Professional Documents

Culture Documents

Check Lis

Uploaded by

haneenapt94Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check Lis

Uploaded by

haneenapt94Copyright:

Available Formats

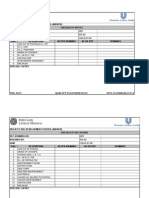

Column Inspection Check List

PROJECT : G+P+6+R RESIDENTIAL BUILDING AT MOTOR CITY

MAIN CONTRACTOR : ATCON CONSTRUCTION DATE

COSNULTANT : CHAWALLA ENGINEERING CONSULTANT COL NAME GRID SIZE REINF TIES

COLUMN NAME/GRIDAND SIZE AND STEEL

ATCON

SUB CONTRACTOR FOREMAN IN SENIOR

IN CHARGE CHARGE SITE ENGINEER ENGINEER COMMENTS

General & reinforcement

1 Plotting of gridline for center of column above plinth / floor slab.

2 Locating & marking the centers of columns.

Binding & placing column reinforcement above upper floor slab as per

3 required height, considering lap length of the bar.

4 Column reinforcement & its arrangement as per drawing.

5 Ring spacing & their arrangement as per R.C.C. drawings.

6 Proper binding of reinforcement with binding wire.

7 Fixing of concrete or P.V.C. cover blocks to reinforcement.

Checking of shuttering for columns

1 The quality of shuttering before placing.

2 Applying deshuttering oil to plywood shuttering.

3 Fixing M.S.clamps (shinkanjas) at every 0.6 m (2’0″) internal.

4 Stiffness of side supports to have formwork in plumb.

Checking of column before concreting

1 Size as per drawing.

2 Diagonals as required.

3 Oiling of shuttering.

4 Plumb on both sides.

5 Line of columns as desired.

6 Sufficient Marking level up to which concreting to be done.

7 Supports.

8 Reinforcement cover provided.

9 Spacing of reinforcement above concrete level, maintained as required.

10 Proper filling of gaps from outside by soil paste.

forman/General Forman Site engineer Senior Engineer

Column Inspection Check List

PROJECT : G+P+6+R RESIDENTIAL BUILDING AT MOTOR CITY

MAIN CONTRACTOR : ATCON CONSTRUCTION

COSNULTANT : CHAWALLA ENGINEERING CONSULTANT

Checking of column while concreting.

1 Quality of materials of concrete.

2 The proportion & mixing of material.

3 Six cube mould are kept ready to cast cubes from different batches.

4 Controlled water cement ratio.

5 Availability of vibrator or labour for tamping.

6 Proper cover after concreting on top level.

7 Casting of concrete cubes as required.

8 Proper numbering on cubes.

9 Fill joints if slurry flows from anywhere.

10 Maintain required concrete level.

11 Cleaning of mixing platform.

Checking of columns after concreting.

1 Deshuttering of columns after 24 hrs-48 hrs.

2 Submission of the deshuttering report to higher authority.

3 Finishing of honey combing, if any, with proper care.

4 Date of casting written on column.

5 Hacking of columns.

Cubes removed next day & kept for curing, with code numbers, cast

6 code, site name on cubes.

Curing of columns done for minimum 15 days. Wet nesian cloth wrapped

7 around it.

8 Testing of cubes on due dates i.e. after seventh & twenty eighth day.

forman/General Forman Site engineer Senior Engineer

BEAMS Inspection Check List

PROJECT : G+P+6+R RESIDENTIAL BUILDING AT MOTOR CITY

MAIN CONTRACTOR : ATCON CONSTRUCTION DATE

COSNULTANT : CHAWALLA ENGINEERING

CONSULTANT BEAM NAME GRID SIZE REINF TIES

BEAM NAME/GRID AND SIZE

ATCON

SUB CONTRACTOR FOREMAN IN SITE SENIOR

IN CHARGE CHARGE ENGINEER ENGINEER COMMENTS

Approved shop drawings and Authorities drawings

1

2 Beam dimensions

3 Bottom reinforcement

4 Top reinforcement

5 Additional top reinforcement

6 Additional bottom reinforcement

Top of concrete in columns / core walls / retaining

7 walls

8 Shear links

9 Columns / walls / core walls starter bars

Reinforcement overlap locations to be in

10 compression zones only

11 MEP Clearances

12 Construction joints at 1/3rd or ½ of the span

13 Pour strip at 1/3rd of the span

14 Pre-camber requirements

15 Concrete spacers / cover blocks

16 Safety

17 Cleaning

18 Openings additional reinforcement

19 Tightening of bars

20 Planted walls / columns

Terminated columns / walls / core walls / retaining

21 walls

Forman/General Forman Site Engineer Construction Manager

You might also like

- Brick&Bolt Quality Assessment System - QASCONDocument10 pagesBrick&Bolt Quality Assessment System - QASCONPulkit Chawla100% (2)

- TEST REPORT After Earth ImprovementDocument3 pagesTEST REPORT After Earth ImprovementShami Mudunkotuwa78% (9)

- Footing - ChecklistDocument2 pagesFooting - ChecklistbsudhareddyNo ratings yet

- METHOD Statement of BRIDGE (Major STR)Document6 pagesMETHOD Statement of BRIDGE (Major STR)venkateswara rao Pothina100% (2)

- Method Statement For Parapet Construction WorksDocument8 pagesMethod Statement For Parapet Construction Workssonusweetyshobha100% (2)

- POUR CARD New FormatDocument5 pagesPOUR CARD New FormatCivil Site 1775% (4)

- 14 A Check Lists - AACDocument3 pages14 A Check Lists - AACVaibhav PatilNo ratings yet

- 009 RCC Job Procedure 1Document15 pages009 RCC Job Procedure 1Shaarun M RamannNo ratings yet

- Cat Fines Presentation SlidesDocument48 pagesCat Fines Presentation SlidescaptkcNo ratings yet

- AXE400P User Manual With Centos6.0 Dahdi V2.0 D130603 enDocument12 pagesAXE400P User Manual With Centos6.0 Dahdi V2.0 D130603 enCartimex S.A.No ratings yet

- 015-Method Statement For Painting Works (Building) PDFDocument21 pages015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- Checklist - Civil WorksDocument25 pagesChecklist - Civil WorksJagoan Neon0% (1)

- Working BOQ (Dec, 2019 To Jan, 2020)Document10 pagesWorking BOQ (Dec, 2019 To Jan, 2020)Muhammad Sarmad SonyalNo ratings yet

- Checklist For VDFDocument1 pageChecklist For VDFGabriel GabeNo ratings yet

- Concrete Work Check List-30-06-2022Document6 pagesConcrete Work Check List-30-06-2022Mobin100% (1)

- IR Bore PilingDocument3 pagesIR Bore PilingalfredoNo ratings yet

- Master List of Checklist New With All LOGOsDocument22 pagesMaster List of Checklist New With All LOGOsRahul Jaiswal100% (1)

- Masonry Work ChecklistDocument2 pagesMasonry Work ChecklisttalemwamartineNo ratings yet

- BDocument28 pagesBJojolasNo ratings yet

- Methodstament For RCC and PCCDocument6 pagesMethodstament For RCC and PCCDeepak Patil100% (1)

- Checklists For Quality Control For RCC WorkDocument4 pagesChecklists For Quality Control For RCC Workwaimaung100% (1)

- Drawing StudyDocument32 pagesDrawing StudyurmilayadavNo ratings yet

- Method Statement With Job Safety Analysis For Road Drains Culverts Road Crossover Final 16 07 2019Document32 pagesMethod Statement With Job Safety Analysis For Road Drains Culverts Road Crossover Final 16 07 2019Imranuddin SyedNo ratings yet

- Editable Checklist Sample Appendix ADocument10 pagesEditable Checklist Sample Appendix Aridwanlawal888No ratings yet

- Pile SpecificationsDocument16 pagesPile SpecificationsHarshini Reddy B.100% (1)

- Consolidated BOQ Civil Tender@ DN50 Saltlake Sector VDocument16 pagesConsolidated BOQ Civil Tender@ DN50 Saltlake Sector VhironmoyapcNo ratings yet

- Installation & Testing of Above Ground Drainage PipingDocument6 pagesInstallation & Testing of Above Ground Drainage PipingmohamedsyedaliNo ratings yet

- Construction Specifications LongDocument7 pagesConstruction Specifications LongLimar SetatraNo ratings yet

- Construction SpecificationsDocument7 pagesConstruction SpecificationsVincent FilomenaNo ratings yet

- Construction SpecificationsDocument7 pagesConstruction SpecificationsVincent FilomenaNo ratings yet

- AAC Blocks With Chemical (R0)Document3 pagesAAC Blocks With Chemical (R0)Omkar AdurkarNo ratings yet

- Marriot Grand Ballroom Concrete Works: Project Title: Contract Package No. Document TitleDocument10 pagesMarriot Grand Ballroom Concrete Works: Project Title: Contract Package No. Document TitleImho TepNo ratings yet

- Concrete Pouring and Form Closure RequestDocument2 pagesConcrete Pouring and Form Closure RequestJefferson Fontanilla Ganado50% (2)

- 4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - ParadeepDocument48 pages4 - Technical Specifications For Piling Works - Pile Foundation For Tanks - Paradeepvignesh_freeboterNo ratings yet

- Good Construction Practise - Handouts - ConcreteDocument18 pagesGood Construction Practise - Handouts - Concretehitesh16No ratings yet

- Sequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualDocument31 pagesSequatchie Concrete Service: Precast Prestressed Hollow Core Concrete Floor and Roof Systems Design ManualNirmal KishorNo ratings yet

- Method Statement: (Continuous Flight Auger)Document15 pagesMethod Statement: (Continuous Flight Auger)sawkariqbal100% (1)

- Check ListDocument19 pagesCheck ListPanruti S SathiyavendhanNo ratings yet

- Method Statement RE Structures-Final-29052011Document5 pagesMethod Statement RE Structures-Final-29052011sanojevNo ratings yet

- Check List For Concreting: Project: Doc. No.: Qa/Cl-Con/ Client: ContractorDocument1 pageCheck List For Concreting: Project: Doc. No.: Qa/Cl-Con/ Client: ContractorBala SubramanianNo ratings yet

- 1.13 Tender Section ADocument12 pages1.13 Tender Section AErMelvinDiasNo ratings yet

- Division 31Document4 pagesDivision 31sbunNo ratings yet

- Pre-Concrete Inspection Checklist IDDocument1 pagePre-Concrete Inspection Checklist IDAndrew AndersonNo ratings yet

- S.No Description Format No Rev RemarksDocument23 pagesS.No Description Format No Rev RemarksGulam Mujtaba KhanNo ratings yet

- Pile CapDocument16 pagesPile CapGANGARAJU N BNo ratings yet

- It Building Boq FinalDocument5 pagesIt Building Boq Finalrehan7421No ratings yet

- Structural Specifications - OakridgeDocument13 pagesStructural Specifications - OakridgeJuliet Lobrino RozosNo ratings yet

- Technical SpecificationsDocument6 pagesTechnical SpecificationsMark SorianoNo ratings yet

- TS StructuralDocument23 pagesTS StructuralMads EscobarNo ratings yet

- 11c - Pile Cap Details - StructuralDocument2 pages11c - Pile Cap Details - StructuralAnthony FedericoNo ratings yet

- Foundation Inspection Checklist: "Partnering To Improve Consistency & Customer Service"Document3 pagesFoundation Inspection Checklist: "Partnering To Improve Consistency & Customer Service"Wai Lin Oo100% (1)

- Manjeera Construction LTD.: ReinforcementDocument5 pagesManjeera Construction LTD.: ReinforcementCivil Site 17100% (1)

- IPS Screed ChecklistDocument2 pagesIPS Screed ChecklistArc FortiusNo ratings yet

- PQC Pour Card FormatDocument1 pagePQC Pour Card FormatChander MohanNo ratings yet

- Tata Consulting Engineers Limited: Concrete Pour C ArdDocument4 pagesTata Consulting Engineers Limited: Concrete Pour C ArdGuna Sekaran100% (1)

- IR Sub Grade ConstructionDocument2 pagesIR Sub Grade ConstructionWr Ar100% (2)

- Adobe Scan 25-Oct-2022Document6 pagesAdobe Scan 25-Oct-2022himanshu koleyNo ratings yet

- Method StatementDocument10 pagesMethod StatementEmmanuel kusimoNo ratings yet

- Highway PlanDocument11 pagesHighway PlanShine AtanosoNo ratings yet

- Gracel'S Enterprises: General SpecificationsDocument17 pagesGracel'S Enterprises: General SpecificationsRhanie Nitsuga GnoldubatNo ratings yet

- Check Lists For Construction Work Activities Ok NewDocument98 pagesCheck Lists For Construction Work Activities Ok Newamare100% (1)

- MS For Plain Cement Concrete.Document4 pagesMS For Plain Cement Concrete.Shan THALANo ratings yet

- Technical Specification of Stay InsulatorDocument11 pagesTechnical Specification of Stay Insulatorraj_stuff006No ratings yet

- GP2500S/GP2501S - STN Color: Pro-Face Graphic Operator InterfacesDocument2 pagesGP2500S/GP2501S - STN Color: Pro-Face Graphic Operator Interfacesthanh_cdt01No ratings yet

- 5 Gaikindo Production Data Jandec2018 Rev HondaDocument3 pages5 Gaikindo Production Data Jandec2018 Rev HondaWira WijayaNo ratings yet

- Air Lift PumpDocument4 pagesAir Lift PumpFoxty67% (3)

- 5 Process SynchronizaionDocument58 pages5 Process SynchronizaionLokesh SainiNo ratings yet

- Standard Operating Procedure-Standard Maintenace ProcedureDocument11 pagesStandard Operating Procedure-Standard Maintenace ProcedureVikram JitNo ratings yet

- VECU - Manual de Producción 70312913Document33 pagesVECU - Manual de Producción 70312913RainorSS100% (2)

- 008 Cat-6060 Attachment Functions FSDocument37 pages008 Cat-6060 Attachment Functions FSenrico100% (3)

- Electrostatic Powder PaintingDocument9 pagesElectrostatic Powder PaintingfirdausNo ratings yet

- Gapura Company Profile - 17mar17Document43 pagesGapura Company Profile - 17mar17als izmiNo ratings yet

- NE5521Document9 pagesNE5521Carlos TibussiNo ratings yet

- Brushbond Ultraflex BFLDocument2 pagesBrushbond Ultraflex BFLpeashNo ratings yet

- Transmission - Approved List 26-09-2017Document554 pagesTransmission - Approved List 26-09-2017bkhNo ratings yet

- 03 Vetotouch Europa - Group 170821Document2 pages03 Vetotouch Europa - Group 170821HalaNo ratings yet

- L6B TFT-LCD TV Service ManualDocument35 pagesL6B TFT-LCD TV Service ManualFrank PaceNo ratings yet

- 002 Danfoss PICV Energy Valve Ver 090821 r0Document2 pages002 Danfoss PICV Energy Valve Ver 090821 r0Pattana MekkhumNo ratings yet

- Red MarsDocument16 pagesRed Marsfz.fathima50% (2)

- Lanko 753 - TdsDocument1 pageLanko 753 - TdskalslingamNo ratings yet

- HP 15-Dy1038ca Emglish ManualDocument78 pagesHP 15-Dy1038ca Emglish ManualRoxana PetrescuNo ratings yet

- Weidmuller HazLoc Catalog 2014 LIT1315EDocument12 pagesWeidmuller HazLoc Catalog 2014 LIT1315Evaseem shaikNo ratings yet

- Application of Theory of Constraints in Health SystemsDocument10 pagesApplication of Theory of Constraints in Health SystemszafarNo ratings yet

- Systemd CheatsheetDocument1 pageSystemd Cheatsheetzaffa11No ratings yet

- Ball Valve FCTDocument16 pagesBall Valve FCTAnggi SujiwoNo ratings yet

- Guidelines For Ceiling Framing WorksDocument3 pagesGuidelines For Ceiling Framing WorksRal GLNo ratings yet

- Qus Mod 4.2 PCBDocument14 pagesQus Mod 4.2 PCBJagbir SinghNo ratings yet