Professional Documents

Culture Documents

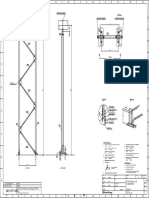

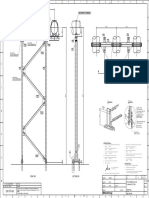

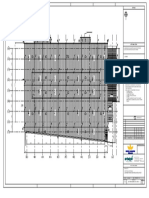

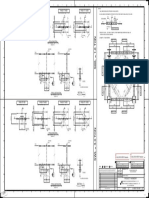

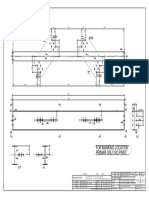

2GPL113777 D02 Assembly Drawing To Print A SUPPORT D2

Uploaded by

MOHAMEDOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2GPL113777 D02 Assembly Drawing To Print A SUPPORT D2

Uploaded by

MOHAMEDCopyright:

Available Formats

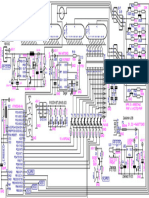

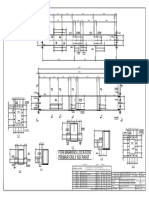

M1

SLIDING ±10 SLIDING ±10 SLIDING ±10

SLIDING ±10

SLIDING ±10 SLIDING ±10 SLIDING ±10

APP.SUPPORT 1HC0069724APP.SUPPORT 1HC0069724APP.SUPPORT 1HC0069724

720 720 APP.SUPPORT 1HC0069724 APP.SUPPORT 1HC0069724 APP.SUPPORT 1HC0069724

APP.SUPPORT1HC0069724

720 720

R7 R5

267

267

R3

PTFE 4

PTFE 4

R3 R3

BOLT M16*50 BOLT M16*80

NUT M16, WASHER M16 NUT M16, WASHER M16 P102

P102

1350

TOP VIEW

P116 FRONT VIEW

P116

t h i ng t o

EARTHING

Y

-

DETAIL

ol e s for ear

g h

D14 Crealegtionfsupport

38

every

a n i zi n g

d i p g a lv d plate

o t te or en

262

e f o r h

s footpla

BOLT M12*40 g h o l e

NUT M12, WASHER M12

R7 Creaetinmade in th

to b

D14

6255

6255

15

P116

X DETAIL

-

P116

NUT M30 - ISO 4032

SCOPE: civil contractor

SPECIAL WASHER - ABB TYPE 2

SCOPE: civil contractor

56mm

PRE-EMBEDDED ANCHOR

ROD M30 - DIN 976

SCOPE: civil contractor

SPECIAL WASHER - ABB TYPE 2

SCOPE: civil contractor

NUT M30 - ISO 4032

SCOPE: civil contractor

R7 R5

CONCRETE SLAB

SCOPE: civil contractor

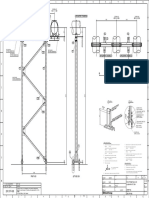

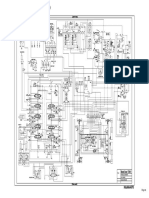

1 GENERAL MANUFACTURING NOTES

1.1 All steel parts have to be hot galvanized according to manufacturing request. 1.7 Dimensions tolerances for non-welded construction according to EN ISO 2768-mK.

Otherwise: 01-TMSS-01 REV 03

1.8 Material quality according to manufacturing request.

- Minimal layer for holes according to manufacturing request. Otherwise: EN 10025, EN 10219

2

Otherwise: 40 μm / 285 g/m

1.9 Material class according to manufacturing request.

- Minimal layer for other parts according to manufacturing request. Otherwise: S275JR

2

Otherwise: 86 μm / 610 g/m

1.10 The additional parts as fasteners, PTFE plates, rollers and etc (items in the bill of

1.2 Hot dip galvanized threads to be brushed prior to assembly. materials) have to be assembled by a supplier.

1.3 Welding to be continuous according to manufacturing request. 1.11 All bolts, nuts, washers and etc (except stainless steel) have to be hot galvanized

P116 Otherwise: EN ISO 3834-1/-2 according to manufacturing notes.

1.4 All welds shall be all around fillet welds unless otherwise noted. Otherwise: 01-TMSS-01 REV 03

Y 1.5 Thickness of welding seams: 2 GENERAL ASSEMBLY NOTES

- t1 2.1 Damaged zinc layers have to be zinc painted after assembling.

a min = 4 mm unless noted otherwise 2.2 The tightening torque is according to HASV600416.

t2 a < max (0,7*t1; 0,7*t2)

56

56

2.3 For sliding connections with PTFE-material:

X a

- - First nut with maximal torque of 0.5% of values of table in document HASV600416.

1.6 Dimensions tolerances for welded construction according to EN ISO 13920-AE. - Second nut with torque according to document HASV600416.

1350

Draft: Derived from: Separate BOM: Scale: Doc.type: Format:

FRONT VIEW LEFT SIDE VIEW 2022-12-05 AJRANOVIC YES 1:10 ZEI A0

Approved: Replaces:

2022-12-05 PAJEVIC SF6 SWITCHGEAR ELK-3/420

A 2022.12.05. SUPPORT D2 FIRST ISSUE Released: Responsible department:

AL BUHAIRAH 380kV Language:

REV. NO. DATE NAME DESCRIPTION 2022-12-05 AKHTAR PTHS-SE EN

Order number: Revision: No sheets:

We reserve all rights in this document and in the information contained therein.

Reproduction, use or disclosure to third parties without express authority is strictly 3002004460 A AJRANOVIC SUPPORT D2 4

forbidden. Document Number: Sheet no.:

© 1970 Hitachi Energy. All rights reserved. 2GPL113777-D02 1

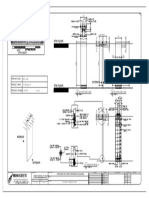

M1

0

APP.SUPPORT 1HC0069724

I D IN G ±1

SL

APP.SUPPORT 1HC0069724 10

ING ±

SLID

0

APP.SUPPORT 1HC0069724 G ±1

SLIDIN

R3

BOLT M16*80, WASHER M16

PTFE 2GPL113777 - 306 M1

P116 ING ±10

SLID

APP.SUPPORT 1HC0069724

P116

BOLT M16*50

Ø40...5 - P102

PTFE 2GPL113777 - 306 M2

R3

R3

NUT M16, WASHER M16

R5,R7

NUT M16, WASHER M16

P116

P116

R5

R7

P116

Draft: Derived from: Separate BOM: Scale: Doc.type: Format:

ISO VIEW 2022-12-05 AJRANOVIC YES ZEI A0

Approved: Replaces:

2022-12-05 PAJEVIC SF6 SWITCHGEAR ELK-3/420

A 2022.12.05. SUPPORT D2 FIRST ISSUE Released: Responsible department:

AL BUHAIRAH 380kV Language:

REV. NO. DATE NAME DESCRIPTION 2022-12-05 AKHTAR PTHS-SE EN

Order number: Revision: No sheets:

We reserve all rights in this document and in the information contained therein.

Reproduction, use or disclosure to third parties without express authority is strictly 3002004460 A AJRANOVIC SUPPORT D2 4

forbidden. Document Number: Sheet no.:

© 1970 Hitachi Energy. All rights reserved. 2GPL113777-D02 2

You might also like

- 2GPL113777 C09 Assembly Drawing To Print A SUPPORT C9Document2 pages2GPL113777 C09 Assembly Drawing To Print A SUPPORT C9MOHAMEDNo ratings yet

- 2GPL113777-B08-assembly Drawing To print-A-SUPPORT B8Document2 pages2GPL113777-B08-assembly Drawing To print-A-SUPPORT B8MOHAMEDNo ratings yet

- 2GPL113777 C08 Assembly Drawing To Print A SUPPORT C8Document2 pages2GPL113777 C08 Assembly Drawing To Print A SUPPORT C8MOHAMEDNo ratings yet

- 2GPL113777 C04 Assembly Drawing To Print A SUPPORT C4Document2 pages2GPL113777 C04 Assembly Drawing To Print A SUPPORT C4MOHAMEDNo ratings yet

- 2GPL113777 C14 Assembly Drawing To Print A SUPPORT C14Document2 pages2GPL113777 C14 Assembly Drawing To Print A SUPPORT C14MOHAMEDNo ratings yet

- 2GPL113777-B61-assembly Drawing To print-A-SUPPORT B61Document2 pages2GPL113777-B61-assembly Drawing To print-A-SUPPORT B61MOHAMEDNo ratings yet

- 2GPL113777 C131 Assembly Drawing To Print A SUPPORT C131Document2 pages2GPL113777 C131 Assembly Drawing To Print A SUPPORT C131MOHAMEDNo ratings yet

- 3.DC ARNIEC Plan ConexiuniDocument1 page3.DC ARNIEC Plan ConexiuniRadu OprișNo ratings yet

- Bat-Dwg-Dd-Me-01-Al-1601.01 - R0 - Lightning Protection Installation LayoutDocument1 pageBat-Dwg-Dd-Me-01-Al-1601.01 - R0 - Lightning Protection Installation LayoutCosphiiiNo ratings yet

- Schema TV Edu JQ Ft2107 - Chassis t2p12 - Tda9353 SCHDocument1 pageSchema TV Edu JQ Ft2107 - Chassis t2p12 - Tda9353 SCHEduard KellermanNo ratings yet

- Floor plan layout with room labelsDocument1 pageFloor plan layout with room labelsJeffrey BeloyNo ratings yet

- GroundDocument1 pageGroundAnonymous zxUL5nNo ratings yet

- Ar02 Denah 100Document9 pagesAr02 Denah 100Nisrina Salsabila AlmiraNo ratings yet

- Shooterbox Mk2 PDFDocument1 pageShooterbox Mk2 PDFKhoirul AnamNo ratings yet

- Metal. Plansa Nr.3.inima Grinda + Stalp + ContravantuireDocument1 pageMetal. Plansa Nr.3.inima Grinda + Stalp + ContravantuireSergiu NastasNo ratings yet

- PAD-1T-0D PAD-1T-90D PAD-1T-45D PAD-1T-135D: J-DmsDocument1 pagePAD-1T-0D PAD-1T-90D PAD-1T-45D PAD-1T-135D: J-DmsMary DenizeNo ratings yet

- R02 ModelDocument1 pageR02 ModelIonela Gabriela GâfeiNo ratings yet

- Schematic - 24 Hour Clock - 2023-12-16Document1 pageSchematic - 24 Hour Clock - 2023-12-16ianguiebNo ratings yet

- 416E Sistema HidraulicoDocument1 page416E Sistema HidraulicoDário Martins da CunhaNo ratings yet

- Design Location: Elev B4 Elev B5 Elev B6 Elev B7Document1 pageDesign Location: Elev B4 Elev B5 Elev B6 Elev B7Hirushan MenukaNo ratings yet

- Proposed home electrical layout comparisonDocument1 pageProposed home electrical layout comparisonElezer BatchoNo ratings yet

- A402 -LIFT DETAILSDocument1 pageA402 -LIFT DETAILSØwięs MØhãmmedNo ratings yet

- Untitled2 PDFDocument1 pageUntitled2 PDFRenzoRiveroNo ratings yet

- Screenshot 2023-11-08 at 7.43.30 AMDocument1 pageScreenshot 2023-11-08 at 7.43.30 AMinfinity.fine.worksNo ratings yet

- WD14H460FF 01 Codes 2 PDFDocument27 pagesWD14H460FF 01 Codes 2 PDFBOSCHCLASSIXX1200No ratings yet

- Carrera CN 7500Document1 pageCarrera CN 7500Ronny ZorroNo ratings yet

- LFBD 6 20 Star Stars 1708865 BDocument1 pageLFBD 6 20 Star Stars 1708865 Bjames.gimenezNo ratings yet

- B&K Amp Service ManualDocument16 pagesB&K Amp Service ManualPhantom GoatlordNo ratings yet

- Circuit Diagrams and PWB Layouts for 26-40Document1 pageCircuit Diagrams and PWB Layouts for 26-40Domingo Arroyo50% (2)

- Galos R01Document1 pageGalos R01Maciej FierdonekNo ratings yet

- Ua 610 MicpreDocument1 pageUa 610 MicpreCharles Austin0% (1)

- EV BR M575 R 2885B - v1 - m56577569830651594Document1 pageEV BR M575 R 2885B - v1 - m56577569830651594GoodBikesNo ratings yet

- How to measure angles and distances in technical drawingsDocument1 pageHow to measure angles and distances in technical drawingsMaría VeraNo ratings yet

- PV 14at - PV 14BTDocument20 pagesPV 14at - PV 14BTVictor Rodriguez MariNo ratings yet

- GND Aref: 1L 470 16H 1L 470 16HDocument1 pageGND Aref: 1L 470 16H 1L 470 16HJhonny MoyonNo ratings yet

- RP8G2 AMP SCH PDFDocument1 pageRP8G2 AMP SCH PDFToto WaltherNo ratings yet

- KRK - Rp8g2 Amp SCHDocument1 pageKRK - Rp8g2 Amp SCHHélio MandecoNo ratings yet

- RS485 Demo For ArduinoDocument1 pageRS485 Demo For ArduinoFriendy PrasetiawanNo ratings yet

- Plot PlanDocument1 pagePlot PlanjhchooiNo ratings yet

- TcvcoDocument1 pageTcvcoPedroVaNo ratings yet

- Mad Professor Snowwhite Autowah Guitar Effects SchematicDocument1 pageMad Professor Snowwhite Autowah Guitar Effects SchematicSangar CrewNo ratings yet

- Schematic Pq3-Ver1.2 Furman-Pq3-Verde 20190311230653Document1 pageSchematic Pq3-Ver1.2 Furman-Pq3-Verde 20190311230653Marco Martino40% (5)

- Universidad Nacional de Colombia-Fac - Ing Empalmes Brayan C. AngaritaDocument1 pageUniversidad Nacional de Colombia-Fac - Ing Empalmes Brayan C. AngaritaBrayan AngaritaNo ratings yet

- Crate BT15 - PWA Bass Amplifier PCB Schematics (848SCH - A)Document2 pagesCrate BT15 - PWA Bass Amplifier PCB Schematics (848SCH - A)Guim EloyNo ratings yet

- Zegar - 4xIN12B Ex SMDsDocument1 pageZegar - 4xIN12B Ex SMDsMaciej FierdonekNo ratings yet

- SCHEMATIC All Models00173 PDFDocument1 pageSCHEMATIC All Models00173 PDFDu TrầnNo ratings yet

- Solar 170W-V with Standard BoomDocument1 pageSolar 170W-V with Standard BoomDu TrầnNo ratings yet

- Fe Stair Details 1:50 1 Ground - 2Nd Floor Fe Stair Details 1:50 2 2Nd - 3Rd FloorDocument1 pageFe Stair Details 1:50 1 Ground - 2Nd Floor Fe Stair Details 1:50 2 2Nd - 3Rd FloorKarl MoralejoNo ratings yet

- Detail H Scale 1: 3: Section E-E SCALE 1: 10Document2 pagesDetail H Scale 1: 3: Section E-E SCALE 1: 10Brahamadandi Achyuth KumarNo ratings yet

- SCHEMATIC All Models00171Document1 pageSCHEMATIC All Models00171Du TrầnNo ratings yet

- Floor plan notes and dimensionsDocument8 pagesFloor plan notes and dimensionsDavid WenzNo ratings yet

- Toilet Detail KyDocument1 pageToilet Detail KyKanak YadavNo ratings yet

- Exercise No. 6 "Coordinates": Technical DescriptionsDocument1 pageExercise No. 6 "Coordinates": Technical DescriptionsFlorenell Faith PacureNo ratings yet

- PDF - Junior Master BathroomDocument1 pagePDF - Junior Master BathroomLIFE STONENo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Fill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredFrom EverandFill Your Glass With Gold-When It's Half-Full or Even Completely ShatteredNo ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- 740-B62 - BEAM - Rev 00Document1 page740-B62 - BEAM - Rev 00MOHAMEDNo ratings yet

- 740-B62 - BEAM - Rev 00Document1 page740-B62 - BEAM - Rev 00MOHAMEDNo ratings yet

- b4065 - Sec BeamDocument1 pageb4065 - Sec BeamMOHAMEDNo ratings yet

- 740-B62 - BEAM - Rev 00Document1 page740-B62 - BEAM - Rev 00MOHAMEDNo ratings yet

- b4063 - Sec BeamDocument1 pageb4063 - Sec BeamMOHAMEDNo ratings yet

- b4063 - Sec BeamDocument1 pageb4063 - Sec BeamMOHAMEDNo ratings yet

- b4047 - Sec BeamDocument1 pageb4047 - Sec BeamMOHAMEDNo ratings yet

- b4048 - Sec BeamDocument1 pageb4048 - Sec BeamMOHAMEDNo ratings yet

- b4063 - Sec BeamDocument1 pageb4063 - Sec BeamMOHAMEDNo ratings yet

- b4047 - Sec BeamDocument1 pageb4047 - Sec BeamMOHAMEDNo ratings yet

- b4047 - Sec BeamDocument1 pageb4047 - Sec BeamMOHAMEDNo ratings yet

- b4053 - Sec BeamDocument1 pageb4053 - Sec BeamMOHAMEDNo ratings yet

- B4004 - Sec BeamDocument1 pageB4004 - Sec BeamMOHAMEDNo ratings yet

- b4060 - Sec BeamDocument1 pageb4060 - Sec BeamMOHAMEDNo ratings yet

- b4060 - Sec BeamDocument1 pageb4060 - Sec BeamMOHAMEDNo ratings yet

- b4048 - Sec BeamDocument1 pageb4048 - Sec BeamMOHAMEDNo ratings yet

- b4053 - Sec BeamDocument1 pageb4053 - Sec BeamMOHAMEDNo ratings yet

- B4004 - Sec BeamDocument1 pageB4004 - Sec BeamMOHAMEDNo ratings yet

- B4004 - Sec BeamDocument1 pageB4004 - Sec BeamMOHAMEDNo ratings yet

- b4065 - Sec BeamDocument1 pageb4065 - Sec BeamMOHAMEDNo ratings yet

- b4047 - Sec BeamDocument1 pageb4047 - Sec BeamMOHAMEDNo ratings yet

- B4004 - Sec BeamDocument1 pageB4004 - Sec BeamMOHAMEDNo ratings yet

- Astm A572Document4 pagesAstm A572Luis Jaramillo100% (3)

- CBT Questions: (2) Peel TestDocument18 pagesCBT Questions: (2) Peel TestMOHAMEDNo ratings yet

- MSDS - Suntex 340Document1 pageMSDS - Suntex 340MOHAMEDNo ratings yet

- LUMIX G Camera DMC-G85HDocument9 pagesLUMIX G Camera DMC-G85HnimodisNo ratings yet

- ECOSYS M2030dn M2530dn M2035dn M2535dn SM UKDocument273 pagesECOSYS M2030dn M2530dn M2035dn M2535dn SM UKMaks Prost60% (5)

- XII Class Assignment Programs 2023-24Document8 pagesXII Class Assignment Programs 2023-24Sudhir KumarNo ratings yet

- Knowledge Paper XDocument28 pagesKnowledge Paper XLaurențiu Cătălin NeagoeNo ratings yet

- COSMETOLOGY-9 Q1 W3 Mod2Document15 pagesCOSMETOLOGY-9 Q1 W3 Mod2Christian Elliot DuatinNo ratings yet

- BCG ReportDocument9 pagesBCG Reportjlgjlj ljglkhNo ratings yet

- Opera Arias and Sinfonias: VivaldiDocument22 pagesOpera Arias and Sinfonias: VivaldiDardo CocettaNo ratings yet

- The Korean MiracleDocument20 pagesThe Korean MiracleDivya GirishNo ratings yet

- Filipino Essay 4Document3 pagesFilipino Essay 4IqbalNo ratings yet

- Julia Henzler - Resume 2 27Document1 pageJulia Henzler - Resume 2 27api-491391730No ratings yet

- GeM Bidding 3702669Document10 pagesGeM Bidding 3702669ANIMESH JAINNo ratings yet

- Yingli CS Centrale-Poggiorsini EN 062011-1 PDFDocument2 pagesYingli CS Centrale-Poggiorsini EN 062011-1 PDFZvonko Trajkov100% (1)

- Basic Load (Individual) Veterinarian Field PackDocument3 pagesBasic Load (Individual) Veterinarian Field PackJohn MillerNo ratings yet

- 5 Tips For Faster Mental Multiplication PDFDocument3 pages5 Tips For Faster Mental Multiplication PDFGonzalo Estrán BuyoNo ratings yet

- STAR GLASS - D66f5e - PDFDocument126 pagesSTAR GLASS - D66f5e - PDFJessie O.BechaydaNo ratings yet

- Standard JKR Spec For Bridge LoadingDocument5 pagesStandard JKR Spec For Bridge LoadingHong Rui ChongNo ratings yet

- Were in The City of Palu in Central Sulawesi, IndonesiaDocument5 pagesWere in The City of Palu in Central Sulawesi, IndonesiaTú AnhNo ratings yet

- Secu Gen Hamster Pro 20Document2 pagesSecu Gen Hamster Pro 20Ashish GusainNo ratings yet

- Group ActDocument3 pagesGroup ActRey Visitacion MolinaNo ratings yet

- Bee WareDocument49 pagesBee WareJayNo ratings yet

- Results and DiscussionsDocument13 pagesResults and DiscussionsEdpher Leo SindolNo ratings yet

- Computer Organization and Assembly Language: Lecture 1 - Basic ConceptsDocument13 pagesComputer Organization and Assembly Language: Lecture 1 - Basic ConceptsNosreffejDelRosarioNo ratings yet

- But Virgil Was Not There": The Lasting Impact of Dante's Homosocial HellDocument7 pagesBut Virgil Was Not There": The Lasting Impact of Dante's Homosocial HellЮлия ЧебанNo ratings yet

- A Detailed Lesson Plan in (Teaching Science)Document8 pagesA Detailed Lesson Plan in (Teaching Science)Evan Jane Jumamil67% (3)

- Unit 1 of EthicsDocument110 pagesUnit 1 of EthicsAbhinav kumar SinghNo ratings yet

- Omega: Mahdi Alinaghian, Nadia ShokouhiDocument15 pagesOmega: Mahdi Alinaghian, Nadia ShokouhiMohcine ES-SADQINo ratings yet

- Kiro Urdin BookDocument189 pagesKiro Urdin BookDane BrdarskiNo ratings yet

- wizBRAINeng20 2Document4 pageswizBRAINeng20 2Deepika AgrawalNo ratings yet

- How To VOR WorksDocument23 pagesHow To VOR WorksHai AuNo ratings yet

- CBSE Class 10 Science Revision Notes Chapter - 2 Acids, Bases and SaltsDocument11 pagesCBSE Class 10 Science Revision Notes Chapter - 2 Acids, Bases and Saltsmilind dhamaniyaNo ratings yet