Professional Documents

Culture Documents

1 Ea14183118

1 Ea14183118

Uploaded by

ikhwanstorage0 ratings0% found this document useful (0 votes)

5 views5 pagesOriginal Title

1-ea14183118

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views5 pages1 Ea14183118

1 Ea14183118

Uploaded by

ikhwanstorageCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

”,/*. COURSE FOR CERTIFICATE ENVIRONMENTAL PROFESSIONAL IN SCHEDULE

WASTES MANAGEMENT (CePSWaM)

Practical Exercise

Dale Time

Name

THE SCENARIO

Alarge Malaysian conglomerate has formed a joint-venture company with 2 multinational company

and they were just recently set-up its offices and plants in Malaysia. The joint-venture company,

Malaysian Multinational Sdn Bhd has formed three separate divisions with individual operating

companies dealing in three industrial sectors that are in the petroleum refining, steel fabrication and

PCB assembly industries. Each operation company has its own separate manufacturing plant and

each of these plants is located separately. The petroleum refining plant is located in Terengganu, the

iron and steel fabrication plant is located in Kedah whilst PCB assembly facility is located in Selangor.

All of these plants just started their operations on ‘st June 2011 and all the wastes were generated

immediately after five days of operations

The detail of the operating companies are as follows :

Malaysian Multinational Petroleum Sdn Bhd Malaysian Multinational Iron and Steel Sdn Bhd

No, 19, Kawasan Perindustrian Kerteh, Lot 641, Jalan Bunga Raya,

24300 Kerteh, Terengganu 08300 Gurun, Kedah

Tel : 609-6011000 Tel : 604-3501000

Malaysian Multinational PCB Assembly Sdn Bhd

No. 349, Jalan Damai 13/21,

Seksyen 13, 40100 Shah Alam,Selangor

Tel : 603-64210000

In producing their respective products, these operating companies are involved in the various types of

industrial processes and plant activities of the companies are described behind

Seonario 4

Peiroieum refining processes and activities can grouped into the following steps

Crude Oil Desalting [emulsifier chemicals

Distillation and |Atmospheric Distillation

Desaiting |Vacuum Distillation

2 | Downstream [Thermal Cracking! Visbreaking _

Processing [Cooking

[Catalytic Cracking Catalysis consist mdures oF

crystalline synthetic silica-alumina,

fermed “zeolites" and amorphous

_ synthetic silica-alumina

[Catalytic Hydrocracking Hydrocracking catalysts consist of

a crystalline mixture of

silica-alumina with small amounts

of rare earth metals

Hydrocracking / Hydro processing ‘Caialysts consist of cobalt or

‘molyadenum oxides on alumina,

nickel and tungsten

[Sulfuric acid or hydrofuoric acid

Alkylation:

Isomerization — (Catalyst that consists of platinum,

lorganic chlorides and caustic

—____fsolution

Polymerization [Phosphoric acid catalyst

Catalytic Reforming [Catalyst consist of platinum and

| rhenium

Solvent Extraction Furfural and phenol

Chemical [Caustic solution

Dewaxing Propane, mixtures of methyl ethyl

ketone (MEK) with methyl isobutyl

ketone (MIBK) or MEK with toluene

Propane Deasphalting Propane

3 [Supporting [Gas Treatment and Sulfur Recovery |Bauxite catalyst, cobalt molybdate

‘Operations catalyst and di-isoproppanotamine

(DIPA)

[Additive Production [Methy| tertiary butyl ether (MTBE)

Malaysian Multinational Petroleum Sdn Bhd

No. 19, Kawasan Perindustrian Kerteh,

24300 Kerteh, Terengganu

Tel : 609-6017000

Scenario 2

fon and steol industrial processes and daily activities are as follows

ron making

Production of moiten iron

Limestone

1

2 [Steelmaking

[Steelmaking processes by basic

oxygen furnace (BOF) and electric

are fumace (EAF)

Fluorspar, dolomite and alloying

agents such as aluminium,

manganese

3 [Forming and

finishing

Operations

Forming - Shaping and cuiting iron

and steel

(Coolant consist of ethylene glycol

Finishing - surface treatment of iron

and steel products

Organic solvenis including

tetrachloroethylene

Alkaline cleaning agents including

Jcaustic soda, soda ash, alkaline

icates, phosphates

Hydrochloric, nitric, and hydrofluoric

acids.

Zinc coating, tin coating, chromium

coating, aluminizing, and terne

lcoating (lead and tin),

Malaysian Multinational Iron and Steel Sdn Bhd

Lot 641, Jalan Bunga Raya,

08300 Gurun, Kedah

Tel : 604-3601000

Scenario 3

‘Common industrial processes for PCB assembly activities are as follows

1_|Construction Soldering parts to te PCB [Solder dross and flux

2 [Testing Quality control for testing the

functionality of electronic board

3 [Coating [Conformal coating using Acrylicand [Halogenated Solvent

Epoxy dichloromethane

Malaysian Multinational PCB Assembly Sdn Bhd

No. 349, Jalan Damai 13/21,

‘Seksyen 13, 40100 Shah Alam,Selangor

Tel : 603-54210000

Other general plant processes or activities conducted daily by all three operating companies are as

follows.

Scenario 4

‘Treatment processes of all wastewater generated from the washing, cleaning and rinsing of materials

and products from all the industrial processes and activities, These wastewater contain hazardous

and toxic components and constituents including :

1.4. Organic component such as mineral oil, grease and solvenis

4.2 Inorganic constituents such as mineral acids and metals including chromium, cooper,

nickel, zine, lead and cadmium,

Scenario 5

Performing schedule or unscheduled maintenance work such as change of engine oil, transmission

oil, hydraulic oil and oil filter, repair services and activities in the workshop for ali company’s motor

vehicles, forklift, hydraulic machines and other mechanical equipment

Scenario 6

Operating in-plant clinic to take care of workers for general sickness such as fever, cold, sore throat

and etc., minor injuries or medical emergencies during office hours and plant operations.

Scenario 7

Conducting plant housekeeping and cleaning activities due to chemicals or mineral oil spillage in the

plant. Scraping off flaking rust and repaint all metal parts to avoid corrosion. Cleaning, washing and

wiping of oil contaminated tools and equipment by using cotton rags

Scenario 8

‘Setting-up collection bins for expired or discarded batteries from company and employee's portable

equipment and hand-phones for reoycling program

YOUR RESPONSIBILITIES

You have been employed by this multinational company as Senior Corporate Environmental Engineer

to be accountable and responsible for all environmental matters of all the three operating companies.

One of your main responsibilities is to ensure regulatory compliance for the schedule waste

generated by these companies in accordance with the Environmental Quality (Schedule Wastes)

Regulations 2005

7° YGUR TASKS.

Ya have been tasked by the Management of the company that all the wastes generated by these

tnree operating companies must be

a

Identified, characterized and classified and determined whether they are scheduled wastes

or not

Record all the information about the wastes generated by the company.

Categorize the wastes in accordance with the waste codes in the First Schedule of the

Environmental Quality (Schedule Wastes) Regulations 2005

Describe briefly the likely sources, origins, processes or activities of how these wastes are

generated. (5 Marks)

Determine one likely principle composition (such as metals, inorganic or organic) and two

main constituents (such as mercury, arsenio, lead, fluoride, phenol, formaldehyde, cyanide,

hydrocarbon, acid, alkaline, mineral oil, organic solvent or mixture of organic and inorganic

ote...) of the wastes. (4 Marks)

Based on the information provided to you, list the appropriate of these wastes for temporary

storage before disposal. (2 Marks)

Determine two types of containers that may be suitable for packaging of these wastes for

temporary storage before disposal. (2 Marks)

Provide the appropriate warning signs and correct labels for each of these wastes and give

appropriate names of the wastes of you choice. (8 Marks)

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Course RESEARCH PROJECTDocument3 pagesCourse RESEARCH PROJECTikhwanstorageNo ratings yet

- Esc5302 HW2Document2 pagesEsc5302 HW2ikhwanstorageNo ratings yet

- 3415f43a-6735-46cb-9e4a-f696f42f0b3bDocument2 pages3415f43a-6735-46cb-9e4a-f696f42f0b3bikhwanstorageNo ratings yet

- Instructional Guidance For LecturerDocument44 pagesInstructional Guidance For LecturerikhwanstorageNo ratings yet

- Esc5302 HW1Document1 pageEsc5302 HW1ikhwanstorageNo ratings yet

- 4.CAC Market ApproachDocument71 pages4.CAC Market ApproachikhwanstorageNo ratings yet

- Esc5302 HW2Document1 pageEsc5302 HW2ikhwanstorageNo ratings yet

- Assignment Fisheries NewDocument8 pagesAssignment Fisheries NewikhwanstorageNo ratings yet

- Incinerator InfoDocument2 pagesIncinerator InfoikhwanstorageNo ratings yet

- Exercise CBA by MarhainiDocument3 pagesExercise CBA by MarhainiikhwanstorageNo ratings yet

- 2.modeling Market ProcessDocument43 pages2.modeling Market ProcessikhwanstorageNo ratings yet

- Img 20150412 0002Document1 pageImg 20150412 0002ikhwanstorageNo ratings yet

- Gross Domestic Product (GDP)Document8 pagesGross Domestic Product (GDP)ikhwanstorageNo ratings yet

- Definisi Pembangunan MampanDocument3 pagesDefinisi Pembangunan MampanikhwanstorageNo ratings yet

- Wastewater Technologyy: Experiment 3: Chemical Oxygen Demands (Cod)Document11 pagesWastewater Technologyy: Experiment 3: Chemical Oxygen Demands (Cod)ikhwanstorageNo ratings yet

- Wastewater EngineeringDocument23 pagesWastewater EngineeringikhwanstorageNo ratings yet

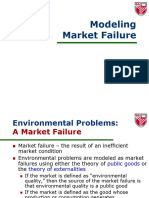

- 3.market FailureDocument30 pages3.market FailureikhwanstorageNo ratings yet

- 1 IntroductionDocument14 pages1 IntroductionikhwanstorageNo ratings yet

- Module 8Document5 pagesModule 8ikhwanstorageNo ratings yet

- Module 1Document11 pagesModule 1ikhwanstorageNo ratings yet

- Module 2Document28 pagesModule 2ikhwanstorageNo ratings yet

- Module 10Document1 pageModule 10ikhwanstorageNo ratings yet

- Module 1Document7 pagesModule 1ikhwanstorageNo ratings yet

- Scan 0003Document1 pageScan 0003ikhwanstorageNo ratings yet

- LDÖ Meter: Pengukuran Dissolved OxygenDocument8 pagesLDÖ Meter: Pengukuran Dissolved OxygenikhwanstorageNo ratings yet

- Module 7Document2 pagesModule 7ikhwanstorageNo ratings yet

- 2017 Monthly Us Holidays CalendarDocument12 pages2017 Monthly Us Holidays CalendarKhairul RizalNo ratings yet

- Scan 0001Document1 pageScan 0001ikhwanstorageNo ratings yet

- Scan 0004Document1 pageScan 0004ikhwanstorageNo ratings yet

- 2024 Excel Calendar Planner 12Document24 pages2024 Excel Calendar Planner 12ikhwanstorageNo ratings yet