Professional Documents

Culture Documents

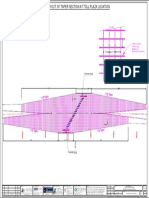

Final Layout Plywood1

Uploaded by

Solo MiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Layout Plywood1

Uploaded by

Solo MiCopyright:

Available Formats

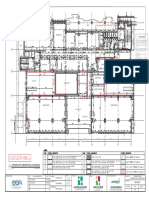

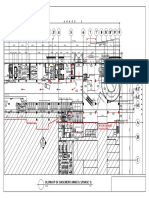

Boiler House (8m high) Form No: WF/DTC/05 Issue No:01

142500

7500 7500 7500 7500 7500 7500 7500 7500 7500 7500 7500 7500 7500 7500 7500 7500 7500 7500 7500

2.5297

8' high speed vacuum adsorption stacker

8' high speed vacuum 8' high speed veneer peeling

8' high speed veneer peeling

machine

13+1 section 3 layer roller type veneer drying

machine (include in and out feeding machine) adsorption stacker machine 8' log cache conveyor

Sharpener

8' veneer belt conveyor

6 5 4 3 2 1

Cold wind section Workshop road 8' log horizontal distribution conveyor

8' debarking machine

Core Workshop

Workshop 8' feeder for debarker

storage area road 14

Wastage veneer Left Log

13 12 11 10 9 8 7

road

Conveyor Conveyor

Drying area

Wastage conveyor

Workshop

30000

Workshop road road 4' high speed veneer peeling machine

Workshop road Workshop road

4' mechanical 4' log cache conveyor

rotary veneer 4' veneer belt

stacking machine conveyor

4' log horizontal distribution conveyor

Wet veneer cache area 4' feeder for debarker

4' log sawing machine

Core Workshop Core storage area Workshop

storage area road road

Wet veneer cache area

4' debarking machine

Mesh type automatic assembly

4 feet glue line (no foundation required) 30m

spreader

Gluing Workshop Road

Workshop working

Finished plate storage area

way area Workshop Veneer

open

way storage

area

Workshop

Workshop way

Hydraulic loading

way platform

Workshop

30000

6700.0005

Workshop way Top mounted 400 ton way Workshop Road

Workshop way Sureface repair

cold press

area

Cooling rack with fun for

Membrane Paper 15 layers hot press

Glue

working

area Sureface repair DD saw (4 sides)

area

Adhesive mixing Non-powered

Inspection

Glue tank

working area Workshop

Veneer

open roller table Membrane Paper Finished plate

& Workshop packing area

High speed way storage (double row)

Road storage area

area

mixer Workshop Surface repair

Storage area

way area Double calibrating

for flour

Workshop and raw glue sanding machine

15 layers 600

way ton hot press

production line

Factory area road

Factory area road Factory area road

TOLERANCE:- xxx

MIE GDTAL-10R grade Rev.No. Revision note Date Name & sign Checked Approved

GENERAL NOTES:- Quantity 1 set Material xxx xxx

Weight

1) Unless otherwise

specified All Title: Plywood factory Option-2 Scale

Dimensions are in Drawing No: xxx

Design&&Technology

TechnologyCenter

Center xxx

millimeters. Design

Designed by Drawn by Checked by Approved by Date

2) Use welding

electrode E60 xxx xxx xxx xxx 18/09/2020

classification THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF MESFIN INDUSTRIAL ENGINEERING (MIE).

series. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER. Sheet

File path C:\Users\SolomonM\Desktop\Final Layout Option-1 & 2.dwg

You might also like

- Liugong Global Product PosterDocument2 pagesLiugong Global Product PosterSandeep Kumar100% (2)

- A04-03 - Landscape - Ground LevelDocument1 pageA04-03 - Landscape - Ground Levelconsultnadeem70No ratings yet

- CJ-TNJ - SO-ST 74260-0501-02 - Rev 0 - ARRANGEMENT OF DECK PLATE UNIT-1 2nd FLOOR (2) - ModelDocument1 pageCJ-TNJ - SO-ST 74260-0501-02 - Rev 0 - ARRANGEMENT OF DECK PLATE UNIT-1 2nd FLOOR (2) - ModelDudi MulyadiNo ratings yet

- CM2 Instrument Panel PDFDocument1 pageCM2 Instrument Panel PDFPablo Contreras100% (1)

- Block 1 - Ground Floor Block 1 - First Floor: WalkwayDocument1 pageBlock 1 - Ground Floor Block 1 - First Floor: Walkwaydikeshwar dewanganNo ratings yet

- Wear Ring Pada PompaDocument12 pagesWear Ring Pada PompaIrma 2019No ratings yet

- Revised Foundation For 315 Mva Transformer 28 10 09 Model PDFDocument1 pageRevised Foundation For 315 Mva Transformer 28 10 09 Model PDFepe civilNo ratings yet

- Ground Level FFL (1) 1: Approval by NCRTC QR CodeDocument1 pageGround Level FFL (1) 1: Approval by NCRTC QR CodeZaid HussainNo ratings yet

- General Notes: Fourth Floor PlanDocument1 pageGeneral Notes: Fourth Floor PlanJuan IstilNo ratings yet

- Calculo de Flujos Normalizados en Un Circuito de FlotacionDocument1 pageCalculo de Flujos Normalizados en Un Circuito de FlotacionJohn Arturo Talavera MendozaNo ratings yet

- Forklift-Bucket ManualDocument4 pagesForklift-Bucket ManualVie LiesnaNo ratings yet

- DC-BVN-CSA-VO.04 - R2 - DrawingDocument3 pagesDC-BVN-CSA-VO.04 - R2 - DrawingRevit EdificeNo ratings yet

- Detail Puddle Flange Pipa GFS PondokDocument1 pageDetail Puddle Flange Pipa GFS Pondokbim.ppselaras.2023No ratings yet

- Chiller 24-10-63-ModelDocument1 pageChiller 24-10-63-ModelTheeranan PhataiNo ratings yet

- Wat Area BaseDocument4 pagesWat Area BaseHeng KimsanNo ratings yet

- Denah Lantai Satu Rs Izza: KeteranganDocument1 pageDenah Lantai Satu Rs Izza: KeteranganivansssssNo ratings yet

- Gray PlatformsDocument1 pageGray Platformsapi-319390606No ratings yet

- General Notes: Fourth Floor PlanDocument1 pageGeneral Notes: Fourth Floor PlanJuan IstilNo ratings yet

- Level 30-AV LayoutDocument1 pageLevel 30-AV Layoutahmad allenNo ratings yet

- Roof Deck Power Layout: Bureau of DesignDocument1 pageRoof Deck Power Layout: Bureau of DesignJuan IstilNo ratings yet

- NEWFLEX - Ban Ve Dau Noi Ha Tang - 230829Document12 pagesNEWFLEX - Ban Ve Dau Noi Ha Tang - 230829ha ducNo ratings yet

- Drawing PlanDocument1 pageDrawing PlanJoshua SitholeNo ratings yet

- Autocad ExtractedDocument1 pageAutocad ExtractedchanjunkaiNo ratings yet

- 250613DLDND2241 Exco00 01Document1 page250613DLDND2241 Exco00 01Mohammed HijaziNo ratings yet

- Ec Ai 11 CS2011 Ec PGPC 12 CS2011Document1 pageEc Ai 11 CS2011 Ec PGPC 12 CS2011Javier GuañunaNo ratings yet

- Washing Filter Leaf - 09072023Document16 pagesWashing Filter Leaf - 09072023bNo ratings yet

- HY 1602F - AV DisplayDocument1 pageHY 1602F - AV Displaykhaled saeedNo ratings yet

- 250613DLDND2243 Exab00 01Document1 page250613DLDND2243 Exab00 01Mohammed HijaziNo ratings yet

- Wegmans Pathway ModelDocument1 pageWegmans Pathway Modelnishant.a23xNo ratings yet

- El Excavator SM SY700HDocument8 pagesEl Excavator SM SY700HHerianto ManikNo ratings yet

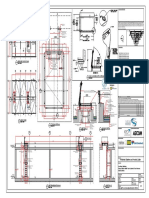

- Boiler House: Feeding Conveyors Plate FormDocument1 pageBoiler House: Feeding Conveyors Plate Formsheraz ahmadNo ratings yet

- GP Process Pump Brochure en 3Document12 pagesGP Process Pump Brochure en 3Yadir BojacaNo ratings yet

- Masterplan of WorkshopDocument1 pageMasterplan of WorkshopemonwreNo ratings yet

- 1-Clave 0+000-2+000Document1 page1-Clave 0+000-2+000jhon charlesNo ratings yet

- Crushing Plant Basir Group Rev.dDocument1 pageCrushing Plant Basir Group Rev.dachmatNo ratings yet

- Ahu Room KeyplanDocument1 pageAhu Room KeyplanPatrick LincunaNo ratings yet

- UntitledDocument1 pageUntitledMarcelo salinasNo ratings yet

- Plhs Footballstadium Extlockerrm TN 20230329Document1 pagePlhs Footballstadium Extlockerrm TN 20230329api-455371619No ratings yet

- Toll Plaza PCC Bar-1Document1 pageToll Plaza PCC Bar-1Praveen KumarNo ratings yet

- Legend: ABM Engg. & SurveyorsDocument1 pageLegend: ABM Engg. & SurveyorsShivangi KocharNo ratings yet

- As-Built: Ground Floor PlanDocument1 pageAs-Built: Ground Floor PlangenricNo ratings yet

- Cash Flow (S-CURVE) : Monthly Cashout Monthly Cashin Cum Cashout Cum CashinDocument6 pagesCash Flow (S-CURVE) : Monthly Cashout Monthly Cashin Cum Cashout Cum CashinZahra NoorNo ratings yet

- RUH8 2021 M-100 Fourth Floor HVAC System Dismantle Layout-M - 1 0 0Document1 pageRUH8 2021 M-100 Fourth Floor HVAC System Dismantle Layout-M - 1 0 0Ata AtefNo ratings yet

- Ad Sheet 9Document1 pageAd Sheet 9Sandip SharmaNo ratings yet

- Fusion Bowling-2 LanesDocument1 pageFusion Bowling-2 LanesdesignNo ratings yet

- J20-014-Permit-Aux FP-210606Document11 pagesJ20-014-Permit-Aux FP-210606Art AV B LimNo ratings yet

- A CambioDocument3 pagesA CambioSantiago BenavidesNo ratings yet

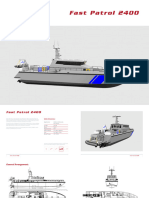

- 24m Fast Patrol Boat - Kewatec Patrol 2400Document6 pages24m Fast Patrol Boat - Kewatec Patrol 2400Peter TayNo ratings yet

- Science Pg9Document1 pageScience Pg9Ashish GuptaNo ratings yet

- 5Document1 page5ahmadtaiyabiNo ratings yet

- HajajaDocument1 pageHajajaMadu NishantNo ratings yet

- Esquema Eletrico e Hidraulico DXDocument20 pagesEsquema Eletrico e Hidraulico DXLuciano GrachaNo ratings yet

- Fractal Protocol Litepaper AF Edit 15.11Document1 pageFractal Protocol Litepaper AF Edit 15.11orelmely meNo ratings yet

- Cultural Hub Site PlanDocument1 pageCultural Hub Site PlanDevika MadhusudhananNo ratings yet

- 1174 ColumnDocument1 page1174 ColumnzaheerNo ratings yet

- 4P - 1450 X 1450 - TSPD - Adjacent OpeningDocument1 page4P - 1450 X 1450 - TSPD - Adjacent OpeningNagarajan SNo ratings yet

- Extra 300Document2 pagesExtra 300EudoraNo ratings yet

- GE3A Power Supply Inverter Sony KDL-32EX705 AZ1-LDocument4 pagesGE3A Power Supply Inverter Sony KDL-32EX705 AZ1-Lsilnei silvaNo ratings yet

- GM InterviewsDocument4 pagesGM InterviewsSolo MiNo ratings yet

- EnvironmentDocument1 pageEnvironmentSolo MiNo ratings yet

- 1 of 1Document3 pages1 of 1Solo MiNo ratings yet

- Art Exhibition Fundraiser and Auction - Google DR 2Document1 pageArt Exhibition Fundraiser and Auction - Google DR 2Solo MiNo ratings yet

- Art Exhibition Fundraiser and Auction - Google DR 2Document1 pageArt Exhibition Fundraiser and Auction - Google DR 2Solo MiNo ratings yet

- Sampling Techniques UsedDocument7 pagesSampling Techniques UsedSolo MiNo ratings yet

- Training Need AssessmentDocument2 pagesTraining Need AssessmentSolo MiNo ratings yet