Professional Documents

Culture Documents

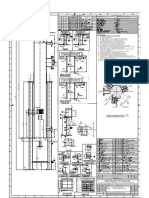

895X B164AXX-ISS04 4inch 164mm Hose Unit

Uploaded by

James AdamsonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

895X B164AXX-ISS04 4inch 164mm Hose Unit

Uploaded by

James AdamsonCopyright:

Available Formats

THIS DRAWING IS AN UNCONTROLLED COPY AND AS SUCH WILL NOT BE AUTOMATICALLY UPDATED Printed by Wayne_Mildenhall on 29 May 2023 at 03:15:40

GMT EXPIRES ON 28 June 2023

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

DRAWING STATUS Production

REVISION 04 SIG J THOMAS 20-Dec-21

129.5 REF

DVN LINK

L LASER MARK THREAD SIZE L

21.0 REF

4" BSP

AS SHOWN IN 2 PLACES

C 180° APART

SECTION C-C

15

27 TIG WELD SELECTIVITY

30 REF PINS IN POSITION

17 6 - PLACES

23 316 STST FILLER WIRE

K K

33 32

8

28

ANGLE 'B'

10 3 - PLACES

18

ANGLE 'A'

J 3 - PLACES J

14

207.9 REF

4

5 24

SECTION E-E

SCALE 5:8

25

30

I MATERIAL 316L STST 1 26 I

FORT VALE

®

SERIAL No ASSY No

123456789 895X/B164AXX

SEAL MATERIAL XXXXX

NOMINAL SIZE DN100 MAWP XX.X BARG 22 31

MAX COUPLING PRESSURE : 4.0 BARG

MAX DESIGN TEMP: XXX°C

MIN DESIGN TEMP: XXX°C

5

4" BSP/164MM HOSE UNIT

7 VIEW ON ARROW 'A' +0.2

29 00

78.0

MADE IN UK

SHOWING SELECTIVITY DETAILS

2

12

H 3

E H

E 21

C

20 16

DESIGN CONDITION - 1 (10.0 barg) LASER MARK HERE 84.4 REF

AS SHOWN 34

DESIGN CODE : BS EN 12516-2 2014 164.5 REF **IMPORTANT**

MAX COUPLING PRESSURE : 4 barg (58 psig) DO NOT TRIM SLIDE

G STATIC DESIGN PRESSURE (MAWP) : 10.0 barg (145.0 psig) STRIP

G

HYDRAULIC TEST PRESSURE : 15.0 barg (217.5 psig) 19

A

}

MAX DESIGN TEMPERATURE : 200 C (392 F)

MIN DESIGN TEMPERATURE : -40 C (-40 F) FOR METAL PARTS

DESIGN CONDITION - 2 (18.9 barg) 9

DESIGN CODE : BS EN 12516-2 2014 6

MAX COUPLING PRESSURE : 4 barg (58 psig) ENSURE ROLLERS ARE

11

13

STATIC DESIGN PRESSURE (MAWP) : 18.9 barg (274.1 psig) FREE TO ROTATE PRIOR TO

0.

0

F HYDRAULIC TEST PRESSURE : 28.4 barg (412.0 psig) POPPET HOUSING INSTALLATION F

R

}

EF

MAX DESIGN TEMPERATURE : 175 C (347 F)

A/

FOR METAL PARTS

F

MIN DESIGN TEMPERATURE : -40 C (-40 F)

895X/B164AFG 895/B642FG 21.0 34.0

REFER TO SEAL OPTION TABLE FOR SEAL TEMPERATURE LIMITATIONS 895X/B164AEG 895/B642EG 21.0 47.0

USE THESE VALUES FOR LASER MARKING 895X/B164AEF 895/B642EF 34.0 47.0

34 895/B648/5 SLIDE STRIP PTFE 2 895X/B164ADG 895/B642DG 21.0 60.0

33 895/B645/6 ROLLER SPINDLE 316 STST 2 DETAIL VIEW SHOWING 895X/B164ADF 895/B642DF 34.0 60.0

PTFE SLIDE IN POPPET GUIDE

32 895/B645/4 PISTON PLATE MACHINED CF3M 1 895X/B164ADE 895/B642DE 47.0 60.0

E E

31 895/B645/1 POPPET HEAD 316L STST 1 895X/B164ACG 895/B642CG 21.0 73.0

30 895/B644 BEARING GLAND 316L STST 1 895X/B164ACF 895/B642CF 34.0 73.0

29 895/B643 PISTON GUIDE MACHINED CF3M 1 895X/B164ACE 895/B642CE 47.0 73.0

28 895/B642XX CAMMED BODY (SEE TABLE 1) 316L STST 1 895X/B164ACD 895/B642CD 60.0 73.0

27 895/B641 OUTER BODY 316 STST 1 895X/B164ABG 895/B642BG 21.0 86.0

26 895/1649 SPRING FACE BEARING RTFE 2 895X/B164ABF 895/B642BF 34.0 86.0

25 895/1648/8 PLAIN THRUST BEARING RTFE 1 895X/B164ABE 895/B642BE 47.0 86.0

D 24 895/1648/7 PLAIN BEARING RTFE 1 895X/B164ABD 895/B642BD 60.0 86.0 D

23 895/1648/6 PLAIN BEARING RTFE 1 895X/B164ABC 895/B642BC 73.0 86.0

895X/B164AAG 895/B642AG 21.0 99.0

22 895/1648/4 SCARF CUT BEARING RTFE 1

895X/B164AAF 895/B642AF 34.0 99.0

21 895/1647 ROLLER SPINDLE PIN 316 STST 3

895X/B164AAE 895/B642AE 47.0 99.0

20 895/1646/1 ROLLER BUSH ASSEMBLY VARIOUS 3

895X/B164AAD 895/B642AD 60.0 99.0

19 895/1645/8 CLEVIS PIN 316 STST 1

895X/B164AAC 895/B642AC 73.0 99.0

18 895/1199L PLASTIC COATED HANDLE ALUMINIUM / PLASTIC 2

895X/B164AAB 895/B642AB 86.0 99.0

C 17 895/1196 ROLLER UNS S21800 (Nitronic 60) 2 NO SELECTIVITY 895X/B164A00 895/B642 N/A N/A C

16 895/0001/3 SELECTIVITY PIN 304L/316L STST 6

15 10456P 164mm HOSE UNIT GASKET VIRGIN PTFE 1 ASSEMBLY CAMMED BODY

ANGLE 'A' ANGLE 'B'

PART NUMBER PART NUMBER

14 10143SS 1/4" DIA BALL 316 STST 70

13 5128-026 GREASE NIPPLE 304 STST 1 13 TABLE 1 SHOWING SELECTIVITY

12 5128-001 1/8DIA.1.25LONG ROLL PIN 304 STST 3 278.5 REF DETAILS TO 'TODO' STANDARDS

11 5118-050 1/8" X 5/8" SPLIT PIN 304/316 STST 1 SALES@FORTVALE.COM WWW.FORTVALE.COM

10 5113-009 M10 PLAIN WASHER A4 ST ST 316 STST 4

FORT VALE

®

895P/B164AXX ORB342K2 ORB234K2 ORB341K2 ORB248K2 PERFLUOROELSTOMER -15 C TO 200°C ENGLAND, USA, CHINA

B 9 5113-003 M8 SPRING WASHER 304 STST 8 B

895B/B164AXX ORB342BU ORB234BU ORB341BU ORB248BU BUTYL -40 C TO 150°C NETHERLANDS, SINGAPORE

8 5111-601 M10 x 50 CAP HEAD A2-70 4 895E/B164AXX ORB342EP ORB234EP ORB341EP ORB248EP EPDM -40 C TO 150°C

7 5111-192 WAVY WASHER 304 STST 2 © FORT VALE ENGINEERING LTD 2021. DO NOT SCALE- IF IN DOUBT ASK

895K/B164AXX ORB342KO ORB234KO ORB341KO ORB248KO KALREZ -15 C TO 200°C FIRST ANGLE MATERIAL:

6 5111-0054 M8 X 35mm CAP SCREW A2-70 8 895N/B164AXX ORB342N ORB234N ORB341N ORB248N NITRILE -30 C TO 100°C UNLESS OTHERWISE STATED PROJECTION

316 STST

5 SEE TABLE 2 BS248 'O' RING (SEE TABLE 2) SEE TABLE 2 1 895V/B164AXX 5005-426V 5005-683V 5005-942 5005-958 VITON -20 C TO 200°C X.X ±0.5

X.XX ±0.25

SURFACE FINISH 3.2um MAX

CORNER RADII 0.8

ISO9001:2015 SCALE: NTS

MASS:

16.70 kg

REGISTERED FIRM:

4 5005-943 BS 254 'O' RING VITON VITON A 1 895Q/ B164AXX ORB342VF ORB234VF ORB341VF ORB248VF

VITON A

FDA APPROVED -20 C TO 200°C X.XXX ±0.125 CORNER CHAMFER 1.0 X 45°

LRQ4007111 CHECKED DVN: 36205

ANGLES ±0.5° REMOVE ALL BURRS AND SHARP EDGES

3 SEE TABLE 2 BS341 'O' RING (SEE TABLE 2) SEE TABLE 2 1

SEAL DESCRIPTION SHEET 1 OF 1

A 2 SEE TABLE 2 BS234 'O' RING (SEE TABLE 2) SEE TABLE 2 1 ASSEMBLY BS342 'O' RING BS234 'O' RING BS341 'O' RING BS248 'O' RING 'O' RING

TEMPERATURE DRAWN BY: DATE: A

1 SEE TABLE 2 BS342 'O' RING (SEE TABLE 2) SEE TABLE 2 1 PART NUMBER PART NUMBER PART NUMBER PART NUMBER PART NUMBER MATERIAL

RANGE 4" BSP/164mm HOSE UNIT P BOULT 18-Nov-15

Index Part Number Description Material Quantity TYPE DRG.NO.

Assembly BOM TABLE 2 SEAL OPTION TABLE 164mm HOSE UNIT 895X/B164AXX

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 A1 UNITS mm

You might also like

- 376X B640axx-Iss05Document1 page376X B640axx-Iss05James AdamsonNo ratings yet

- AHIBA IR Pro Assembly Manual - REV BDocument13 pagesAHIBA IR Pro Assembly Manual - REV BAniceto Fernandez LimachiNo ratings yet

- Etihad Rail Network: Jebel Ali Branch Contract C0306 (Package C Dubai) Structures - Drawing ListDocument1 pageEtihad Rail Network: Jebel Ali Branch Contract C0306 (Package C Dubai) Structures - Drawing ListDanielVadjkeVađinaNo ratings yet

- La213x.ca100v-111 R01-CLGDocument1 pageLa213x.ca100v-111 R01-CLGRicardo TurinNo ratings yet

- Scheme Legends: L&T Electrical & AutomationDocument1 pageScheme Legends: L&T Electrical & AutomationSivachandran RNo ratings yet

- The New Cairo Mall: Cairo Company For Housing &developmentDocument1 pageThe New Cairo Mall: Cairo Company For Housing &developmentMahmud MaherNo ratings yet

- R420-FR-2130 A/B: NotesDocument1 pageR420-FR-2130 A/B: NotesMubashir fareed100% (1)

- Map GP SingapourDocument1 pageMap GP SingapourquentinvhNo ratings yet

- Tagas Ga Vacuum Trap Pot s6l 0.2kl 31 R1-ModelDocument1 pageTagas Ga Vacuum Trap Pot s6l 0.2kl 31 R1-Modelinfo.metafirmNo ratings yet

- 24 MP 0202.03 MP0202.03Document1 page24 MP 0202.03 MP0202.03ISH-QUENo ratings yet

- Etihad Rail Network: Jebel Ali Branch Contract C0306 (Package C Dubai) Structures - Drawing ListDocument1 pageEtihad Rail Network: Jebel Ali Branch Contract C0306 (Package C Dubai) Structures - Drawing ListDanielVadjkeVađinaNo ratings yet

- PPG01 RB01 MTL03 15434 Ou110184323 R2Document2 pagesPPG01 RB01 MTL03 15434 Ou110184323 R2Mahmoud AllamNo ratings yet

- CSP MILL-Model3Document1 pageCSP MILL-Model3Mitul PatelNo ratings yet

- SB 13006 01Document192 pagesSB 13006 01soorajsundaran93No ratings yet

- PE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1Document1 pagePE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- Detail-C7 2: Typical Door Details in Specialist AreasDocument1 pageDetail-C7 2: Typical Door Details in Specialist AreasKumudu PereraNo ratings yet

- Map VSBDocument1 pageMap VSBrhinoricoNo ratings yet

- Detail Z (1: 5) : Rabigh 3 Independent Water ProjectDocument1 pageDetail Z (1: 5) : Rabigh 3 Independent Water ProjectrenjithyesodharanNo ratings yet

- HFD01045.02.0101 Schema Hydraulique Complet Low Spec LS G4Document1 pageHFD01045.02.0101 Schema Hydraulique Complet Low Spec LS G4aldeirtrabalho001No ratings yet

- L&T Electrical & Automation: Scheme LegendsDocument1 pageL&T Electrical & Automation: Scheme LegendsSivachandran RNo ratings yet

- 0 35 511 27069 1 0 PDFDocument1 page0 35 511 27069 1 0 PDFbrjsekarNo ratings yet

- For Praveen SirDocument1 pageFor Praveen SirArushi SharmaNo ratings yet

- Raft Section A-A: 50 Thk. PCC 1:3:6 4 Thk. Water Proofing Membrane 100 Thk. PCC 1:4:8Document1 pageRaft Section A-A: 50 Thk. PCC 1:3:6 4 Thk. Water Proofing Membrane 100 Thk. PCC 1:4:8Omer HayatNo ratings yet

- Detail C - Cable Detail D - Height Detail A - : Routing Powertail/FeederDocument1 pageDetail C - Cable Detail D - Height Detail A - : Routing Powertail/Feedervinod 7No ratings yet

- La233r1.ca100v-000 R03Document1 pageLa233r1.ca100v-000 R03Ricardo TurinNo ratings yet

- MH102 - Ground Floor PlanDocument1 pageMH102 - Ground Floor PlankarimNo ratings yet

- Door DetailDocument1 pageDoor DetailsadafNo ratings yet

- For Approval: Ceiling Space To Be Airtight by OthersDocument1 pageFor Approval: Ceiling Space To Be Airtight by Othersavinash3479No ratings yet

- 19-MP10201 03-MP0201 03Document1 page19-MP10201 03-MP0201 03ISH-QUENo ratings yet

- Construcciones Del Pacífico: Acquad or C.ADocument1 pageConstrucciones Del Pacífico: Acquad or C.AMiguel Sebastián MoralesNo ratings yet

- Grupo de Potência HidráulicaDocument24 pagesGrupo de Potência HidráulicaelizeuNo ratings yet

- Example of Building PDFDocument8 pagesExample of Building PDFTheuns DuvenhageNo ratings yet

- Key Plan: Detail - XDocument1 pageKey Plan: Detail - XSamitha SoysaNo ratings yet

- 3x2000kVA DG SYNCRONISING + OUTGOING PANEL - JSPL - GA+Control+Bom - AS BUILT - 02.07.11Document76 pages3x2000kVA DG SYNCRONISING + OUTGOING PANEL - JSPL - GA+Control+Bom - AS BUILT - 02.07.11RITENDRA GHOSHNo ratings yet

- Cable Trench and Road Jamui Combine PDFDocument3 pagesCable Trench and Road Jamui Combine PDFManas MondalNo ratings yet

- P94-1986 Inversor NGPDocument2 pagesP94-1986 Inversor NGPGonzalo GalvezNo ratings yet

- Detail - C11 1: Key PlanDocument1 pageDetail - C11 1: Key PlanKumudu PereraNo ratings yet

- Dayly ReportDocument2 pagesDayly ReportJaycee PagadorNo ratings yet

- DSF 1104801 1758 3690 43 1 014 - 3Document2 pagesDSF 1104801 1758 3690 43 1 014 - 3Goulet KostNo ratings yet

- SKP CGGC CD 04 Uza 13 109Document1 pageSKP CGGC CD 04 Uza 13 109Sidra AslamNo ratings yet

- ABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGDocument1 pageABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGPrabu KumarNo ratings yet

- ABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGDocument1 pageABS-J-089-03-DRG-002 - Detail Fabrication Drawing Instrument Air Receiver - 39 Cu.m-paRT DRAWINGPrabu KumarNo ratings yet

- Detail A: Assembly and Detail Shipping Lug Detail 54" Steam Drum FM 120-124 LH BOILERDocument1 pageDetail A: Assembly and Detail Shipping Lug Detail 54" Steam Drum FM 120-124 LH BOILERmorrisonNo ratings yet

- Single Barrel Box CulvertDocument6 pagesSingle Barrel Box CulvertRaul DiazNo ratings yet

- Bej 3Document4 pagesBej 3rekcah1019No ratings yet

- For Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-003 & 004Document1 pageFor Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-003 & 004naveenNo ratings yet

- For Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-006: Otak InternationalDocument1 pageFor Continuation Refer Drawing No: Imk-C-163-Sw-Nw-Ts-006: Otak InternationalnaveenNo ratings yet

- Cie51C: Oo Thifijm Ffi Ith #Document1 pageCie51C: Oo Thifijm Ffi Ith #Munching MercadoNo ratings yet

- p94-1738 Instrumentation t2000Document6 pagesp94-1738 Instrumentation t2000AaronNo ratings yet

- LP1 RP5 A1 Drawings-1Document1 pageLP1 RP5 A1 Drawings-1praloy dasNo ratings yet

- Carvin 8 BusDocument1 pageCarvin 8 BusRobby AhyanaNo ratings yet

- Length of Lap of Bars To Be Provided As Per Table 15.4 of Irc 112:2011 (For Fe550D Grade Steel)Document1 pageLength of Lap of Bars To Be Provided As Per Table 15.4 of Irc 112:2011 (For Fe550D Grade Steel)Satyavijet ChilakapatiNo ratings yet

- HS372221 26 Pip Iso 0168 0000 1 - Rm01aDocument1 pageHS372221 26 Pip Iso 0168 0000 1 - Rm01aibrahim qasimovNo ratings yet

- Crest Audio Ca12Document15 pagesCrest Audio Ca12Juan Carlos MayNo ratings yet

- Drawings r90 160 Fs Ss Electrical SchematicDocument2 pagesDrawings r90 160 Fs Ss Electrical Schematicingenieria4.0No ratings yet

- Modele de BearingsDocument1 pageModele de BearingsmikorizNo ratings yet

- Showroom - 2021-RC-01-03-FOUNDATION DRG - R0-16.11.2021-ModelDocument1 pageShowroom - 2021-RC-01-03-FOUNDATION DRG - R0-16.11.2021-Modelswapnil bokadeNo ratings yet

- Y96-1026S05 Y96-1026S05: Pro Engineer Pro EngineerDocument1 pageY96-1026S05 Y96-1026S05: Pro Engineer Pro EngineerGonzalo GalvezNo ratings yet