Professional Documents

Culture Documents

TI Manual Y Series Elevator

Uploaded by

Daniel Adorno HernàndezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TI Manual Y Series Elevator

Uploaded by

Daniel Adorno HernàndezCopyright:

Available Formats

TECHNICAL MANUAL

Y Center Latch Elevator

Operation Manual

© 2005-2014 Texas International Oilfield Tools, LTD.

Published by Texas International Oilfield Tools, LTD, Engineering

14620 Henry Road. • Houston, TX 77060

www.texasinternational.com

CONFIDENTIALITY STATEMENT

This document contains confidential information. All rights including copyright, confidential information, trade

secrets and design rights are owned by Texas International Oilfield Tools, LTD (TIOT, Texas International,

and Texas International Oilfield Tools). No use or disclosure is to be made without prior written permission of

Texas International Oilfield Tools, LTD.

Revision History

Rev Date Reason

A 10/15/14 Issued for Use

Description of Change

Rev Change

A -

2 Texas International Oilfield Tools, LTD. OM002-A

TABLE OF CONTENTS

GENERAL ...................................................................................................................... 4

CONVENTIONS ............................................................................................................. 5

SAFETY ......................................................................................................................... 5

SPECIFICATIONS ......................................................................................................... 5

ACCESSORIES ............................................................................................................. 6

SLIP INSTALLATION/REMOVAL .................................................................................. 7

PREVENTIVE MAINTENANCE ..................................................................................... 8

ELEVATOR WEAR LIMITS .......................................................................................... 11

CRITICAL AREA MAP ................................................................................................. 12

TROUBLESHOOTING ................................................................................................. 12

STORAGE AND TRANSPORTATION ......................................................................... 13

SPARE PARTS LIST.................................................................................................... 14

OM002-A www.TEXASINTERNATIONAL.com | www. OILTOOLS.ru 3

GENERAL

Figure 1 – HYC 200 ton elevator

Texas International Oilfield Tools (TIOT) offers “Y” center latch, slip type manual

elevators for tubing (YT, MYT) and casing (YC, HYC, MYC). See Specification table on

page 5 for load capacity and size ranges. The elevators hoist a variety of small casing

and tubing with the proper size slips and slip setting ring installed. The slips are easily

changed. The elevator is designed with two (2) halves of similar weights for good

balance and easier opening and closing. A guarded operating latch and an extra

handle at the rear of the elevator allow for easier, safer operation. Elevators are

equipped with a latch and latch lock combination. To open, pull the latch lock handle

out and swing the elevator apart. The latch and latch lock secures automatically when

the elevator is closed around the pipe. The load causes the slips to set when the

elevator is raised, pushing down on the slip setting ring.

Ensure all slip inserts are free in the up position when latching the elevator

Use the ears for lifting elevator – NOT the rear handle.

4 Texas International Oilfield Tools, LTD. OM002-A

CONVENTIONS

IMPORTANT SYMBOL IDENTIFICATION

WARNING to Operators / Users

CAUTION to Operators / Users

NOTIFICATION to Operators / Users

Table 1

SAFETY

Texas International’s equipment is used and installed in controlled rig environments

involving hazardous operations and situations.

All personnel performing installation, operations, repair or maintenance on this elevator

must have knowledge of rig procedure. All crew in the vicinity of operations should be

trained on rig safety and tool operation.

SPECIFICATIONS

Part Capacity

Size Range Number Model (Tons)

3‐1/2" ‐ 7‐5/8" T55310 HYC 200

3‐1/2" ‐ 7" T200360 MYC 125

3‐1/2" ‐ 7" T24140 YC 75

1.315" ‐ 3‐1/2" T55600 YT 75

1.315" ‐ 2‐7/8" T29238 MYT 40

Table 2

OM002-A www.TEXASINTERNATIONAL.com | www. OILTOOLS.ru 5

ACCESSORIES

SLIP SETTING RING

Description

INSERT RETAINER

SLIP ASSEMBLY

GUIDE PLATE

SLIP BODY

SPACER

INSERT

PIPE SIZE

SLIP SIZE

HYC‐ Frame T55310 ‐ 200 Ton ‐ Casing Elevator Weight=991 Lbs*

4 1/2" x 3 1/2" T55509 T55303 24779 T30214 T55516 T26827‐1

4 1/2" x 4" T55510 T55303 24781 T30214 T55517 T26827

4 1/2" T55511 T55303 16408 T30214 T55518 T24071‐4

5 1/2" x 5" T55512 T55304 24783 T30221 T55519 T24071

5 1/2" T55513 T55304 16407 T30224 T55520 T24071‐1

7" x 6 5/8" T55514 T55305 24748 T30227 T55521 T24071‐3

7" T55515 T55305 16407 T30230 T55522 T24071‐2

7 5/8" T70009 T56305‐1 70010 T70011 T70012 T24071‐6

MYC ‐ Frame T200360 ‐125 Tons ‐ Casing Elevator Weight=610 Lbs*

4 1/2" x 4" T26830 T24072‐4 24781 T24506 T30214 T30209 T26827

4 1/2" T24072‐5 T24072‐4 16408 T24506 T30214 T30219 T24071‐4

5 1/2" x 5" T24072‐7 T24072 24783 T24506 T30221 T30220 T24071

5 1/2" T24072‐2 T24072 16407 T24506 T30224 T30223 T24071‐1

7" x 6 5/8" T24077‐7 T24077 24748 T24506 T30227 T30226 T24071‐3

7" T24077‐1 T24077 16407 T24506 T30230 T30229 T24071‐2

YC ‐ Frame T24140 ‐ 75 Tons ‐ Casing Elevator Weight=442 Lbs*

4‐1/2" T24072‐5 T24072‐4 16408 T24506 T30214 T30219 T24071‐4

5‐1/2" x 5" T24072‐7 T24072 24783 T24506 T30221 T30220 T24071

5‐1/2" T24072‐2 T24072 16407 T24506 T30224 T30223 T24071‐1

7" x 6‐5/8" T24077‐7 T24077 24748 T24506 T30227 T30226 T24071‐3

7" T24077‐1 T24077 16407 T24506 T30230 T30229 T24071‐2

MYT ‐ Frame T29328 ‐ 40 Tons ‐ Tubing Weight=140 Lbs*

2‐1/16 x 1.315" T29343‐7 T29343‐10 29259 T29344 T29354

2‐1/16 x 1.660" T29343‐6 T29343‐10 29258 T29344 T29353

2‐1/16 x 1.900" T29343‐5 T29343‐10 29257 T29344 T29352

2‐1/16 x 2" T29343‐4 T29343‐10 29256 T29344 T29351

2‐1/16" T29343‐3 T29343‐10 29256 T29344 T29350

2‐7/8 x 2‐3/8" T29343‐2 T29343‐10 29255 T29344 T29345

2‐7/8" T29343‐1 T29343‐10 24773 T29344 T29348

6 Texas International Oilfield Tools, LTD. OM002-A

Accessories continued

Description

SLIP ASSEMBLY

GUIDE PLATE

SLIP SETTING

SLIP BODY

RETAINER

SPACER

INSERT

INSERT

RING

PIPE SIZE

SLIP SIZE

YT ‐ Frame T55600 ‐ 75 Tons ‐ Tubing Weight=345 Lbs*

2‐7/8 x 1.315" T23108‐11 T23108‐2 29259 T24508 T27451 T29001

2‐7/8 x 1.600" T23108‐10 T23108‐2 29258 T24508 T27451 T27810

2‐7/8 x 1.900" T23108‐9 T23108‐2 29257 T24508 T27451 T27811

2‐7/8 x 2" T23108‐8 T23108‐2 29256 T24508 T27451 T27821

2‐7/8 x 2‐1/16" T23108‐7 T23108‐2 29256 T24508 T27451 T27812

2‐7/8 x 2‐3/8" T23108‐6 T23108‐2 29255 T24508 T27451 T27694

2‐7/8" T23108‐4 T23108‐2 24773 T24508 T27451 T27695

3‐1/2" T23108‐5 T23108 24774 T24507 T27530 T27813

Table 3

* Nominal weight of elevator only

SLIP INSTALLATION/REMOVAL

1. To install slips, TIOT suggests starting with slip #2 or slip #4 (see Figure 2).

Unscrew slip bolt assembly at starting slip location and set bolt aside.

The slip spring may pop out – set back in its cavity

2. Holding the slip from the bottom with one hand, compress the spring using the

hinge on the back of the slip and using the opposite palm, push slip under the

elevator frame/edge. See Figure 3. Use a long screwdriver to secure the slip

temporarily. Remove screwdriver and then reinstall the slip bolt assembly. Push

slip down and release to verify free movement.

If slip does not move freely, remove and reinstall

3. Install the adjoining slip. The slip’s side notch will fit into the side cavity.

Repeat steps 1 through 3 to install slips on the opposite side.

4a. On the body side, place the insert retainer on each slip.

4b. Set the setting ring on top of retainers. For the YT and YC series, put rubber

bushings inside the setting ring’s holes and place the setting ring retainers on top of

the setting ring.

OM002-A www.TEXASINTERNATIONAL.com | www. OILTOOLS.ru 7

Slip Installation/Removal continued

4c. Install threaded bolts either into either the retainer (YT and YC series) or setting

ring (MYT).

4d. Secure bolts with wire.

5. On opposite side, install insert retainers (see Figure 2) with bolts.

6. On YT model, install guide plate.

To remove slips, reverse steps above.

Figure 2 – YT 75 ton elevator with slips Figure 3 – Compressing spring to install slip

TIOT recommends removing inserts after each use and coat insert slot

with light machine oil.

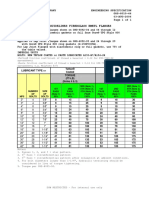

PREVENTIVE MAINTENANCE

This is a suggested PM schedule. The tool owner has the responsibility to

adjust the program according to actual tool usage

When there is suspicion that the elevator has been overloaded, it should be

pulled from operation for an Annual type PM.

8 Texas International Oilfield Tools, LTD. OM002-A

Preventative Maintenance continued

Normal wear in course of use will eventually reduce the elevator’s capability. Inspect

the latch, latch pin and hinge pin regularly for wear. Cracks or the appearance of

damage can indicate the need for repair, even impending failure, and requires prompt

attention. The elevator must be either pulled from operation immediately or repaired.

Daily (PM1) – While in use

Apply EP 4 grease to grease port and ears, as needed

Inspect the contact surface of the ears. If surfaces are flattened or metal is

rolled, the elevator should be pulled from operation for Annual (PM3)

Open and close the elevator 5 times slowly and 5 times quickly to ensure

elevator works properly

Press slips down and release - slips should come up if springs are operational

Clean slip inserts and inspect for wear and missing teeth – if found, replace

Visually check elevator for damage and cracks – if found, pull from operation for

repair

Look for worn, damaged, loose or missing parts – replace or tighten

Verify retainer shoulder screws are Grade 8. If not, replace

Check for wear on hinge pin by checking the vertical play between latch, body,

and door

Inspect tack welds (see Figure 5). On YC model elevator, check underside hinge

pin and latch lock pin. On all other Y series, check latch lock pin. If broken,

remove from operation and repair

Semi-Annual (PM2)

Try to open the latch by prying the latch between body and latch with a steel bar

or screw driver – the latch lock must prevent the latch from being opened (Figure

4). If the elevator opens during pry test, pull from operation for repair

Check for corrosion and breakage on pins and springs – if found, replace

Remove coating and debris from critical areas

Disassemble and perform Magnetic Particle Inspection (MPI) on critical areas as

indicated on API Specification 8C

Carry on daily PM

OM002-A www.TEXASINTERNATIONAL.com | www. OILTOOLS.ru 9

Preventative Maintenance continued

Annual (PM3)

Repeat daily and semi-annual PMs

Performance load test

MPI critical areas twenty four (24) hours after load test

Repair cast as needed - recommend repairs be done by TIOT

Proof of load test and MPI are required after remanufacture or a major weld

repair in a critical area

Figure 4 - Pry test Instructions

Figure 5 - YC tack welds

10 Texas International Oilfield Tools, LTD. OM002-A

ELEVATOR WEAR LIMITS

The wear of the elevator affects its ability to support the required load. Elevators for

which the ear measurements are lower than the minimum shown in Table 4 shall either

be remanufactured or scrapped.

Ear Radius ( R ) Minimum

based on tons in inches

40 1¼

75 1¼

Figure 6

125 1 3/8

200 2

Table 4

Model HYC MYC YC YT MYT

Total Clearance

Hinge Pin 0.045 0.040 0.035 0.030 0.025

Latch Pin 0.045 0.035 0.035 0.030 0.025

Table 5

OM002-A www.TEXASINTERNATIONAL.com | www. OILTOOLS.ru 11

CRITICAL AREA MAP

Darken areas are defined as critical

Figure 7

TROUBLESHOOTING

Failure Mode Possible Cause Possible Solution

Deformed pin holes Scrap the tool

Overload

Pull elevator from operation and carry on PM 3

Wear Verify pin clearance (see Table 5)

Bent pins Overload Perform PM 3

Elevator does not open Corrosion Pry open, clean and lubricate.

Carry on PM 3

Overload

Scrap the tool

Elevator does not close Oversized tubular Select properly sized elevator

Elevator does not hang

Link length Use same length slings/links

level

Spring Incorrect spring installed ‐ change

Setting plate Loosen bolts to remove bind

Slips do not move freely Verify bolt floats freely and correct size

Slip bolt installed

Check spacer/washer is installed

Table 6

12 Texas International Oilfield Tools, LTD. OM002-A

STORAGE AND TRANSPORTATION

Unpainted surfaces should be coated with rust preventing agent

Prevent excessive exposure to water and moisture

Clean the tool after use - steam clean as needed; remove mud, debris and any

other substances

Transport the unit on a suitable container or pallet

OM002-A www.TEXASINTERNATIONAL.com | www. OILTOOLS.ru 13

SPARE PARTS LIST

Figure 8 – MYT exploded

MYT Spare Parts List

# Component Req P/N

1 LATCH LOCK 1 T30653

2 LATCH LOCK SPRING 2 T29349

3 LATCH 1 T30652

4 LATCH SPRING 1 T29338

5 LINK BLOCK 2 T29337

6 SLIP SPRING 4 29340

7 LATCH PIN 2 T29334

8 LATCH LOCK PIN RETAINER 2 T947129‐151

9 LATCH LOCK PIN 1 T29335

10 LATCH PIN RETAINER 2 T947129‐238

11 HINGE PIN 1 T29333

12 SLIP BOLT 4 29336

Table 7

14 Texas International Oilfield Tools, LTD. OM002-A

Spare Parts List continued

Figure 9 – YC Series exploded

Spare Parts List

Model HYC MYC YC

# Component Req P/N

1 LATCH LOCK 1 T13152 T12972

2 LATCH 1 T55503 T200363 T15348

3 LATCH LOCK SPRING 2 T13188 N/A

4 LATCH LOCK PIN 1 T13619 T13531 T13530

5 LATCH LOCK BOLT 1 T15101 T200371 N/A

6 LATCH SPRING 1 T34909 T200367 T12978

7 SLIP SPRING 1 T945044‐2 T24049

8 LINK BLOCK 2 T9519

9 HINGE PIN RETAINER 2 T55504 T36901‐1 N/A

10 LATCH PIN 2 T55312 T200365 T24182

11 LATCH PIN RETAINER 2 T55505 T36951‐1 T29448

12 HINGE PIN 1 T55311 T200364 T24181

13 SLIP BOLT ASSEMBLY 4 T50003697‐2

14** LATCH CAM 1 N/A N/A T12008

** Not shown Table 8

OM002-A www.TEXASINTERNATIONAL.com | www. OILTOOLS.ru 15

Spare Parts List continued

Figure 10 – YT exploded

YT Spare Parts List

# Component Req P/N

1 LATCH LOCK PIN 2 T13530

2 LATCH LOCK 1 T12972

3 LATCH 1 T15348

4 LATCH CAM 1 T12946

5 LATCH SPRING 1 T12978

6 SLIP SPRING 1 T23113

7 HINGE PIN RETAINER 2 T39253

8 LINK BLOCK 2 T9519

9 LATCH PIN 2 T24182

10 LATCH PIN RETAINER 2 T29464

11 HINGE PIN 1 T23116‐1

12 SLIP BOLT 4 T23115‐MOD

Table 9

16 Texas International Oilfield Tools, LTD. OM002-A

Every Company has to have a Toolbox

at Texas International Oilfield Tools.

We provide the tools to fuel the

world!

The terms VARCO, VARCO-BJ, and BJ are trademarks of Varco I/P, Inc., National Oilwell Varco, L.P., or their affiliates. Texas International Oilfield

Tools is not an authorized distributor of any Varco I/P or NATIONAL OILWELL VARCO product. Texas International Oilfield Tools is not affiliated with

Varco I/P, Inc., National Oilwell Varco, L.P., or their affiliates. Varco I/P, Inc., National Oilwell Varco, L.P., and their affiliates do not endorse any Texas

International Oilfield Tools' products or replacement parts.

OM002-A www.TEXASINTERNATIONAL.com | www. OILTOOLS.ru 17

You might also like

- TI Manual Safety Clamp OM008 CDocument22 pagesTI Manual Safety Clamp OM008 Cedinson piñerosNo ratings yet

- Fishing Tools PDFDocument16 pagesFishing Tools PDFjardelbrunoNo ratings yet

- Heavy Duty Impact Sockets Metric Sizes GuideDocument3 pagesHeavy Duty Impact Sockets Metric Sizes GuideMiguel RuizNo ratings yet

- Homelite Parts ListDocument10 pagesHomelite Parts Listmecrea1No ratings yet

- Safety Clamp: Operation ManualDocument21 pagesSafety Clamp: Operation ManualDavid Venegas AndradeNo ratings yet

- Isuzu 4Bg1 - Cylinder Head Cover AssyDocument75 pagesIsuzu 4Bg1 - Cylinder Head Cover AssyTasha RozsokhaNo ratings yet

- Kembla Astm B280Document6 pagesKembla Astm B280sigithvacNo ratings yet

- WOT - Tech Data Sheets PDFDocument43 pagesWOT - Tech Data Sheets PDFAmbroise RICHARDNo ratings yet

- Part Manual 35DV - MQDocument30 pagesPart Manual 35DV - MQantonioNo ratings yet

- Drill Pipe & Casing Tongs: Product CatalogDocument12 pagesDrill Pipe & Casing Tongs: Product CatalogAnonymous fBIEWgmRzNo ratings yet

- Tex 220 230 SP Atlas CopcoDocument12 pagesTex 220 230 SP Atlas CopcosebastianNo ratings yet

- Precision Bearing Trolley: Service Instructions and Parts ListDocument2 pagesPrecision Bearing Trolley: Service Instructions and Parts Listedark2009No ratings yet

- 45D-MQ Full Freelift 4-Stage Quad Mast: Arts ManualDocument62 pages45D-MQ Full Freelift 4-Stage Quad Mast: Arts Manualjuan antonio hdezNo ratings yet

- DST Tools CatalogDocument103 pagesDST Tools CatalogSikander Mushtaq100% (1)

- He Va Vip Roller 33 45 Spare PartsDocument16 pagesHe Va Vip Roller 33 45 Spare PartstotcsabNo ratings yet

- Operation & Maintenance Manual: T3 Model 6012 Ram BOPDocument21 pagesOperation & Maintenance Manual: T3 Model 6012 Ram BOPerickson nievesNo ratings yet

- Halliburton: Rtts PackerDocument2 pagesHalliburton: Rtts PackermehrdadNo ratings yet

- Installation and Maintenance Instructions For Three Phase Induction MotorsDocument9 pagesInstallation and Maintenance Instructions For Three Phase Induction MotorsAnibal QuezadaNo ratings yet

- Team Oil ToolsDocument54 pagesTeam Oil ToolssitaNo ratings yet

- THIELE Lifting Products: Grade 80Document53 pagesTHIELE Lifting Products: Grade 80Héctor Raúl Bustos BernalNo ratings yet

- Wire Line Set Retrievable Packer: Drilling & Down-Hole Completion ToolsDocument11 pagesWire Line Set Retrievable Packer: Drilling & Down-Hole Completion Toolsparag padoleNo ratings yet

- QY50KD Truck Crane Packing ListDocument12 pagesQY50KD Truck Crane Packing ListAndrea FilottoNo ratings yet

- Telescopic Frame 7,5t / 16550 LB 690 X 323 X 126 (22'6"x10'7"x4'1")Document6 pagesTelescopic Frame 7,5t / 16550 LB 690 X 323 X 126 (22'6"x10'7"x4'1")Drajat DarmawanNo ratings yet

- Macmasterpricelist PDFDocument2 pagesMacmasterpricelist PDFRad CowNo ratings yet

- Torque Guidelines Fiberglass Emetl FlangesDocument1 pageTorque Guidelines Fiberglass Emetl FlangesvesselyNo ratings yet

- TTS-LMG Marine Cargo Cranes Spec SheetDocument6 pagesTTS-LMG Marine Cargo Cranes Spec SheetAttar AkbarNo ratings yet

- Detroit Diesel 92 Service ManualDocument167 pagesDetroit Diesel 92 Service ManualVer Ghom100% (1)

- DW1020 - Capscrew Torque Chart & InstructionsDocument4 pagesDW1020 - Capscrew Torque Chart & InstructionsAlex RamirezNo ratings yet

- Blind Bolt Catalog Fy 02Document54 pagesBlind Bolt Catalog Fy 02tangyuNo ratings yet

- TI Manual Side ElevatorDocument18 pagesTI Manual Side ElevatorMANUFACTURA PETROLERA SERVICES (ADMINISTRACIÓN)No ratings yet

- OUTER MAST (Figure 10-1) : Two Stage Limited Free-LiftDocument14 pagesOUTER MAST (Figure 10-1) : Two Stage Limited Free-LiftMelwyn FernandesNo ratings yet

- 2023 10.75 TST-2 Service PackerDocument15 pages2023 10.75 TST-2 Service PackerDhenny FarialNo ratings yet

- Guia Parafusos, Arruelas E Porcas 1Document156 pagesGuia Parafusos, Arruelas E Porcas 1Adrian VerattiNo ratings yet

- 845 #1 Cone PartsDocument60 pages845 #1 Cone PartsFrank GORMLEYNo ratings yet

- PG-1028-T (HOS) General Data and Specifications: Table 5-3. Prestress Levels For HOSDocument4 pagesPG-1028-T (HOS) General Data and Specifications: Table 5-3. Prestress Levels For HOSAnkush SehgalNo ratings yet

- FL52 Technical Data SheetDocument2 pagesFL52 Technical Data Sheetaxisd47No ratings yet

- Model V45 Manual Assembly DisassemblyDocument51 pagesModel V45 Manual Assembly Disassemblyysabel martinezNo ratings yet

- Caterpillar Replacement Parts CatalogueDocument20 pagesCaterpillar Replacement Parts CatalogueEbrahim SabouriNo ratings yet

- Wireline Retriever: Instruction Manual 8820Document5 pagesWireline Retriever: Instruction Manual 8820john odonnellNo ratings yet

- WELL SERVICE PUMP REFERENCE GUIDE - Weir Oil & Gas DivisionDocument55 pagesWELL SERVICE PUMP REFERENCE GUIDE - Weir Oil & Gas DivisionjulioramcaNo ratings yet

- Eaton Series 1 Model 33 64 Variable Motor PartsDocument4 pagesEaton Series 1 Model 33 64 Variable Motor PartsOrlando Torres CueroNo ratings yet

- Yanmar Engine 917105c sl3635 sl3935 sl3640 sl38400 sl4240 Parts ManualDocument5 pagesYanmar Engine 917105c sl3635 sl3935 sl3640 sl38400 sl4240 Parts Manualsantos100% (28)

- MCT 85 F5Document8 pagesMCT 85 F5DanielMolanoMedinaNo ratings yet

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDocument350 pagesCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- Casing SlipsDocument11 pagesCasing SlipsAdrian CantaragiuNo ratings yet

- Yanmar 3TNV88XMS 3TNV88XMS2 4TNV88XMS 4TNV88XMS2 Engines: Engine Parts ManualDocument52 pagesYanmar 3TNV88XMS 3TNV88XMS2 4TNV88XMS 4TNV88XMS2 Engines: Engine Parts Manualshajesh100% (1)

- обгонна муфтаDocument2 pagesобгонна муфтаVolodymуr VorobetsNo ratings yet

- ข้อมูลทางเทคนิค Torque ValueDocument4 pagesข้อมูลทางเทคนิค Torque Valuetigernew269226No ratings yet

- THIELE Grade80 A5 EnglishDocument53 pagesTHIELE Grade80 A5 EnglishAlberth Mauricio Casteblanco GomezNo ratings yet

- Td80d Plus 2009Document1,029 pagesTd80d Plus 2009aldhanyNo ratings yet

- Micro Fiche GS550Document152 pagesMicro Fiche GS550moiNo ratings yet

- TOPDRILL E CatalogueDocument14 pagesTOPDRILL E CatalogueHodumi JosefNo ratings yet

- Series YD - YS Instruction ManualDocument16 pagesSeries YD - YS Instruction ManualEnerprec SASNo ratings yet

- GFR..F2F3 GFR..F3F4: Self-Contained FreewheelsDocument2 pagesGFR..F2F3 GFR..F3F4: Self-Contained FreewheelsJUNIOR BAONo ratings yet

- Ryco Hose Ends CatalogsDocument55 pagesRyco Hose Ends Catalogsjob saputraNo ratings yet

- 08 - Magazine 680Document30 pages08 - Magazine 680pedrojrandradeNo ratings yet

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Working Guide to Drilling Equipment and OperationsFrom EverandWorking Guide to Drilling Equipment and OperationsRating: 5 out of 5 stars5/5 (9)

- Security & Safety ManagementDocument51 pagesSecurity & Safety ManagementMichaela Ramos Beato100% (1)

- 8185-8186 Fitting InstructionsDocument8 pages8185-8186 Fitting InstructionsSirLotusNo ratings yet

- Lea 4 Lea 3 Cdi 3 TeminologiesDocument4 pagesLea 4 Lea 3 Cdi 3 TeminologiesPelaez Vincent100% (1)

- Qashqai j10 DLKDocument875 pagesQashqai j10 DLKa2s100% (6)

- Miata Door LocksDocument47 pagesMiata Door LocksCaleb HartlineNo ratings yet

- Alfa Romeo 156 1.9 JTD 2004 User ManualDocument357 pagesAlfa Romeo 156 1.9 JTD 2004 User ManualVili Krznar100% (2)

- SHP-DP609+Manual (EN) 20190613 PDFDocument4 pagesSHP-DP609+Manual (EN) 20190613 PDFAlf AlsudairyNo ratings yet

- MF520 525 1Document328 pagesMF520 525 1p_jankoNo ratings yet

- The National Locksmith July 2005Document147 pagesThe National Locksmith July 2005Albert100% (1)

- AV UM AV Outriggers EN 7845448-03 A5 2017-12Document33 pagesAV UM AV Outriggers EN 7845448-03 A5 2017-12JunaedyNo ratings yet

- Hardware and Safes CatalogueDocument142 pagesHardware and Safes CatalogueprakashkolliNo ratings yet

- TESA Security Door LocksDocument34 pagesTESA Security Door LockscapoNo ratings yet

- Understandthe EWS BMWDocument25 pagesUnderstandthe EWS BMWh3ll88% (8)

- Pro Wedge VM 20 ManualDocument31 pagesPro Wedge VM 20 ManualJohan SongohanNo ratings yet

- ZW 310-6 MaintenanceDocument141 pagesZW 310-6 MaintenanceDraganNo ratings yet

- Diagramas Nissan Altima 2010Document228 pagesDiagramas Nissan Altima 2010040763jlhNo ratings yet

- General Motors Die Design StandardsDocument133 pagesGeneral Motors Die Design Standardscasber serviciosNo ratings yet

- Lea 3 Industrial SecDocument38 pagesLea 3 Industrial SecJacquiline Acosta100% (3)

- Maintenance and unlocking swing gatesDocument20 pagesMaintenance and unlocking swing gatesDaniel PrataNo ratings yet

- Manually Operated Tcg-1000 Gangway: Instruction ManualDocument36 pagesManually Operated Tcg-1000 Gangway: Instruction ManualGeorgi KalchevNo ratings yet

- Manual Lifan Suv x60Document1,071 pagesManual Lifan Suv x60cesarincass100% (2)

- Locksmith Aliso Viejo - TheorangecountylocksmithDocument4 pagesLocksmith Aliso Viejo - Theorangecountylocksmithlocksmith californiaNo ratings yet

- Dorma-Ahus Pl25!1!15 LoDocument314 pagesDorma-Ahus Pl25!1!15 LoawwalnafiNo ratings yet

- Chun Jiang Liu 2010Document4 pagesChun Jiang Liu 2010Dorothy ManriqueNo ratings yet

- R6 - For CGN Dan SJU - List Hardware - Ironmongeries - ST Regis Hotel Public - SRJH - 20220112 (R)Document73 pagesR6 - For CGN Dan SJU - List Hardware - Ironmongeries - ST Regis Hotel Public - SRJH - 20220112 (R)ikadek artaNo ratings yet

- 2022 Safehotels Standards ManualDocument78 pages2022 Safehotels Standards ManualameralmobayedNo ratings yet

- Interior Lighting System: SectionDocument81 pagesInterior Lighting System: SectionMax RughfiddNo ratings yet

- Owners Guide: Dumbwaiters & Service LiftsDocument8 pagesOwners Guide: Dumbwaiters & Service LiftsAshank PaiNo ratings yet

- Notes On Industrial Security ManagementDocument23 pagesNotes On Industrial Security Managementcriminologyalliance100% (2)

- Manual de Peças Do Elevador BVM Ta-100Document3 pagesManual de Peças Do Elevador BVM Ta-100Alexsandro CordeiroNo ratings yet