Professional Documents

Culture Documents

9A - Paper 8-2015

9A - Paper 8-2015

Uploaded by

Shailesh RanawareOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9A - Paper 8-2015

9A - Paper 8-2015

Uploaded by

Shailesh RanawareCopyright:

Available Formats

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 6, June 2015

Design of Pick and Place Robot

S. Sentil Kumar

Assistant Professor, Robotics Research Centre, Bharath University, Chennai, India

ABSTRACT : The popular concept of a robot is of a machine that looks and works like a human being. The industry is

moving from current state of automation to Robotization, to increase productivity and to deliver uniform quality. The

industrial robots of today may not look the least bit like a human being although all the research is directed to provide

more and more anthropomorphic and humanlike features and super-human capabilities in these. One type of robot

commonly used in industry is a robotic manipulator or simply a robotic arm. It is an open or closed kinematic chain of

rigid links interconnected by movable joints. In some configurations, links can be considered to correspond to human

anatomy as waist, upper arm and forearm with joint at shoulder and elbow. At end of arm a wrist joint connects an end

effect which may be a tool and its fixture or a gripper or any other device to work.

I. INTRODUCTION

Robotics is the branch of engineering science & Technology related to robots, and their design, manufacture,

application, and structural disposition. Robotics is related to electronics, mechanics, and software. Robotics research

today is focused on developing systems that exhibit modularity, flexibility, redundancy, fault-tolerance, a general and

extensible software environment and seamless connectivity to other machines, some researchers focus on completely

automating a manufacturing process or a task, by providing sensor based intelligence to the robot arm, while others try

to solidify the analytical foundations on which many of the basic concepts in robotics are built.

In this highly developing society time and man power are critical constrains for completion of task in large

scales. The automation is playing important role to save human efforts in most of the regular and frequently carried

works. One of the major and most commonly performed works is picking and placing of jobs from source to

destination.

Present day industry is increasingly turning towards computer-based automation mainly due to the need for

increased productivity and delivery of end products with uniform quality. The inflexibility and generally high cost of

hard-automation systems, which have been used for automated manufacturing tasks in the past, have led to a broad

based interest in the use of robots capable of performing a variety of manufacturing functions in a flexible environment

and at lower costs. The use of Industrial Robots characterizes some of contemporary trends in automation of the

manufacturing process. However, present day industrial robots also exhibit a monolithic mechanical structure and

closed-system software architecture. They are concentrated on simple repetitive tasks, which tend not to require high

precision.

The pick and place robot is a microcontroller based mechatronic system that detects the object, picks that

object from source location and places at desired location. For detection of object, infrared sensors are used which

detect presence of object as the transmitter to receiver path for infrared sensor is interrupted by placed object.

II. HISTORY OF ROBOTS

Robot is a word that is both a coinage by an individual person and a borrowing. It has been in English since

1923 when the Czech writer Karel Capek's play R.U.R. was translated into English and presented in London and New

York. R.U.R., published in 1921, is an abbreviation of Rossum's Universal Robots, robot itself comes from Czech

robota, "servitude, forced labor," from rab, "slave." The Slavic root behind robota is orb-, from the Indo-European root

orbh, referring to separation from one's group or passing out of one sphere of ownership into another. Czech robota is

also similar to another German derivative of this root, namely Arbeit, "work”. Arbeit may be descended from a word

that meant "slave labor," and later generalized to just "labor."

Copyright to IJAREEIE DOI: 10.15662/ijareeie.2015.0406112 4887

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 6, June 2015

COMPONENTS OF ROBOT:-

1. STRUCTURE

The structure of a robot is usually mostly mechanical and can be called a kinematic chain. The chain is formed

of links, actuators, and joints which can allow one or more degrees of freedom. Most contemporary robots use open

serial chains in which each link connects the one before to the one after it. These robots are called serial robots and

often resemble the human arm. Robots used as manipulators have an end effector mounted on the last link. This end

effector can be anything from a welding device to a mechanical hand used to manipulate the environment.

2. POWER SOURCE

At present mostly (lead-acid) batteries are used, but potential power sources could be:

Pneumatic (compressed gases)

Hydraulics (compressed liquids)

Flywheel energy storage

Organic garbage (through anaerobic digestion)

Still untested energy sources (e.g. Nuclear Fusion reactors)

3. ACTUATION

Actuators are like the "muscles" of a robot, the parts which convert stored energy into movement. By far the most

popular actuators are electric motors that spin a wheel or gear, and linear actuators that control industrial robots in

factors. But there are some recent advances in alternative types of actuators, powered by electricity, chemicals, or

compressed air.

4. TOUCH

Current robotic and prosthetic hands receive far less tactile information than the human hand. Recent research has

developed a tactile sensor array that mimics the mechanical properties and touch receptors of human fingertips. The

sensor array is constructed as a rigid core surrounded by conductive fluid contained by an elastomeric skin. Electrodes

are mounted on the surface of the rigid core and are connected to an impedance-measuring device within the core.

When the artificial skin touches an object the fluid path around the electrodes is deformed, producing impedance

changes that map the forces received from the object.

Copyright to IJAREEIE DOI: 10.15662/ijareeie.2015.0406112 4888

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 6, June 2015

5. VISION

Computer vision is the science and technology of machines that see. As a scientific discipline, computer vision is

concerned with the theory behind artificial systems that extract information from images. The image data can take

many forms, such as video sequences and views from cameras.

In most practical computer vision applications, the computers are pre-programmed to solve a particular task, but

methods based on learning are now becoming increasingly common.

Computer vision systems rely on image sensors which detect electromagnetic radiation which is typically in the

form of either visible light or infra-red light. The sensors are designed using solid-state physics. The process by which

light propagates and reflects off surfaces is explained using optics. Sophisticated image sensors even require quantum

mechanics to provide a complete understanding of the image formation process.

6. MANIPULATION

Robots which must work in the real world require some way to manipulate objects; pick up, modify, destroy, or

otherwise have an effect. Thus the 'hands' of a robot are often referred to as end effectors, while the arm is referred to as

a manipulator. Most robot arms have replaceable effectors, each allowing them to perform some small range of tasks.

Some have a fixed manipulator which cannot be replaced, while a few have one very general purpose manipulator, for

example a humanoid hand.

Mechanical Grippers: One of the most common effectors is the gripper. In its simplest manifestation it consists of just

two fingers which can open and close to pick up and let go of a range of small objects. Fingers can for example be

made of a chain with a metal wire run trough it.

Vacuum Grippers: Pick and place robots for electronic components and for large objects like car windscreens, will

often use very simple vacuum grippers. These are very simple astrictive devices, but can hold very large loads

provided the pretension surface is smooth enough to ensure suction.

III. CLASSIFICATION OF ROBOTS

Industrial robots are found in a variety of locations including the automobile and manufacturing industries. Robots

cut and shape fabricated parts, assemble machinery and inspect manufactured parts. Some types of jobs robots do: load

bricks, die cast, drill, fasten, forge, make glass, grind, heat treat, load/unload machines, machine parts, handle parts,

measure, monitor radiation, run nuts, sort parts, clean parts, profile objects, perform quality control, rivet, sand blast,

change tools and weld.

Outside the manufacturing world robots perform other important jobs. They can be found in hazardous duty

service, CAD/CAM design and prototyping, maintenance jobs, fighting fires, medical applications, military warfare

and on the farm.

2.1 TYPES OF ROBOTS AS PER APPLICATIONS

Nowadays, robots do a lot of different tasks in many fields. And this number of jobs entrusted to robots is

growing steadily. That's why one of the best ways how to divide robots into types is a division by their application.

INDUSTRIAL ROBOTS: Robots today are being utilized in a wide variety of industrial applications.

Copyright to IJAREEIE DOI: 10.15662/ijareeie.2015.0406112 4889

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 6, June 2015

Any job that involves repetitiveness, accuracy, endurance, speed, and reliability can be done much better by robots,

which is why many industrial jobs that used to be done by humans are increasingly being done by robots.

MOBILE ROBOTS: Also known as Automated Guided Vehicles, or AGVs, these are used for transporting material

over large sized places like hospitals, container ports, and warehouses, using wires or markers placed in the floor, or

lasers, or vision, to sense the environment they operate in. An advanced form of the AGV is the SGV, or the Self

Guided Vehicle, like PatrolBot Gofer, Tug, and Speci-Minder, which can be taught to autonomously navigate within a

space.

AGRICULTURE ROBOTS: Although the idea of robots planting seeds, ploughing fields, and gathering the harvest

may seem straight out of a futuristic science fiction book, nevertheless there are several robots in the experimental

stages of being used for agricultural purposes, such as robots that can pick apples.

TELEROBOTS: These robots are used in places that are hazardous to humans, or are inaccessible or far away. A

human operator located at a distance from a telerobot controls its action, which was accomplished with the arm of the

space shuttle.

Copyright to IJAREEIE DOI: 10.15662/ijareeie.2015.0406112 4890

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 6, June 2015

Telerobots are also useful in nuclear power plants where they, instead of humans, can handle hazardous material or

undertake operations potentially harmful for humans.

SERVICE ROBOTS: The Japanese are in the forefront in these types of robots. Essentially, this category comprises of

any robot that is used outside an industrial facility, although they can be sub-divided into two main types of robots: one,

robots used for professional jobs, and the second, robots used for personal use. Amongst the former type are the above

mentioned robots used for military use, and then there are robots that are used for underwater jobs, or robots used for

cleaning hazardous waste, and the like.

TYPES OF ROBOTS BY LOCOMOTION & KINEMATICS

As you can understand, robot's application alone does not provide enough information when talking about a

specific robot. For example an industrial robot - usually, when talking about industrial robots we think of stationary

robots in a work cell that do a specific task.

Cartesian robot /Gantry robot: Used for pick and place work, application of sealant, assembly operations, handling

machine tools and arc welding. It's a robot whose arm has three prismatic joints, whose axes are coincident with a

Cartesian coordinator.

Cylindrical robot: Used for assembly operations, handling at machine tools, spot welding, and handling at die-casting

machines. It's a robot whose axes form a cylindrical coordinate system.

Spherical/Polar robot: Used for handling at machine tools, spot welding, die-casting, fettling machines, gas welding

and arc welding. It's a robot whose axes form a polar coordinate system.

SCARA robot: Used for pick and place work, application of sealant, assembly operations and handling machine tools.

It's a robot which has two parallel rotary joints to provide compliance in a plane.

Articulated robot: Used for assembly operations, die-casting, fettling machines, gas welding, arc welding and spray

painting. It's a robot whose arm has at least three rotary joints.

Parallel robot: One use is a mobile platform handling cockpit flight simulators. It's a robot whose arms have

concurrent prismatic or rotary joints.

Copyright to IJAREEIE DOI: 10.15662/ijareeie.2015.0406112 4891

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 6, June 2015

IV. SELECTION OF TASK

TASKS

The various tasks which a pick and place robot can perform are as follows:-

Robot pick-and-place

The use of robots for placing products in cartons and transfer of cartons and products between different stations in the

packaging lines is very common in all industries. High speed pick-and-place robots for placing small items like candy

and cookies in packages are often combined with a visual observation system for identifying products.

Handling of flexible packages

Flexible packaging material is the generic term for soft packages made of film, foil or paper sheeting. Popular forms

are stand-up pouches, bags, sachets and envelopes. These packages are often formed, filled and sealed in a vertical or

horizontal form-fill-seal machine. The package is then finally put into a case by top loading.

Cartooning machines

Cartooning machines erect boxes from flat sheets of corrugated material. The erected boxes are then filled with

products or individual cartons and are then prepared for the palletizing process. As with most packaging machines,

vacuum cups, vacuum pumps and other pneumatic components are an essential part of the cartooning.

Rotary cartoners

Rotary cartoner is one of the most popular types of cartooning machines. These machines use a series of vacuum bars

equipped with suction cups that move in a continuous rotary motion. Rotary cartoners utilize a "pick-and-carry" motion

to move cartons.

PALLETIZING AND DEPALLETIZING

Palletizing is the process of placing packages on a pallet alternatively removing them from a pallet (depalletizing).

Palletizing machines use vacuum pumps, suction cups and other pneumatic components. These machines typically pick

up multiple boxes at a time and place them on a stack (or remove them from a stack).

AUTOMATED PICK & PLACE ROBOTS

The use of specialized machines for high speed pick-and-place of small items with suction cups is very common in the

electronics and consumer industries. This application is typically characterized by short cycle times, high acceleration

forces and large variations on the parts to be handled.

SEAL MACHINES

During the pouch/bag forming phase vacuum is often applied to transport belts that help provide a grip on both sides of

the pouch/bag material. The vacuum belt moves the pouch material from a web roll into position to receive the product

from the filler. Holes in the belt allow vacuum to hold the pouch while the belt is rotating and the pouch is been

removed.

Copyright to IJAREEIE DOI: 10.15662/ijareeie.2015.0406112 4892

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 6, June 2015

BAG OPENING

Vacuum and suction cups are used to pick and open paper and plastic bags. Suction cups with stiffer bellows and a soft

sealing lip are preferred in these quite often high-speed applications.

SELECTION OF TASK

From the various tasks which can be done using the pick and place robots we have particularly meshed the

two process of picking & placing along with pallezting process.

We have decided to pick an Automobile Battery (Dimensions 45x45x65mm. Weight 250 grams) from the

conveyor.

Then placing it at the packing center, also picking a packed battery from the packing station and moving

towards the Box-packing center.

Placing of Battery at Box-packing center and again movement to the conveyor to pick an unpacked battery.

So both the picking & placing along with the packing procedure can be accompanied using this pick and place

robot.

WHY PICK & PLACE ROBOTS

We have selected the pick and place robots for this particular process due to the following reasons:-

Using of Human labour for the loading and unloading of the Batteries and also for packing purpose will consume

more time.

Even though Number of laborers is required more, the loading and unloading time should include allowances if

laborers are considered.

Moreover the work can be done easily using a single pick and place robot, which is used for both loading and

unloading and pallezting purpose.

DEFINING WORK STATION

The work station for this operation of pick & place and pallezting is been designed in such a way that:-

The unpacked battery coming from the belt conveyor is been sensed by a sensor and the moment of the conveyor

is been controlled by the sensor.

As one by one the battery comes, the Robot picks one battery and moves towards the packing station, keeps the

battery on the conveyor there.

Then picks the Packed Battery from there and moves towards the Box-packing center and places the Battery for

Box-packaging.

Further Robot movement continuous towards the return journey takes a Battery from conveyor and again the

above procedure is been carried out.

V. DESIGN PROCEDURE

FACTORS TO BE CONSIDERED

The various factors to be considered while designing of pick and place robots are been discussed as follows.

The factors are all important while designing procedure of the robot.

Copyright to IJAREEIE DOI: 10.15662/ijareeie.2015.0406112 4893

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 6, June 2015

CONTROLS

The mechanical structure of a robot must be controlled to perform tasks. The control of a robot involves three

distinct phases - perception, processing, and action. Sensors give information about the environment or the robot itself

(e.g. the position of its joints or its end effector). This information is then processed to calculate the appropriate signals

to the actuators (motors) which move the mechanical.

The processing phase can range in complexity. At a reactive level, it may translate raw sensor information

directly into actuator commands. Sensor fusion may first be used to estimate parameters of interest (e.g. the position of

the robot's gripper) from noisy sensor data. An immediate task (such as moving the gripper in a certain direction) is

inferred from these estimates. Techniques from control theory convert the task into commands that drive the actuators.

At longer time scales or with more sophisticated tasks, the robot may need to build and reason with a

"cognitive" model. Cognitive models try to represent the robot, the world, and how they interact. Pattern recognition

and computer vision can be used to track objects. Mapping techniques can be used to build maps of the world. Finally,

motion planning and other artificial intelligence techniques may be used to figure out how to act. For example, a

planner may figure out how to achieve a task without hitting obstacles, falling over, etc.

AUTONOMY LEVELS

Control systems may also have varying levels of autonomy. Direct interaction is used for hap tic or tale-

operated devices, and the human has nearly complete control over the robot's motion. Operator-assist modes have the

operator commanding medium-to-high-level tasks, with the robot automatically figuring out how to achieve them. An

autonomous robot may go for extended periods of time without human interaction. Higher levels of autonomy do not

necessarily require more complex cognitive capabilities. For example, robots in assembly plants are completely

autonomous, but operate in a fixed pattern.

Another classification takes into account the interaction between human control and the machine motions.

1. Teleportation: - A human controls each movement; each machine actuator change is specified by the

operator.

2. Supervisory: - A human specifies general moves or position changes and the machine decides specific

movements of its actuators.

3. Task-level autonomy: - The operator specifies only the task and the robot manages itself to complete it.

4. Full autonomy: - The machine will create and complete all its tasks without human interaction.

BASIC METHODS OF PROGRAMMING ROBOTS

There are three basic methods for programming Industrial robots but currently over 90% are programmed

using the teach method.

A Teach Method

The logic for the program can be generated either using a menu based system or simply using a text editor but

the main characteristic of this method is the means by which the Robot is taught the positional data. A teach pendant

with Controls to drive the robot in a number of different co-ordinate systems is used to manually drive the robot to the

desired locations. These locations are then stored with names that can be used within the robot program. The co-

ordinate systems available on a standard jointed arm robot are:-

Copyright to IJAREEIE DOI: 10.15662/ijareeie.2015.0406112 4894

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 6, June 2015

Joint Co-ordinates

The robot joints are driven independently in either direction.

Global Co-ordinates

The tool centre point of the robot can be driven along the X, Y or Z axes of the Robots global axis system.

Rotations of the tool around these axes can also be performed

Tool Co-ordinates

Similar to the global co-ordinate system but the axes of this one are attached to the tool centre point of the

robot and therefore move with it. This system is especially useful when the tool is near to the work piece.

Work piece Co-ordinates

With many robots it is possible to set up a co-ordinate system at any point within the working area. These can

be especially useful where small adjustments to the program are required as it is easier to make them along a

major axis of the co-ordinate system than along a general line. The effect of this is similar to moving the

position and orientation of the global co-ordinate system.

B LEAD THROUGH

This system of programming was initially popular but has now almost disappeared. It is still however used by

many paint spraying robots. The robot is programmed by being physically moved through the task by an operator. This

is exceedingly difficult where large robots are being used and sometimes a smaller version of the robot is used for this

purpose. Any hesitations or inaccuracies that are introduced into the program cannot be edited out easily without

reprogramming the whole task. The robot controller simply records the joint positions at a fixed time interval and then

plays this back.

C OFF-LINE PROGRAMMING

Similar to the way in which CAD systems are being used to generate NC programs for milling machines it is

also possible to program robots from CAD data. The CAD models of the components are used along with models of the

robots being used and the fixturing required. The program structure is built up in much the same way as for teach

programming but intelligent tools are available which allow the CAD data to be used to generate sequences of location

and process information. At present there are only a few companies using this Technology as it is still in its infancy but

its use is increasing each year. The benefits of this form of programming are:-

Reduced down time for programming.

Programming tools make programming easier.

Enables concurrent engineering and reduces product lead time.

PROGRAMMING LANGUAGES

A KAREL

Karel is an educational programming language, created by Richard E. Pattis in his book “Karel the Robot: A

Gentle Introduction to the Art of Programming”. This language was first used in courses at Stanford University. The

language is named after Karel Capek,

Copyright to IJAREEIE DOI: 10.15662/ijareeie.2015.0406112 4895

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 6, June 2015

Principles

A program in Karel is used to control a simple robot that lives in an environment consisting of a grid of streets

and avenues. Karel understands five basic instructions:

1. move (Karel moves by one square in the direction he is facing),

2. turn left (Karel turns 90 ° left),

3. put beeper (Karel puts a beeper on the square he is standing at),

4. pick beeper (Karel lifts a beeper off the square he is standing at),

5. Turnoff (Karel switches himself off, the program ends).

SAFETY REQUIREMENTS

The various safety requirements which were considered while designing the robot are decided as follows:

1. The Robot should not be programmed such that it should damage the Battery while holding it in its gripper.

2. Correct holding position should be set as if it not set then while movement of the Robot it may drop the Lead

Batteries which can arise a Hazardous situation in the industry.

3. The Robot should be interfaced properly with the sensors been placed near the Belt conveyor so as to know

when the belt conveyor is to be stopped or to be started to move the batteries ahead.

4. Load carrying capacity should be maintained as it should be always more than the default load which is to be

shifted.

VI. STEPS OF DESIGN

SELECTION OF PRODUCT

From the number of products available we selected the Battery of automobiles for been used in our project.

We had number of options for the selection of product, as per our requirement the Battery was matching the conditions.

The other products which we considered were as follows:-

BEARING:- Due to radial cross section of the bearing, it would be little bit difficult for the Robot Gripper to

hold the bearing in it and transport from one place to another holding it. So we rejected this product.

BAGS OF IRON ORE: - The fines bagging system was pre-decided but due to the weight limit we switched

over the other products.

CELL PHONE PACKING: - As due to the light and sensitive parts of the Cell phones we also skipped it as

there are chances of causing damage to the Cell phones while holding in the grippers of the Robots.

BOTTLE PACKING: - The radial shape of the bottles was not able to grip inside the grippers of the robots.

Though pick and place robots are used in bottle packing industries but they are been designed very precisely

and are costly so as the grippers are to be such that it can hold the bottles and move towards the decided target.

Copyright to IJAREEIE DOI: 10.15662/ijareeie.2015.0406112 4896

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 6, June 2015

DESIGNING OF WORKSPACE

The designing of work space have been done by keeping following points in mind:-

1. It should utilize Minimum time for doing the job.

2. No obstructions should be there in between the workspace envelope.

3. Idle time should be reduced as much as possible.

4. Efficient and safe transportation of the Batteries should be under gone.

The design of work space includes a Belt conveyor which brings the charged batteries from the plant and it is

been transferred to the Packing centre Using the Robotic arm. There is moment of 90 degrees; the robot picks a packed

Battery from the packed centre after placing the unpacked Battery. Then the robots proceed towards the Box packing

centre where it unloads the Battery and further moves towards the Belt conveyor to repeat the same procedure.

VII. WORKS TO BE DONE

SELECTION OF PARTS

Various components of appropriate specifications should be selected so as to complete the fabrication and

assembly of the Robot. If the selection is not done properly then the proper working of the robot cannot be obtained. It

includes the parts like selection of actuators, motors, sensors etc. Thus the selection procedure of various components is

also an important issue for the project work.

COMPLETION OF MODEL

Future work is to fabricate and manufacture the complete body structure of the robot, then the assembly of all

the manufactured parts are to be done so that the required load is lifted and been transported to the targeted place.

PROGRAMMING

Programming of the Pick and place Robot is to be done using a suitable Programming Language. The Robot is

to been interfaced with the computer by the programmed software, which will guide the robot to do its job for which it

is been programmed. There are numbers of various programming languages available now a days in the market, so the

appropriate programming language is to be selected for the programming purpose and the programming is to be done.

INTERFACING WITH THE COMPUTER

In the industrial design field of human-machine interaction, the user interface is where interaction between

humans and machines occurs. The goal of interaction between a human and a machine at the user interface is effective

operation and control of the machine, and feedback from the machine which aids the operator in making operational

decisions.

A user interface is the system by which people (users) interact with a machine. The user interface includes

hardware (physical) and software (logical) components. User interfaces exist for various systems, and provide a means

of:

Input, allowing the users to manipulate a system,

Copyright to IJAREEIE DOI: 10.15662/ijareeie.2015.0406112 4897

ISSN (Print) : 2320 – 3765

ISSN (Online): 2278 – 8875

International Journal of Advanced Research in Electrical,

Electronics and Instrumentation Engineering

(An ISO 3297: 2007 Certified Organization)

Vol. 4, Issue 6, June 2015

Output, allowing the system to indicate the effects of the users' manipulation

After completion of the model of the pick and place robot and selection of programming language both should

be interfaced. The interfacing of robot and computer using the software is the most important thing in the project. It

should be interfaced using trial and error method, and then final movement should be set using the software’s. The

movement of robot should be precisely managed causing no harm to the operator, and also the batteries which are to be

moved from one station to another.

VIII. CONCLUSION

Robot pick and place automation speeds up the process of picking parts up and placing them in new locations,

while also increasing production rates. These pick and place robots are more accurate and do not fatigue while doing

back-breaking or hard to maneuver movements that may be difficult for humans. The consistency, quality and

repeatability of a pick and place robot system is unmatched. These systems are also versatile and can be reprogrammed

and tooled to provide multiple applications for consumers.

REFERENCES

1. RK Mittal and IJ Nagarath “Robotics and Control” BITS Pilani, 2003

2. Ratheesh Rajan “Foundation Studies for an Alternate Approach to Motion Planning of Dynamic Systems” M.S.E., the University of Texas at

Austin, 2001

3. Richard E. Pattis. Karel the Robot: A Gentle Introduction to the Art of Programming. John Wiley & Sons, 1981. ISBN 0-471-59725-2.

4. The MathWorks Inc. MATLAB 7.0 (R14SP2). The MathWorks Inc., 2005.

5. Nam Sun Wang, Department of Chemical & Bimolecular Engineering, University of Maryland

6. www.robotis.com

Copyright to IJAREEIE DOI: 10.15662/ijareeie.2015.0406112 4898

You might also like

- QuizDocument1 pageQuizMichelle LapuzNo ratings yet

- Proposal of Robot ThesisDocument15 pagesProposal of Robot ThesisHus Forth CorrentyNo ratings yet

- Easiest Chopin Nocturne - A Beginner Starter Piece - CMUSEDocument5 pagesEasiest Chopin Nocturne - A Beginner Starter Piece - CMUSEsuoivietNo ratings yet

- Courses List IiDocument15 pagesCourses List IiShareef Sabi100% (1)

- LEED GA Exam Questions Set 2Document22 pagesLEED GA Exam Questions Set 2CEG BangladeshNo ratings yet

- GAS FLOW MEASUREMENT - PPSXDocument47 pagesGAS FLOW MEASUREMENT - PPSXMasood Alam Farooqui100% (2)

- Soft Robotics An OverviewDocument7 pagesSoft Robotics An OverviewEditor IJTSRDNo ratings yet

- Profiting With Ichimoku CloudsDocument46 pagesProfiting With Ichimoku Cloudsram100% (2)

- Computer Bus Architecture, Pipelining and Memory ManagementDocument13 pagesComputer Bus Architecture, Pipelining and Memory ManagementniroseNo ratings yet

- Hand Gesture Recognition and Cleaning RobotDocument8 pagesHand Gesture Recognition and Cleaning RobotIJRASETPublicationsNo ratings yet

- A Review On Robot Arm Using Haptic TechnologyDocument8 pagesA Review On Robot Arm Using Haptic TechnologyRaghu VaranNo ratings yet

- Automatic Pick and Place Robotic Arm Vehicle: IjarcceDocument3 pagesAutomatic Pick and Place Robotic Arm Vehicle: Ijarccebendali nadirNo ratings yet

- Paper 1025Document4 pagesPaper 1025Ankitha ShettyNo ratings yet

- SR211122201836Document6 pagesSR211122201836Shailesh RanawareNo ratings yet

- 66 20 GestureDocument8 pages66 20 GestureAfsin RabbaniNo ratings yet

- Animatronic Hand Based On Arduino Controller: P.Gurusamy, A.Muthuraman, P.RanjithDocument3 pagesAnimatronic Hand Based On Arduino Controller: P.Gurusamy, A.Muthuraman, P.RanjithOBAID MUFIZNo ratings yet

- IOT Based Vehicle Tracking & Vehicular Emergency System-A Case Study and ReviewDocument12 pagesIOT Based Vehicle Tracking & Vehicular Emergency System-A Case Study and ReviewJay Prakash RaikaNo ratings yet

- PLC Based Pick and Place Robot With 4 DOF: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocument5 pagesPLC Based Pick and Place Robot With 4 DOF: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyGS AshishNo ratings yet

- Wireless Control of Pick and Place Robotic Arm Using An Android ApplicationDocument7 pagesWireless Control of Pick and Place Robotic Arm Using An Android ApplicationChandan Kumar SharmaNo ratings yet

- Library Management Robot: Bomble Pranit R. G. Dipika Dr. ShaikhmeeravaliDocument4 pagesLibrary Management Robot: Bomble Pranit R. G. Dipika Dr. ShaikhmeeravaliAnandu KBNo ratings yet

- Fire Fighting Drone Using CO Boll ExtinguisherDocument3 pagesFire Fighting Drone Using CO Boll ExtinguisherLinson JohnsonNo ratings yet

- Micro RobotDocument5 pagesMicro RobotIJRASETPublicationsNo ratings yet

- DrawingRobotusingFirebirdV PDFDocument5 pagesDrawingRobotusingFirebirdV PDFBikram ChowdhuryNo ratings yet

- Gesture Replication Robo-ArmDocument10 pagesGesture Replication Robo-ArmIJRASETPublicationsNo ratings yet

- Low Cost Automation For Sorting of Objects On Conveyor BeltDocument6 pagesLow Cost Automation For Sorting of Objects On Conveyor BeltGautham KrishnanNo ratings yet

- 3 DOF ManipulatorDocument6 pages3 DOF ManipulatorKhaled SaadNo ratings yet

- Ijarcce2h A Seetha RescueDocument5 pagesIjarcce2h A Seetha RescuehidaiNo ratings yet

- 40 AutomatedDocument5 pages40 AutomatedColeen TorresNo ratings yet

- Pick and Place Robotic Arm Using Arduino: December 2017Document7 pagesPick and Place Robotic Arm Using Arduino: December 2017visionNo ratings yet

- IOT Based Social Distancing and Monitoring Robot For QueueDocument8 pagesIOT Based Social Distancing and Monitoring Robot For QueueIJRASETPublicationsNo ratings yet

- A Wireless Implementation of A Prosthetic Animatronic HandDocument5 pagesA Wireless Implementation of A Prosthetic Animatronic HandOBAID MUFIZNo ratings yet

- Design and Implementation of Real-Time Robot Operating System Based On FreertosDocument7 pagesDesign and Implementation of Real-Time Robot Operating System Based On FreertosThiago Alberto Ramos GabrielNo ratings yet

- Multipurpose Robotic ArmDocument7 pagesMultipurpose Robotic ArmIJRASETPublicationsNo ratings yet

- Gesture Control of Robotic Arm: Institute of Research AdvancesDocument9 pagesGesture Control of Robotic Arm: Institute of Research AdvancesaarthiNo ratings yet

- Actuators: Robotics Is The Branch ofDocument6 pagesActuators: Robotics Is The Branch ofNicoleSantosNo ratings yet

- Abs 1Document31 pagesAbs 1sharon. thellaNo ratings yet

- Ijsetr Vol 6 Issue 12 1568 1573Document7 pagesIjsetr Vol 6 Issue 12 1568 1573Siddhartha PvpNo ratings yet

- Fire Detection RobotDocument7 pagesFire Detection Robotsantoshi reddyNo ratings yet

- DEVELOPMENT OF ROBOTIC ARM USing (1) - 1Document27 pagesDEVELOPMENT OF ROBOTIC ARM USing (1) - 1Keshav Salgotra CEC208020No ratings yet

- Ros Integrated Api2Document7 pagesRos Integrated Api2Samuel Garcia CerdaNo ratings yet

- Distributed Robotics A PrimerDocument6 pagesDistributed Robotics A PrimerEditor IJTSRDNo ratings yet

- Waste Segregator Ijirset April 17-With-Cover-Page-V2Document7 pagesWaste Segregator Ijirset April 17-With-Cover-Page-V2aastree01No ratings yet

- Smart Tanker Robot For Security Operations in The Protected Area With Wireless Secured CommunicationDocument70 pagesSmart Tanker Robot For Security Operations in The Protected Area With Wireless Secured CommunicationSaran SivaprasadNo ratings yet

- Automated Domestic Vacuum Cleaner RobotDocument10 pagesAutomated Domestic Vacuum Cleaner RobotIJRASETPublicationsNo ratings yet

- A System For Electrotactile Feedback Using Electronic SkinDocument18 pagesA System For Electrotactile Feedback Using Electronic Skinrazankhalife4No ratings yet

- Robotic Pick and Place ArmDocument32 pagesRobotic Pick and Place Armrock star100% (1)

- 105 SmartDocument4 pages105 SmarttasibkhanNo ratings yet

- g1 PosterDocument1 pageg1 PosterVivek RahangdaleNo ratings yet

- Wireless Industrial Automtion Using ArduinoDocument5 pagesWireless Industrial Automtion Using ArduinoAbhijith SurendranNo ratings yet

- Bluetooth Control Pick and Place Robot Using Arduino IJERTCONV10IS11043Document3 pagesBluetooth Control Pick and Place Robot Using Arduino IJERTCONV10IS11043Ernest ChiwaleNo ratings yet

- Robotics: Author 1 Author 2Document4 pagesRobotics: Author 1 Author 2ARVINDNo ratings yet

- Robotic ArmDocument23 pagesRobotic ArmJapnam SodhiNo ratings yet

- Android and Bluetooth Technology Enabled Remote Control Using Smart PhoneDocument8 pagesAndroid and Bluetooth Technology Enabled Remote Control Using Smart Phonejehan11No ratings yet

- A Driverless Metro Train Using ARM7: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyDocument8 pagesA Driverless Metro Train Using ARM7: Nternational Ournal of Nnovative Esearch in Cience, Ngineering and EchnologyGumma naga gopiNo ratings yet

- Implementation of Automated Waste SegregDocument6 pagesImplementation of Automated Waste Segregsgbnablo18No ratings yet

- First PreviewDocument15 pagesFirst Previewnarendraa nathNo ratings yet

- Bet'S Basavakalyan Engineering College BASAVAKALYAN-585327: "RF Controlled Multi-Terrain Robot"Document20 pagesBet'S Basavakalyan Engineering College BASAVAKALYAN-585327: "RF Controlled Multi-Terrain Robot"Abhay BhujNo ratings yet

- Kalb Report - CseDocument20 pagesKalb Report - CseabrarmuzzammilNo ratings yet

- Robotics: Past, Present & Future in India: H.S. Gill P. M. Menghal Vaibhaw Kala Archana SinghDocument7 pagesRobotics: Past, Present & Future in India: H.S. Gill P. M. Menghal Vaibhaw Kala Archana SinghNaveenSharmaNo ratings yet

- Solar Power Control & Monitoring Using Iot & Automatic Stret Light ControlDocument6 pagesSolar Power Control & Monitoring Using Iot & Automatic Stret Light ControlNusrat NehaNo ratings yet

- MTE Riset OtomasiDocument28 pagesMTE Riset OtomasiAsal ReviewNo ratings yet

- IJARCCE.2019.81218 Human Activity Recog TechnqDocument7 pagesIJARCCE.2019.81218 Human Activity Recog TechnqUma MaheshwarNo ratings yet

- The Open Mechanical Engineering JournalDocument8 pagesThe Open Mechanical Engineering JournalSrinivas ReddyNo ratings yet

- Information Science and Engineering Virtual HandDocument42 pagesInformation Science and Engineering Virtual HandGouty XavieriteNo ratings yet

- Live Human Detecting Robot For Earthquak PDFDocument3 pagesLive Human Detecting Robot For Earthquak PDFsiddharthNo ratings yet

- Graphical User Interface Based Wireless Controlled Environment Monitoring RobotDocument12 pagesGraphical User Interface Based Wireless Controlled Environment Monitoring RobotIJRASETPublicationsNo ratings yet

- Data SheetDocument38 pagesData SheetHassan AlviNo ratings yet

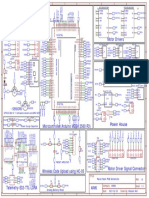

- Schematic Rover PCB1Document1 pageSchematic Rover PCB1Hassan AlviNo ratings yet

- Fyp Script For VideoDocument2 pagesFyp Script For VideoHassan AlviNo ratings yet

- Issa 2017Document6 pagesIssa 2017Hassan AlviNo ratings yet

- Industrial Electronics Exam PreparationDocument3 pagesIndustrial Electronics Exam PreparationHassan AlviNo ratings yet

- Karachi Churches Temples and ShrinesDocument71 pagesKarachi Churches Temples and ShrinesHassan AlviNo ratings yet

- Lean and Green Combine To Impact Environmental and Operational PerformanceDocument18 pagesLean and Green Combine To Impact Environmental and Operational PerformancesapientesgladioNo ratings yet

- Blood Banking: By: Anie Jan K. SegoviaDocument19 pagesBlood Banking: By: Anie Jan K. SegoviaArshie08No ratings yet

- OpenScape Business V1 Integration Guide Migration From HiPath 3000 V9 PDFDocument27 pagesOpenScape Business V1 Integration Guide Migration From HiPath 3000 V9 PDFmarcosendlerNo ratings yet

- Byzanz Rules (English) v3 PDFDocument5 pagesByzanz Rules (English) v3 PDFAlexander ZhitchenkoNo ratings yet

- DOWNS & MOHR - Conceptual Issues in The Study of InnovationDocument16 pagesDOWNS & MOHR - Conceptual Issues in The Study of InnovationTiago BrandãoNo ratings yet

- FOCGB4 AK Rtest W 1Document2 pagesFOCGB4 AK Rtest W 1makica66No ratings yet

- School-Based Management (SBM) Validation: Division of BukidnonDocument20 pagesSchool-Based Management (SBM) Validation: Division of BukidnonMarcus JuanNo ratings yet

- As 4962-2005 Electronic Toll Collection - Transaction Specification For Australian Interoperability On The DSDocument7 pagesAs 4962-2005 Electronic Toll Collection - Transaction Specification For Australian Interoperability On The DSSAI Global - APACNo ratings yet

- Capitol SteelDocument13 pagesCapitol SteelJIMMY CARREONNo ratings yet

- JHS LCP English Grade 7 10Document25 pagesJHS LCP English Grade 7 10Daryl RiveraNo ratings yet

- Mrs - Nandini - Villa-56 BOQDocument3 pagesMrs - Nandini - Villa-56 BOQAlemeluNo ratings yet

- Grade 7 Writing A DiaryDocument4 pagesGrade 7 Writing A DiaryJohn christopher Baria100% (2)

- Becoming A Cisco Select Certified Partner-Step by Step GuideDocument7 pagesBecoming A Cisco Select Certified Partner-Step by Step Guidemwaseemno181No ratings yet

- English, Science, Mathematics and Health Electromagnetic RadiationDocument3 pagesEnglish, Science, Mathematics and Health Electromagnetic RadiationSofia GabrellaNo ratings yet

- Synthetic Dyeing of Indigenous FibersDocument22 pagesSynthetic Dyeing of Indigenous FiberskleomarloNo ratings yet

- Upside Down Pineapple Cake Parsi Style by Tanaz Daruwalla Medhora - Bawi BrideDocument2 pagesUpside Down Pineapple Cake Parsi Style by Tanaz Daruwalla Medhora - Bawi BridefatduckNo ratings yet

- HX200 Installation Guide Rev BDocument160 pagesHX200 Installation Guide Rev Bcarliemorsey9No ratings yet

- Unit2 Part 2 Notes Sem5 Communication NetworkDocument17 pagesUnit2 Part 2 Notes Sem5 Communication Network054 Jaiganesh MNo ratings yet

- Cast Application Form 2023Document1 pageCast Application Form 2023arvin supanNo ratings yet

- EN - Ditec Rex Technical ManualDocument20 pagesEN - Ditec Rex Technical ManualJoao Paulo mecanicaNo ratings yet

- FAQ Partitions and Isolation Groups in SAP CPS by RedwoodDocument2 pagesFAQ Partitions and Isolation Groups in SAP CPS by Redwoodshashidhar thummaNo ratings yet

- Statement of Client RightsDocument2 pagesStatement of Client RightsYojanny Reyes De la RosaNo ratings yet

- PRC Form DAVEDocument1 pagePRC Form DAVEDave Sayson33% (3)