Professional Documents

Culture Documents

John Deere 265, 275 & 285 Disc Mowers Diagnostic & Repair Technical Manual TM1795 PDF

Uploaded by

Equipment ManualsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

John Deere 265, 275 & 285 Disc Mowers Diagnostic & Repair Technical Manual TM1795 PDF

Uploaded by

Equipment ManualsCopyright:

Available Formats

265, 275 & 285 Rotary

Disk Mowers Diagnostic

and Repair

TECHNICAL MANUAL

Mowers models 265, 275 & 285

TM1795 01 SEP 00 (ENGLISH)

John Deere Agriculture

Pinted by Belgreen

tm1795-TECHNICAL MANUAL (g) by Belgreen v2.5

Table of contents

FORWARD

Section 10 - GENERAL INFORMATION

Group 05 - Safety

Group 10 - General Specifications

Group 15 - Lubricants

Section 20 - POWER TRAIN

Group 05 - General Information

Group 10 - Diagnosing Malfunctions

Group 15 - Driveline Repair

Group 20 - Drive Belts

Group 25 - Gear Case Repair

Section 30 - CUTTING COMPONENTS

Group 05 - General Information

Group 10 - Diagnosing Malfunctions

Group 15 - Knives

Group 20 - Disks and Converging Disk/Cones

Group 25 - Cutterbar

Group 30 - Swath Wheels

Section 40 - FRAME COMPONENTS

Group 05 - General Information

Group 10 - Parking Latch and Compensating Spring

Group 15 - Break-Away Latch

Section 50 - HYDRAULICS

Group 05 - General Information

Group 10 - Hydraulic Lift Cylinder and Linkage

<- Go to Global Table of contents tm1795-TECHNICAL MANUAL

<- Go to Global Table of contents tm1795-TECHNICAL MANUAL

GENERAL INFORMATION (g) by Belgreen v2.0

Forward

265 Rotary Disk Mower

This manual is written for an experienced technician. Essential tools required in performing certain service work are identified

in this manual and are recommended for use.

Live with safety: Read the safety messages in the introduction of this manual and the cautions presented throughout the text

of the manual.

This is the safety-alert symbol. When you see this symbol on the machine or in this manual, be alert to the potential for

personal injury.

Information is organized in groups for the various components requiring service instruction. At the beginning of each group are

summary listings of all applicable essential tools, service equipment and tools, other materials needed to do the job, service

parts kits, specifications, wear tolerances, and torque values.

Technical Manuals are concise guides for specific machines. They are on-the-job guides containing only the vital information

needed for diagnosis, analysis, testing, and repair.

Fundamental service information is available from other sources covering basic theory of operation, fundamentals of

troubleshooting, general maintenance, and basic type of failures and their causes.

<- Go to Section TOC Section 10 page 1 tm1795-TECHNICAL MANUAL

tm1795-TECHNICAL MANUAL (g) by Belgreen v2.5

Section 10 - GENERAL INFORMATION

Table of contents

Group 05 - Safety ..................................................................................................................................... 1

Recognize Safety Information ............................................................................................................... 1

Understand Signal Words ..................................................................................................................... 1

Follow Safety Instructions ..................................................................................................................... 1

Operate Mower Safely .......................................................................................................................... 2

Keep Riders Off Machine ...................................................................................................................... 3

Handle Fluids Safely-Avoid Fires ........................................................................................................... 3

Prepare for Emergencies ...................................................................................................................... 3

Handle Chemical Products Safely ......................................................................................................... 4

Avoid High-Pressure Fluids ................................................................................................................... 4

Stay Clear of Rotating Drivelines .......................................................................................................... 5

Avoid Injury from Thrown Objects ........................................................................................................ 5

Use Safety Lights and Devices ............................................................................................................. 6

Tow Loads Safely .................................................................................................................................. 6

Support Machine Properly .................................................................................................................... 7

Wear Protective Clothing ...................................................................................................................... 8

Work in Clean Area ............................................................................................................................... 8

Service Machines Safely ....................................................................................................................... 8

Illuminate Work Area Safely ................................................................................................................. 9

Replace Safety Signs ............................................................................................................................ 9

Use Proper Lifting Equipment ............................................................................................................... 9

Remove Paint Before Welding or Heating ........................................................................................... 10

Avoid Heating Near Pressurized Fluid Lines ........................................................................................ 11

Practice Safe Maintenance ................................................................................................................. 12

Use Proper Tools ................................................................................................................................. 12

Dispose of Waste Properly .................................................................................................................. 13

Live With Safety ................................................................................................................................. 13

Group 10 - General Specifications ....................................................................................................... 14

Machine Description ........................................................................................................................... 14

265 and 275 Rotary Disk Mower Specifications (Specifications and design are subject to change

without notice.) ........................................................................................................................... 15

Metric Bolt and Cap Screw Torque Values .......................................................................................... 16

Unified Inch Bolt and Cap Screw Torque Values ................................................................................. 17

Group 15 - Lubricants ............................................................................................................................ 18

Lubricating and Maintaining Machine Safely ...................................................................................... 18

Grease ................................................................................................................................................ 19

Cutterbar and Gear Case Oil ............................................................................................................... 19

Alternative and Synthetic Lubricants .................................................................................................. 19

Mixing of Lubricants ........................................................................................................................... 20

Lubricant Storage ............................................................................................................................... 20

Perform Lubrication and Maintenance ................................................................................................ 20

<- Go to Global Table of contents tm1795-TECHNICAL MANUAL

Section 10 - GENERAL INFORMATION Group 05: Safety

Group 05 - Safety

Recognize Safety Information

Safety-alert symbol

This is a safety-alert symbol. When you see this symbol on your machine or in this manual, be alert to the potential for personal

injury.

Follow recommended precautions and safe operating practices.

Understand Signal Words

Signal Words

A signal word-DANGER, WARNING, or CAUTION-is used with the safety-alert symbol. DANGER identifies the most serious

hazards.

DANGER or WARNING safety signs are located near specific hazards. General precautions are listed on CAUTION safety signs.

CAUTION also calls attention to safety messages in this manual.

Follow Safety Instructions

<- Go to Section TOC Section 10 page 1 tm1795-TECHNICAL MANUAL

Section 10 - GENERAL INFORMATION Group 05: Safety

Safety Messages

Carefully read all safety messages in this manual and on your machine safety signs. Keep safety signs in good condition.

Replace missing or damaged safety signs. Be sure new equipment components and repair parts include the current safety

signs. Replacement safety signs are available from your John Deere dealer.

Learn how to operate the machine and how to use controls properly. Do not let anyone operate without instruction.

Keep your machine in proper working condition. Unauthorized modifications to the machine may impair the function and/or

safety and affect machine life.

If you do not understand any part of this manual and need assistance, contact your John Deere dealer.

Operate Mower Safely

Safety - Fingers Cut Off

Safety - Toes Cut Off

Before each use, inspect entire machine. Check tightness of all nuts and bolts, particularly those securing the disks and knives.

<- Go to Section TOC Section 10 page 2 tm1795-TECHNICAL MANUAL

Section 10 - GENERAL INFORMATION Group 05: Safety

Keep all shields and cover in place.

Stop the tractor engine and wait until all moving parts have stopped before leaving operator′s station to adjust, lubricate, clean

or unclog machine.

Never hand feed material into machine.

Do not lean against, sit or stand on cutterbar cover or its supporting framework.

Make certain everyone is clear of machine before starting tractor engine or beginning operation.

Do not operate mower with cutterbar raised to vertical (transport) position.

Always operate machine at rated speed.

Drive slowly over rough ground.

Keep Riders Off Machine

Safety - Keep Riders Off Machine

Keep riders off.

Riders are subject to injury such as being struck by foreign objects and being thrown off of the machine. Riders also obstruct

the operator′s view resulting in the machine being operated in an unsafe manner.

Handle Fluids Safely-Avoid Fires

Handle Fluids Safely-Avoid Fires

When you work around fuel, do not smoke or work near heaters or other fire hazards.

Store flammable fluids away from fire hazards. Do not incinerate or puncture pressurized containers.

Make sure machine is clean of trash, grease, and debris.

Do not store oily rags; they can ignite and burn spontaneously.

<- Go to Section TOC Section 10 page 3 tm1795-TECHNICAL MANUAL

Section 10 - GENERAL INFORMATION Group 05: Safety

Prepare for Emergencies

Be prepared if a fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service, hospital, and fire department near your telephone.

Handle Chemical Products Safely

Direct exposure to hazardous chemicals can cause serious injury. Potentially hazardous chemicals used with John Deere

equipment include such items as lubricants, coolants, paints, and adhesives.

A Material Safety Data Sheet (MSDS) provides specific details on chemical products: physical and health hazards, safety

procedures, and emergency response techniques.

Check the MSDS before you start any job using a hazardous chemical. That way you will know exactly what the risks are and

how to do the job safely. Then follow procedures and recommended equipment.

(See your John Deere dealer for MSDS′s on chemical products used with John Deere equipment.

Avoid High-Pressure Fluids

<- Go to Section TOC Section 10 page 4 tm1795-TECHNICAL MANUAL

Section 10 - GENERAL INFORMATION Group 05: Safety

Escaping fluid under pressure can penetrate the skin causing serious injury.

Avoid the hazard by relieving pressure before disconnecting hydraulic or other lines. Tighten all connections before applying

pressure.

Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically removed within a few hours

or gangrene may result. Doctors unfamiliar with this type of injury should reference a knowledgeable medical source. Such

information is available from Deere & Company Medical Department in Moline, Illinois, U.S.A.

Stay Clear of Rotating Drivelines

Entanglement in rotating driveline can cause serious injury or death.

Keep tractor master shield and driveline shields in place at all times. Make sure rotating shields turn freely.

Wear close fitting clothing. Stop the engine and be sure PTO driveline is stopped before making adjustments, connections, or

cleaning out PTO driven equipment.

Avoid Injury from Thrown Objects

<- Go to Section TOC Section 10 page 5 tm1795-TECHNICAL MANUAL

For the full PDF version of this

manual, Please click on the above

download PDF button.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- John Deere 318D, 319D, 320D and 323D Skid Steer Loader Technical Service Repair Manual TM11399Document31 pagesJohn Deere 318D, 319D, 320D and 323D Skid Steer Loader Technical Service Repair Manual TM11399Equipment Manuals0% (1)

- John Deere 331G, 333G Compact Track Loader Operation & Diagnostic Test Technical Service Manual TM14062X19 PDFDocument31 pagesJohn Deere 331G, 333G Compact Track Loader Operation & Diagnostic Test Technical Service Manual TM14062X19 PDFEquipment Manuals0% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- John Deere 4044M, 4044R, 4049M, 4049R, 4052M, 4052R, 4066M, 4066R Tractor Manual TM131019 PDFDocument31 pagesJohn Deere 4044M, 4044R, 4049M, 4049R, 4052M, 4052R, 4066M, 4066R Tractor Manual TM131019 PDFEquipment Manuals0% (3)

- John Deere XUV835E, XUV835M, XUV835R Vehicle Repair Manual TM145519 - PDF DownloadDocument31 pagesJohn Deere XUV835E, XUV835M, XUV835R Vehicle Repair Manual TM145519 - PDF DownloadEquipment Manuals0% (1)

- John Deere STX38, STX46, STX30D Riding Lawn Tractor Technical Service Repair Manual TM1561Document31 pagesJohn Deere STX38, STX46, STX30D Riding Lawn Tractor Technical Service Repair Manual TM1561Equipment ManualsNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Toyota 7FBEF 15-20Document671 pagesToyota 7FBEF 15-20Hushanji91% (23)

- John Deere 540G-III, 548G-III, 640G-III, 648G-III, 748G-III Operation, Maintenance & Diagnostic Test Service Manual TM1870Document31 pagesJohn Deere 540G-III, 548G-III, 640G-III, 648G-III, 748G-III Operation, Maintenance & Diagnostic Test Service Manual TM1870Equipment ManualsNo ratings yet

- John Deere 710D Backhoe Loader Technical Service Repair Manual TM1538 - PDF DownloadDocument31 pagesJohn Deere 710D Backhoe Loader Technical Service Repair Manual TM1538 - PDF DownloadEquipment Manuals0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- John Deere 458, 558, 458 Balers Service Repair Manual TM1735Document26 pagesJohn Deere 458, 558, 458 Balers Service Repair Manual TM1735Equipment Manuals0% (1)

- Mitsubishi 4g92 Engine Manual PDFDocument2 pagesMitsubishi 4g92 Engine Manual PDFMohammed Hanafi60% (5)

- Cx31 Cat Transmission-Student HandoutDocument25 pagesCx31 Cat Transmission-Student Handouteng_ebrahim_2000100% (4)

- John Deere 470G LC Excavator Operation, Maintenance & Diagnostic Test Service Manual TM13173X19 - PDF DownloadDocument31 pagesJohn Deere 470G LC Excavator Operation, Maintenance & Diagnostic Test Service Manual TM13173X19 - PDF DownloadEquipment ManualsNo ratings yet

- John Deere 160CLC Excavator Operation, Test Manual TM1932Document31 pagesJohn Deere 160CLC Excavator Operation, Test Manual TM1932Equipment ManualsNo ratings yet

- John Deere 9650 CTS Combine Repair Technical Manual TM2021 PDFDocument31 pagesJohn Deere 9650 CTS Combine Repair Technical Manual TM2021 PDFEquipment ManualsNo ratings yet

- John Deere 630FD, 635FD, 640FD, 645FD Flexible Draper Repair Technical Manual TM806419 - PDF File DownloadDocument31 pagesJohn Deere 630FD, 635FD, 640FD, 645FD Flexible Draper Repair Technical Manual TM806419 - PDF File DownloadEquipment Manuals100% (1)

- John Deere Tractor 6215, 6415, 6615, 6715 Diagnostic & Test Service Manual TM4648 PDFDocument31 pagesJohn Deere Tractor 6215, 6415, 6615, 6715 Diagnostic & Test Service Manual TM4648 PDFEquipment Manuals100% (1)

- John Deere 250G LC Excavator Technical Service Repair Manual TM13209X19Document31 pagesJohn Deere 250G LC Excavator Technical Service Repair Manual TM13209X19Equipment Manuals0% (1)

- John Deere 624K 4WD Loader With Engine 6068HDW79, 6068HDW83 Service Repair Manual TM10691 - PDF DownloadDocument31 pagesJohn Deere 624K 4WD Loader With Engine 6068HDW79, 6068HDW83 Service Repair Manual TM10691 - PDF DownloadEquipment ManualsNo ratings yet

- Genset - New C 250 (CPG)Document4 pagesGenset - New C 250 (CPG)phredlovNo ratings yet

- Annual ReportDocument132 pagesAnnual ReportANUBHAV NARWALNo ratings yet

- Fichas Fanfaro - 10KDocument53 pagesFichas Fanfaro - 10Koscar baezNo ratings yet

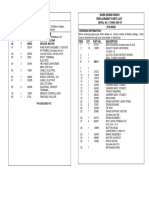

- Warn Xd9000 Winch Replacement Parts List Warn Xd9000 Winch Replacement Parts ListDocument2 pagesWarn Xd9000 Winch Replacement Parts List Warn Xd9000 Winch Replacement Parts ListTegal jatiNo ratings yet

- Wireless Automation - ABBDocument16 pagesWireless Automation - ABBajit_ahuja1737No ratings yet

- Quick Reference IndexDocument3 pagesQuick Reference IndexDinator CortésNo ratings yet

- Brochure XE215SLLDocument2 pagesBrochure XE215SLLFernanda RizaldoNo ratings yet

- Urania Supremo CI-4 PDFDocument1 pageUrania Supremo CI-4 PDFHazrulnizam HassanNo ratings yet

- Affidavit of Damage To VehicleDocument2 pagesAffidavit of Damage To VehiclehillaryNo ratings yet

- Composites For Automotive IndustryDocument52 pagesComposites For Automotive IndustryPaul Murray100% (1)

- LR Guidance Note WebDocument8 pagesLR Guidance Note WebOscar Marino Campo BonellNo ratings yet

- Lab Report 2 (Me160p-2, Bellen)Document14 pagesLab Report 2 (Me160p-2, Bellen)AndreNo ratings yet

- Unit VIII Reciprocating PumpsDocument16 pagesUnit VIII Reciprocating PumpsRICHARD VALIENTENo ratings yet

- Bearing NotesDocument132 pagesBearing NotesSarvagnaMNNo ratings yet

- Product Catalogue WEBDocument48 pagesProduct Catalogue WEBSidy Semba DagnogoNo ratings yet

- If A Worker Has Suffered From Electric Shock, He Should Be: Sample Question 1 (Remove Sample Question) Id 1Document15 pagesIf A Worker Has Suffered From Electric Shock, He Should Be: Sample Question 1 (Remove Sample Question) Id 1TUFAN GAMINGNo ratings yet

- 05-737-800 Ramp & Transit FuelDocument90 pages05-737-800 Ramp & Transit FuelNicolas SalNo ratings yet

- Choose The Correct Answer by Crossing 12 KPJN 7& SBPCDocument12 pagesChoose The Correct Answer by Crossing 12 KPJN 7& SBPCTenthnia Putri PratiwiNo ratings yet

- DLP Pneumatic System Components LANCE ANDREI SEGUIDocument6 pagesDLP Pneumatic System Components LANCE ANDREI SEGUIJude SedaNo ratings yet

- Checkball Book Import Volume IDocument103 pagesCheckball Book Import Volume IEryk NowickiNo ratings yet

- Mow Modulating Worm Gearbox Sizing ChartDocument2 pagesMow Modulating Worm Gearbox Sizing Chartren kaiNo ratings yet

- Maths Multiple ChoiceDocument5 pagesMaths Multiple ChoiceQueen Ayana TysonNo ratings yet

- Maintenance Book: H28TJ+ (HB86TJ+) H43TPX (HB135JRT)Document196 pagesMaintenance Book: H28TJ+ (HB86TJ+) H43TPX (HB135JRT)Henry Joe Escriba LozanoNo ratings yet

- Manual For Toyota Hilux 3lDocument5 pagesManual For Toyota Hilux 3lArcadio DuronNo ratings yet

- Cycle Innovations GL1000Document32 pagesCycle Innovations GL1000CaptainMidnight85100% (1)

- Carrying Children Safely in Taxis Coaches Buses and MinibusesDocument8 pagesCarrying Children Safely in Taxis Coaches Buses and MinibusesAndreea CalinNo ratings yet

- High Lift Hydraulic Transmission Jacks "AF25082" "AF50080" "AF100080"Document6 pagesHigh Lift Hydraulic Transmission Jacks "AF25082" "AF50080" "AF100080"Alain DefoeNo ratings yet