Professional Documents

Culture Documents

SR211122201836

Uploaded by

Shailesh RanawareCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SR211122201836

Uploaded by

Shailesh RanawareCopyright:

Available Formats

International Journal of Science and Research (IJSR)

ISSN: 2319-7064

SJIF (2020): 7.803

Design and Fabrication of Pick and Place Robot

using Microcontroller

Avinash N Bhat1, Abhishek Yalnaik2

1

Department of Mechanical Engineering, Bapuji Institute of Engineering and Technology, Davangere, Karnataka, India

avinash.n.bhat10[at]gmail.com

2

Department of Mechanical Engineering, Basaveshwar Engineering College, Bagalkot, Karnataka, India

yalnaikabhishek[at]gmail.com

Abstract: Robotic arm has become popular in the world of robotics. The essential part of the robotic arm is a programmable

microcontroller-based brick capable of driving basically 3 stepper motors design to form an anthropomorphic structure. In this

anticipate an automated arm with four degrees of opportunity is composed and can pick the items with a particular weight and place

them in a sought area. To encourage the lifting of the items, Servomotors are utilized. This abstract explains the method of interfacing

the robotic arm stepper motors with the programmed PIC16F877A based microcontroller which are used to control the robot

operations. A sample robot which can grab and release small objects is built for demonstrating the method explained. In this project, the

main application is control of multiple operations and movement of conveyer using time-based Microcontroller. The initial phase of the

project focuses on passing the inputs to the microcontroller so as to identify the number of different workstations available in the

industry which are specified by the user. Automated pick and place a framework comprises of a preparing station, testing station, and

sorting station.

Keywords: Robotic arm, Gripper, Gear motor, Actuator, Controller, End effector

1. Introduction acquiring robotic system is quite expensive but as today's

rapid development and a very high demand in quality with

The field of robotics has its origins in science fictions. The IS0 standards, human are no longer capable of such

word robot comes from the Czech word "robota" means demands. Research and development of future robots is

forced labor in 1920. It took another 40 years before the moving at a very rapid pace due to the constantly improving

modern technology of industrial robotics began. Today, and upgrading of the quality standards of products. [2].

robots are highly automated mechanical manipulators

controlled by computers. A robot may appear like a human Robotic manipulators resembling the human arm is known

being or an animal or a simple electro-mechanical device. A as robotic arms. They are constructed by a structure

robot may act under the direct control of a human (e. g. the consisting of structurally robust links coupled by either

robotic arm of the space shuttle) or autonomously under the rotational joints or translating joints. A robotic arm is thus a

control of a programmed computer. Robots may be used to type of mechanically coupled or joined arm, run by

perform tasks that are too dangerous or difficult for humans programmable commands, with similar functions to a human

to implement directly (e. g. nuclear waste cleanup) or may arm. It may be the sum total of the mechanism links or may

be used to automate repetitive tasks that can be performed be part of a more complex sized robot. A typical robotic arm

more cheaply by a robot than by the employment of a human has the following components: • Links and joints • Actuators

(e. g. automobile production) or may be used to automate • Controller • End-effector A link is considered as a rigid

mindless repetitive tasks that should be performed with more body that defines the relationship between two

precision by a robot than by a human (material handling, corresponding joint axes of a manipulator. Manipulators

material transfer applications, machine loading and consist of rigid links, which are connected by joints that

unloading, processing operations, assembly and inspection). allow relative motion of corresponding links. The links

[1] move to position with the end-effector. Actuators perform

the same role the muscles perform in the human arm – they

The last two decades have witnessed a significant advance in convert stored energy into movement energy. Actuators are

the field of robots application. Many more applications are used force to move a robot’s manipulator joints. The three

expected to appear in space exploration, battlefield and in common types of actuators currently using in contemporary

various actives of daily life in the coming years. A robot is a robots are pneumatic, hydraulic, and electrical actuators. [3]

mechanical device that performs automated tasks and

movements, according to either pre-defined program or a set The robots play important roles in our lives and are able to

of general guidelines and direct human supervision. These perform the tasks which cannot be done by humans in terms

tasks either replace or enhance human work, such as in of speed, accuracy and difficulty. Robots can be employed

manufacturing, contraction or manipulation of heavy or to imitate human behaviours and then apply these

hazardous material. Robot is an integral part in automating behaviours to the skills that leads the robot to achieve a

the flexible manufacturing system that one greatly in certain task [1]. They do not get tired or face the commands

demand these days. Robots are now more than a machine, as emotionally, and since they are designed by humans. They

robots have become the solution of the future as cost labour can be programmed and expected to obey and perform some

wages and customers demand. Even though the cost of specific tasks. In some cases the use of a robotic hand

Volume 10 Issue 11, November 2021

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: SR211122201836 DOI: 10.21275/SR211122201836 1143

International Journal of Science and Research (IJSR)

ISSN: 2319-7064

SJIF (2020): 7.803

becomes remarkable. Robotic is applied in different forms performance of this device depends on the application of the

and fields to simulate human behaviour and motions [4]. robot. Typical functions of the end-effector consist grasping,

pushing and pulling, twisting, using tools, performing

The first usage of the word ‘robot’ was in a 1921 Czech insertions, welding and various types of assembly activities.

science fiction play – ‘Rossum’s Universal Robots’ – by Thus, the major types of robot end-effectors are:

Karel Capek. The robots were artificial people or androids

and the word was derived from the word ‘Robata’, a Czech Grippers: Grippers are the most commonly used type of

word for slave. A question of perpetual interest is to define a end-effectors. They can use different gripping methods

robot. Since the beginning of the study of robotics, there has (such as vacuum or use of fingers).

been some controversy in the definition of a robot. So long Material removal tools: These include cutting, drilling

as the evolution of robotics continues, the definition of the and deburring tools installed as robot tools.

robot will change from time to time, depending on the Welding torches: Welding is a widely using operation in

technological advances in its sensory capability and level of robotic application. Welding torches have become very

intelligence. However, the most widely accepted definition efficient end-effectors that can be controlled in a

of a robot was given by the Robotic Institute of America sophisticated way for optimized welding.

(RIA) in 1979. Tool changers: Tool changers are used when many

different end effectors need to be used in sequence by one

Robotic manipulators resembling the human arm is known robot. They are used to standardize the interface between

as robotic arms. They are constructed by a structure the robot flange and the base of the tool. They can be

consisting of structurally robust links coupled by either manual or automatic

rotational joints or translating joints. A robotic arm is thus a

type of mechanically coupled or joined arm, run by 1.1 Material Selection

programmable commands, with similar functions to a human

arm. It may be the sum total of the mechanism links or may The most suitable material to fabricate the structure of the

be part of a more complex sized robot. A typical robotic arm arm has to be light and strong. Otherwise, the servo motor

has the following components: will not be able to pull up the arm and to perform the desired

turning degree. Among the materials that can be considered

Links and joints to fabricate the structure are aluminum, Perspex, plastic

Actuators polymer and carbon fiber. In choosing the fabrication

Controller materials, the aspect of availability of the materials, the

End-effector overall cost and the flexibility to be shaped, should also be

taken into consideration. Thus among the four materials

A link is considered as a rigid body that defines the considered, the aluminium is the most ideal material to be

relationship between two corresponding joint axes of a chosen as fabrication material.

manipulator. Manipulators consist of rigid links, which are

connected by joints that allow relative motion of 1.2 Design Consideration

corresponding links. The links move to position with the

end-effector. Actuators perform the same role the muscles The following were put into consideration in the design

perform in the human arm – they convert stored energy into process,

movement energy. Actuators are used force to move a

robot’s manipulator joints. The three common types of 1) Electrical actuators DC servo are chosen instead of

actuators currently using in contemporary robots are hydraulic and pneumatic actuators because of the little

pneumatic, hydraulic, and electrical actuators. power requirement and its light weight which is suitable

for this design.

Electric motor-driven actuators perform smoother 2) Materials used for the fabrication were locally sourced

movements, can be controlled very accurately, and are very from available materials.

reliable. However, these actuators cannot deliver as much 3) The materials which will be used for the design will be

power as hydraulic actuators of comparable mass. light in weight so as to reduce the weight concentration

Nevertheless, for modest power actuator functions, electrical on the base and the shoulder.

actuators are often preferred. The various types of electric 4) A continuous path controller was chosen (PIC

motors used as actuators for robotic applications are direct microcontroller was used).

current (DC) motors, stepper motors and servo motors. The 5) The torque is fully balanced by the inertia of the electric

controller is the main part that processes information and motors.

carries out instructions in a robot. It is the robot’s ‘brain’ and

controls the robot’s movements. It is usually a computer of 1.3 Robot Arm Details and Summary

some type which is used to keep information about the robot

and the working process and execute programs which The robotic arm will be controlled via the designed

operate the robot. It contains programs, data algorithms, controller and it will be able to grab, pick up and move

logic analysis and various other processing activities which objects according to their weights and shape. The

enable the robot to perform its intended function. manipulator design is mostly expected to pick up cubes and

the geometric shapes like a box. Depending on the numbers

End-effector is a device at the end of a robotic arm, designed of joints, DOF differs, but generally robotic arms operate

to interact with the open world. The exact nature of

Volume 10 Issue 11, November 2021

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: SR211122201836 DOI: 10.21275/SR211122201836 1144

International Journal of Science and Research (IJSR)

ISSN: 2319-7064

SJIF (2020): 7.803

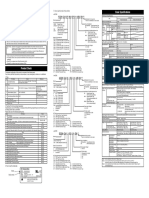

using 4 or 5 servo motors. The servo motors are popular for analog capture and comparator circuit, universal

their desirable characteristics for robotic application [6]. synchronous receiver transmitter (USART), internal and

external interrupt capabilities. Figure 21 shows the pin

1.4 Problem Statement and Proposed Solution configuration of the PIC 16F877A microcontroller and the

pins which are used for PWM generation are marked [7].

This study intends to investigate the design, implementation

and control of a 5 DOF articulated robotic arm using servo 3.2 Block Diagram

motors and PIC 16F877A microcontroller. The advantage of

this microcontroller its low cost and in-circuit

programmability [5]. A pulse could have a different effect

on servos with different specifications. Therefore, most of

the time it is crucial to be able to give the exact PWM pulse

in order to rotate a servo to a specific rotation. The main

advantage of controlling the servo motors with PWM signals

is that they can be programmed to have an initial position

and to rotate with an exact degree with respect to the

requirements [6].

2. Objectives

The primary objective is to make the Robotic arm, which Figure 3.2.1: Block Diagram of the model

comprises of three stepper motors, to interface with the PIC-

based micro-controller. It provides more interfaces to the

outside world and has larger Memory to store many

programs.

1) To develop automated robotic handling system in

manufacturing plant for multi-tasking application. Figure 3.2.2: Regulated Power Supply

2) To synchronize multi-tasking functions using

microcontroller sequencing by distributed time.

3) To validate the functioning of automated robotic system

(qualitative and quantitative analysis).

4) To monitor and control the overall functioning of the

manufacturing plant by connecting it with the LCD

Screen or a computer by attaching a camera to the

robotic arm.

3. Project Methodology

This project is designed with,

Hardware Requirements:

Microcontroller (PIC16F877A)

Oscillator Circuit

Relay driver Figure 3.2.3: Block Diagram of PIC16F877A

Relay Microcontroller

Power Supply

Battery (12v) 3.3 Power Supply (Lead Acid Battery)

DC Geared motor

Wiper motor A power supply is an electronic device that supplies electric

energy to an electrical load. The primary function of a power

3.1 PIC 16F877A Microcontroller supply is to convert one form of electrical energy to another.

PIC 16F877A microcontroller has 40 pins and is a popular 3.4 D C Geared Motor

microcontroller capable of doing complex tasks. This

microcontroller has 8192 × 14 flash program memory which A geared motor is a specific type of electrical motor that is

consists of 368 bytes of RAM and 256 bytes of non-volatile designed to produce high torque while maintain the low

EEPROM memory.33 pins are dedicated for input/output speed, motor output. A gear motor can be either an AC or a

pins and 8 multiplexed analog/digital converters with 10 bits DC electric motor. In this project we are using DC geared

resolution. This microcontroller also has specifications such motor which has the output about10-30 revolutions per

as PWM (Pulse Width Modulation) generator, 3 timers, minute. Gear motors are primarily used to reduce speed in a

Volume 10 Issue 11, November 2021

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: SR211122201836 DOI: 10.21275/SR211122201836 1145

International Journal of Science and Research (IJSR)

ISSN: 2319-7064

SJIF (2020): 7.803

series of gears, which in turn creates more torque. Gear 4. Calculations

motors are commonly used in commercial applications

where a piece of equipment needs to be able to exert a high 1. Servo Motor of 12V with Power 3W

amount of force in order to move very heavy object. P=2*3.142*N*T/60 where N=60rpm

Examples of these types of equipment would include a crane 3=2*3.142*60*T/60

or lift jack, and in smaller applications like Pick and Place T= 3*60/2*3.142*60

Robots also. T= 0.47Nm

Torque= Force * Perpendicular Distance

Force= Toque / Distance where Distance= 0.08m

Force= 0.47 / 0.08

Force= 5.878 N

Force= Mass * Acceleration Due to Gravity

Mass= Force / Acceleration Due to Gravity

Mass= 5.878 / 9.81

Mass= 0.58Kg (Robot can lift)

2. Torque of DC geared motor of 12V with Power 5W and

N=20rpm

Power= 2*3.142*N*T / 60

Torque= 5*60 / 2*3.142*20

` Torque= 2.38Nm

3. Wheel Motor with a Torque of 5Nm

Torque= Force * Perpendicular Distance

Force= 5 / 0.07

Force= 71.42 N

Mass= Force / Acceleration Due to Gravity

Mass= 71.42 / 9.81

Mass= 7.28 Kg

4.1 Results

Figure 3.4.1: DC Geared Motor

This work is able to successfully accomplish the defined

functionality. A sample robot which can rotate, magnetize an

object, lower and raise its arm, by being controlled by the

8051 microcontroller is built successfully. The 8051-

development board is soldered and it used the required

procedure for the correct operation of the controller. The

8051 development board has been interfaced to the stepper

motors such that the anthropomorphic like structure can be

controlled from the buttons at the base of the structure

(robotic arm).

There are four buttons being controlled by the control unit at

the base of the arm:

Figure 3.4.2: Wiper Motor

1) ON/OFF: the ON button puts on the system while the

OFF button puts off the system

2) START/STOP: the START button starts the movement

of the whole arm from its reset point, while the STOP

button takes the arm back to its reset button after

completion of its movement.

3) RIGHT-LEFT/LEFT-RIGHT: when this button is

switched to the RIGHT-LEFT part it causes movement

from right to left, while the LEFT-RIGHT part causes

movement from left to right.

4) 4.180/90: when the button is on 180, it causes a rotation

of 180 degree of the base stepper motor, but when put on

90 degrees, it causes rotation of 90 degrees.

Figure 3.4.3: Servo Motor or Mini DC Motor

Volume 10 Issue 11, November 2021

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: SR211122201836 DOI: 10.21275/SR211122201836 1146

International Journal of Science and Research (IJSR)

ISSN: 2319-7064

SJIF (2020): 7.803

5. Advantages, Disadvantages and 5.3 Applications

Applications

1) Material Handling

5.1 Advantages 2) Industrial Robotic Application

3) Welding

1) Accuracy and Pick and Place Robots: Robots are 4) Spraying

outfitted with wide reaches and slim arms, steady 5) Trimming and Sealing

repeatability and precise tooling-all of which allows 6) Coal Mining

them to be extremely accurate. This high precision 7) Military Operations

capability makes them a good match for pick and place

applications. 6. Conclusion

2) Flexible Pick and Place: One of the main advantages

of robotics is flexibility. Pick and place robots are easily In this project we have interfaced the robot with different

programmable. They are able to accommodate multiple kinds of I/O devices and our method allows for storing more

changes in product shape and type. In addition, robots programs to enhance more functionality. From our work, we

provide a high level of movement flexibility. deduced that in comparison to humans, robots can be much

3) Increase Consistency with Pick and Place: Pick and stronger and are therefore able to lift heavier weights and

place robot systems have the ability to improve product exert larger forces. They can be very precise in their

quality and cycle time. Robotic movements are movements, reduce labor costs, improve working conditions,

regulated, so the results are always the same. Quality is reduce material wastage and improve product quality. This

improved because of this regularity. Furthermore, this is why they’re very important in industries because the

consistency allows the processes to take place. overall objective of industrial engineering is productivity.

4) Robots are Space-Efficient: Because they are designed

with compact bases, pick and place robots are ideal if In this project, the procedure of building an articulated arm

you are looking to conserve floor space. Robots can be robot using a microcontroller (PIC16F877A) and servo

programmed to move within strict work envelope motors with the help of PWM has been discussed. The

limits-leading to even better use of space. building procedure consists of building the kinematic

5) Robots Maximize Safety: Pick and place applications structure of robot, hardware design and implementation,

can be physically demanding. They are labor-intensive, software design and implementation and microcontroller

repetitive, and monotonous. Depending on the weight programming.

and size of a part, moving it from one place to another

can be very demanding work. Pick and place robots are It is important to recall that each servo motor has a different

unaffected by the stresses of the application. They are pulse width range where a pulse can have different effects

able to work without taking breaks or making mistakes. on each servo, therefore it is important to first simulate the

6) Save with Pick and Place Robots: Incorporating pick system and then implement it accordingly. It is also essential

and place robots can effectively cut your costs. Robotic to consider the built-in oscillator of the microcontroller

precision and reliability allow for less wasted material which is usually 1MHz. Different values of the oscillator can

and more efficient use of time. Plus, the initial cause the system to not operate properly.

investment in robots is quickly recouped-making pick

and place robots an extremely cost-effective solution.

5.2 Disadvantages

1) Expense: The initial investment to integrated automated

robotics into your business is significant, especially

when business owners are limiting their purchases to

new robotic equipment. The cost of robotic automation

should be calculated in light of a business' greater

financial budget. Regular maintenance needs can have a

financial toll as well.

2) ROI: Incorporating industrial robots does not guarantee

results. Without planning, companies can have

difficulty achieving their goals.

3) Expertise: Employees will require training program

and interact with the new robotic equipment. This

normally takes time and financial output.

4) Safety: Robots may protect workers from some

hazards, but in the meantime, their very presence can

create other safety problems. These new dangers must

be taken into consideration.

Volume 10 Issue 11, November 2021

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: SR211122201836 DOI: 10.21275/SR211122201836 1147

International Journal of Science and Research (IJSR)

ISSN: 2319-7064

SJIF (2020): 7.803

Figure 6.1 and 6.2: Final ready Working Model Picture

References

[1] Lin, I. H., Liu, C. Y., Chen, L. C., "Evaluation of

Human-Robot Arm Movement Imitation", Proceedings

of 8th Asian Control Conference (ASCC), pp.287-292,

2011.

[2] Sanjay Lakshminarayan, Shweta Patil, “Position

Control of Pick and Place Robotic Arm”, Department of

Electrical Engineering MS Ramaiah Technology,

Bangalore, India.

[3] Design and fabrication of pick and place robotic arm by

Dr Sunil Kumar Talakayala, Research gate 343738510.

[4] Nikku, S., “Introduction to Robotics” USA: John Wiley

& Sons, 2011.

[5] Haidari, A. M. A., Benachiba, C., Zahir, M., “Software

Interfacing of Servo Motor with Microcontroller”,

Journal of Electrical Systems (JES), pp.84-99, 2013.

[6] International federation of robotics (IFR), “World

Robotics”, Switzerland: United Nation, 2005.

[7] Gieras, F. J., Piech, J. Z., Tomczuk, I. “Linear

Synchronous Motors: Transportation and Automation

Systems, Second Edition” USA: Taylor and Francis

Group, LLC, pp.407-413, 2012.

Volume 10 Issue 11, November 2021

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: SR211122201836 DOI: 10.21275/SR211122201836 1148

You might also like

- Design and Development of a 6-DOF Pick and Place Robotic ArmDocument7 pagesDesign and Development of a 6-DOF Pick and Place Robotic ArmAravindNo ratings yet

- Advanced Android Controlled Pick and Place Robotic ARM Using Bluetooth TechnologyDocument9 pagesAdvanced Android Controlled Pick and Place Robotic ARM Using Bluetooth Technologypramo_dassNo ratings yet

- Pick and Place Robotic Arm Using Arduino: December 2017Document7 pagesPick and Place Robotic Arm Using Arduino: December 2017visionNo ratings yet

- Objective & Outcome of RoboticsDocument3 pagesObjective & Outcome of RoboticsMechanicalNo ratings yet

- Design and Development of Robotic With 4-Degree of Freedom: Imayam College of EngineeringDocument14 pagesDesign and Development of Robotic With 4-Degree of Freedom: Imayam College of EngineeringvinothkumarNo ratings yet

- Ijsetr Vol 6 Issue 12 1568 1573Document7 pagesIjsetr Vol 6 Issue 12 1568 1573Siddhartha PvpNo ratings yet

- Robotics 1Document24 pagesRobotics 1Rahul RoyNo ratings yet

- Fabrication & Controling of A Manipulator With Specific Coloured Object DetectionDocument18 pagesFabrication & Controling of A Manipulator With Specific Coloured Object DetectionTusher Saha50% (8)

- Design and Construction of A Robotic Arm For Industrial Automation IJERTV6IS050539Document5 pagesDesign and Construction of A Robotic Arm For Industrial Automation IJERTV6IS050539Narayan ManeNo ratings yet

- Robotics Seminar on ApplicationsDocument31 pagesRobotics Seminar on ApplicationsPriyaranjan BeheraNo ratings yet

- Unit I INTRODUCTION AND ROBOT KINEMATICSDocument11 pagesUnit I INTRODUCTION AND ROBOT KINEMATICShicet mechhodNo ratings yet

- Robotics: Past, Present & Future in India: H.S. Gill P. M. Menghal Vaibhaw Kala Archana SinghDocument7 pagesRobotics: Past, Present & Future in India: H.S. Gill P. M. Menghal Vaibhaw Kala Archana SinghNaveenSharmaNo ratings yet

- ROBOTIC ARM GIVEN A THREE DEGREE OF FREEDOMDocument28 pagesROBOTIC ARM GIVEN A THREE DEGREE OF FREEDOMEmmanuel OmaleNo ratings yet

- P&P Report PDFDocument10 pagesP&P Report PDFJûstîn TiwariNo ratings yet

- DEVELOPMENT OF ROBOTIC ARM USing (1) - 1Document27 pagesDEVELOPMENT OF ROBOTIC ARM USing (1) - 1Keshav Salgotra CEC208020No ratings yet

- Thesis Designandfabricationofpickandplace PDFDocument12 pagesThesis Designandfabricationofpickandplace PDFWolderuphael KassahunNo ratings yet

- Practical, Made Easy Guide To Robotics & Automation [Revised Edition]From EverandPractical, Made Easy Guide To Robotics & Automation [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- 3 DOF ManipulatorDocument6 pages3 DOF ManipulatorKhaled SaadNo ratings yet

- Proposal of Robot ThesisDocument15 pagesProposal of Robot ThesisHus Forth CorrentyNo ratings yet

- SynopsisDocument8 pagesSynopsisSahil RajputNo ratings yet

- Physics Rough DraftDocument23 pagesPhysics Rough DraftDinesh DammalapatiNo ratings yet

- Industrial Robotic Arm Report SummaryDocument19 pagesIndustrial Robotic Arm Report SummaryKshitij BandarNo ratings yet

- Pick and Place ReviewDocument9 pagesPick and Place ReviewaditdharkarNo ratings yet

- Robotic ArmDocument9 pagesRobotic ArmRohit KumarNo ratings yet

- SETR 07: RoboticsDocument13 pagesSETR 07: RoboticsHoover InstitutionNo ratings yet

- Report 1Document25 pagesReport 1electrical engineeringNo ratings yet

- AN044 Robotic ArmDocument9 pagesAN044 Robotic Armhussien amare100% (1)

- Introduction To RoboticsDocument54 pagesIntroduction To RoboticsEjidokun TemitayoNo ratings yet

- ESME Tadele B. Tuli and Tesfaye O. TerefeDocument9 pagesESME Tadele B. Tuli and Tesfaye O. TerefeTesfayeNo ratings yet

- Research PaperDocument11 pagesResearch PaperIshan BhargaveNo ratings yet

- COE101-MODULE 1 IntroductionDocument6 pagesCOE101-MODULE 1 IntroductionOliver MedinaNo ratings yet

- 4-Degree-Of-Freedom Voice-Controlled Robotic ArmDocument11 pages4-Degree-Of-Freedom Voice-Controlled Robotic ArmIAES International Journal of Robotics and AutomationNo ratings yet

- Design and Control of A Robotic ArmDocument107 pagesDesign and Control of A Robotic ArmDave100% (8)

- Literature Reviewon Designand Simulationof Industrial Robotic Armusing CADCAMSoftwareDocument4 pagesLiterature Reviewon Designand Simulationof Industrial Robotic Armusing CADCAMSoftwareSamuel AbraghamNo ratings yet

- Introduction to Robotics Components and ClassificationsDocument28 pagesIntroduction to Robotics Components and ClassificationsDhaba AlemuNo ratings yet

- Gesture Controlled Robot With Robotic ArmDocument10 pagesGesture Controlled Robot With Robotic ArmIJRASETPublicationsNo ratings yet

- Soft Robotics An OverviewDocument7 pagesSoft Robotics An OverviewEditor IJTSRDNo ratings yet

- Robotics: Author 1 Author 2Document4 pagesRobotics: Author 1 Author 2ARVINDNo ratings yet

- Introduction To Robotics'Document12 pagesIntroduction To Robotics'rahul bhattNo ratings yet

- Example-Final Work PDFDocument18 pagesExample-Final Work PDFHanna FraustoNo ratings yet

- Robotics IeeeDocument38 pagesRobotics IeeePraveena AnnaduraiNo ratings yet

- Min - 184 (1-5) Final (Ok)Document5 pagesMin - 184 (1-5) Final (Ok)Nirmal KushwahaNo ratings yet

- Design and Analysis of An Articulated Robot Arm For Various Industrial ApplicationsDocument12 pagesDesign and Analysis of An Articulated Robot Arm For Various Industrial Applicationsاقْرَأْ وَرَبُّكَ الْأَكْرَمُNo ratings yet

- Tree ClimbingDocument37 pagesTree ClimbingJeevan Landge PatilNo ratings yet

- Introduction To RoboticsDocument89 pagesIntroduction To RoboticsFelipe AmorimNo ratings yet

- Introduction to Robotics FundamentalsDocument34 pagesIntroduction to Robotics FundamentalsErdem Yusuf GökdumanNo ratings yet

- Introduction to Robotics Arms FundamentalsDocument23 pagesIntroduction to Robotics Arms FundamentalsHritikNo ratings yet

- AMP Microproject CoDocument23 pagesAMP Microproject CovvppolycoNo ratings yet

- Futech2024 03 01 03 +princewillDocument7 pagesFutech2024 03 01 03 +princewillNIKHIL ASNo ratings yet

- Design and Analysis of An Articulated Robot ArmDocument8 pagesDesign and Analysis of An Articulated Robot ArmSamuel AbraghamNo ratings yet

- GIS PPTDocument17 pagesGIS PPTCS084Rishav SinghNo ratings yet

- Pick and Place Arm Movement Control by AndroidDocument61 pagesPick and Place Arm Movement Control by Androidnagaraju75% (4)

- Chapter 1Document34 pagesChapter 1Gerardo Cruz EspinosaNo ratings yet

- Gesture Control of Robotic Arm: Institute of Research AdvancesDocument9 pagesGesture Control of Robotic Arm: Institute of Research AdvancesaarthiNo ratings yet

- Chapter 2Document19 pagesChapter 2Aung ThikeNo ratings yet

- Technical English Ii: Practical WorkDocument14 pagesTechnical English Ii: Practical WorkMelissa Haydee Acosta ArmoaNo ratings yet

- Raspberry Pi Based Dual-ARM Tele Robotic System With Live Video StreamingDocument5 pagesRaspberry Pi Based Dual-ARM Tele Robotic System With Live Video StreamingYusmi MaulanaNo ratings yet

- Abs 1Document31 pagesAbs 1sharon. thellaNo ratings yet

- JPNR 2022 S03 158Document9 pagesJPNR 2022 S03 158Shailesh RanawareNo ratings yet

- DC MotorDocument2 pagesDC MotorShailesh RanawareNo ratings yet

- Solar Powered Reciprocating Pump - SynopsisDocument15 pagesSolar Powered Reciprocating Pump - SynopsisShailesh RanawareNo ratings yet

- 9A - Paper 8-2015Document12 pages9A - Paper 8-2015Hassan AlviNo ratings yet

- DC MotorDocument2 pagesDC MotorShailesh RanawareNo ratings yet

- 16x2 LCDDocument3 pages16x2 LCDShailesh Ranaware0% (1)

- Ultrasonic Automatic Braking System For Forward Collision Avoidance With Accelerator Pedal Disengagement Mechanism - Nishad Vivek Kumbhojkar & Chaitanya Avadhutchintan KuberDocument12 pagesUltrasonic Automatic Braking System For Forward Collision Avoidance With Accelerator Pedal Disengagement Mechanism - Nishad Vivek Kumbhojkar & Chaitanya Avadhutchintan KuberShailesh RanawareNo ratings yet

- Automatic Breaking System Using Ultrasonic Sensor: © AUG 2021 - IRE Journals - Volume 5 Issue 2 - ISSN: 2456-8880Document6 pagesAutomatic Breaking System Using Ultrasonic Sensor: © AUG 2021 - IRE Journals - Volume 5 Issue 2 - ISSN: 2456-8880Shailesh RanawareNo ratings yet

- Fitter 1st - SEM AT PDFDocument72 pagesFitter 1st - SEM AT PDFShailesh Ranaware100% (1)

- AMC-servo Drive OverviewDocument28 pagesAMC-servo Drive OverviewjoonimNo ratings yet

- 40 RT-flex Control SystemDocument66 pages40 RT-flex Control SystemKesavan Vimal KumarNo ratings yet

- Smart Water Management System Using ArduinoDocument4 pagesSmart Water Management System Using ArduinoGRD JournalsNo ratings yet

- 65264EN Servo Tuning Alfa Fanuc PDFDocument58 pages65264EN Servo Tuning Alfa Fanuc PDFCzeburaszko87No ratings yet

- DG 95 106 e 07-07 Programmer 2Document56 pagesDG 95 106 e 07-07 Programmer 2Javier Ramirez MedinaNo ratings yet

- Arduino Automated Car Parking System: Smart System Design Project ReportDocument48 pagesArduino Automated Car Parking System: Smart System Design Project ReportSujit reddy80% (5)

- Afro Esc 30A ManualDocument4 pagesAfro Esc 30A ManualmikipamplonaNo ratings yet

- ESDA Series Driver User's ManualDocument43 pagesESDA Series Driver User's ManualByronD88No ratings yet

- Technical Report: Project TitleDocument34 pagesTechnical Report: Project TitleMuhammad SalmanNo ratings yet

- Mitsubishi MELSERVO-J2S-S099: For Engineering SampleDocument84 pagesMitsubishi MELSERVO-J2S-S099: For Engineering SampleBrendisNo ratings yet

- Man Propeller Vbs 1460Document30 pagesMan Propeller Vbs 1460ANGEL VALHONDONo ratings yet

- Using the 9XR Pro for More than Eight ChannelsDocument9 pagesUsing the 9XR Pro for More than Eight ChannelsPatricio Daniel Villalobos RojasNo ratings yet

- LFS PM T43 Operating Manual V1.3Document47 pagesLFS PM T43 Operating Manual V1.3cassioalvarengaNo ratings yet

- PLC Manual FinalDocument32 pagesPLC Manual FinalMuhammad Usama Muhammad SaleemNo ratings yet

- Vị Trí Main Xoay Ngáng Trên Main NgángDocument1 pageVị Trí Main Xoay Ngáng Trên Main NgángNguyễn Văn HùngNo ratings yet

- 5000Document6 pages5000royal1979No ratings yet

- Industrial Control Electronics by Michael JacobDocument606 pagesIndustrial Control Electronics by Michael JacobNarasimha Sai Sangapu88% (8)

- High Precision Position Control of Electro-Hydraulic Servo SystemDocument10 pagesHigh Precision Position Control of Electro-Hydraulic Servo Systemamin342No ratings yet

- AIDA Product Catalogue 2018Document32 pagesAIDA Product Catalogue 2018Yose Must100% (1)

- Precision Bearing House, Industrial AutomationDocument244 pagesPrecision Bearing House, Industrial AutomationPrecision Bearing HouseNo ratings yet

- XGY1000 Head TrackerDocument14 pagesXGY1000 Head TrackerjesusifcNo ratings yet

- Arduino Based Door Automation System Using Ultrasonic Sensor and Servo MotorDocument10 pagesArduino Based Door Automation System Using Ultrasonic Sensor and Servo MotorRockstar GmailNo ratings yet

- Actuater Lab ReportDocument7 pagesActuater Lab ReportMuath AfeshatNo ratings yet

- 1Document17 pages1Darryl Santos100% (1)

- Angular Position Control Laboratory ExperimentDocument8 pagesAngular Position Control Laboratory ExperimentDevin RajNo ratings yet

- Servo Drivers For Positioning Using Omron CP1L PLCDocument8 pagesServo Drivers For Positioning Using Omron CP1L PLCMinh DươngNo ratings yet

- Syntec CNC Application Manual v10.0Document155 pagesSyntec CNC Application Manual v10.0Ga Bicho De SavorNo ratings yet

- Pcon-Ca/Cfa/Cb/Cfb, Acon-Ca/Cb/Cgb, Dcon-Ca/Cb/Cgb First Step Guide Sixth EditionDocument5 pagesPcon-Ca/Cfa/Cb/Cfb, Acon-Ca/Cb/Cgb, Dcon-Ca/Cb/Cgb First Step Guide Sixth EditionKhải PhạmNo ratings yet

![Practical, Made Easy Guide To Robotics & Automation [Revised Edition]](https://imgv2-2-f.scribdassets.com/img/word_document/253466853/149x198/4281882d40/1709916831?v=1)