Professional Documents

Culture Documents

Flexpro Whitepaper Guide - To - A - Successful - Drug Development Technology - Transfer 1

Uploaded by

zakarya wadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flexpro Whitepaper Guide - To - A - Successful - Drug Development Technology - Transfer 1

Uploaded by

zakarya wadiCopyright:

Available Formats

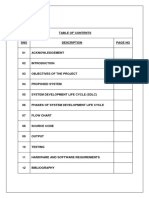

Guide to a Successful Drug

Development Technology Transfer

Steps to Conducting an Efficient and Effective Technology Transfer

Inside: The FlexPro Group

Introduction: Why Tech Transfers Occur, and the 620 West Germantown Pike Suite 260

Importance of Project Management Plymouth Meeting, PA 19462

Creating a Technology Transfer Plan info@theflexprogroup.com

Creating the Technology Transfer Package 484.674.7838 x101

Completing the Comparability Report

Doing a Risk Assessment

Issuing Master Batch Records

Formalizing Training

Validating the Process

Developing the Final Technology Transfer Report

A Note About COVID-19 and Tech Transfers

Sources/For More Information

Introduction: Why Technology Transfers Occur, and

the Importance of Project Management

During a drug development technology transfer, the focus is on moving products from one manufacturing

site to another while preserving process and product integrity. Ultimately, the goal is reaching the

commercialization of the drug product. These are complex projects that require a high degree of

pharmaceutical project management experience.

The transfer team must be cross-functional and should include key team members, which will be described

in detail below. Because the transfer typically involves a minimum of two locations and perhaps several more,

the transfer team provides disciplined coordination during the process and serves as a central repository of

information about the transfer.

This cohesiveness is especially important in situations that involve vast geographical distances and multiple

languages. There may be a high level of complexity involved in the pharmaceutical development itself, which

requires sophisticated technical expertise—and perhaps translation—for all involved parties.

This isn’t the type of project that’s well suited to a brand-new project manager or someone who is still in the

learning stage of their professional development. It takes a project manager with a high level of expertise as

well as excellent interpersonal and organizational skills, so keep this in mind as you explore the guide you’ll

find on the following pages.

This guide will provide insights into the technology transfer process and help your company understand the

key elements of a tech transfer. We’ll address nine key steps you’ll need to take, including conducting these

transfers during the COVID-19 pandemic.

Guide to a Successful Drug Development Technology Transfer

2

theflexprogroup.com

Create a Technology Transfer Plan

As you create the tech transfer plan, formalize it in writing and keep it in a safe, centralized location with

credentialed access that maintains security for the relevant data. Make the plan highly detailed with as much

input from team members early in the process as possible.

Include input from all departments and visit the existing site or sites in an information-gathering capacity. Ask

questions that reveal the issues and roadblocks that may potentially arise throughout a technology transfer.

Visit the new site or sites and work with the team members. Gather information not only from the senior

executives but also from the technical teams who are most familiar with the details of the process and

equipment. The analytical personnel and engineers from the receiving site must visit the current sending

manufacturing site to see how things are done now. Key team members need to understand the differences

between the two sites.

The tech transfer plan, at its core, facilitates communication. Here are some of the project management

communication factors to take into consideration as you design your transfer plan.

Key project management skills and factors are:

• Serves as the communications nexus

• Should be able to address issues and concerns efficiently

• Acts as a repository of information plus a hub of information sharing

• Will need to prioritize among initiatives, escalate issues, and seek support from appropriate areas

• Manages inputs and outputs

• Provides expertise with both resource management and stakeholder management

• Time tracking against milestones

• Budget adherence

• Risk management and mitigation

The project manager provides the essential service of establishing an effective communications plan and

ensuring that all team members and stakeholders receive information in a timely manner. The focus should

be on defining the scope of the project, conducting gap analysis, and getting the right team in place to

conduct the tech transfer successfully.

A project manager must, at all times, find solutions that work for the company and its team members. They

should proactively identify and manage risks and manage issue escalation to remove all barriers as they arise,

using the communication channel between the two sites for a successful tech transfer.

Guide to a Successful Drug Development Technology Transfer

3

theflexprogroup.com

Create a Technology Transfer Plan

Certain team members are almost always involved in a tech transfer at both the transmitting and receiving

sites. Identifying and assigning these individuals to the team will take time and will involve reassigning some

of their day-to-day activities to free up enough time if team members are not dedicated to the project. These

projects may require a large number of team members from a diverse cross-section of company departments.

Key team members from the receiving site will need to be involved in the tech transfer planning process.

Team members typically involved in the process include some of the following expertise or functions.

• Analytics chemists • Planning

• Chemists • Process engineers

• Core functions • Procurement

• Engineers • Quality assurance

• ERP system specialists • Quality control (QC)

• Labeling and artwork/packaging engineers • Regulatory specialists

• Logistics • Sending/receiving at both sites

• Manufacturing • Statisticians

• Marketing • Supply chain

• Medical affairs • Trainers

• Operations

The above team members must be involved in the development of the technical transfer plan at an early stage

of the project. They will identify the information that needs to be transferred and the amount of time needed

to do so. This team will also be providing estimates of time, cost, and resources associated with equipment

setup and qualification, validation batch manufacturing, intermediate and finished product testing, and the

creation and approval of protocol and reports. The tech transfer plan will require a preliminary timeline with

input from the core and extended teams.

Now that we have begun to create the tech transfer plan, we can look at how the process plan should be laid

out at the receiving site. Next, we’ll address how this happens and how it involves the technical package.

Guide to a Successful Drug Development Technology Transfer

4

theflexprogroup.com

Create the Technology Transfer Package

The tech transfer plan needs to include the activities associated with the sending site. As part of the timeline

development process, it’s time to map out the tech transfer plan at the receiving site and create the technical

package for the transfer. The technical package is any technical information that needs to be replicated from

the existing site to the new site.

A project manager typically receives only portions of the technical package during the transfer planning

process but the planning process should have a rather complete list of information that will be transferred.

When the process takes place, the entirety of the transfer package will be transferred.

The project manager will be tracking and facilitating the transfer of technical information like processes,

specifications, and qualifications along with ensuring there is a solid plan in place for the replication and

transmission of this information.

Common categories of transmitted technical information include:

• Equipment specifications • Tolerances. • Timeframe constraints

• Regulatory information • Vendor data • Product specifications

• Previous processes • Test methods. • Control strategy

• Quality control package • Operating conditions

Process planning tips from The FlexPro Group:

1. Don’t expect this process to be too neat and tidy. It’s an ongoing, ever-changing process that occurs

over time. The client may not have clearly-documented procedures or practices. A gap analysis will

help uncover and address some of the unknowns.

2. Pharma companies are required to adhere to GMP guidelines for drug development and

manufacturing which includes having appropriate documentation. Their business is complex and

usually requires dedication from the project manager to create full documentation. This is why it is

critical for experienced technical personnel to witness how things are currently done.

3. Interpersonal skills are essential here. Connect with the people at the highest and lowest levels of

the organization and work on building their trust so they’re willing to provide key insights that lead

to success.

It should be noted that sometimes, introducing a new process with its associated raw materials and

intermediates may require new permits or changes to existing permits before manufacturing can begin. It’s

important not to miss this crucial step. Additionally, the supply chain should be reviewed for lead time and

qualification of new raw materials.

Next, we’ll look at the importance of the comparability report.

Guide to a Successful Drug Development Technology Transfer

5

theflexprogroup.com

Complete the Comparability Report

A comparability report, also known as a gap analysis, examines the technical gaps between the existing site

and the new site. It should assess the manufacturing capacity, packaging capabilities, environmental controls,

and sampling and testing capabilities. It should occur before the technical package is approved.

The technical documentation package prepared by the sending site is the foundation upon which

the receiving site performs a site readiness assessment and the accompanying risk assessment. These

assessments, in turn, form the basis of the comparability report. The comparability report is then used to

create the transfer plan, timeline, and budget for the tech transfer. In many cases, a final post-validation tech

transfer report is never created.

In the comparability report, look at a variety of areas, including manufacturing, packaging, and testing

equipment, raw materials, packaging supplies, equipment and infrastructure upgrades, personal protective

equipment, and potential changes due to the industry and regulatory environment. In some cases,

new and stricter local safety environments require adjustments to meet these higher standards. Make

recommendations about adjustments that would need to take place if certain contingencies occur.

This is a key part of the process, and without the comparability report, the rest of the process won’t happen

smoothly. Prepare a thorough comparability report, and refer to it frequently as the process continues.

The receiving site should make at least one demonstration batch. In addition to the demonstration batch, an

analytical transfer process should involve the receiving site and the sending site analyzing samples from the

same lot and comparing results.

To be clear, there should be two parallel efforts occurring. One is for the manufacturing process, in which

batches are made at the receiving site and are checked by the sending site. The batches should cover all steps

of the intended manufacturing and packaging process. The other effort involves testing identical samples at

both sites to ensure both sites are getting the same test results.

Based on the comparability report and the other efforts taking place at this stage in the process, it is likely

the preliminary timelines and possibly the cost estimates will need to be revised and shared with senior

leadership.

Guide to a Successful Drug Development Technology Transfer

6

theflexprogroup.com

Do a Risk Assessment

The risk assessment is a critical part of the process and should occur early in the process. Risk assessment is a

continuous process that lasts for the duration of the transfer. Typically, a risk register is created as part of the

planning process and is reviewed and updated throughout the technology transfer project with some risks

being resolved and new risks being added, evaluated, and tracked.

Risk assessment enriches the process and helps create a deeper understanding of the process so that all team

members - including the highest-level executives who are in charge of resource allotment - can understand

what is occurring with the tech transfer and potential risks involved.

It should involve multiple team members, including sourcing, manufacturing, packaging, and more. As the

project manager, you can help identify relevant attributes and parameters using input from the experts

you’ve been working with during the earlier stages of the process.

At this stage, the project manager is serving the crucial role of highlighting successes and identifying threats

to the stability of the process. In clear terms, document in writing which types of things could go wrong,

including any type of disruption that could slow or stop the process.

Rate risks according to their likelihood and describe the potential impact of each risk. Include factors like raw

materials availability, manufacturing delays, inaccurate specs, and shifting deadlines that could threaten the

transfer.

Encompass all levels of risk, including time-based, technical, and financial issues. For example, if the tech

transfer will involve a dangerous process, describe it in detail, and create a contingency plan. This helps

mitigate risk for the team members and shows you’ve done your due diligence in managing the details of the

tech transfer.

Guide to a Successful Drug Development Technology Transfer

7

theflexprogroup.com

Conduct a Test Transfer

The manufacture of test batches and the testing of the receiving site’s new capabilities typically occur during

the same timeframe. Now let’s take a closer look at the testing process.

The testing process involves two sub-steps:

1. Order all necessary supplies, like reactants and raw materials, and allow appropriate lead times.

2. Prepare to test small-scale batches.

Although this is a brief summary of the test transfer process, each of these three steps will take a significant

amount of preparation and planning. Help your team members accept and adjust to the idea that the test

transfer is a necessary part of the process and sets everyone up for success later when the actual transfer

must take place.

Next up, we’ll look at the value of master batch records in the pharmaceutical tech transfer process.

Issue Master Batch Records

At this point, it’s time to issue the master batch records that will preserve essential information during the

transfer process. Start this step by preparing the receiving site to receive master batch records.

Follow all protocols and specifications, including those that are regulatory. The team’s subject matter experts

provide a deep well of intellectual resources within the pharmaceutical company. Experts oversee the process

and look for issues on both ends, at the existing site and the new site. Remember to document the entire

process down to the small details and note any adjustments that are needed.

Guide to a Successful Drug Development Technology Transfer

8

theflexprogroup.com

Formalize Training

As the project manager, you have a high-level view of the essential tasks involved and will begin to get a

sense of where additional training will be necessary to ensure success. You can also seek the input of your

team members on this front.

The formalization of training usually includes the creation of training packages associated with operating

new equipment as well as the new manufacturing and testing processes. Retrievable training records and

proof of competency must be available for health authorities and auditors.

The workers at the new location will almost certainly need training to cope with the influx of new processes

and demands. This includes analysts and operators who are conducting the tech transfer itself.

It also includes people who may not be directly involved with the transfer but will be involved in the future

on an ongoing basis, like people who will work around the production line.

Consider using a “train the trainer” approach, where those with firsthand observation of the tech transfer

become trainers themselves. Your first trainers will train the second batch of trainers and so on. Soon you have

a large pool of trainers who are not only great teachers but have also educated themselves more thoroughly

as a result of taking the time to teach the information.

Process validation is next, and it reinforces the validity of your tech transfer process.

Guide to a Successful Drug Development Technology Transfer

9

theflexprogroup.com

Validate the Process

Now let’s look at process validation. While newer, smaller companies may go straight into validation after

the test batches are complete, some companies have a gating process before test batches are run and again

before validation batches are allowed to begin. Quality assurance is often a critical factor in the approval of

validation protocols and giving the final word on moving forward.

Process validation involves creating a protocol that points to and leverages the content of the master batch

records. This process resolves uncertainties discovered in the previous steps and wraps things up in an

organized way. It also shows the value and validity of the tech transfer process.

What happens during process validation:

• Start with your specifications and develop protocols.

• Manufacture three batches under specified conditions.

• Align on a sampling plan that includes in-process and final samples.

• Quantify what the acceptable results are.

• Determine prerequisites and qualified equipment.

• Set forth the criteria for success in all areas.

• Collect batches, collect data, and create reports.

During process validation, note any deviations that should be investigated. Determine whether deviations

are within the acceptable range or if adjustments will need to be made.

Generally speaking, most issues should have been resolved before starting validation. Validation batches are

not supposed to have surprises or issues requiring additional batches. On the other hand, outside factors

unrelated to the tech transfer - for example, a loss of utilities - may make it necessary to repeat a batch.

Document everything thoroughly along the way.

In the next stage, we’ll develop the final transfer report as we get closer to wrapping up the transfer process.

Guide to a Successful Drug Development Technology Transfer

10

theflexprogroup.com

Develop the Final Technology Transfer Report

In this part of the process, the project manager serves the key role of developing the final tech transfer report

and delivering it to the client. This is the key document that results from the process and serves as the archive

and reference document for the transfer.

It’s important to include a high level of detail in this document without forgetting to take a step back

and provide a big-picture view of the process. Include a justification for why it took place, and review the

parameters that were set forth at the beginning of the project.

Draw overall conclusions, summarize persistent problems, mention future risks, and conclude with a look

at the triumph of the project. Sending and receiving units should evaluate the success of the tech transfer

through analysis of the product and data. At this point, the project manager ensures that the technology was

transferred successfully and ownership has been finalized with the receiving site. This is an opportunity to

showcase the value of project management in technology transfers, in achieving project goals successfully.

A Note About COVID-19 and Tech Transfers

The COVID-19 crisis has highlighted the fact that there is an art to the science of tech transfers. As tech

transfers have been urgently required during the development of the COVID-19 vaccine, the value of project

management for the life sciences has been clearer than ever.

McKinsey & Company, one of the most respected names in the pharma world, describes today’s vaccine tech

transfers as a turning point in human history, saying, “How quickly COVID-19 vaccine production ramps up will

depend on technology transfer—the capabilities and processes that can speed vaccines from development

to manufacturing.”

One of the critical components of a fast and successful vaccine tech transfer is subject matter expertise.

FlexPro offers strong project management expertise that can help a busy pharma company accelerate

timelines while managing a large pool of vital team members and team members.

“Tech transfer may be critical to

beating COVID-19.”

-McKinsey & Company

Guide to a Successful Drug Development Technology Transfer

11

theflexprogroup.com

For More Information

As you can see from the information presented in this whitepaper, the success of a tech transfer for a life

sciences organization depends largely on its project management. With a high level of project management

expertise, a company can conduct a smooth and successful tech transfer that supports fast innovation and

global human health.

To learn more about tech transfer project management for pharmaceutical companies, connect with

the experts at FlexPro. We specialize in serving the project management needs of the world’s life sciences

companies.

The FlexPro Group

620 West Germantown Pike Suite 260

Plymouth Meeting, PA 19462

info@theflexprogroup.com

484.674.7838 x101

Sources

https://www.linkedin.com/pulse/9-essential-steps-technology-transfer-pharmaceutical-product-grenier/

https://www.aniglobalsource.com/blog/what-is-technology-transfer-in-pharmaceutical-contract-manufacturing

http://www.pharmtech.com/keys-executing-successful-technology-transfer

https://lifesciencespa.org/

https://njbio.com/

https://www.fiercepharma.com/

https://www.pmi.org/learning/library/project-portfolio-management-techniques-7624

https://www.pmi.org/-/media/pmi/documents/public/pdf/white-papers/pmo-strategy-implement.pdf

https://theflexprogroup.com/case-studies/flexpro-helps-a-natural-products-company-become-revenue-generating/

https://www.mckinsey.com/industries/pharmaceuticals-and-medical-products/our-insights/why-tech-transfer-may-

be-critical-to-beating-covid-19?cid=other-eml-alt-mip-mck&hlkid=b954ee84d2b041febc309b32da83e9d6&hct-

ky=9847703&hdpid=cb86c83a-dd2e-4d4b-ac0b-f23402fc3960

Guide to a Successful Drug Development Technology Transfer

12

theflexprogroup.com

You might also like

- Planning For Successful Technology TransferDocument5 pagesPlanning For Successful Technology TransfermmmmmNo ratings yet

- The Planning Phase: The Project Is PlannedDocument3 pagesThe Planning Phase: The Project Is PlannedsunsgangNo ratings yet

- Managing Outsource TransitionsDocument11 pagesManaging Outsource TransitionsNa Jaejaemie50% (2)

- Technology Transfer From R&D To ProductionDocument16 pagesTechnology Transfer From R&D To ProductionRutuja Chougale100% (1)

- BP702T Ip IiDocument29 pagesBP702T Ip IiMukund JhaNo ratings yet

- BPO Module 4Document95 pagesBPO Module 4Denrich CabadduNo ratings yet

- BP702T Ip IiDocument29 pagesBP702T Ip IiTurbo ChargedNo ratings yet

- Bpo Module4Document95 pagesBpo Module4rochelle regencia100% (3)

- SMPBPO101 - 004 v2013 QCCIDocument95 pagesSMPBPO101 - 004 v2013 QCCIJohn Dave GentuyaNo ratings yet

- By Phani Krishna EsciDocument23 pagesBy Phani Krishna EsciPhani KrishnaNo ratings yet

- Managing Outsourcing Transition MIADocument27 pagesManaging Outsourcing Transition MIAAsh LeyNo ratings yet

- From Single To A Multiproduct Facility, Key ConsiderationsDocument8 pagesFrom Single To A Multiproduct Facility, Key ConsiderationsCathal DoranNo ratings yet

- Technology Transfer: What ? How ?: Hopefully You Should Be Able To Answer These Questions at The End of This SeminarDocument38 pagesTechnology Transfer: What ? How ?: Hopefully You Should Be Able To Answer These Questions at The End of This Seminarm.asuncionNo ratings yet

- ECA Product TransferDocument4 pagesECA Product TransfermmmmmNo ratings yet

- Gnipst 4 30 5694 2.1Document5 pagesGnipst 4 30 5694 2.1Antar GayenNo ratings yet

- Project Synopsis TanujDocument8 pagesProject Synopsis TanujAnshul SinghNo ratings yet

- Class 12 IP ProjectDocument26 pagesClass 12 IP ProjectShivendra100% (2)

- It Management ContextDocument28 pagesIt Management ContextAquasereneNo ratings yet

- GA3 Final Project PlanDocument7 pagesGA3 Final Project Planuser700No ratings yet

- Technology TransferDocument68 pagesTechnology TransferPhúc CaoNo ratings yet

- Implementation Success Best PracticesDocument16 pagesImplementation Success Best PracticesEvosys & LTECHNo ratings yet

- What Is Technology Transfer ?Document17 pagesWhat Is Technology Transfer ?Shaifali GargNo ratings yet

- 6 Agile Cutover Phase PDFDocument6 pages6 Agile Cutover Phase PDFpablo zuñigaNo ratings yet

- Program Management: Coordinating The Dependencies Among A Group of Related Product Development ProjectsDocument4 pagesProgram Management: Coordinating The Dependencies Among A Group of Related Product Development ProjectsSaravana KadirvelNo ratings yet

- ECA Product Transfer 2023Document4 pagesECA Product Transfer 2023Angel Fernando Santamaria MoralesNo ratings yet

- Project 18Document17 pagesProject 18mukesh lannaNo ratings yet

- GROUP 1 RoadmappingDocument25 pagesGROUP 1 Roadmappingkainat KhalidNo ratings yet

- Railway Reservation SystemDocument38 pagesRailway Reservation SystemI'M POPZSHA GAMERNo ratings yet

- Mb0028 Set 02 VKGDocument12 pagesMb0028 Set 02 VKGAmbrishNo ratings yet

- Bpo 2Document17 pagesBpo 2Jeanzell MendozaNo ratings yet

- SPPM Unit-5 NotesDocument16 pagesSPPM Unit-5 NotesKASAM ŠRÎKÀÑŤH M.S.CS50% (2)

- Project 17Document18 pagesProject 17mukesh lannaNo ratings yet

- Sales Management SystemDocument29 pagesSales Management SystemAshwinNo ratings yet

- Oracle Unified Methodology (Oum) : Project Execution and Control PhaseDocument5 pagesOracle Unified Methodology (Oum) : Project Execution and Control PhaseKeshav ChittipoluNo ratings yet

- Standard Process of Implementing ErpDocument19 pagesStandard Process of Implementing ErpNT HNo ratings yet

- Sales Management SystemDocument28 pagesSales Management SystemramyaNo ratings yet

- Ranadeer Resume Jul 21Document6 pagesRanadeer Resume Jul 21Ravikarthik GurumurthyNo ratings yet

- Techlogix Final CaseDocument19 pagesTechlogix Final CaseAreeba AmjadNo ratings yet

- Incorporate Maintainability Into Revamp and Greenfield ProjectsDocument9 pagesIncorporate Maintainability Into Revamp and Greenfield Projectsmg2001No ratings yet

- Define Job ShadowingDocument3 pagesDefine Job ShadowingSYDNEY MARASIGANNo ratings yet

- TT ForwardDocument28 pagesTT ForwardKeshavTiwariNo ratings yet

- Cycle ProjekDocument10 pagesCycle ProjekTyla Tylala ReginaNo ratings yet

- 2.4 Technology ApplicationDocument36 pages2.4 Technology ApplicationNisha MalhotraNo ratings yet

- Cs ProjectDocument41 pagesCs Projectavan joNo ratings yet

- Project 23Document21 pagesProject 23mukesh lannaNo ratings yet

- What's So Special About Process Control Projects?Document7 pagesWhat's So Special About Process Control Projects?Pere GilNo ratings yet

- Data Migration EbookDocument20 pagesData Migration EbookamoyeedNo ratings yet

- Project Synopsis SampleDocument7 pagesProject Synopsis SampleDhwani PatelNo ratings yet

- Booklet: Section: Subsection:: Systems Development Life CycleDocument11 pagesBooklet: Section: Subsection:: Systems Development Life CycleShellyNo ratings yet

- Gnipst 4 30 5694 2.2Document2 pagesGnipst 4 30 5694 2.2Antar GayenNo ratings yet

- PMLCDocument5 pagesPMLCiyappanaNo ratings yet

- Project Report: Online Railway Reservation System B.TechDocument22 pagesProject Report: Online Railway Reservation System B.TechAzhar HusainNo ratings yet

- Classification: Genpact InternalDocument6 pagesClassification: Genpact InternalSA1234567No ratings yet

- Cosmetic Shop Management SystemDocument27 pagesCosmetic Shop Management Systemcloakedknight456No ratings yet

- Introduction GroceryDocument5 pagesIntroduction Grocery11F10 RUCHITA MAARANNo ratings yet

- Project Report On Railway Reservation System by Amit MittalDocument53 pagesProject Report On Railway Reservation System by Amit Mittalamit431mittal63% (65)

- Summary PDFDocument24 pagesSummary PDFMULUGETA ANBESSIANo ratings yet

- Tool 10 Develop A Work PlanDocument3 pagesTool 10 Develop A Work PlanAkmal RestuNo ratings yet

- Law of Mongolia Technology Transfer Law May 7, 1998 UlaanbaatarDocument6 pagesLaw of Mongolia Technology Transfer Law May 7, 1998 UlaanbaatarBulgantamir TuvshinjargalNo ratings yet

- Lecture 5 - Technology ExploitationDocument21 pagesLecture 5 - Technology ExploitationUsmanHaiderNo ratings yet

- Report On National IP Yatra by Sonu KumarDocument3 pagesReport On National IP Yatra by Sonu Kumarsonukumarfk19No ratings yet

- Tech TransferDocument51 pagesTech Transferkunalprabhu148No ratings yet

- BCILDocument15 pagesBCILSanika MungekarNo ratings yet

- Transfer of TechnologyDocument26 pagesTransfer of TechnologyAteeq Khan100% (1)

- Patent and Intellectual Property Rights Issues With Technology Transfer in BhutanDocument16 pagesPatent and Intellectual Property Rights Issues With Technology Transfer in BhutanTsher Ing Ong MoNo ratings yet

- Good Practice Report On Innovative Business Incubators in CroatiaDocument43 pagesGood Practice Report On Innovative Business Incubators in CroatiaNikhil AIC-SRS-NDRINo ratings yet

- Logo Contest Guidelines - Indovation and YUKTI and Icube Innovation CouncilDocument4 pagesLogo Contest Guidelines - Indovation and YUKTI and Icube Innovation CouncilMysterr EverythingNo ratings yet

- Exam ReviewerDocument18 pagesExam ReviewerDiane DominiqueNo ratings yet

- Pharmaceutical Technology Transfer An OverviewDocument9 pagesPharmaceutical Technology Transfer An OverviewedgarpalominofNo ratings yet

- IJPSR (2013), Vol. 4, Issue 5 (Review Article) : ISSN: 0975-8232Document17 pagesIJPSR (2013), Vol. 4, Issue 5 (Review Article) : ISSN: 0975-8232Nitin SheokandNo ratings yet

- Datos - Analisis BibliométricoDocument383 pagesDatos - Analisis BibliométricoSofia RodiNo ratings yet

- Academic-Government Relation in Technology TransferDocument16 pagesAcademic-Government Relation in Technology TransferPurnama AlamsyahNo ratings yet

- Technological Environment: - Debashree MukherjeeDocument9 pagesTechnological Environment: - Debashree Mukherjeeshahid_ashrafNo ratings yet

- Service Fellow Recruitment RG-0601Document3 pagesService Fellow Recruitment RG-0601Yasir RasoolNo ratings yet

- Technology Transfer From Public Research OrganizationsDocument15 pagesTechnology Transfer From Public Research OrganizationsFarooqChaudharyNo ratings yet

- Accelerating Commercialization Cost Saving Health Technologies ReportDocument25 pagesAccelerating Commercialization Cost Saving Health Technologies ReportBrazil offshore jobsNo ratings yet

- Module 1 - Universities and National DevelopmentDocument13 pagesModule 1 - Universities and National DevelopmentTOBI JASPER WANGNo ratings yet

- Translation and Commercialization of Pharmaceutical Scientific Innovations: AnDocument12 pagesTranslation and Commercialization of Pharmaceutical Scientific Innovations: AnpratikNo ratings yet

- Ethiopia - Proclamation On Investment (English)Document21 pagesEthiopia - Proclamation On Investment (English)Biniyam EtichaNo ratings yet

- Bozeman 2015Document16 pagesBozeman 2015yordanNo ratings yet

- PDP 2023 2028 - Chapter 8Document16 pagesPDP 2023 2028 - Chapter 8Ajoc NoelNo ratings yet

- Management of Technology PDFDocument54 pagesManagement of Technology PDFYashwanth S DNo ratings yet

- Prof Pract Rev Ra 9266Document10 pagesProf Pract Rev Ra 9266jia jiaNo ratings yet

- Technical Analysis 2Document5 pagesTechnical Analysis 2Viral OkNo ratings yet

- Chapter Four EntreDocument47 pagesChapter Four EntreeyoyoNo ratings yet

- Geography of Technology Transfer in China A Glocal Network Approach Liu Full ChapterDocument51 pagesGeography of Technology Transfer in China A Glocal Network Approach Liu Full Chaptermark.martinez904100% (16)