Professional Documents

Culture Documents

Flexural Strength of Concrete

Flexural Strength of Concrete

Uploaded by

Nemo Secret0 ratings0% found this document useful (0 votes)

14 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views3 pagesFlexural Strength of Concrete

Flexural Strength of Concrete

Uploaded by

Nemo SecretCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

526 Appendix

Experiment No. 17

Flexural Strength of Concrete

ASTM Designation

ASTM C78—Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading)

™ Purpose

To determine the flexural strength of portland cement concrete by using a simple beam with

third-point loading.

@ Significance and Use

The flexural strength of concrete is a measure of concrete quality.

@ Apparatus

™ Loading machine capable of applying loads at a uniform rate

™ Loading device capable of applying load configuration as shown in Figure 7.36. Forces

applied to the beam shall be perpendicular to the face of the specimen and applied

without eccentricity.

© Test Specimens

‘The standard ASTM specimen dimensions are 152 mm X 152 mm (6 in. X 6 in.) in cross

section and a length of not less than 508 mm (20 in.) for a maximum aggregate size up to 50

mm (2 in).

™ Sides of the specimen should be at right angles to its top and bottom. All surfaces in

contact with load-applying and support blocks should be smooth and free of scars,

indentations, holes, or inscribed identifications.

@ Test Procedure

1. Turn the test specimen on its side, with respect to its position as molded, and center it

on the bearing blocks.

2, Center the loading system in relation to the applied force. Bring the load-applying blocks in

contact with the surface of the specimen at the third points between the supports

(Figure A.42).

3. If full contact is not obtained at no load between the specimen and the load-applying

blocks and the supports so that there is a 25 mm (1 in.) or larger gap in excess of 0.1 mm

(0.004 in.), grind or cap the contact surfaces of the specimen, or shim with leather strips.

4. Apply the load rapidly up to approximately 50% of the breaking load. Thereafter,

apply the load continuously at a rate that constantly increases the extreme fiber stress

between 860 kPa and 1210 kPa (125 psi and 175 psi)/min until rupture occurs.

@ Analysis and Results

‘Take three measurements across each dimension (one at each edge and at the center) to

the nearest 1.3 mm (0.05 in.) to determine the average width, average depth, and line of

fracture location of the specimens at the section of fracture.

17 Flexural Strength of Concrete 527

FIGURE A.42 Testing concrete beam in the flexure testing machine.

| Ifthe fracture initiates in the tension surface within the middle third of the span length,

calculate the modulus of rupture as follows:

Me _ PL

oa be

where

R = modulus of rupture, MPa (psi)

M = maximum bending moment, N-mm (Ib.in.)

c= 4,mm (in)

1 = moment of inertia

= oD am (in),

12° oe

P = maximum load, N (Ib)

L = span length, mm (in.)

b = average width, mm (in.)

d = average depth, mm (in,)

= Ifthe fracture occurs in the tension surface outside the middle third of the span length,

by not more than 5% of the span length, calculate the modulus of rupture as follow:

3Pa

aa oe

528 Appendix

where

= average distance between line of fracture and the nearest support on

the tension surface of the beam in millimeters (inches)

| If the fracture occurs in the tension surface outside the middle third of the span length,

by more than 5% of the span length, discard the results of the test.

Report

Specimen identification number

Average width

Average depth

Span length

Maximum applied load

Modulus of rupture to the nearest 0.03 MPa (5 psi) ;

Curing history and apparent moisture condition at time of testing

If specimens were capped, ground, or if leather shims were used

Defects in specimens

Age of specimens

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Integrative Reflection Paper in Understanding The Self PDFDocument12 pagesIntegrative Reflection Paper in Understanding The Self PDFNemo Secret100% (2)

- Penny Boat Lab ReportDocument6 pagesPenny Boat Lab Reportapi-2033208490% (1)

- HGEDocument30 pagesHGENemo SecretNo ratings yet

- Assignment Number 01Document3 pagesAssignment Number 01Nemo SecretNo ratings yet

- Network DiagramDocument7 pagesNetwork DiagramNemo SecretNo ratings yet

- Dynamics FormatDocument4 pagesDynamics FormatNemo SecretNo ratings yet

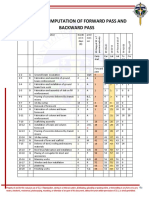

- Forward and Backward PassDocument1 pageForward and Backward PassNemo SecretNo ratings yet

- Steel Design Midterm NotesDocument10 pagesSteel Design Midterm NotesNemo SecretNo ratings yet

- Dynamics FormatDocument4 pagesDynamics FormatNemo SecretNo ratings yet

- Black and White Modern Marketing Agency Trifold BrochureDocument2 pagesBlack and White Modern Marketing Agency Trifold BrochureNemo SecretNo ratings yet

- Planning and Development of Highway Engineering: What Are Highway Plans?Document3 pagesPlanning and Development of Highway Engineering: What Are Highway Plans?Nemo SecretNo ratings yet

- Construction of HighwaysDocument3 pagesConstruction of HighwaysNemo SecretNo ratings yet

- Source:: What Is A Dowry?Document2 pagesSource:: What Is A Dowry?Nemo SecretNo ratings yet

- Purpose:: Friction LabDocument5 pagesPurpose:: Friction LabNemo SecretNo ratings yet

- Bio ClimateDocument3 pagesBio ClimateNemo SecretNo ratings yet

- Bill JoyDocument2 pagesBill JoyNemo SecretNo ratings yet

- Buidling System DesignDocument2 pagesBuidling System DesignNemo SecretNo ratings yet

- NameDocument1 pageNameNemo SecretNo ratings yet

- Netflix Business Model Canvas: Key Partners Key Activities Value Propositions Customer Relationship Customer SegmentsDocument1 pageNetflix Business Model Canvas: Key Partners Key Activities Value Propositions Customer Relationship Customer SegmentsNemo SecretNo ratings yet

- Guidelines For The Animation of Justice, Peace and The Integrity of Creation (Jpic)Document43 pagesGuidelines For The Animation of Justice, Peace and The Integrity of Creation (Jpic)Nemo SecretNo ratings yet

- 12 Static Friction LAb 6Document6 pages12 Static Friction LAb 6Nemo SecretNo ratings yet

- 5 4-AnalysisoffunctionDocument17 pages5 4-AnalysisoffunctionNemo SecretNo ratings yet

- Hydraulics and Fluid Mechanics Lab - College of Engineering. (2021) - Ksu - Edu.saDocument4 pagesHydraulics and Fluid Mechanics Lab - College of Engineering. (2021) - Ksu - Edu.saNemo SecretNo ratings yet

- Discharge Measurements in Open Channels Using Compound Sharp-Crested WeirsDocument8 pagesDischarge Measurements in Open Channels Using Compound Sharp-Crested WeirsNemo SecretNo ratings yet