Professional Documents

Culture Documents

Pressure Drop Across Orifice

Pressure Drop Across Orifice

Uploaded by

Mostafa Mahmoud0 ratings0% found this document useful (0 votes)

2 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views1 pagePressure Drop Across Orifice

Pressure Drop Across Orifice

Uploaded by

Mostafa MahmoudCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

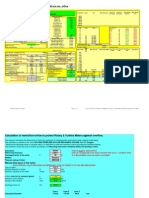

FLUID POWER DATA

PRESSURE DROPS THROUGH ORIFICES

CV FACTORS & ORIFICES

FLOW THRU ORIFICES

TO DETERMINE DESIRED ORIFICE SIZE USE THE FOLLOWING FORMULA:

Q = KA ΔP

= 18.94 X D2 ΔP WHEN C = ORIFICE COEFFICIENT .6 AND

.02

5 SG = .895, NO ALLOWANCE FOR VISCOSITY CHANGE

6

.03 7 Q = FLOW, GPM

8 D = DIAMETER, IN

.04 9 P = PRESSURE, PSI

10

.05

.06

.07

.08

20 EXAMPLE:

Fluid Power Data

.09

.10 1 gpm will pass through a

1/16 diameter hole with a 140 psi

30

pressure drop. (See dashed line)

40

.2

50 10,000

.0001 8,000

60

6,000

.3 70 .00015

80 1/64 .0002 4,000

.4 90 3,000 LIQUID FLOW THRU VALVE

100 .0003

.0004

.5 2,000

.6 .0006

1,500 Q = Cv ΔP / SG

150

.7 1/32 .0008 1,000

.001 800

.8

.9 200 600

.0015

1.0 3/64 .002

400

300 1/16 .003 300 SHARP EDGE ORIFICE

.004

5/64 200

400

2 3/32 .006 150 Q = 29.81 (C) (I.D.)2 ΔP / SG

500 .008

7/64 .01 100 = 18.9 D2

600 80

1/8

3 .015 60

700 WHEN SG IS .895

800 .02

40

4 900 3/16 .03 30 NO ALLOWANCE FOR VISCOSITY CHANGE

1000

.04

5 1/4 20

6 .06 15

1500 5/16 .08 C = .6 FOR SHARP EDGE

7 10

.1 WALL THICKNESS IS LESS THAN

8 3/8 8

9 2000 7/16 .15 6 HOLE DIAMETER

10 1/2 .2 5

2500 4 CV = GIVEN FACTOR

3000 5/8 .3 3

.4 2.5 I.D. = INSIDE DIA, IN

15

3/4 2 Δ P = CHANGE IN PRESS, (PSI)

4000 .6

20 7/8 SG = SPECIFIC GAVITY

5000 1 .8

1.5 Q = FLOW, GPM, OR SCFM

1.0

25 6000 1 1/4

30 7000 1.5

1 1/2 2 1

8000

9000 1 3/4 2.5

40 10,000 2 3

4

50 2 1/2 5

60 6

15,000 3 7

8

70 3 1/2 9 .5

10

80 4

90 20,000 15

100 4 1/2 PSI

PRESSURE

30,000 HOLE AREA DROP

150 SQ. IN.

DIA.

40,000

200

50,000 CV FACTORS FOR SHARP EDGE ORIFICES

GPM CU-IN

MIN DIA CV DIA CV DIA CV DIA CV

.020 009 .125 .35 .395 3.50 .750 12.50

.025 .014 .163 .60 .423 4.00 .875 17.30

.030 .02 .200 .90 .448 4.50 1.00 22.80

.044 .04 .212 1.00 .472 5.00 1.25 36.30

.052 .06 .250 1.50 .515 6.00 1.50 51.20

.060 .08 .300 2.00 .539 6.50 1.75 71.00

.067 .10 .333 2.50 .578 7.00 2.00 90.00

.095 .20 .375 3.13 .625 8.80 2.10 100.00

You might also like

- Drilling HydraulicsDocument22 pagesDrilling Hydraulicsdrilling moneytree100% (5)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Orifice CalculationsDocument23 pagesOrifice CalculationsYatish Kumar Jain0% (1)

- Lee Duct Size by Dp100 (Rev5)Document11 pagesLee Duct Size by Dp100 (Rev5)Sam Jose100% (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Validation Report On The 2-Phase Line SizingDocument18 pagesValidation Report On The 2-Phase Line SizingEbby Onyekwe100% (1)

- Jet Bit Nozzle Size SelectionDocument46 pagesJet Bit Nozzle Size SelectionBharat BhattaraiNo ratings yet

- Chapter 06 Pressure Losses in The Circulating SystemDocument22 pagesChapter 06 Pressure Losses in The Circulating SystemAbrar HassanNo ratings yet

- Esp SizingDocument17 pagesEsp SizingAmin ElfatihNo ratings yet

- Strainer SizingDocument20 pagesStrainer Sizingaliscribd46No ratings yet

- MPQT Alishar SPM 3 31.08.2013 To 02.09.2013Document68 pagesMPQT Alishar SPM 3 31.08.2013 To 02.09.2013mdsajidalamNo ratings yet

- Addi Examples Pipe3Document10 pagesAddi Examples Pipe3Diego MorenoNo ratings yet

- FGCP Line Sizing CalculationsDocument86 pagesFGCP Line Sizing CalculationsToyinNo ratings yet

- Kill Sheet HHHHHDocument5 pagesKill Sheet HHHHHRyan Llaneta67% (3)

- Input Data (To Find Inlet Pressure) Input Data (To Find Outlet Pressure) Input Data (To Find Flow)Document1 pageInput Data (To Find Inlet Pressure) Input Data (To Find Outlet Pressure) Input Data (To Find Flow)Aiyappa DevrajNo ratings yet

- Rupture Disc SizingDocument8 pagesRupture Disc Sizing이가람100% (1)

- Tech Drilling JetBitNozzleDocument46 pagesTech Drilling JetBitNozzlealvarex007100% (1)

- Gas LooplinestptDocument64 pagesGas Looplinestptniyo7No ratings yet

- Estimate Subsonic Flare Tip Pressure Drop With Graph Derived CorrelationDocument3 pagesEstimate Subsonic Flare Tip Pressure Drop With Graph Derived CorrelationbtjajadiNo ratings yet

- Perancangan CycloneDocument20 pagesPerancangan CycloneDavid LambertNo ratings yet

- Section 17 - Fluid Flow and PipingDocument11 pagesSection 17 - Fluid Flow and PipingCHANADASNo ratings yet

- Pipe Sizing Steam Supply and Condensate Return Lines Sizing Charts Chart CG-25, page CG-51, is the basic chart for determining the flow rate and velocity of steam in Schedule 40 pipe for various values of pressure drop per 100 ft, based on 0 psig saturated steam. Using the multiplier chart (Chart CG-24), Chart CG-25 can be used at all saturation pressures between 0 and 200 psig (see Example). These Charts are based on the Moody Friction Factor, which considers the Reynolds number and the roughness of the internal pipe surfaces. Notes: Based on Moody Friction Factor where flow of condensate does not inhibit the flow of steam. See Chart CG-24 for obtaining flow rates and velocities of all saturation pressures between 0 to 200 psig: see Example. Pipe Sizing Two principal factors determine pipe sizing in a steam system: 1. The initial pressure at the boiler and the allowable pressure drop of the total system. The total pressure drop in the system should not exceed 20% ofDocument3 pagesPipe Sizing Steam Supply and Condensate Return Lines Sizing Charts Chart CG-25, page CG-51, is the basic chart for determining the flow rate and velocity of steam in Schedule 40 pipe for various values of pressure drop per 100 ft, based on 0 psig saturated steam. Using the multiplier chart (Chart CG-24), Chart CG-25 can be used at all saturation pressures between 0 and 200 psig (see Example). These Charts are based on the Moody Friction Factor, which considers the Reynolds number and the roughness of the internal pipe surfaces. Notes: Based on Moody Friction Factor where flow of condensate does not inhibit the flow of steam. See Chart CG-24 for obtaining flow rates and velocities of all saturation pressures between 0 to 200 psig: see Example. Pipe Sizing Two principal factors determine pipe sizing in a steam system: 1. The initial pressure at the boiler and the allowable pressure drop of the total system. The total pressure drop in the system should not exceed 20% of1970acoNo ratings yet

- 14 Jet Bit Nozzle Size SelectionDocument46 pages14 Jet Bit Nozzle Size Selectiontotos20100% (2)

- Ductulator May 2010Document8 pagesDuctulator May 2010haroub_nasNo ratings yet

- Inlet Separator Design APIDocument8 pagesInlet Separator Design APIIlham Dwiyanto Emzar100% (1)

- Pneumatic - Book (5-17) PDFDocument13 pagesPneumatic - Book (5-17) PDFibnu100% (1)

- MSS SP 99 10 PDFDocument12 pagesMSS SP 99 10 PDFhisaj4u100% (1)

- Pressure Regulator Control Valve Sizing PetroDocument16 pagesPressure Regulator Control Valve Sizing PetroCH1253No ratings yet

- Control Valve Sizing. BaumanDocument12 pagesControl Valve Sizing. BaumanEdgar HuancaNo ratings yet

- Fire Calculation1Document7 pagesFire Calculation1Jesús Yarleque RamosNo ratings yet

- Hydraulic Calculation For Automatic Wet Sprinkler Systems: HENRY E. SUAREZ, Rmp/pmeDocument20 pagesHydraulic Calculation For Automatic Wet Sprinkler Systems: HENRY E. SUAREZ, Rmp/pmeHenry Suarez100% (2)

- Meter Selection Rev 031Document5 pagesMeter Selection Rev 031andrew_c_potocki902No ratings yet

- MagiCAD Ventilation CalculationsDocument20 pagesMagiCAD Ventilation CalculationsAdrian DavidNo ratings yet

- Bosch HFM5 SensorsDocument2 pagesBosch HFM5 Sensorsrestinho100% (1)

- R-Pump Cal Sheet2Document3 pagesR-Pump Cal Sheet2ggdgdfgdfgdfgdgddddNo ratings yet

- Tech Memo - y FactorDocument4 pagesTech Memo - y FactorsumitrochakrabortiNo ratings yet

- Mathcad - 3B - Tut - 2 - PumpsDocument2 pagesMathcad - 3B - Tut - 2 - PumpsFabrizio NEBESSENo ratings yet

- D3 Lab Report-3Document10 pagesD3 Lab Report-3azharNo ratings yet

- t-10 SensusDocument7 pagest-10 SensusAlam Garcia RodriguezNo ratings yet

- Critical Flow Restricting Orifices: D-Zero Engineering Note: 3740.S10-EN-173 C.H. Kurita August 9, 1988Document6 pagesCritical Flow Restricting Orifices: D-Zero Engineering Note: 3740.S10-EN-173 C.H. Kurita August 9, 1988JeEJyZaNo ratings yet

- HydraulicsDocument3 pagesHydraulicsItzikRazonNo ratings yet

- Gear Pump (Hoist and Rear Brake Cooling) Efficiency - Test: Pruebas y AjustesDocument3 pagesGear Pump (Hoist and Rear Brake Cooling) Efficiency - Test: Pruebas y AjustesLENIN JHAIR VALDERRAMA SEGURANo ratings yet

- MCM SiapDocument13 pagesMCM SiapNajmi GAnuNo ratings yet

- Afv TDB 9610.6 Capacity TablesDocument24 pagesAfv TDB 9610.6 Capacity TablesJorge BaronNo ratings yet

- The Rod Pumping - System DesignDocument37 pagesThe Rod Pumping - System Designdoubleuland100% (2)

- Tebodin Consultants & Engineers India P LTD.: Pump Calculation Basic Pump DataDocument2 pagesTebodin Consultants & Engineers India P LTD.: Pump Calculation Basic Pump DataAjay TiwariNo ratings yet

- Gas Well Testing Field Case StudiesDocument26 pagesGas Well Testing Field Case Studies77bgfaNo ratings yet

- Screen Openings For Y-StrainersDocument6 pagesScreen Openings For Y-Strainersboom10No ratings yet

- 1742Document4 pages1742lampropeltisNo ratings yet

- Fenomenos Taller de GasesDocument20 pagesFenomenos Taller de GasesDavid MontoyaNo ratings yet

- Deep Analysis Pinion FinalDocument30 pagesDeep Analysis Pinion Finalazadsingh1No ratings yet

- Experiment No: 05 Experiment Name: Designing of Lift Curve of A Gas Well With Down Hole Gas CompressorDocument6 pagesExperiment No: 05 Experiment Name: Designing of Lift Curve of A Gas Well With Down Hole Gas CompressorSwagata SahaNo ratings yet

- Quick Reference Conversion Chart: Power Requirement CalculationsDocument1 pageQuick Reference Conversion Chart: Power Requirement CalculationsJossyNo ratings yet

- Numerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityFrom EverandNumerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- A096 1361 1153 Enq Rev0 PDFDocument310 pagesA096 1361 1153 Enq Rev0 PDFhisaj4uNo ratings yet

- Siemens PDFDocument2 pagesSiemens PDFhisaj4uNo ratings yet

- Thread Chart PDFDocument9 pagesThread Chart PDFhisaj4uNo ratings yet

- SS Tubing (Wall Thickness)Document1 pageSS Tubing (Wall Thickness)hisaj4uNo ratings yet

- Weight & Thickness of Schedule Pipe: Sch.80 Sch.160 XS XXS Nominal Sch.5 Sch.10 Sch.40Document1 pageWeight & Thickness of Schedule Pipe: Sch.80 Sch.160 XS XXS Nominal Sch.5 Sch.10 Sch.40hisaj4uNo ratings yet

- Home Company Trainings Global Sales Contacts Career News DownloadDocument2 pagesHome Company Trainings Global Sales Contacts Career News Downloadhisaj4uNo ratings yet

- GaugesDocument6 pagesGaugeshisaj4uNo ratings yet

- GaugesDocument6 pagesGaugeshisaj4uNo ratings yet

- Tube Clamp HydacDocument28 pagesTube Clamp Hydachisaj4uNo ratings yet

- Plugs PDFDocument116 pagesPlugs PDFhisaj4uNo ratings yet

- Receipe 80Document20 pagesReceipe 80hisaj4uNo ratings yet

- Forging ToleranceDocument44 pagesForging Tolerancehisaj4uNo ratings yet