G.I.D.C. Chhatral, Ta: Kalol, Dist.: Gandhinagar, • North Zone : sales.delhi@precisionmass.com

Chhatral 382 729, Gujarat, India. • East zone : sales.kolkata@precisionmass.com

Telephone: +91-2764 233681/82/83 Fax: +91-2764-233440 • West zone : sales.mumbai@precisionmass.com

Email: sales@precisionmass.com www.precisionmass.com • South zone : sales.chennai@precisionmass.com

You might also like

- SFS Solid Front Process Pressure GaugeDocument2 pagesSFS Solid Front Process Pressure GaugeTlehony HaryNo ratings yet

- Stainless Steel Process Gauges Model ZPS: FeaturesDocument2 pagesStainless Steel Process Gauges Model ZPS: FeaturesRoopa MahtoNo ratings yet

- CPB Low Pressure Capsule GaugesDocument2 pagesCPB Low Pressure Capsule GaugesTlehony HaryNo ratings yet

- BMT-Rev oDocument2 pagesBMT-Rev oRaj Saurabh PandeyNo ratings yet

- Differential Pressure Gauge Model 1130/1131/1132/1133: Max. Static Pressure 400 BarDocument2 pagesDifferential Pressure Gauge Model 1130/1131/1132/1133: Max. Static Pressure 400 BarFIRMANSYAHNo ratings yet

- WPP Solid Front Process Pressure GaugeDocument2 pagesWPP Solid Front Process Pressure GaugeTlehony HaryNo ratings yet

- Stainless Steel Liquid Filled Gauges Model GFS: FeaturesDocument2 pagesStainless Steel Liquid Filled Gauges Model GFS: FeaturesKamitkumar PatelNo ratings yet

- All Stainless Steel Process Gauge Open or Solid Front Model T5500 and T6500Document2 pagesAll Stainless Steel Process Gauge Open or Solid Front Model T5500 and T6500Ferdinand LizadaNo ratings yet

- WPS Open Front Process Pressure GaugeDocument2 pagesWPS Open Front Process Pressure GaugeTlehony HaryNo ratings yet

- Quality Pressure G Auge: All Stainless Steel Construction Robust, Designed For Severe Operating ConditionsDocument2 pagesQuality Pressure G Auge: All Stainless Steel Construction Robust, Designed For Severe Operating ConditionsChhomNo ratings yet

- Oetiker SV Dn8 PlasticoDocument6 pagesOetiker SV Dn8 PlasticoHIDRAFLUIDNo ratings yet

- 2/2, 3/2 Manifold Mounting Compact Design High Flow Rate High Cycle Rate of Up To 1200 Cycles Per Minute Up To KV 14 (Orifice 8 MM)Document4 pages2/2, 3/2 Manifold Mounting Compact Design High Flow Rate High Cycle Rate of Up To 1200 Cycles Per Minute Up To KV 14 (Orifice 8 MM)Venkatesan ManikandanNo ratings yet

- Industrial Pressure Gauge Model: P52: Standard SpecificationDocument2 pagesIndustrial Pressure Gauge Model: P52: Standard SpecificationPort VideoNo ratings yet

- Low Pressure SW Series Compression FittingsDocument20 pagesLow Pressure SW Series Compression FittingsShankar RajNo ratings yet

- Diferensial Pressure GateDocument2 pagesDiferensial Pressure GateipunggNo ratings yet

- Manometro Badotherm BP-004-005Document2 pagesManometro Badotherm BP-004-005Luis Alberto Portugal MariacalNo ratings yet

- Solido 500 enDocument3 pagesSolido 500 enFariyad AnsariNo ratings yet

- En - 5 - 3 - 460 - Super - X 03040402Document22 pagesEn - 5 - 3 - 460 - Super - X 03040402Alessandro FontesNo ratings yet

- Valvula en Linea Norgren x30Document6 pagesValvula en Linea Norgren x30Base SistemasNo ratings yet

- Valvula en Linea Norgren 030Document6 pagesValvula en Linea Norgren 030Base SistemasNo ratings yet

- Manual CM Ia enDocument5 pagesManual CM Ia enJose Luis GallegoNo ratings yet

- Datasheet DR2-06 Ha0026 ENDocument2 pagesDatasheet DR2-06 Ha0026 ENBryan AlexisNo ratings yet

- Diaphragm Sensing Pressure Gauges 1Document2 pagesDiaphragm Sensing Pressure Gauges 1Wency JavateNo ratings yet

- Oetiker SV Dn8Document6 pagesOetiker SV Dn8HIDRAFLUIDNo ratings yet

- Solenoid Valve ST-SA-series: 2/2-WAY Semi-Direct Operated Normally ClosedDocument5 pagesSolenoid Valve ST-SA-series: 2/2-WAY Semi-Direct Operated Normally ClosedVicente Moll ZamoranoNo ratings yet

- Conductivity sensor-SC4Document12 pagesConductivity sensor-SC4Ziyaur RahmanNo ratings yet

- Oetiker SV Dn6Document6 pagesOetiker SV Dn6HIDRAFLUIDNo ratings yet

- General Catalogue Nuova FimaDocument314 pagesGeneral Catalogue Nuova FimaChirag MehtaNo ratings yet

- Panduan Part Number 4008 - E Aschroft Pressure GaugeDocument2 pagesPanduan Part Number 4008 - E Aschroft Pressure GaugerahmanNo ratings yet

- Serie 080 RTC CouplingsDocument2 pagesSerie 080 RTC CouplingsHIDRAFLUIDNo ratings yet

- Ucd Ac005 0013 L100 PRMDocument5 pagesUcd Ac005 0013 L100 PRMArtur ArturowskiNo ratings yet

- TMT401 EyhDocument28 pagesTMT401 EyhAlfredo UriarteNo ratings yet

- SS-E-04 - RID Air ToqueDocument8 pagesSS-E-04 - RID Air ToqueagrovadoNo ratings yet

- Technical Specification: DescriptionDocument2 pagesTechnical Specification: DescriptionAnonymous RcxX0FcNo ratings yet

- F5001 Product GuideDocument2 pagesF5001 Product GuideHendra darmantoNo ratings yet

- A-630 B&G Field Adjustable, Pressure Independent Flow-Limiting Valves For Small Coils BrochureDocument2 pagesA-630 B&G Field Adjustable, Pressure Independent Flow-Limiting Valves For Small Coils Brochurekeith dietrichNo ratings yet

- Functional Description: HA 5009 11/2010 Check ValvesDocument4 pagesFunctional Description: HA 5009 11/2010 Check ValvesSusmit patelNo ratings yet

- Alia APF810 Oval Gear FlowmeterDocument4 pagesAlia APF810 Oval Gear FlowmeterRexCrazyMindNo ratings yet

- Catalogo de Transductores de PresionDocument13 pagesCatalogo de Transductores de PresionAnthony ZamoraNo ratings yet

- Modul Flow Meter SiemensDocument85 pagesModul Flow Meter SiemensMuhammad BushTomyNo ratings yet

- Karta Katalogowa 1638283 Enkoder Obrotowy Inkrementalny Posital Fraba Ucd Iph00 02048 Y06s PRM Magnetyczny Synchro 58 MMDocument6 pagesKarta Katalogowa 1638283 Enkoder Obrotowy Inkrementalny Posital Fraba Ucd Iph00 02048 Y06s PRM Magnetyczny Synchro 58 MMElektronikNo ratings yet

- Posital Ucd-iph00-Xxxxx-y06s-2aw Incremental Encoder Data SheetDocument5 pagesPosital Ucd-iph00-Xxxxx-y06s-2aw Incremental Encoder Data SheetdennnNo ratings yet

- (°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Document16 pages(°F) (Psi (G) ) (Psi (G) ) (Galus/Min) (MMSCFD) (CP) (Psi (A) )Elias EliasNo ratings yet

- 1145 Series: Medium Pressure FiltersDocument8 pages1145 Series: Medium Pressure FiltersRangga NugrahaNo ratings yet

- SR Sanitary Electronic Pressure Transmitter: Food Product Information - SRDocument2 pagesSR Sanitary Electronic Pressure Transmitter: Food Product Information - SROmar Velazquez HernandezNo ratings yet

- Oetiker SV Dn6 PlasticoDocument6 pagesOetiker SV Dn6 PlasticoHIDRAFLUIDNo ratings yet

- Datasheet 1008s 40 50 Stainless Steel Press GaugeDocument5 pagesDatasheet 1008s 40 50 Stainless Steel Press GaugeJeisson RodriguezNo ratings yet

- SB67 AfrDocument3 pagesSB67 AfrAnand AsangiNo ratings yet

- Folleto 75Document4 pagesFolleto 75ricardoNo ratings yet

- GF Signet Pressure TransmitterDocument4 pagesGF Signet Pressure TransmitterDielon PatikNo ratings yet

- IFS Stancor SEW50 DatasheetDocument2 pagesIFS Stancor SEW50 DatasheetMaruRojaNo ratings yet

- Miniature PCB Relays 8 - 10 - 12 - 16 A: SеriesDocument22 pagesMiniature PCB Relays 8 - 10 - 12 - 16 A: SеriesAdnan BeganovicNo ratings yet

- Vco Type B Rev 6 (Ms-02-40)Document2 pagesVco Type B Rev 6 (Ms-02-40)herysyam1980No ratings yet

- RTD Temperature Sensor, Type SPT: TYPE SPT100-X-xx, With Class B (1/3-DIN) Pt100 ElementDocument4 pagesRTD Temperature Sensor, Type SPT: TYPE SPT100-X-xx, With Class B (1/3-DIN) Pt100 ElementMohamed BenounaNo ratings yet

- Catalog of F5001 Electromagnetic FlowmeterDocument2 pagesCatalog of F5001 Electromagnetic FlowmeterGelora MandiriNo ratings yet

- VFM5000 Medidor de FlujoDocument8 pagesVFM5000 Medidor de FlujoHUGONo ratings yet

- General Specifications: Conductivity Sensors and Fittings For 2-Electrode Systems Model SC4A and PR4ADocument8 pagesGeneral Specifications: Conductivity Sensors and Fittings For 2-Electrode Systems Model SC4A and PR4AHolicsNo ratings yet

- Rath Sanitary Tube Uid182010340122 PDFDocument2 pagesRath Sanitary Tube Uid182010340122 PDFthanhquang1001No ratings yet

- Ucd Ac005 0413 L06S PRMDocument5 pagesUcd Ac005 0413 L06S PRMHussain BagasrawalaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- BQ RC Wall SendayanDocument2 pagesBQ RC Wall Sendayanroslan a rahmanNo ratings yet

- Health Informatics SDocument4 pagesHealth Informatics SnourhanNo ratings yet

- Action-Plan Ipbt of SbnhsDocument2 pagesAction-Plan Ipbt of SbnhsLORLIE ABIERANo ratings yet

- P2P Ariba: 1. Which of The Following Statements Are True Regarding Invoice Reconciliation (IR) ?Document6 pagesP2P Ariba: 1. Which of The Following Statements Are True Regarding Invoice Reconciliation (IR) ?shivamdubey12No ratings yet

- Error in HTTP RECEIVE 1 PDFDocument3 pagesError in HTTP RECEIVE 1 PDFKumud RanjanNo ratings yet

- Kaixin: User's ManualDocument49 pagesKaixin: User's ManualRicardo PérezNo ratings yet

- ISEA94 CatalogueDocument229 pagesISEA94 CatalogueAna ZarkovicNo ratings yet

- 6 HGX 73 WWDocument21 pages6 HGX 73 WWNella GronNo ratings yet

- SACS Basic TrainingDocument4 pagesSACS Basic Traininganil100% (1)

- ElecschDocument11 pagesElecschchaitanyaNo ratings yet

- Ansible BasicsDocument48 pagesAnsible Basicsshrinath bhat0% (1)

- Patari: Pakistan's Largest Pakistani Music Streaming PlatformDocument57 pagesPatari: Pakistan's Largest Pakistani Music Streaming PlatformMohsin ChaudharyNo ratings yet

- Creating A Healthy Balance: Technology AddictionDocument4 pagesCreating A Healthy Balance: Technology AddictionAnurag VishwakarmaNo ratings yet

- Differential Protection - Need For Large Size Essential HT MotorDocument6 pagesDifferential Protection - Need For Large Size Essential HT Motorpankaj_kumar97No ratings yet

- CommSwift Product DraftDocument18 pagesCommSwift Product DraftSingh PankazNo ratings yet

- LV Full CatalogueDocument8 pagesLV Full CatalogueRicardo TavaresNo ratings yet

- Aruf DaikinDocument12 pagesAruf DaikinJorge Manuel Meza NavarroNo ratings yet

- 63173en1 PDFDocument1,198 pages63173en1 PDFALeXS280856No ratings yet

- Seating Plan For PH.D Students During Mid Semester (Odd) Exam 2018-19Document6 pagesSeating Plan For PH.D Students During Mid Semester (Odd) Exam 2018-19Aakash PathakNo ratings yet

- Nasa Power Dav User GuideDocument17 pagesNasa Power Dav User GuideCARLOS FERNANDO LUNA CARLOSAMANo ratings yet

- Manual - Skin DiMkaDocument20 pagesManual - Skin DiMkaGatu CristianNo ratings yet

- Technical Reference Guide: Product OverviewDocument114 pagesTechnical Reference Guide: Product OverviewRonny Kimer Fiestas VargasNo ratings yet

- MODEL NO.: M185B1-P01: TFT LCD Approval SpecificationDocument25 pagesMODEL NO.: M185B1-P01: TFT LCD Approval Specificationcesar calderonNo ratings yet

- Textaizer Pro - HelpDocument44 pagesTextaizer Pro - HelpfarhoodNo ratings yet

- Mandatory DisclosureDocument153 pagesMandatory Disclosurerages56No ratings yet

- Cost Reduction Through Industrialization, Standardization and SimplificationDocument16 pagesCost Reduction Through Industrialization, Standardization and SimplificationRoo FaNo ratings yet

- MotorolaDocument19 pagesMotorolaYashupriya ThakurNo ratings yet

- 5036maa cw1 2223 Janmay v1.0Document9 pages5036maa cw1 2223 Janmay v1.0Julius KudoroNo ratings yet

- 1.testing of CT, PT and Insulator StringsDocument8 pages1.testing of CT, PT and Insulator StringsBhanu100% (2)