Professional Documents

Culture Documents

CT MotionWorksIEC 01 eLM MWiec3 CertificationTestdd

Uploaded by

chinhnguyen.robot.ipOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CT MotionWorksIEC 01 eLM MWiec3 CertificationTestdd

Uploaded by

chinhnguyen.robot.ipCopyright:

Available Formats

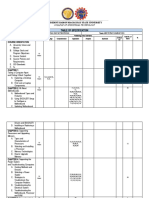

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Student Name:

Company Name:

Address:

Phone:

Email:

Test Date:

Answers:

1 26 51 76 101

2 27 52 77 102

3 28 53 78 103

4 29 54 79 104

5 30 55 80 105

6 31 56 81 106

7 32 57 82 107

8 33 58 83 108

9 34 59 84 109

10 35 60 85 110

11 36 61 86 111

12 37 62 87 112

13 38 63 88 113

14 39 64 89

15 40 65 90

16 41 66 91

17 42 67 92

18 43 68 93

19 44 69 94

20 45 70 95

21 46 71 96

22 47 72 97

23 48 73 98

24 49 74 99

25 50 75 100

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page1 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Taking the Test

The purpose of this test is to validate the learning experience corresponding to the

applicable eLearning Module.

The test is open book. You may use any website, manuals, software, demo, etc. The test

must be taken individually; you may not contact another person for help.

Each question has only one correct answer unless otherwise noted. Please clearly record

all answers on the answer sheet. All questions are equally weighted. A passing score is

90%.

It is recommended to preview the questions before viewing the module, and answer them

as the module progresses.

This test applies to the following eLearning modules. These videos may be viewed at

https://www.youtube.com/playlist?list=PLNAENlyEDCkyqEthP3ahIzfOGqoRxnrWM

1. eLM.MotionworksIEC.01.MWiec3_VIPA_CFG

2. eLM.MotionworksIEC.02.MWiec3_LGCANLYZ

3. eLM.MotionworksIEC.03.MWiec3_MP3000

4. eLM.MotionworksIEC.04.MWiec3_PLCOPN4

5. eLM.MotionworksIEC.05.MWiec3_SimAxis

6. eLM.MotionworksIEC.06.MWiec3_MCE_BAS

7. eLM.MotionworksIEC.07.MWiec3_MCE_GEN

8. eLM.MotionworksIEC.08.MWiec3_MCE_BLND

9. eLM.MotionworksIEC.09.MWiec3_MCE_SS

10. eLM.MotionworksIEC.10.MWiec3_HMI_TAG

11. eLM.MotionWorksIEC.12.MWiec3_MULTIRST

12. eLM.MotionWorksIEC.13.MWiec3_Optimize

13. eLM.MotionWorksIEC.14.MWiec3_SWp7

14. eLM.MotionWorksIEC.15.MWiec3_Mech

15. eLM.MotionWorksIEC.16.MWiec3_MltRsrce

16. eLM.MotionWorksIEC.17.MWiec3_FBupdate

17. eLM.MotionWorksIEC.18.MWiec3_CR_IMPROV

18. eLM.MotionWorksIEC.25_MWIEC3_PCS

19. eLM.MotionWorksIEC.26.MWiec3_CBTrack

20. eLM.MotionWorksIEC.27.MWIEC3_IZone

21. eLM.MotionWorksIEC.28.MWIEC3_Smooth

22. eLM.MotionWorksIEC.29.MWIEC3_PTgroup

23. eLM.MotionWorksIEC.30.MWIEC3_TanAux

24. eLM.MotionWorksIEC.31.MWIEC3_UserLib

25. eLM.MotionWorksIEC.32.MWIEC3_Startup

26. eLM.MotionWorksIEC.33.MWIEC3_PTcont

27. eLM.MotionWorksIEC.34.MWIEC3_PTmwiec

28. eLM.MotionWorksIEC.35.MWIEC3_PThc

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page2 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Returning the Test

Please return only the first page of the test (the answer sheet) with completed answers

and contact information.

e-mail a scan, photo, or edited pdf of the answer sheet with all answers and contact

information to training@yaskawa.com.

Receiving Your Score

You may review your answers only if a passing score is received. You will receive a system-

generated email with your score. Please allow up to 5 business days.

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page3 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Yaskawa SLIO (eLM.MotionWorksIEC.01.MWiec3_VIPA_CFG)

1. What is the function of the Load Factor?

A. Live online monitor of the current draw

B. Estimation of the current draw

C. Calculation of worst-case current draw

2. How are the slice parameters saved in the MotionWorks IEC project when using the

Ethernet/IP SLIO interface module?

A. Included in hardware configuration

B. Written with function blocks

3. How are IO addresses determined when (assume the Ethernet/IP SLIO interface

module)?

A. The addresses are set by hardware configuration

B. The addresses are copied from the SLIO Web UI

C. The addresses are imported using function blocks

4. What is the maximum number of inputs or outputs available on a slice?

A. 2

B. 4

C. 8

D. 12

E. 16

5. Which SLIO interface module protocol supported in MotionWorks IEC Hardware

Configuration is appropriate for time-critical IO?

A. Modbus TCP/IP

B. ProfiNet

C. EtherNet/IP

D. DeviceNet

E. MECHATROLINK-III

F. CANopen

G. All of the above

H. Answers A and B only

I. Answers C and E only

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page4 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Logic Analyzer (eLM.MotionWorksIEC.02.MWiec3_LGCANLYZ)

6. When using Logic Analyzer, why is it important to know the setting of the task

interval?

A. To set the trigger configuration sample time

B. To read the cursor measurement data

C. To read the Duration axis data

7. What unit of measurement is used by default on the horizontal axis in Logic

Analyzer?

A. Seconds

B. Application Scans

C. Samples

D. Milliseconds

8. How many cursors can be displayed simultaneously in Logic Analyzer

A. 1

B. 2

C. 3

D. 4

9. Which mouse buttons are used to zoom in on the trace?

A. Left

B. Right

C. Left and Right

D. Middle

E. Scroll wheel

10. Which operations are possible in Logic Analyzer?

A. Save and Load zoom settings

B. Save and load curves

C. Save and load triggers

D. Save and load cursors

E. Both B and C

F. Both A and D

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page5 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

MP3300iec Series Networking (eLM.MotionWorksIEC.03.MWiec3_MP3000)

11. What is the maximum number of bytes in an Ethernet/IP instance in the MP3300iec?

A. 128

B. 256

C. 496

D. 512

12. How many EtherNet/IP adapters can be connected to one MP3000iec series

controller?

A. 50

B. 100

C. 128

D. 256

13. What is the benefit of %M bidirectional holding registers when the MPiec controller is

used as a Modbus/TCP slave?

A. The function code sizes are increased

B. The network speed and number of adapters is increased

C. Uses less memory and less programming

14. A controller is sending the integer data “1234” over Ethernet/IP to another device,

but that device reads “-11772”. What might be necessary?

A. Use the %M registers for Ethernet/IP data

B. Use the Endian conversion functions

C. Add another Ethernet/IP Instance

D. Configure the controller as an Ethernet/IP scanner instead of adapter

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page6 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

PLCopen Part 4 (eLM.MotionWorksIEC.04.MWiec3_PLCOPN4)

15. What does the PLCopen Part 4 standard define?

A. Single Axis Motion Control

B. User Guidelines for PLC Programming

C. Coordinated Multi-Axis Motion

D. Homing Procedures

16. What part of MotionWorks IEC is used to assign specific axes to a multi-axis

mechanism?

A. Global Variables

B. Hardware Configuration

C. I/O Configuration

D. Web UI

E. Local Variables Worksheet

17. Which coordinate system has a fixed origin at the base of the mechanism?

A. Tool coordinate system (TCS)

B. Axis coordinate system (ACS)

C. World coordinate system (WCS)

D. Machine coordinate system (MCS)

18. Which type of coordinated move commands a multi-axis mechanism to move as an

arc between two points?

A. Linear

B. Blended

C. Circular

D. Direct

E. Intermediate

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page7 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Simulated Axis

(eLM.MotionWorksIEC.05.MWiec3_SimAxis)

19. What is the purpose of Switch Hardware Mode?

A. To run the MECHATROLINK axis as a virtual

axis without hardware

B. To accomplish servo positioning with a variable

frequency drive

C. To increase the number of axes without

additional hardware requirements

D. All of the above

20. What is the advantage of Switch Hardware Mode compared to virtual axis?

A. All MECHATROLINK parameters are retained

B. Minimal programming and configuration changes

C. All of the above

21. Which area within MotionWorks IEC is used to switch the axis hardware mode?

A. Hardware Configuration

B. Initialize POU

C. Global Variables

D. Resource Dialog

E. All of the above

22. Which of the following is NOT supported when an axis is simulated?

A. Speed Control

B. Position Control

C. I/O

D. Position Feedback

E. All of the above

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page8 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Cam Editor – Basics (eLM.MotionWorksIEC.06.MWiec3_MCE_BAS)

23. Which function block moves the cam table from the CSV file into the controller

RAM?

A. CamGenerator

B. Y_CamStructSelect

C. Y_CamFileSelect

D. Y_CamIn

24. Which button launches Cam Editor?

A. B. C. D. E. F. G.

25. What slave data can be seen on the left side of the Cam Editor

A. Slave position

B. Slave Velocity

C. Slave Acceleration

D. Slave Jerk

E. A,B,D

F. A,B,C

G. All of the above

26. A lower value in the Resolution column results in..

A. More master-slave points

B. Fewer master-slave points

C. No effect on the master-slave points

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page9 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Cam Editor – Cam Generator (eLM.MotionWorksIEC.07.MWiec3_MCE_GEN)

27. How can variables from the code be imported into Cam Editor?

A. Use the Export variables to HMI button in Hardware Configuration

B. Import from a CSV file using the CSV button in Cam Editor

C. Paste from a structured text program and use Convert ST Code

28. What is the purpose of the CamGenerator function block?

A. Calculates a cam table structure from several cam segments

B. Generates motion in the servo motor based on a cam table

C. Outputs a CSV file or structure for import into Cam Editor

D. Moves the cam table from the CSV file into the controller RAM?

29. What type of data can be entered in Cam Editor for Master, Slave, and Resolution in

the Cam Segment Table tab?

A. Numeric Values

B. Variables

C. Mathematical Expressions

D. All of the above

E. Answers A and B only

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page10 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Cam Editor – Cam Blend (eLM.MotionWorksIEC.08.MWiec3_MCE_BLND)

30. Which cam profiles are required to use CamBlend?

A. Start, End

B. Ramp In, Ramp Out

C. Ramp In, Running, Ramp Out

D. Start, Running, End

31. How many cam table IDs are required by the CamBlend Function Block?

A. 2

B. 3

C. 4

D. 7

32. What function block controls the transition between the Blend profiles?

A. CamBlend

B. CamIn

C. CamGenerator

D. Y_CamStructSelect

33. What type of application can benefit the most from CamBlend?

A. Point-to-Point Positioning

B. Multi-axis Coordinated Motion

C. Linear Flying Shear

D. Rotary Knife

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page11 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Cam Editor – Cam Sigma Select (eLM.MotionWorksIEC.09.MWiec3_MCE_SS)

34. What methods can be used to model the motion profile with Yaskawa’s Sigma

Select servo sizing software?

A. The built-in profile editor

B. A CSV file

C. Active Cam Editor project

D. All of the above

E. A and C only

35. What is the benefit of using Cam Editor with Sigma Select servo sizing software?

A. Complex motion profiles can be accurately modeled for motor sizing

B. Sigma Select can be used to create cam profiles for motion programming

C. Variables from Sigma Select can be used in Cam Editor

36. In Sigma Select, the “Connect to CamEditor” button is active. What button in Cam

Editor links it to Sigma Select?

A. B. C. D.

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page12 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

HMI Tag Import/Export (eLM.MotionworksIEC.10.MWiec3_HMI_TAG)

37. What does the result of pressing the “Export MWIEC Variables to HMI Tags” button?

A. Sends the Modbus/TCP tags directly to the HMI

B. Creates a CSV file that can be imported to the HMI

C. Exports the Modbus/TCP settings from Hardware configuration

D. Reads the HMI tags into MotionWorks IEC.

38. Where in MotionWorks IEC are the supported HMI export formats listed?

A. Global Variables

B. WebUI

C. Hardware Configuration

D. I/O Configuration

39. Which menu button listed initiates “Export MWIEC Variables to HMI Tags”?

A.

B.

C.

D.

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page13 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Multi-Turn Reset (eLM.MotionWorksIEC.12.MWiec3_MULTIRST)

40. In what circumstances can the alarm A.CC0(multi turn limit disagreement) occur?

A. When the machine is first deployed

B. After motor replacement

C. When encoder cable is disconnected

D. All of the above

E. Answers A and B only

41. What is the meaning of the alarm A.CC0 (multi turn limit disagreement)?

A. All the power supplies for the absolute encoder have failed

B. The connection between the amplifier and the command option module is faulty

C. Data in the encoder does not match what is in the amplifier

D. The amplifier and motor capacities do not match

42. Which button in MotionWorks IEC Hardware Configuration resets the Multi-turn limit

in the encoder?

A.

B.

C.

D.

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page14 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Optimize Axis (eLM.MotionWorksIEC.13.MWiec3_Optimize)

43. To use the Optimize Axis button, first navigate to the _____ (choose the best

answer).

A. Hardware Configuration

B. Project Tree

C. Edit Wizard

D. Web UI

E. SigmaWin+ ver7

44. It is recommended to use the Optimize Axis button for which servo axes?

A. No servo axes

B. All existing servo axes already operating in the field

C. Every newly commissioned servo axis

D. Only axes that require high performance

E. Only axes that do not require servo tuning

45. Which SigmaWin trace corresponds to an axis to which Optimize Axis has been

applied?

A. Figure 1

B. Figure 2

Figure 1 Figure 2

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page15 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

SigmaWin+7 with Controller (eLM.MotionWorksIEC.14.MWiec3_SWp7)

46. Which of the following controller products support connection of SigmaWin+7 to the

Servopacks through the MPiec controller?

A. Sigma-7Siec, firmware ≥ 3.3

B. MP3300iec, firmware ≥ 3.2

C. MP2310iec, firmware ≥ 3.2

D. MP3200iec, firmware ≥ 3.3

E. All of the above

47. What connection method is selected in SigmaWin+7 in order to connect to the

Servopacks through the MP3300iec?

A. USB Connection

B. Ethernet Connection

C. Controller Connection

D. PCI/PCe Connection

E. Remote PCI/PCe Connection

F. MECHATROLINK Relay Device

48. An MP3300iec controller is connected by MECHATROLINK-III to four (4)

Servopacks. SigmaWin+7 is used to connect the Servopacks through the controller.

How many Servopacks can be monitored at once?

A. 1

B. 2

C. 3

D. 4

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page16 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

MECHATROLINK Mechanisms (eLM.MotionWorksIEC.15.MWiec3_Mech)

49. Which types of multi-axis mechanisms can the MP3000iec controllers operate using

MECHATROLINK servos, when the kinematic equations exist at the MPiec firmware

level? (Assume firmware version 3.7.)

A. Gantry

B. H-Bot & T-Bot

C. SCARA

D. Delta Robot

E. GP8 6-axis articulated robot arm

F. Answers A, B and C

G. Answers A, B, C, and D

H. All of the above

50. What is the minimum number of servo axes that exist in a Delta Robot mechanism

supported by MECHATROLINK groups? (Assume kinematic equations at firmware

level, firmware version 3.7)

A. 2

B. 3

C. 4

D. 5

E. 6

51. How many belts exist in a T-Bot or H-Bot?

A. 1 belt

B. 2 belts

C. 3 belts

D. No belts

52. Where do the kinematic equations reside if the MP3000iec controls a custom multi-

axis mechanism?

A. MPiec Application Code

B. External Controller

C. MPiec Firmware

D. Servopack

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page17 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Multi Resource (eLM.MotionWorksIEC.16.MWiec3_MltRsrce)

53. A machine uses four (4) M3300iec controllers and thirty-three (33) Servopacks.

What is the minimum number of MotionWorks IEC 3 projects required?

A. 1

B. 2

C. 3

D. 4

54. To add a controller to the project, first navigate to the _____ (choose the best

answer).

A. Hardware Configuration

B. Project Tree

C. Edit Wizard

D. Web UI

E. SigmaWin+ ver7

55. What is true about a project with multiple controllers?

A. A task from one controller can be used in another controller

B. A program instance from one controller can be used in another

C. A global variable from one controller can be used in another

D. Answers A and B only

E. Answers B and C only

F. Answers A and C only

G. All answers, A, B and C

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page18 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Programming Tips – 1 (eLM.MotionWorksIEC.17.MWiec3_FBupdate)

56. Troubleshooting a custom machine condition such as “Low Material” can be

accomplished in the application code by recording a text string in the Web UI using

which function block?

A. Y_DebugPrint

B. YDeviceComm

C. Debugging Output

D. MC_GroupReadStatus

57. What is the function of Y_BrakeRelease?

A. Release all holding brakes for a group while “Servo On”

B. Release all holding brakes for a group without “Servo On”

C. Release the holding brake for one axis while “Servo On”

D. Release the holding brake for one axis without “Servo On”

58. Winding applications can benefit from which of the following modes?

A. Y_ControlMode#VelocityTrqFFMode

B. Y_ControlMode#PositionTrqFFMode

C. Y_EngageMethod#AtAbsolutePosition

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page19 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Cross Reference Improvements (eLM.MotionWorksIEC.18.MWiec3_CR_IMPROV)

59. Why use the single variable lookup function?

A. Simpler than using the Cross-Reference window

B. Is quicker because it does not need to build a full Cross-Reference list

C. Cross–Reference lists don’t search local variable lists

D. A,C

E. A,B

F. All of the above

60. What actions can be performed by the navigation keys?

A. Cycle backwards or forwards through the worksheets

B. Trace or retrace where the user’s cursor has been

C. In debug mode it resets or restores the previous action

D. User can navigate through the toolbox projects

61. What does “refactor” do to a global variable?

A. Break a structure into individual components

B. Break an array into individual elements

C. Rename the variable throughout the project

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page20 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Part Coordinate System (eLM.MotionWorksIEC.25.MWIEC3_PCS)

62. Where is the origin located for a PCS move?

A. In the base of the robot

B. At a convenient location on the part

C. At the tool center point

D. All of the above

63. What is the reference coordinate system for the PCS offset?

A. MCS

B. ACS

C. PCS

D. TCS

E. WCS

64. Which are benefits of programming with PCS moves

A. More convenient for position calculations than the MCS

B. Easily adjustable for variations in part position

C. Same position sequence applies between different mechanisms

D. All of the above

E. Answers A & B only

F. Answers B & C only

65. Which steps are involved to determine what the PCS offset should be for a given

part?

A. Calculate the MCS position in world coordinates

B. Use the Y_GroupSetFrameOffset function block

C. Teach 3 positions on the part

D. Use the FrameTypeTransform function block

E. All of the above

F. Answers A & B only

G. Answers B & C only

H. Answers C & D only

66. Which steps are involved to apply the PCS offset once it is calculated?

A. Calculate the MCS position in world coordinates

B. Use the Y_GroupSetFrameOffset function block

C. Teach 3 positions on the part

D. Use the FrameTypeTransform function block

E. All of the above

F. Answers A & B only

G. Answers B & C only

H. Answers C & D only

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page21 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Conveyor Tracking (eLM.MotionWorksIEC.26.MWIEC3_CBTrack)

67. In addition to the MPiec controller and the multi-axis mechanism it controls, which

physical components comprise a valid system capable of conveyor tracking?

A. [Servo-Driven Conveyor] + [Vision System]

B. [Servo-Driven Conveyor] + [Product Sensor]

C. [External Encoder On Conveyor] + [Vision System]

D. [External Encoder On Conveyor] + [Product Sensor]

E. All of the above

F. Answers A & C only

G. Answers A & B only

68. What coordinate frame is required to command moves while tracking remains

active?

A. MCS

B. ACS

C. PCS

D. TCS

E. WCS

69. Which device provides the IOP (Initial Object Position) data to the MPiec controller?

A. External Encoder on Conveyor

B. Vision System

C. Product Sensor

D. All of the above

70. Which point is established as a fixed vector offset from the machine origin (MCS)?

A. Initial Object Position

B. Conveyor Belt Origin

C. Start Distance

D. End Distance

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page22 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Interference Zones (eLM.MotionWorksIEC.27.MWIEC3_IZone)

71. Which coordinate systems can be used to define the boundaries of the cuboid

interference zone?

A. MCS

B. PCS

C. WCS

D. TCS

E. ACS

F. All of the above

G. A, B and C only

H. D and E only

72. Entry into the interference zone of which of the following is detected?

A. Any moving part of the mechanism

B. The tool moved by the mechanism

C. The TCP moved by the mechanism

D. All of the above

73. Which are proper uses of interference zones?

A. Prevent mechanism collisions

B. Improve programming sequences

C. Satisfy safety certification

D. All of the above

E. A and B only

F. B and C only

74. What function block is used for interference zones in MotionWorks IEC?

A. MLX_RobotSetIZTwoCorner

B. Y_ActivateIZ

C. MLX_SetIZ

D. IZViolated

75. What response can automatically result when the interference zone is violated?

A. Abort motion

B. Redirect motion around the zone

C. Return to original position

D. All of the above

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page23 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Smooth Multi-Axis Coordinated Motion (eLM.MotionWorksIEC.28.MWIEC3_Smooth)

76. What transition mode applies to 6-axis articulated robots controlled over Ethernet IP

(such as YRC1000)

A. TMConstantVelocity

B. TMCornerDistance

C. TMMaxCornerDeviation

D. TMMaxCornerDistance

E. TMMLXBlend

77. What application benefits from the TCP S-Curve Filter?

A. 3D Printer

B. Pick and Place

C. Shape Cutting

D. Welding

78. What coordinate systems can be used with s-curve?

A. Axis Coordinate System (ACS)

B. Machine Coordinate System (MCS)

C. Part Coordinate System (PCS)

D. World Coordinate System (WCS)

E. A,B,C

F. B,C,D

79. An application requires many short segments for a custom path, but the TCP must

accelerate smoothly over an extended distance. What feature allows this?

A. Collinearity Threshold

B. Path Mode

C. S-Curve

D. Transition Mode

80. What application benefits from the Collinearity Threshold feature?

A. Assembly

B. Packing

C. Part Sorting

D. Shape Cutting

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page24 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Programming Tips - Groups (eLM.MotionWorksIEC.29.MWIEC3_PTgroup)

81. What function block can be used to detect whether a group is moving with

synchronized, discrete, or continuous motion?

A. MC_GroupReadStatus

B. Y_GroupReadVectorParam

C. MC_GroupSetOverride

82. The TCP of a group is in motion. Motion must be paused in order to troubleshoot

part of the machine. When finished, the machine must complete the original motion.

What feature is appropriate?

A. MC_GroupInterrupt

B. MC_GroupContinue

C. MC_GroupSetOverride

D. All of the above

E. Answers A and B only

F. Answers B and C only

83. A robot should run at 50% normal speed for troubleshooting purposes. What

function block is appropriate?

A. MC_GroupSetOverride

B. MC_GroupContinue

C. Y_GroupReadVectorParam

D. All of the above

84. What function block gives the programmer access to information such as Group

Feedrate Override?

A. Y_GroupReadParameter

B. MC_GroupReadStatus

C. MC_ReadParameter

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page25 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Tangent Following and Aux Axis (eLM.MotionWorksIEC.30.MWIEC3_TanAux)

85. Which function block is used to control the Tangent Axis?

A. Y_SyncTangentAxisToGroup

B. MC_MoveAbsolute

C. MC_MoveCircularAbsolute

D. MC_MoveLinearAbsolute

86. Which application(s) would benefit from using an auxiliary axis?

A. 3D printer Extruder

B. Spindle

C. Wire Feed Welder

D. Glass Cutter

E. A, C

F. A, D

G. C, D

87. Which type of axis receives position command through the group vector?

A. Aux

B. Tangent

88. Tangent axis can operate on which of the following mechanisms?

A. XY or XYZ Gantry

B. YRC1000 with MotoMini

C. Custom Delta Robot

D. H-Bot, T-bot, Core-XY

E. SCARA

F. All of the above

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page26 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

User Libraries (eLM.MotionWorksIEC.31.MWIEC3_UserLib)

89. Why is it important to know the version number of a user library?

A. So that each project can be automatically updated to the latest version

B. So that each project can use the version for which it was designed

90. What actions can change library compile order?

A. Drag and drop libraries

B. Save in Hardware Configuration

C. Make Dependencies

D. All of the above

E. Answers A and B only

91. What information is displayed in the tooltip when holding

the mouse over the body of a function block from a user

library?

A. Name of user library

B. Version of release

C. Date of release

D. Author of library

E. All of the above

F. Answers A and B only

92. What feature allows the programmer to lock a project to prevent unintentional edits?

A. Released

B. Version

C. Dependency

93. What feature allows the programmer to compile the libraries and the project at once?

A. Make

B. Make Dependencies

C. Rebuild Project

D. Download Changes

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page27 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Controller Startup Options (eLM.MotionWorksIEC.32.MWIEC3_Startup)

94. What data can be backed up and restored using the archive?

A. Program

B. Configuration

C. Servo Parameters

D. IP address

E. Data of variables marked “Retain”

F. All of the above

G. Answers A, B, C & D

H. Answers A, B, C & E

95. What data can be backed up and restored from the SRAM?

A. Program

B. Configuration

C. Servo Parameters

D. IP address

E. Data of variables marked “Retain”

F. All of the above

G. Answers D & E

96. Under what conditions is the controller IP address overwritten at reboot by data in

the archive?

A. When the file Network.xml exists in the archive

B. When the file AutoColdBoot.xml exists in the archive

C. When the IP address is at default

D. When the hardware configuration is saved online

97. Which of the following occur during warm start?

A. Variables marked retain are set to the initial value

B. Variables NOT marked retain are set to the initial value

C. The warm start task runs

D. The cold start task runs

E. All of the above

F. Answers A, B & C

G. Answers B & C

98. If a controller (firmware 3.7+) cannot boot with warm start, under what conditions will

it automatically boot with cold start?

A. When the file Network.xml exists in the archive

B. When the file AutoColdBoot.xml exists in the archive

C. When the data of variables marked “Retain” are restored

D. All of the above

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page28 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

99. An application contains unique calibration data stored in retain variables. What is

the recommended method for cold start?

A. Automatic Cold Start

B. Manual Cold Start

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page29 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Programming Tips - Controller (eLM.MotionWorksIEC.33.MWIEC3_PTcont)

100. The programmer would like the IEC code to verify the controller firmware level

before initiating motion. What feature is required?

A. Controller [CONTROLLER_INFO] system variable

B. Y_PostUserAlarm function block

C. Y_DebugPrint function block

D. Y_Write7LEDMessage function block

E. Y_GetAlarmDesc function block

101. When a variable reaches a threshold level, the programmer would like the

controller to enter the alarm state and record the event in alarm history. What

feature is required?

A. Controller [CONTROLLER_INFO] system variable

B. Y_PostUserAlarm function block

C. Y_DebugPrint function block

D. Y_Write7LEDMessage function block

E. Y_GetAlarmDesc function block

102. The programmer would like a specific event to be silently logged in the Web UI

without entering an alarm state. What feature is required?

A. Controller [CONTROLLER_INFO] system variable

B. Y_PostUserAlarm function block

C. Y_DebugPrint function block

D. Y_Write7LEDMessage function block

E. Y_GetAlarmDesc function block

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page30 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

103. The programmer would like a custom message to scroll on the front panel display

of the MP3300iec controlle. What feature is required?

A. Controller [CONTROLLER_INFO] system variable

B. Y_PostUserAlarm function block

C. Y_DebugPrint function block

D. Y_Write7LEDMessage function block

E. Y_GetAlarmDesc function block

104. The programmer would like to send alarm codes and descriptions to the HMI as

text strings without importing a table of alarm codes to the HMI. What feature is

required?

A. Controller [CONTROLLER_INFO] system variable

B. Y_PostUserAlarm function block

C. Y_DebugPrint function block

D. Y_Write7LEDMessage function block

E. Y_GetAlarmDesc function block

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page31 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Programming Tips – Editor (eLM.MotionWorksIEC.34.MWIEC3_PTmwiec)

105. What feature can be used to transfer a POU from an existing project to a new

project?

A. Copy/Paste

B. Export/Import

C. Insert Code Worksheet

D. Compile Unused POUs

E. All of the above

F. Answers A and B only

G. Answers B and C only

106. The programmer has transferred a logical POU from one project to another.

What elements are included?

A. Datatype Definitions

B. User Libraries

C. VAR_GLOBAL variables

D. VAR variables

E. VAR_EXTERNAL variables

F. All of the above

107. What methods can be used to adjust the value that a global variable (with a

structure datatype) will have immediately after cold start?

A. Create Global Variables from Externals

B. Initialize Multi-Element Variables

C. Structured Text code worksheet

D. Project Events Log

E. All of the above

F. Answers A and B only

G. Answers B and C only

H. Answers C and D only

108. The programmer would like to have partially completed sample code for

reference in the project, but it does not run in a task. What feature applies?

A. Toggle Boolean

B. Show Operation Log

C. Compile Worksheet

D. Compile Unused POUs

E. Insert code worksheet

F. Create globals from externals

G. Update externals from globals

H. Initialize Multi-element Variables

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page32 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

Programming Tips – Hardware Config (eLM.MotionWorksIEC.35.MWIEC3_PThc)

109. The programmer would like to determine what changes have been made to the

offline configuration. What feature is appropriate?

A. Show Differences in Configuration Comparison

B. Web UI in Hardware Configuration

C. Cascaded Master/Slave Depth

D. Switch Hardware Mode

E. Set Parameters on Multiple Axes

F. Copy Parameters / Paste Parameters

G. Logical Axis Number

110. The programmer would like to use an axis parameter configuration from another

project. What feature is appropriate?

A. Show Differences in Configuration Comparison

B. Web UI in Hardware Configuration

C. Cascaded Master/Slave Depth

D. Switch Hardware Mode

E. Set Parameters on Multiple Axes

F. Copy Parameters / Paste Parameters

G. Logical Axis Number

111. The application requires that axes be used in a complex electronic camming

relationship. What feature might be useful?

A. Show Differences in Configuration Comparison

B. Web UI in Hardware Configuration

C. Cascaded Master/Slave Depth

D. Switch Hardware Mode

E. Set Parameters on Multiple Axes

F. Copy Parameters / Paste Parameters

G. Logical Axis Number

112. An OEM wants to standardize the hardware configuration for different versions of

the machines with different axes. What feature might be useful?

A. Show Differences in Configuration Comparison

B. Web UI in Hardware Configuration

C. Cascaded Master/Slave Depth

D. Switch Hardware Mode

E. Set Parameters on Multiple Axes

F. Copy Parameters / Paste Parameters

G. Logical Axis Number

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page33 of 34

Certification Test

CT.MotionWorksIEC.01.eLM.MWiec3.CertificationTest

113. The programmer wants to test code changes on the controller and run the servos

virtually. What feature may be appropriate?

A. Show Differences in Configuration Comparison

B. Web UI in Hardware Configuration

C. Cascaded Master/Slave Depth

D. Switch Hardware Mode

E. Set Parameters on Multiple Axes

F. Copy Parameters / Paste Parameters

G. Logical Axis Number

CONGRATULATIONS! YOU COMPLETED THE LONGEST TEST IN THE HISTORY OF YASKAWA

AMERICA INC.

Yaskawa America Inc. June 25, 2021

2121 Norman Drive South Rev 1.00

Waukegan IL 60085 Page34 of 34

You might also like

- Call Center Misdirected CallsDocument2 pagesCall Center Misdirected CallsAshok KunapareddyNo ratings yet

- Prova 1Document43 pagesProva 1nick100% (1)

- Synopsys HashDocument55 pagesSynopsys Hashvigneshk85No ratings yet

- Current carrying capacity of cablesDocument3 pagesCurrent carrying capacity of cablesStefanita100% (1)

- Logic Analyzer TutorialDocument25 pagesLogic Analyzer TutorialJames OwenNo ratings yet

- Logic AnalyzerDocument27 pagesLogic AnalyzerMohammad Umar RehmanNo ratings yet

- Teaching Digital Logic Courses With Altera Technology: Tutorial #1Document49 pagesTeaching Digital Logic Courses With Altera Technology: Tutorial #1Giovanni OrsariNo ratings yet

- Manual Descritivo Funções Osciloscopio Automotivo Autoscope 4Document30 pagesManual Descritivo Funções Osciloscopio Automotivo Autoscope 4Diogov32100% (1)

- Difference between DC and MC/DC Test CasesDocument71 pagesDifference between DC and MC/DC Test CasesTuyen DinhNo ratings yet

- Output Analysis PracticesDocument9 pagesOutput Analysis Practicestrần thị ngọc trâmNo ratings yet

- CSCP - 300pq NEW 1Document104 pagesCSCP - 300pq NEW 1Shana MNo ratings yet

- Highway & Traffic EngineeringDocument14 pagesHighway & Traffic EngineeringAim ZalainiNo ratings yet

- OPERATIONS MANAGEMENT AssignmentDocument6 pagesOPERATIONS MANAGEMENT AssignmentArk ShahiNo ratings yet

- OPERATIONS MANAGEMENT AssignmentDocument6 pagesOPERATIONS MANAGEMENT AssignmentRajesh Singh100% (1)

- SMS Project ReportDocument13 pagesSMS Project Reportshafikul37No ratings yet

- Open Source DFT ToolchainDocument3 pagesOpen Source DFT ToolchainPARMAR PREXABENNo ratings yet

- Assignment Chapter 10Document2 pagesAssignment Chapter 10Gloria Lisa SusiloNo ratings yet

- Tutorial Questions Managing Quality: Observation Sample 1 2 3 4 5 6 7 8Document5 pagesTutorial Questions Managing Quality: Observation Sample 1 2 3 4 5 6 7 8lianliang0% (1)

- Laporan Praktikum Teknik Transportasi Modul 1 Spot SpeedDocument14 pagesLaporan Praktikum Teknik Transportasi Modul 1 Spot SpeedfaizmalfaNo ratings yet

- Chapter 2 QuestionDocument15 pagesChapter 2 QuestionHarshil RathodNo ratings yet

- Image Classification ReportDocument7 pagesImage Classification Reportali.nabeel246230No ratings yet

- WORK BOOK 8 - SegmentationDocument12 pagesWORK BOOK 8 - Segmentationakash bathamNo ratings yet

- Week004-MachineProblem - AnswerDocument2 pagesWeek004-MachineProblem - Answerazs88.bscpe.amauniversityNo ratings yet

- Week004-MachineProblem - Answer-SolutionDocument4 pagesWeek004-MachineProblem - Answer-Solutionazs88.bscpe.amauniversityNo ratings yet

- DVCon Europe 2015 TA2 1 PresentationDocument13 pagesDVCon Europe 2015 TA2 1 PresentationJon DCNo ratings yet

- CSE316 Assignment QuestionsDocument6 pagesCSE316 Assignment QuestionsHimanshuNo ratings yet

- Excercise DemandPlan&InvMgmtDocument7 pagesExcercise DemandPlan&InvMgmtkarthik sNo ratings yet

- STAT 2601 Final Exam Extra Practice QuestionsDocument9 pagesSTAT 2601 Final Exam Extra Practice Questionssubui613No ratings yet

- Problem Set 2Document2 pagesProblem Set 2GdeNo ratings yet

- 6.AIML - To Develop Classification Model and Evaluate Its PerformanceDocument4 pages6.AIML - To Develop Classification Model and Evaluate Its PerformanceGAURAV CHAVANNo ratings yet

- EDM V1.10.02 Upgrade Activity UAT - Issues Recording SheetDocument56 pagesEDM V1.10.02 Upgrade Activity UAT - Issues Recording SheetShraddhanand MoreNo ratings yet

- AI CUP 2020 Mango Image Recognition ChallengeDocument3 pagesAI CUP 2020 Mango Image Recognition ChallengeS KumarNo ratings yet

- Unit IV - MCQsDocument8 pagesUnit IV - MCQsMission Gate2021No ratings yet

- ETCSi Report Sept242012Document321 pagesETCSi Report Sept242012Rafael Monzon0% (1)

- SMS Project ReportDocument12 pagesSMS Project Reportshafikul37No ratings yet

- FORCES IN PLANE REDUNDANT TRUSSDocument8 pagesFORCES IN PLANE REDUNDANT TRUSSEdmund TiewNo ratings yet

- Electronic Diagnostic Device PERKINS Set 1Document11 pagesElectronic Diagnostic Device PERKINS Set 1ahmedalgaloNo ratings yet

- Statistics-Exercise 3Document4 pagesStatistics-Exercise 3Phanna MongNo ratings yet

- Blastreport - 1530002C6 - Py61A-4276 Fase 13B - 2023-03-04Document4 pagesBlastreport - 1530002C6 - Py61A-4276 Fase 13B - 2023-03-04hector lopez isidroNo ratings yet

- Module 5 Practice ProblemsDocument3 pagesModule 5 Practice Problemsdaniel bimoNo ratings yet

- Assignment 4: Spring 2020Document6 pagesAssignment 4: Spring 2020kant734No ratings yet

- MATLAB Command Window: Unrecognized Function or Variable 'NW1'. Error in Masa (Line 3) M (n1. NW1) 'Document28 pagesMATLAB Command Window: Unrecognized Function or Variable 'NW1'. Error in Masa (Line 3) M (n1. NW1) 'Abrahan MaciasNo ratings yet

- Programming Fundamentals Lab FinalDocument1 pageProgramming Fundamentals Lab FinalMuhammad Nawaz AwanNo ratings yet

- Soal SG Week 5 - RevisedDocument2 pagesSoal SG Week 5 - Revisedbismillahotw dewakipasNo ratings yet

- Instructions For Assignment Submission: Question Allocation TableDocument10 pagesInstructions For Assignment Submission: Question Allocation TableYash SharmaNo ratings yet

- Cascade ControllerDocument5 pagesCascade Controllerblub blueNo ratings yet

- Applied Numerical Methods With MATLAB For Engineers and Scientists 2nd Edition Steven Chapra Solutions Manual 1Document36 pagesApplied Numerical Methods With MATLAB For Engineers and Scientists 2nd Edition Steven Chapra Solutions Manual 1eugenehallgqdcsamwtn100% (22)

- Tutorial 1Document2 pagesTutorial 1Amirul ImanNo ratings yet

- Notes On SimulationDocument21 pagesNotes On SimulationWarren LemonNo ratings yet

- Umts Performance ReportDocument34 pagesUmts Performance ReportPrasad KaleNo ratings yet

- CT - AFD.01.eLM - Certification - Test Version 1.3Document5 pagesCT - AFD.01.eLM - Certification - Test Version 1.3pc100xohmNo ratings yet

- Thursday, September 20, 2007 1 Hourly Examination: Course: TTE 3004-Transportation Engineering Date: TaskDocument3 pagesThursday, September 20, 2007 1 Hourly Examination: Course: TTE 3004-Transportation Engineering Date: TaskzaidNo ratings yet

- Report#19615955Document34 pagesReport#19615955sushmapoudel2427No ratings yet

- CHEE3741 2016 Assignments PDFDocument16 pagesCHEE3741 2016 Assignments PDFJoshua MitchellNo ratings yet

- AWS Certified Developer - Associate (DVA-C01) Cert GuideDocument815 pagesAWS Certified Developer - Associate (DVA-C01) Cert Guideamit_post2000No ratings yet

- QM Answer Script EPGP Student Antesh KumarDocument9 pagesQM Answer Script EPGP Student Antesh KumarAntesh SinghNo ratings yet

- Rantuningreport 1290689169722 Phpapp02Document29 pagesRantuningreport 1290689169722 Phpapp02Tosin Adeniyi Adekunle INo ratings yet

- MutuDocument5 pagesMutudhitadhitNo ratings yet

- OSAssignment 2Document5 pagesOSAssignment 2Muskan AgrawalNo ratings yet

- Lab 7Document6 pagesLab 7Nicole ValerioNo ratings yet

- E20-624 VceDocument14 pagesE20-624 Vcenancy adam0% (1)

- Hw5 3223 SP17Document3 pagesHw5 3223 SP17Jennifer HellerNo ratings yet

- Tos TT3 MidDocument9 pagesTos TT3 MidPeter PadiosNo ratings yet

- Technical Data UM202 - UM203Document6 pagesTechnical Data UM202 - UM203Anonymous 8rb48tZSNo ratings yet

- Manual de Proteus VSMDocument152 pagesManual de Proteus VSMlocopisco18100% (2)

- Project Proposal - Home Climate ControlDocument11 pagesProject Proposal - Home Climate ControlPTAIYATNo ratings yet

- Mwee 201111Document32 pagesMwee 201111Petros TsenesNo ratings yet

- Report 6 VinDocument8 pagesReport 6 Vinapi-3696675No ratings yet

- DS1000E DS1000D Series DatasheetDocument1 pageDS1000E DS1000D Series DatasheetJuanNo ratings yet

- 16803A Data SheetDocument36 pages16803A Data SheetcciproductsNo ratings yet

- 3.EC8791 - ERTS - 2 Mark Q&ADocument39 pages3.EC8791 - ERTS - 2 Mark Q&AVinothkumar Uruman88% (8)

- Exercise: Xercise BjectiveDocument23 pagesExercise: Xercise BjectiveKrishna PriyaNo ratings yet

- Feeling Comfortable With Logic Analyzers PDFDocument24 pagesFeeling Comfortable With Logic Analyzers PDFJ dosherNo ratings yet

- TLA7Bxx Logic Analyzer Series Product Specifications & Performance Verification Technical ReferenceDocument30 pagesTLA7Bxx Logic Analyzer Series Product Specifications & Performance Verification Technical Referenceapi-19827677No ratings yet

- Ap7102 Adsd SyllabiDocument6 pagesAp7102 Adsd SyllabishankarNo ratings yet

- Intronix: 34 Channel La1034 Logicport Logic AnalyzerDocument2 pagesIntronix: 34 Channel La1034 Logicport Logic AnalyzerbogrocaNo ratings yet

- Logic Analyzer Vs OscilloscopeDocument2 pagesLogic Analyzer Vs OscilloscopeAsif HassanNo ratings yet

- Bit Scope ProgrammingDocument16 pagesBit Scope Programminggeodaesie13No ratings yet

- Figuras Livro PDFDocument1,149 pagesFiguras Livro PDFMarcelo Renato FilhoNo ratings yet

- ISDS205 User GuideDocument9 pagesISDS205 User GuidesutranNo ratings yet

- Tutorial On Logic Analyzer BasicsDocument5 pagesTutorial On Logic Analyzer BasicsGil HaleNo ratings yet

- OSCILLATORS AND GENERATORSDocument20 pagesOSCILLATORS AND GENERATORSswetha bagadi it's good but how it will workNo ratings yet

- Magnetic Tape RecorderDocument3 pagesMagnetic Tape RecorderNoman M HasanNo ratings yet

- ATM18 Logic Analyzer: For Deft Data AcquisitionDocument4 pagesATM18 Logic Analyzer: For Deft Data AcquisitionGiancarloRichardRivadeneyraMirandaNo ratings yet

- Frequency Divider Using VHDLDocument27 pagesFrequency Divider Using VHDLPallavi NalawadeNo ratings yet

- Signaltap Ii Logic Analyzer Tutorial: IntroDocument3 pagesSignaltap Ii Logic Analyzer Tutorial: IntroShaik IliyasNo ratings yet

- PLA Series Manual - Setup, Operation & Maintenance GuideDocument73 pagesPLA Series Manual - Setup, Operation & Maintenance Guideb4suraNo ratings yet